Flexible substrate, preparation method thereof, and display device

A flexible substrate and flexible display technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of affecting the manufacturing process, increasing the off-state current, and unable to planarize the functional layer, so as to prevent adverse effects, The effect of preventing carbonization by heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

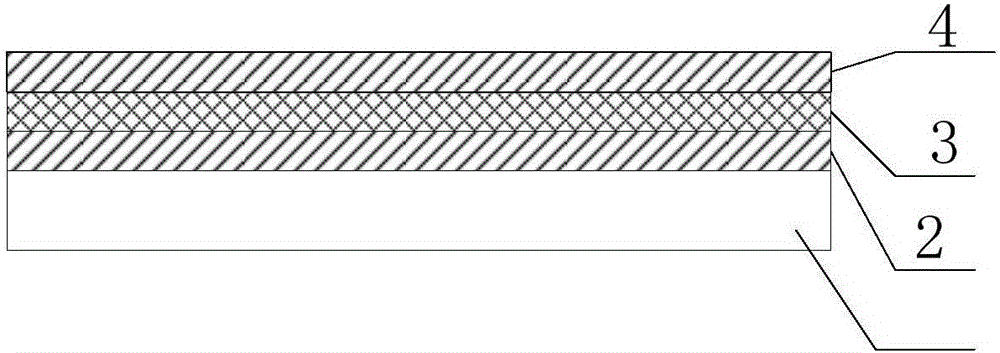

[0031] Such as figure 1 As shown, this embodiment provides a flexible substrate, including a first flexible layer and a second flexible layer 4, and an ultraviolet light absorbing layer 3 disposed between the first flexible layer 2 and the second flexible layer 4 , wherein, the absorption capacity of the ultraviolet light absorbing layer 3 to ultraviolet light is greater than or equal to the absorption capacity of the first flexible layer 2 and the second flexible layer 4 to ultraviolet light.

[0032] In the flexible substrate and its preparation method and display device provided by the present invention, since the flexible substrate includes an ultraviolet light absorbing layer 3 arranged between two flexible layers, the ultraviolet light absorbing layer 3 can be irradiated with an excimer laser on the active layer When converting amorphous silicon to polysilicon, the flexible substrate with a sandwich ultraviolet absorbing layer 3 can absorb excess laser energy by using th...

Embodiment 2

[0040] This embodiment provides a method for preparing the above-mentioned flexible substrate, comprising the following steps:

[0041] forming a first flexible layer 2 on the substrate;

[0042] forming an ultraviolet light absorbing layer 3 on the first flexible layer 2;

[0043] A second flexible layer 4 is formed on the ultraviolet light absorbing layer 3 .

[0044] specifically,

[0045] S1-1, forming a first polyimide layer on the glass substrate 1;

[0046] The specific preparation method is in the scope of the prior art and will not be repeated here. For example, the coating method can be used to control the thickness of the coating film layer, and the first polyimide film with a thickness of 5-30 microns can be formed according to the specific application situation. amine layer.

[0047] S1-2, forming an amorphous silicon layer on the first flexible layer 2;

[0048] Specifically, the a-si film layer can be deposited on the first polyimide layer by plasma vapor d...

Embodiment 3

[0053] This embodiment provides a flexible display device and a manufacturing method thereof, wherein the flexible display device includes the above-mentioned flexible substrate and a thin film transistor disposed on the flexible substrate, and an active layer of the thin film transistor includes a polysilicon layer.

[0054] The preparation method of the flexible display device comprises the following steps:

[0055] Prepare a flexible substrate;

[0056] Fabricating a thin film transistor including a polysilicon active layer on a flexible substrate;

[0057] The flexible display device is separated from the substrate.

[0058] specifically,

[0059] S2-1, preparing a flexible substrate;

[0060] For the preparation method of the flexible substrate, see S1-1 to S1-3 in Example 2;

[0061] S2-2 Preparation of a thin film transistor including a polysilicon active layer on a flexible substrate

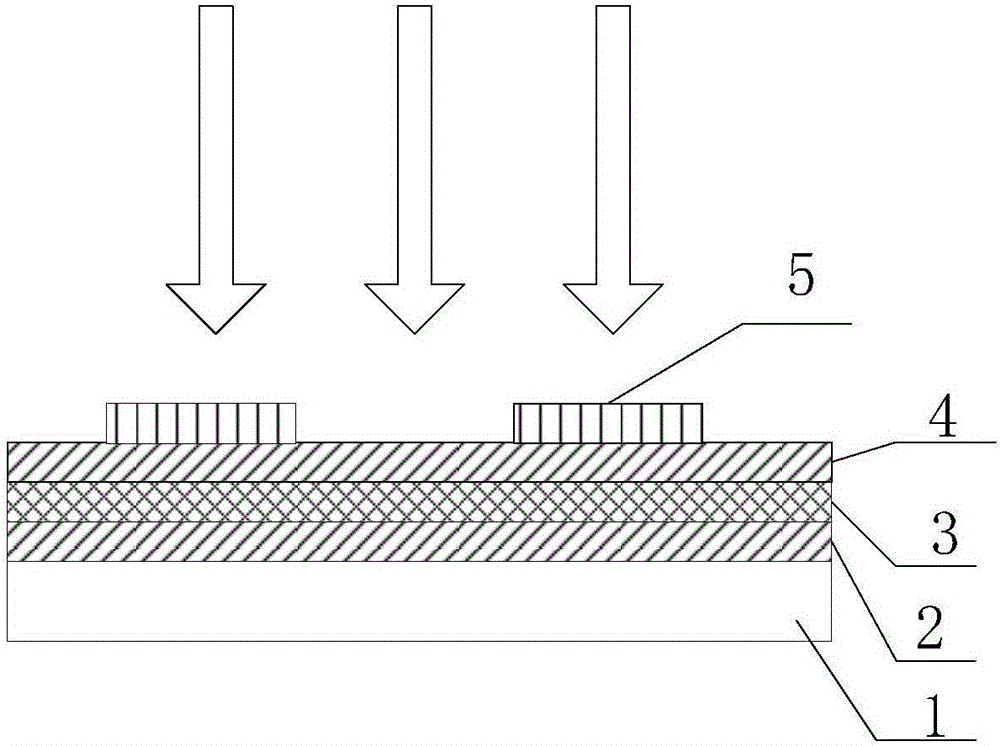

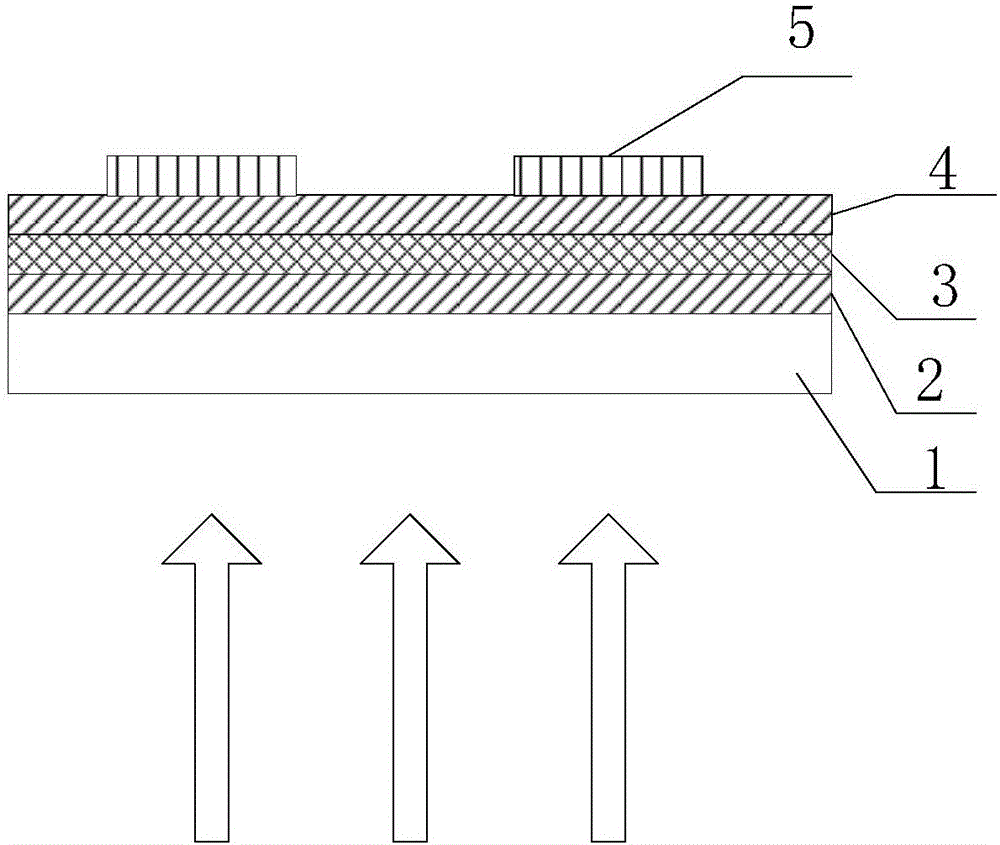

[0062] Such as figure 2 As shown, a thin film transistor including a polysilico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com