Silicate-modified PVC foamed composite decorative sheet and manufacturing method thereof

A silicate and decorative board technology, applied in the field of composite materials, can solve the problems of not being widely used, high cost, and high quality of decorative boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

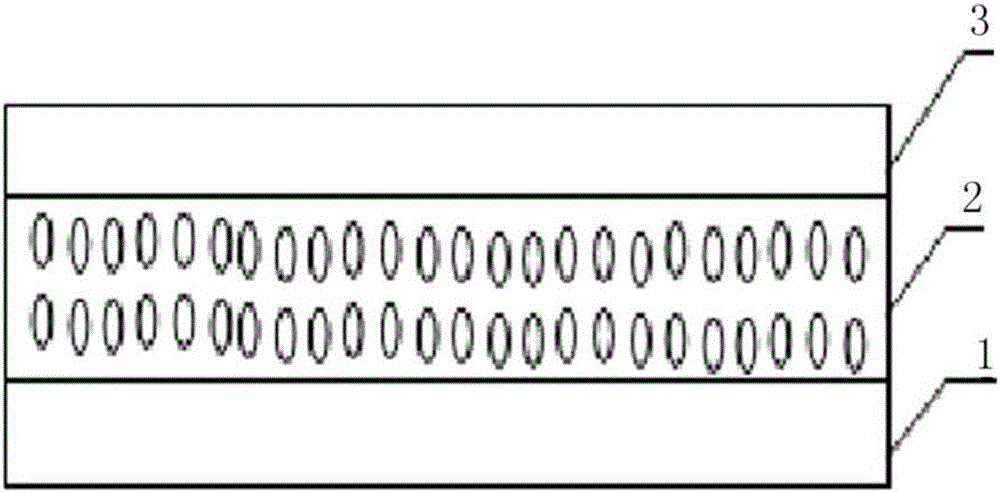

[0073] The silicate modified PVC foamed composite decorative board is characterized in that it includes a supporting layer 1, a foaming layer 2 and a decorative layer 3.

[0074] The support layer 1 and the decoration layer 3 sandwich the foam layer 2 to form a three-layer structure.

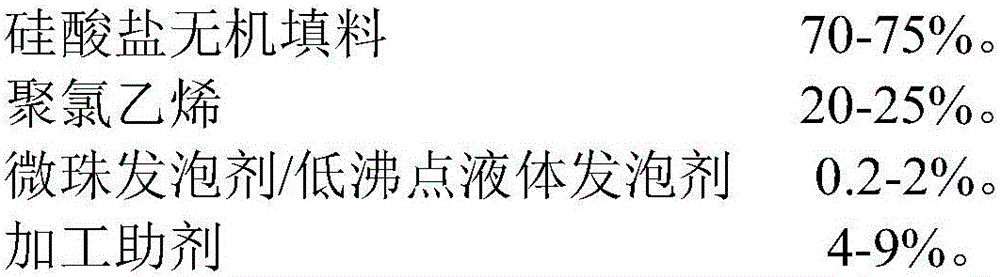

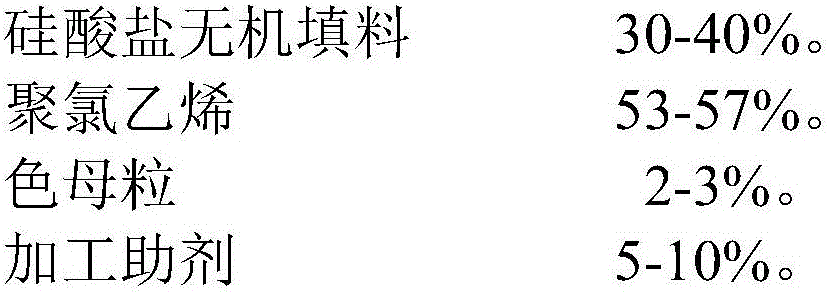

[0075] The components and weight percentages of the materials used for the supporting layer 1, the foam layer 2 and the decorative layer 3 are:

[0076] 1. Support layer 1 formula:

[0077] Silicate inorganic filler 65%.

[0078] PVC 25%.

[0079] Processing aid 10%.

[0080] The weight percentage of the processing aid composition is: coupling agent 1%, heat stabilizer 2%, flame retardant 1%, antioxidant 1%, light stabilizer 1%, modifier 2%, lubricant 1% and plasticizer 1%.

[0081] Wherein the composition of various processing aids is as follows:

[0082] 1) The coupling agent is: aluminate coupling agent.

[0083] 2) Heat stabilizers are: 0.5% lead stearate, 0.5% barium stearate and 1% ...

Embodiment 2

[0146] The silicate modified PVC foamed composite decorative board is characterized in that it includes a supporting layer 1, a foaming layer 2 and a decorative layer 3.

[0147] The support layer 1 and the decoration layer 3 sandwich the foam layer 2 to form a three-layer structure.

[0148] The components and weight percentages of the materials used for the supporting layer 1, the foam layer 2 and the decorative layer 3 are:

[0149] 1. Ingredients for support layer 1:

[0150] Silicate inorganic filler 70%.

[0151] PVC 25%.

[0152] Processing aid 5%.

[0153] The weight percentage of processing aids is: coupling agent 0.3%, heat stabilizer 1%, flame retardant 0.5%, antioxidant 0.5%, light stabilizer 0.5%, modifier 1%, lubricant 0.7% and plasticizer 0.5%.

[0154] Wherein the composition of various processing aids is as follows:

[0155] 1) The coupling agent is: aluminate coupling agent.

[0156] 2) The heat stabilizer is: lead stearate.

[0157] 3) The flame reta...

Embodiment 3

[0219] The silicate modified PVC foamed composite decorative board is characterized in that it includes a supporting layer 1, a foaming layer 2 and a decorative layer 3.

[0220] The support layer 1 and the decoration layer 3 sandwich the foam layer 2 to form a three-layer structure.

[0221] The components and weight percentages of the materials used for the supporting layer 1, the foam layer 2 and the decorative layer 3 are:

[0222] 1. Raw material of support layer 1:

[0223] Silicate inorganic filler 65%.

[0224] PVC 30%.

[0225] Processing aid 5%.

[0226] The weight percent of processing aid composition is: coupling agent 0.3%, heat stabilizer 1%, flame retardant 0.5%, antioxidant 0.5%, light stabilizer 0.5%, modifier 1%, lubricant 0.7% and Plasticizer 0.5%.

[0227] Wherein the composition of various processing aids is as follows:

[0228] 1) The coupling agent is: aluminate coupling agent.

[0229] 2) Heat stabilizers are: 0.5% lead stearate and 0.5% barium s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com