Patents

Literature

38results about How to "Strong combination fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An antibacterial textile product and a preparing method thereof

InactiveCN107044053AStrong combination fastnessExcellent abrasion resistanceFibre treatmentPolymer scienceIonic liquid

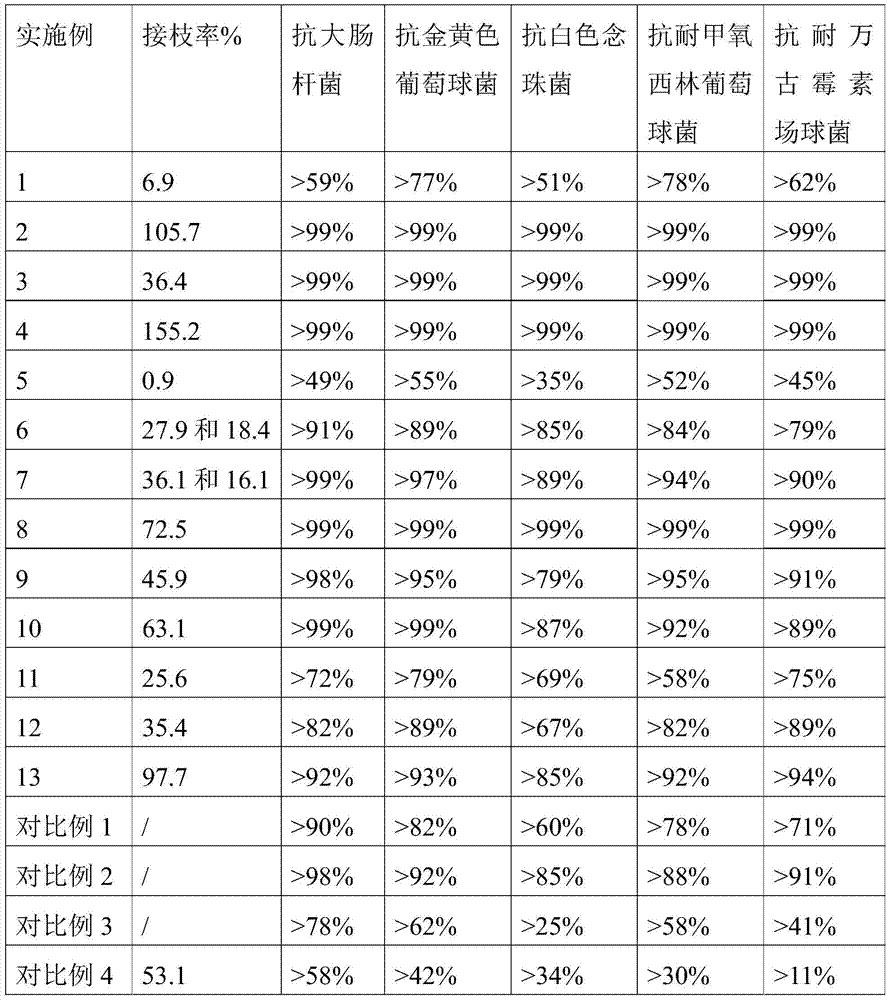

An antibacterial textile product and a preparing method thereof are disclosed. The method includes triggering production of active free radicals on a textile substrate, and performing polymerization with an organic monomer containing an ionic liquid. The textile product prepared by the method has a durable wide-spectrum antibacterial function. The range of a suitable textile product substrate is wide. The method is simple, feasible, low in cost, suitable for batch production and easy to popularize.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

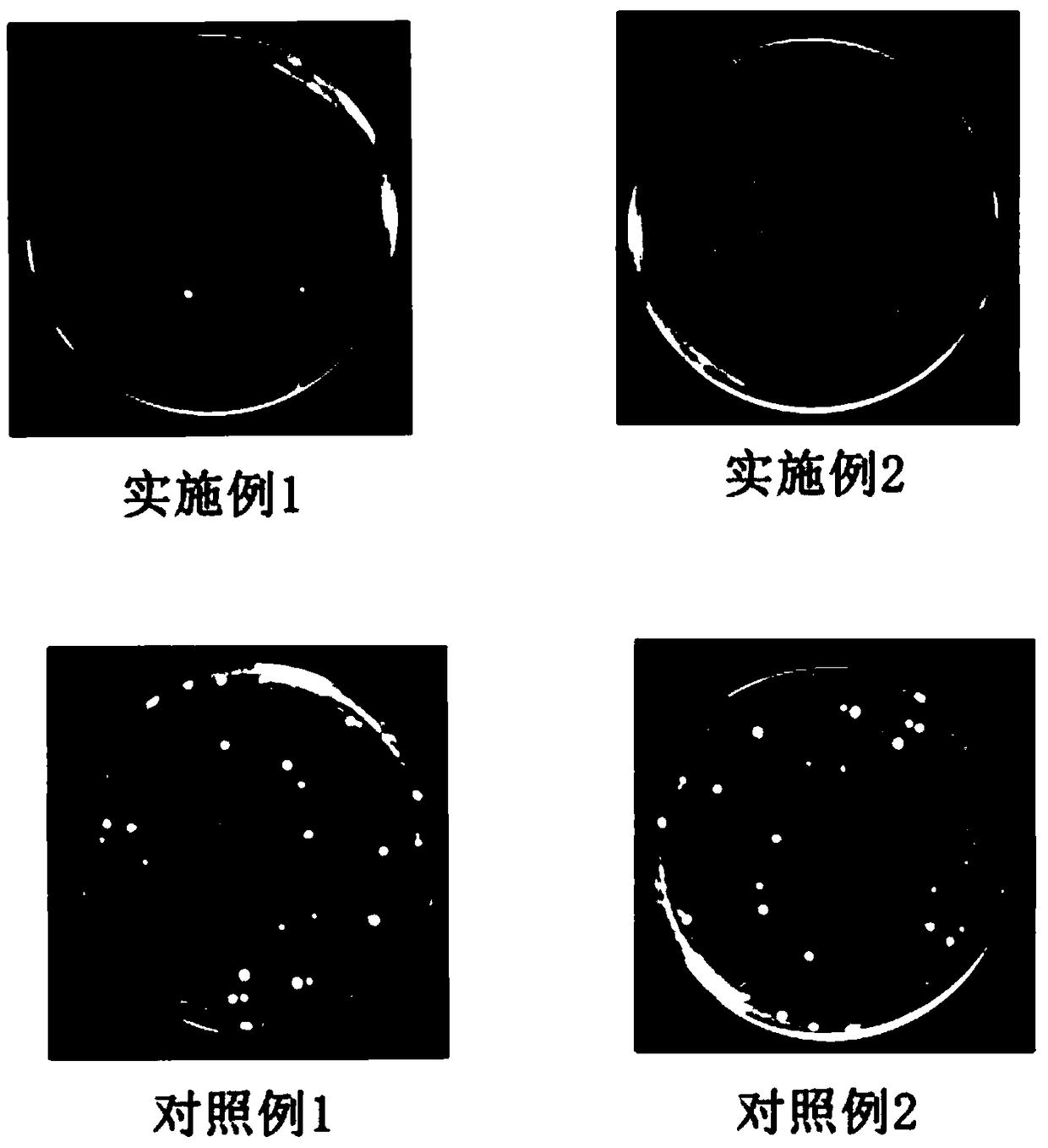

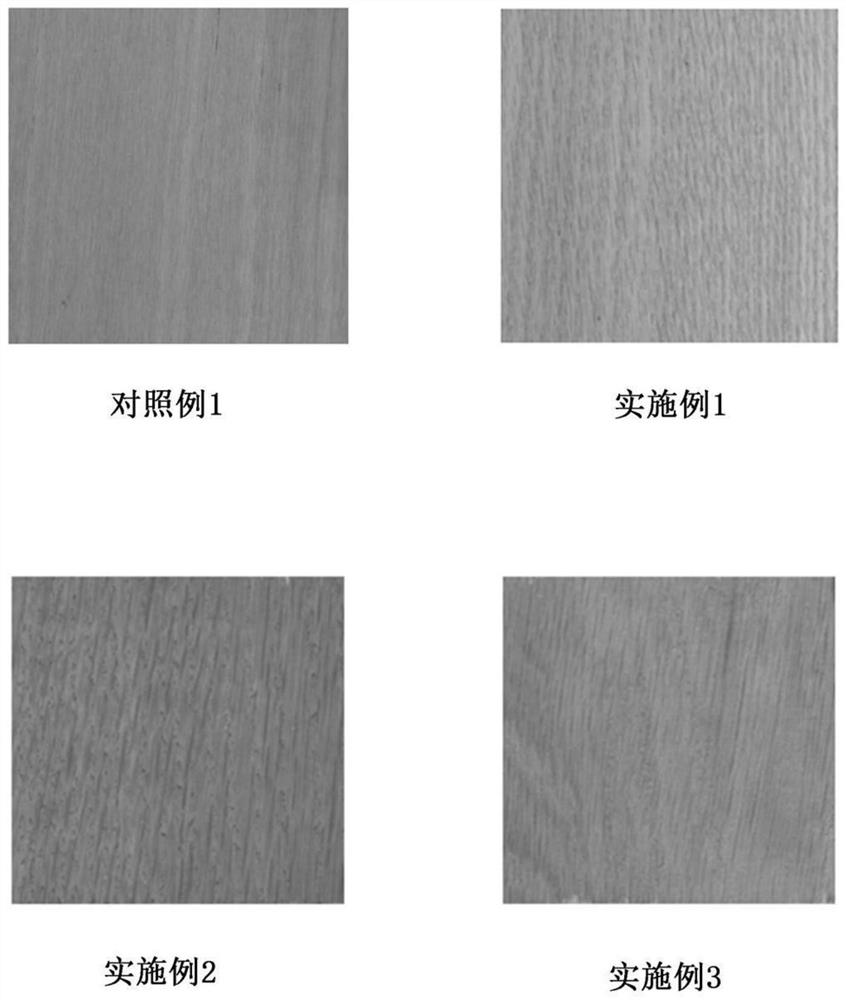

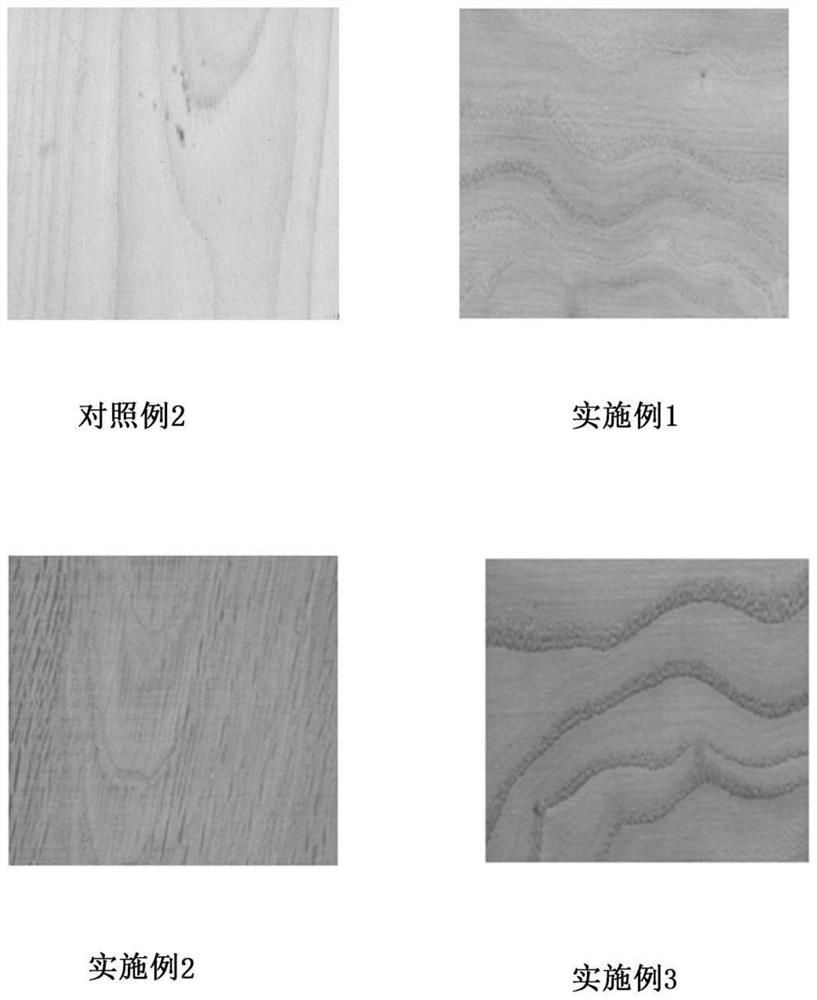

Method for inducing wood discoloration by using chemical color-changing agent

ActiveCN109434993AImprove color saturationStrong sense of hierarchyWood treatment detailsThermal wood treatmentColor saturationColor changes

The invention discloses a method for inducing wood discoloration by using a chemical color-changing agent. The method comprises the following steps that firstly, a precursor substance solution is coated on the surface of wood, then the surface of the wood is coated with the color-changing agent after drying, and drying is carried out again to complete the color change of the wood to obtain a finished product. According to the method, the color saturation after chemical color change of the wood can be improved, so that the color of the wood is more easy to display after the wood is subjected tothe color change, the excellent permeability performance is achieved, the bonding strength of the wood color-changing layer is higher, the loss resistance is better, moreover, the displayed color isnatural and beautiful, the texture is clearer, the layering sense is stronger, and the color is richer.

Owner:ZHEJIANG FORESTRY UNIVERSITY

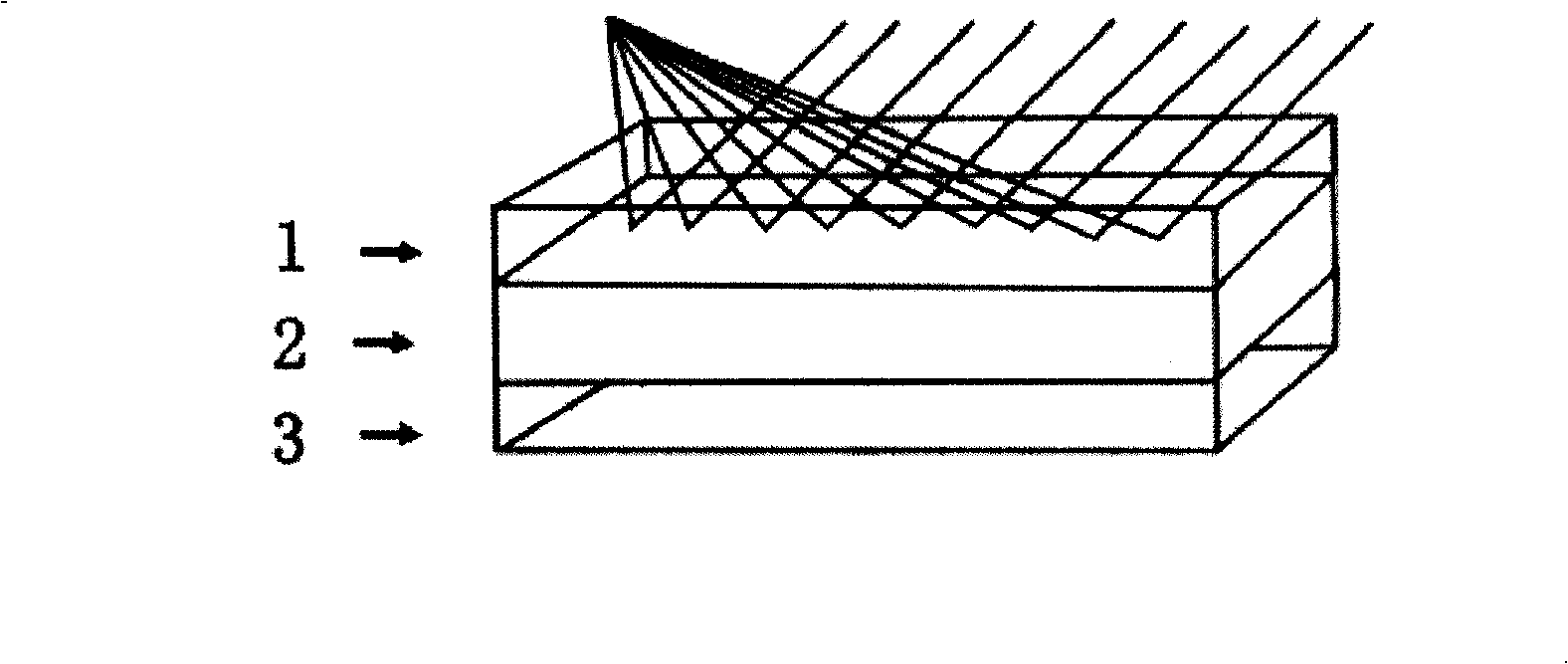

Selective coating for absorbing solar light and heat

InactiveCN101769648AReduce thermal emissivityGood weather resistanceSolar heat devicesVacuum evaporation coatingCompound aSolar light

The invention discloses a selective coating for absorbing solar light and heat which belongs to field of solar energy equipment, particularly, relates to a selective absorbing coating which is used on the surface of the flat-plate solar collector and is used for absorbing and utilizing solar energy. The selective coating for absorbing solar light and heat is formed by compounding a plurality of layers of metal and non-metal, the selective solar energy is attached on a metal flat plate; the characteristics are as follows: the attachment sequence of the coating on the metal flat plate is as follows: a bottom layer-aluminum nitride composite layer-aluminum nitride composite layer- aluminum oxide (wherein, after the second layer of aluminum reacts with N2, whether new aluminum nitride composite material is generated). The invention provides a selective absorbing film with excellent selective absorption characteristic of solar energy and firm film, which is provided with high binding strength, good weatherability, as well as high production efficiency in production.

Owner:SHENZHEN PROSUNPRO SOLAR ENERGY

Modified silica sol, fireproof liquid, composite fireproof glass as well as preparation method and application thereof

ActiveCN112320807AStrong adhesionHigh bonding strengthFireproof paintsSilicon compoundsOrageneOrganic polymer

The invention belongs to the technical field of inorganic nano materials, and particularly relates to modified silica sol, fireproof liquid, composite fireproof glass and a preparation method and application thereof. The preparation method of the modified silica sol comprises the following steps: 1) mixing silica sol to be modified with a silane coupling agent and reacting; and 2) mixing an organic polymer containing a reaction group with the material obtained in the step 1) and reacting to obtain the modified silica sol. The modified silica sol is prepared by the preparation method and is used for preparing the fireproof liquid, and the obtained fireproof liquid is high in crosslinking density and good in adhesive force.

Owner:SHANGHAI XINANNA ELECTRONICS TECH +2

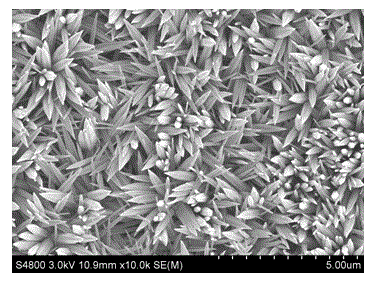

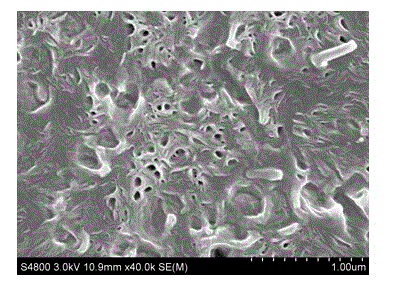

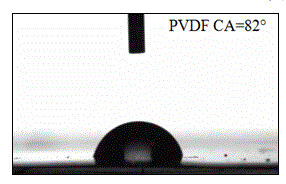

Method for preparing copper-based nanometer zinc oxide-polyvinylidene fluoride composite material

ActiveCN104877152AImprove antifouling performanceStrong combination fastnessMaterial nanotechnologySynthetic resin layered productsComposite filmFilm material

The invention relates to a method for preparing a copper-based nanometer zinc oxide-polyvinylidene fluoride composite material. The method comprises the following specific preparation steps: (1) preparing a zinc oxide nanometer cone film through a chemical bath deposition method in a hot bath by taking a copper sheet as a base material; (2) preparing an azo dimethyl formamide solution with low solid content of polyvinylidene fluoride; (3) preparing a polyvinylidene fluoride film on the surface of the zinc oxide nanometer cone film through a heat curing film formation method to obtain a copper-based nanometer zinc oxide-polyvinylidene fluoride composite film material with certain hydrophobicity, wherein the copper-based nanometer zinc oxide-polyvinylidene fluoride composite film material can be widely applied to the surface modification of a copper-based material and applied to the field of piezoelectric and ferroelectric materials in future. The method disclosed by the invention has the advantages of simple preparation process and low cost and is beneficial to industrial operation and production.

Owner:SHAANXI UNIV OF SCI & TECH

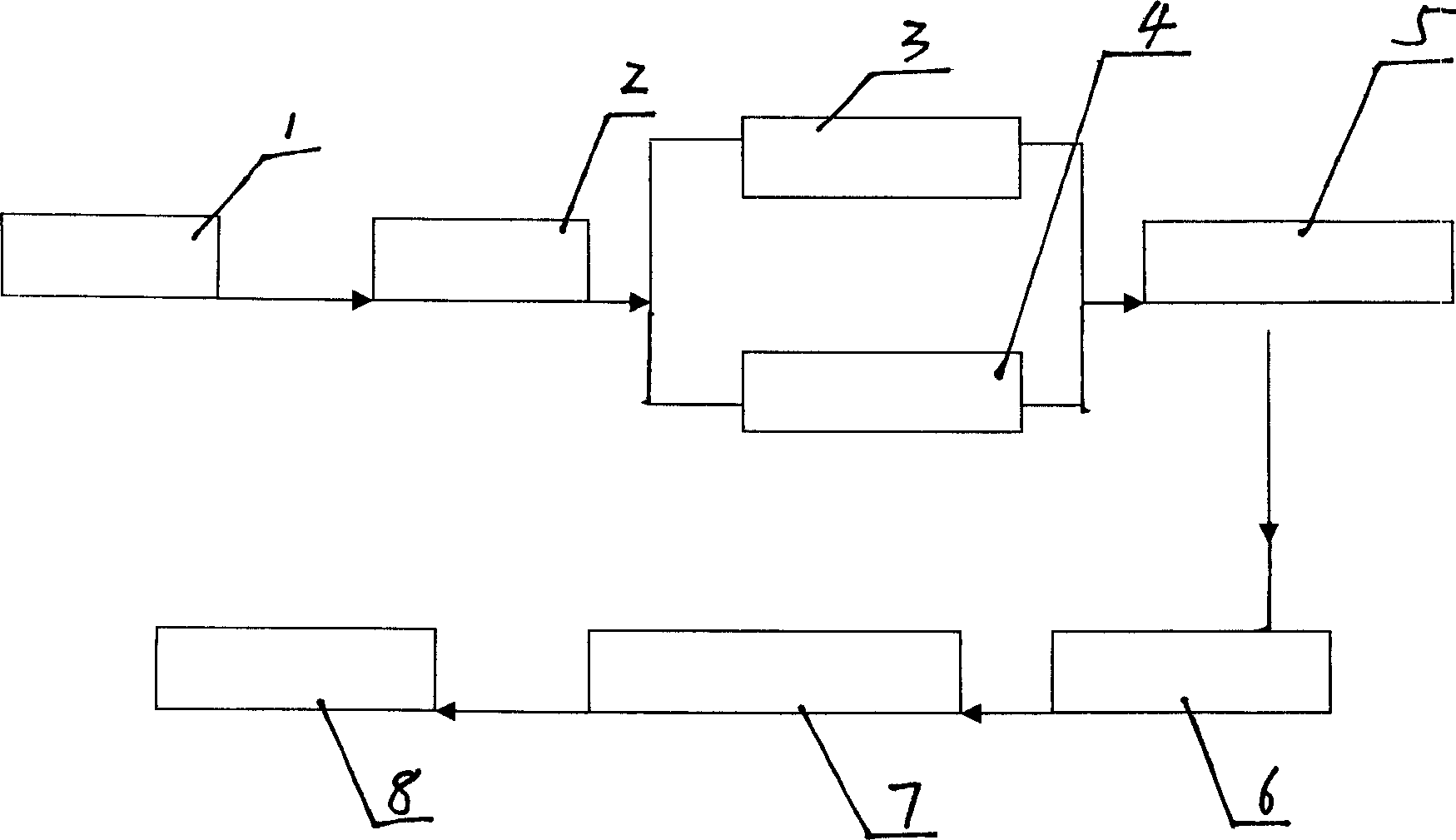

Nano wave adsorption compound coating composition and its preparation and spraying method thereof

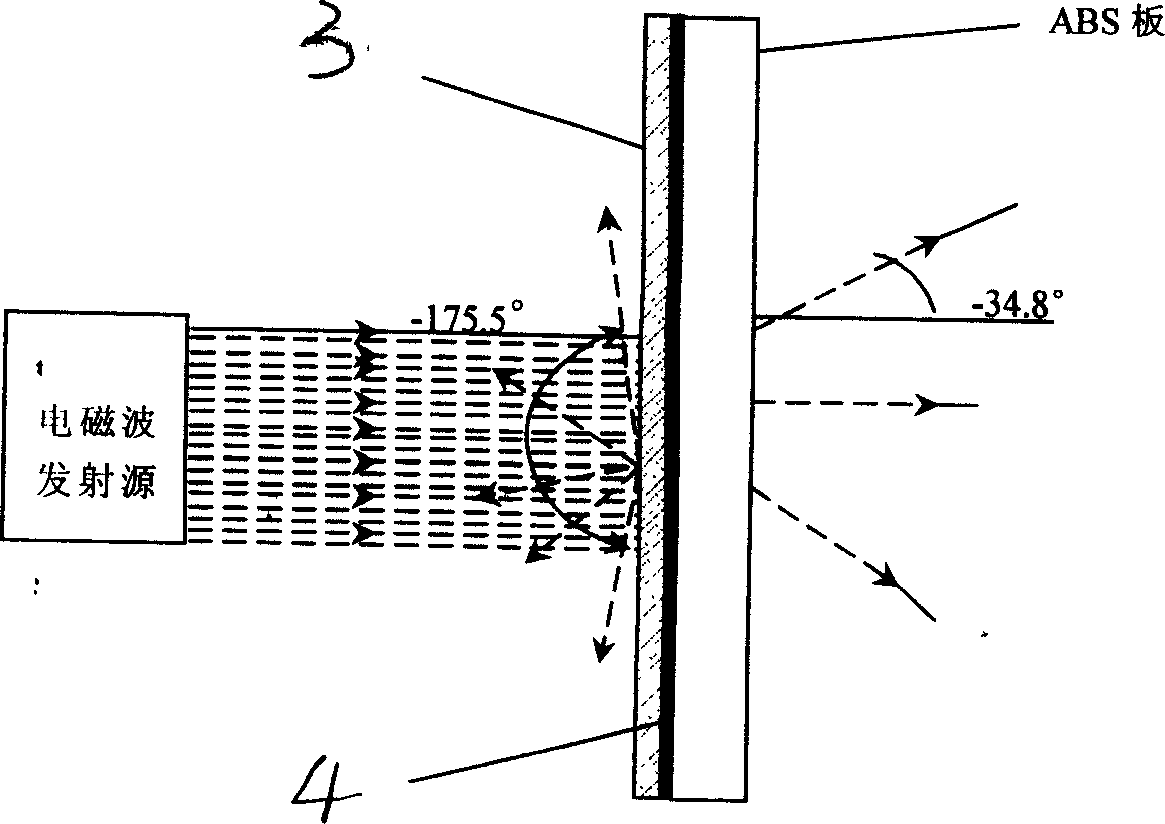

InactiveCN1624052AStrong surface bonding fastnessStrong combination fastnessRadiation-absorbing paintsNano siliconN-Butanol

A wave-absorbing composite nano-paint for military purpose, communication equipment, etc is prepared from methylisobutyl methanone, ethanediol butylether, n-butanol, resin, nano-silicon carbide, Ni nanoparticlels and carbon black through dissolving resin in solvent, preparing the bottom and surface wave-absorbing materials, mixing, stirring, and ball grinding. Its advantages are high absorptivity to electromagnetic waves, with bandwich, and low cost.

Owner:西安华捷科技发展有限责任公司

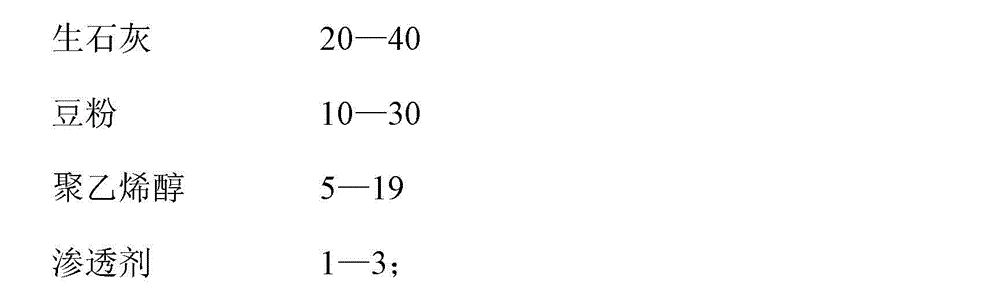

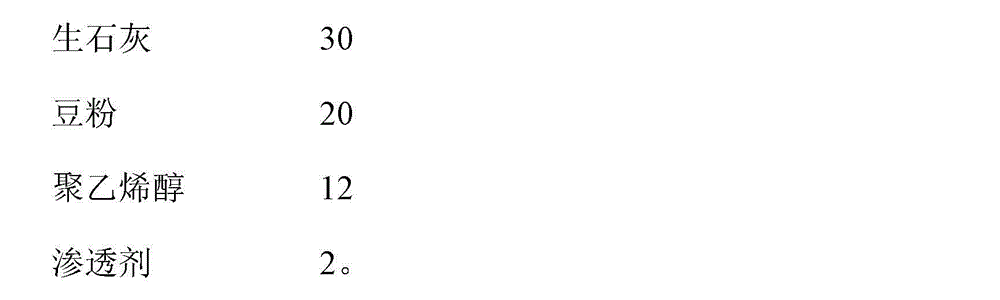

Resist agent for blue calico

InactiveCN102127874ALittle impact on purityStrong combination fastnessDyeing processPolymer sciencePolyvinyl alcohol

The invention relates to the technical field of blue calico production and manufacture, in particular to a resist agent for blue calico, aiming to provide a resist agent for blue calico, being simple to make and process and having high adhesive rate. The invention adopts the technical scheme that the resist agent for blue calico comprises quicklime, soybean meal, polyvinyl alcohol and penetrant. The invention has the advantages of simpleness in preparation and processing, less influence by raw material purity, high adhesive rate, good adsorption property and strong bonding firmness with cotton cloth, and the blue calico made by the resist agent can be normally used after being aired, wherein the airing time is shortened from 7 days to18h.

Owner:滨州技师学院

Wood surface chemical color changing method

ActiveCN109333716ARich in colorRich color varietyWood treatment detailsThermal wood treatmentCopper chlorideColor changes

The invention discloses a wood surface chemical color changing method. According to the wood surface chemical color changing method, the surface of wood is coated with copper chloride solution first,after drying, the surface of the wood is coated with a color changing agent, drying is conducted again, color changing of the wood is completed, and a finished product is obtained. The wood surface chemical color changing method has superior permeability, bonding strength of the color changing solution and the wood is higher, loss resistance is better, thus the color presented by the product madethrough the wood surface chemical color changing method is richer, lines are clearer, the layered feeling is higher, the color changing method is simple to operate, and the processing process is moreenvironmentally friendly.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for producing agricultural residue wheat straw/waste plastic pencil

InactiveCN102205765ANo glue phenomenonMeet usage habitsNon-propelling pencilsNib holdersAdhesiveAgricultural residue

The invention relates to a method for producing an agricultural residue wheat straw / waste plastic pencil, which is characterized by comprising the steps of sieving sand, gravel and metal solid impurities from waste plastics and grinding; airing, drying, smashing and sieving wheat straws; mixing dried wheat straw whole powder with the sheet waste plastic broken materials at a high speed, spraying an isocyanate adhesive, stirring and blending; and filling the spray gel blending material in a pencil moulding press, hot-pressing, filling in a pencil lead, cold-pressing and decorating the appearance by utilizing paint. The pencil produced by utilizing the method has a nature appearance similar to wood and high penholder bonding fastness; the wood is replaced by the wheat straws and the waste plastics; the raw material resource in our country is vast; and therefore, the price is low and a very important significance is provided for environmental protection of our country.

Owner:匡赞辉

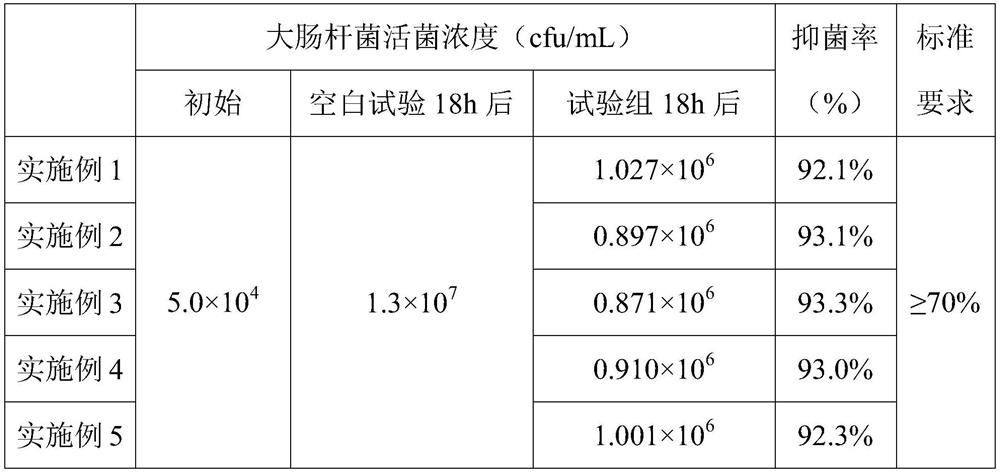

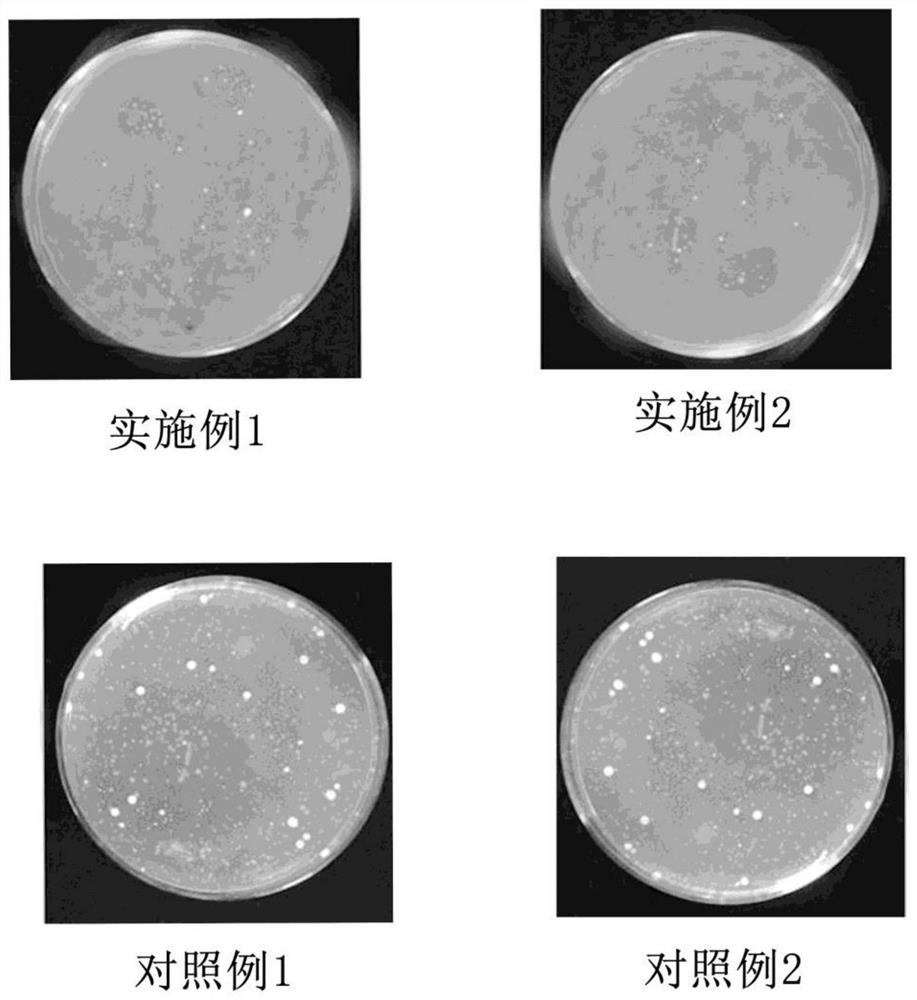

Preparation method of household antibacterial carpet

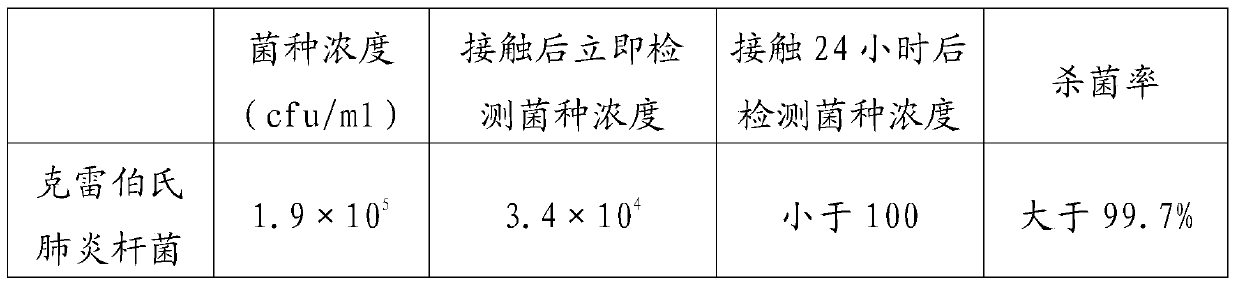

InactiveCN108252089AImprove antibacterial propertiesStable structureOrganic chemistryBiochemical treatment with wool-protecting/anti-moth agentsEscherichia coliStaphylococcus aureus

The invention provides a preparation method of a household antibacterial carpet and an antibacterial agent, which comprises the following steps: soaking carpet cloth into a triazinyl quaternized N-halamine solution for treating for 5-15 minutes at 50-70 DEG C; and heating to 80-90 DEG C, adding sodium hydroxide for reacting for 1-3 hours, cleaning and drying to obtain the household antibacterial carpet. Compared with the prior art, the invention has the advantage that triazinyl quaternized N-halamine is used as the antibacterial agent, quaternary ammonium salt and N-halamine can adsorb pathogenic microorganism with negative charge, destroy the cell wall structure of the microorganism so that dissoluble matter leaks out, and inhibit pathogen oxidase and dehydrogenase. Because the quaternaryammonium salt and the N-halamine coexist, the prepared antibacterial carpet performs excellent organism-killing activity on staphylococcus aureus and escherichia coli. An experiment result shows thatthe household antibacterial carpet prepared by the invention has good antibacterial effect.

Owner:天台圣安伦地毯股份有限公司

Antistatic protective film

ActiveCN109776836AReduce surface tensionGood weather resistanceElectrically-conductive paintsPolyesterAntistatic agent

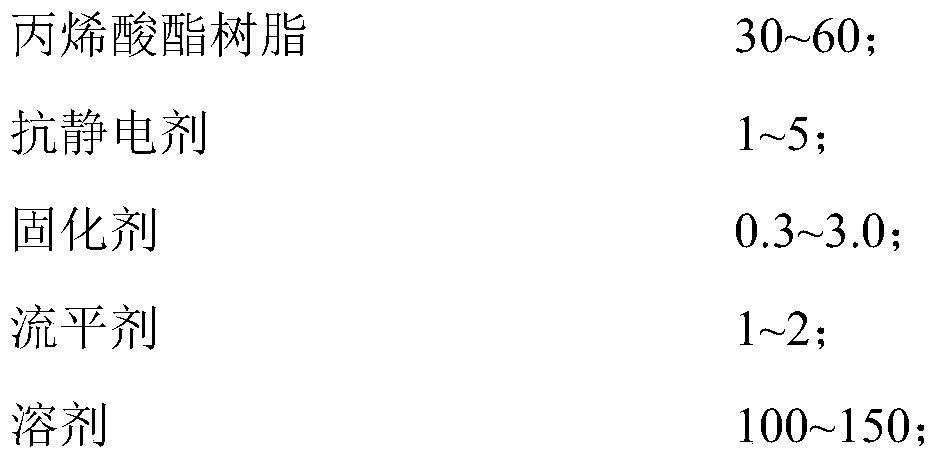

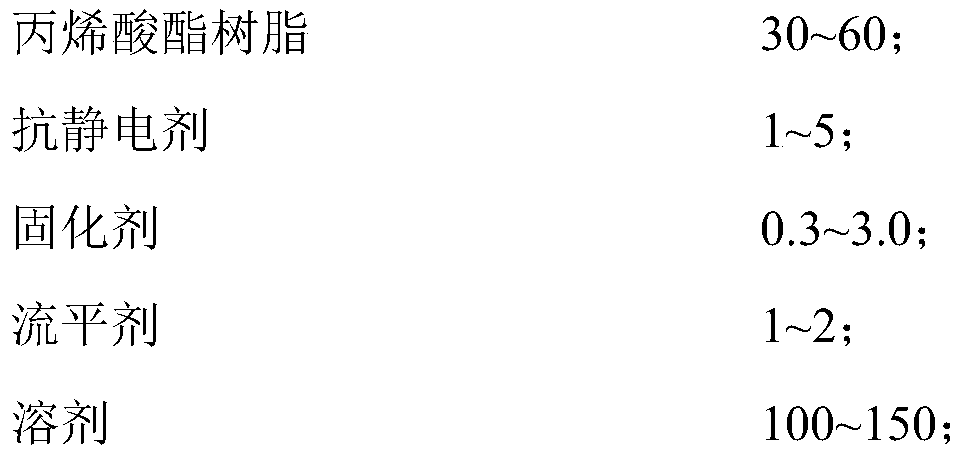

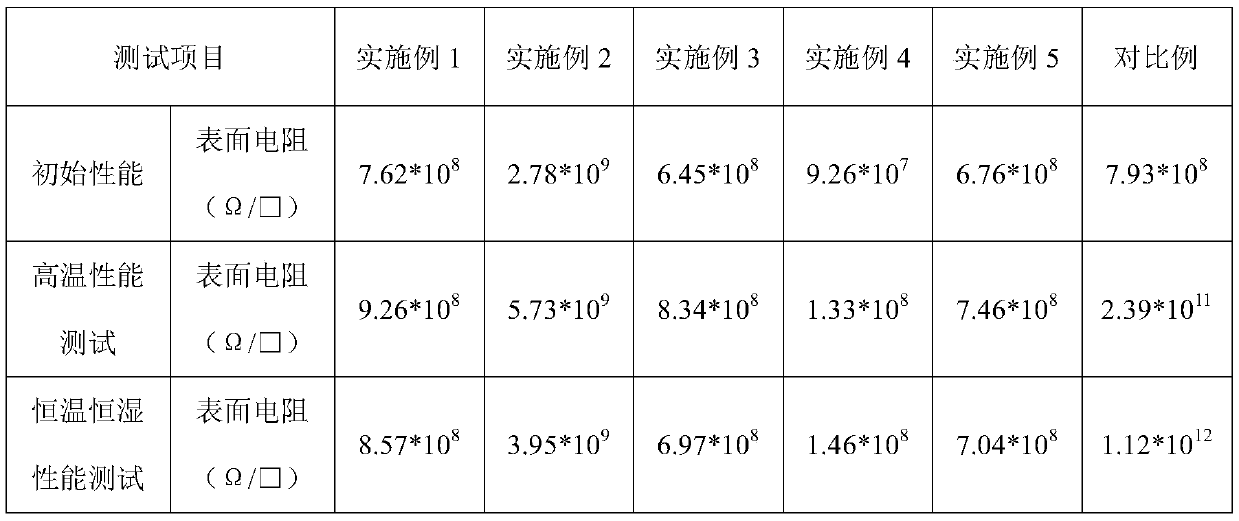

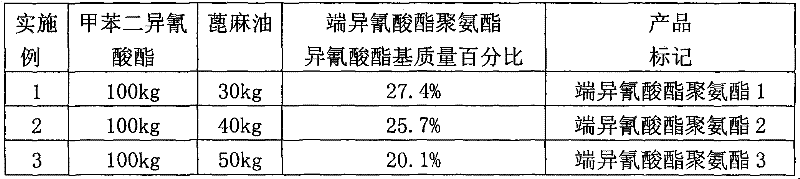

The invention relates to an antistatic protective film. The antistatic protective film comprises a polyester film and antistatic coating which coats the polyester film, wherein the antistatic coatingcomprises the following components in parts by weight: 30-60 parts of acrylate resin, 1-5 parts of an antistatic agent, 0.3-3.0 parts of a curing agent, 1-2 parts of a leveling agent and 100-150 partsof a solvent. An organosiloxane monomer and a fluorine-containing acrylic monomer are directly introduced into a main chain, silicon-oxygen chain segments are formed during polymerization, and fluorine-containing chain segments can form shielding protection for the main chain and internal molecules, so that the stability of polymer molecules is improved; the cohesive force of the polymer molecules is increased after crosslinking of the acrylate resin, and the three-dimensional network structure of the antistatic coating is compact and water molecules difficultly penetrate therein, so that theweather resistance of the antistatic coating is improved; after the antistatic protective film provided by the invention is placed for 500 hours under high-temperature, constant-temperature and constant-humidity conditions, the antistatic coating can still maintain a good antistatic property.

Owner:HEFEI LUCKY SCI & TECH IND

Preparation method of novel pencil

InactiveCN102205764ANo glue phenomenonMeet usage habitsNon-propelling pencilsNib holdersBond strengthImpurity

The invention discloses a preparation method of a novel pencil. The preparation method is characterized by comprising the following steps of: screening sands, stones and metal solid impurities out of waste plastics, and grinding; airing rice straws, drying, crushing and sieving; crushing dried rice straw whole powder and sheet-like waste plastics, mixing at a high speed, spraying an isocyanate adhesive, stirring and mixing; and filling a sprayed adhesive blended material into a pencil mould press, hot-pressing, putting into a pencil core, cold-pressing, and decorating appearance by using paint. A pencil which is prepared by the method has natural appearance similar to wood; a penholder is high in bonding strength; the wood is replaced by the rice straws and the waste plastics; China has abundant raw material resources which are low in cost; and the preparation method has great significance for environmental protection of China.

Owner:匡赞辉

Preparation method of novel pencil

InactiveCN102205767AEffective resourcesLow priceNon-propelling pencilsNib holdersMixed materialsBond strength

The invention discloses a preparation method of a novel pencil. The method is characterized by comprising the following steps of: drying rice straws, crushing into rice straw whole powder of less than 20 meshes; and mixing an isocyanate adhesive and the rice straw whole powder, hot-pressing a mixed material, putting into a pencil core, and cold-pressing to prepare the pencil. The pencil which is prepared by the method has natural appearance similar to wood; a penholder is high in bonding strength; the wood is replaced by agricultural wastes such as the maize straws; China has abundant raw material resources which are low in cost; and the preparation method has great significance for environmental protection of China.

Owner:匡赞辉

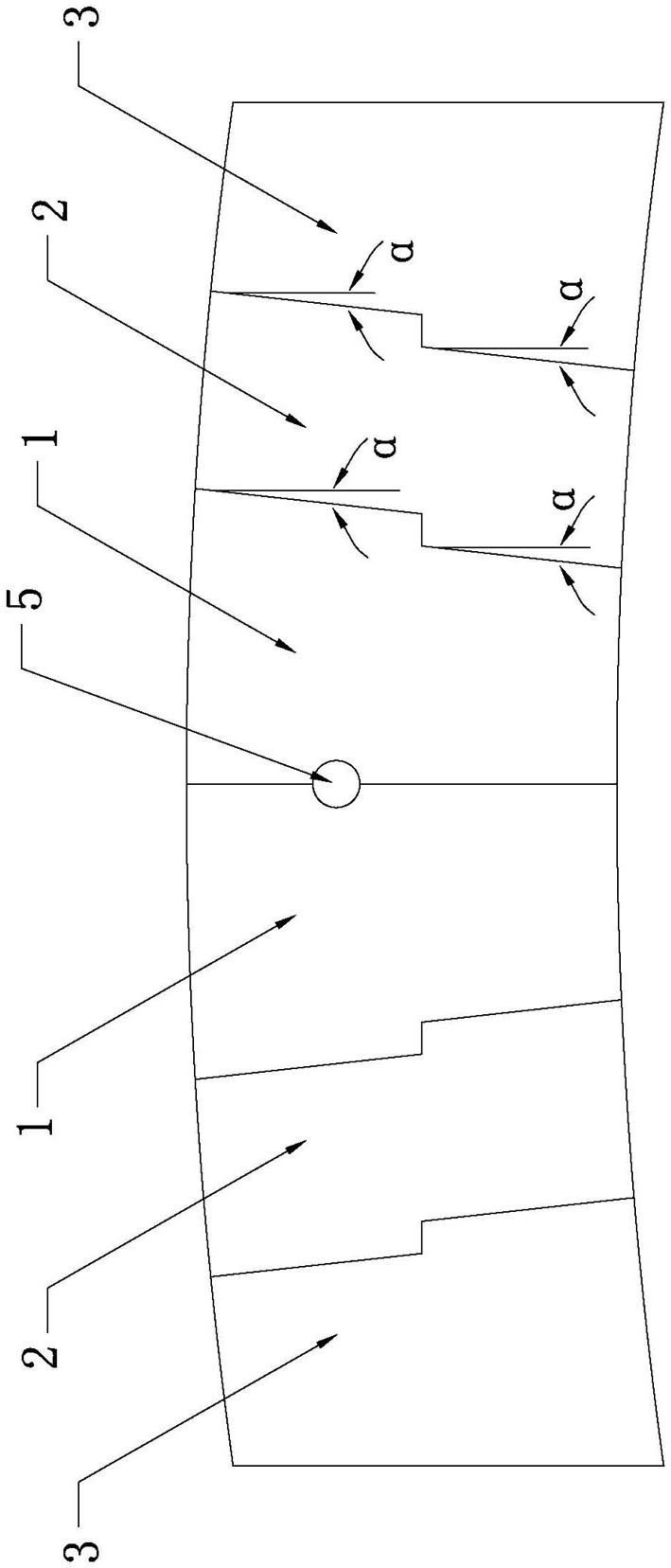

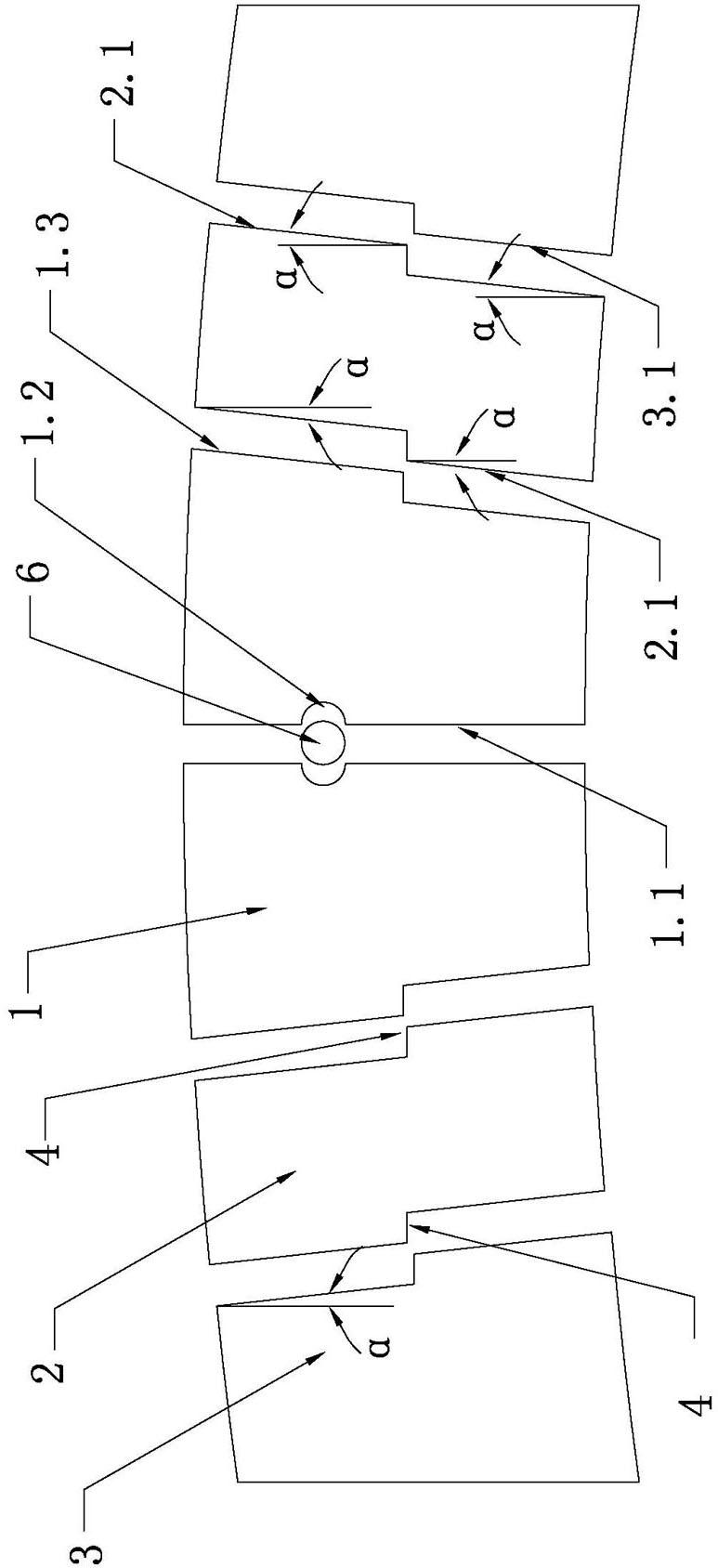

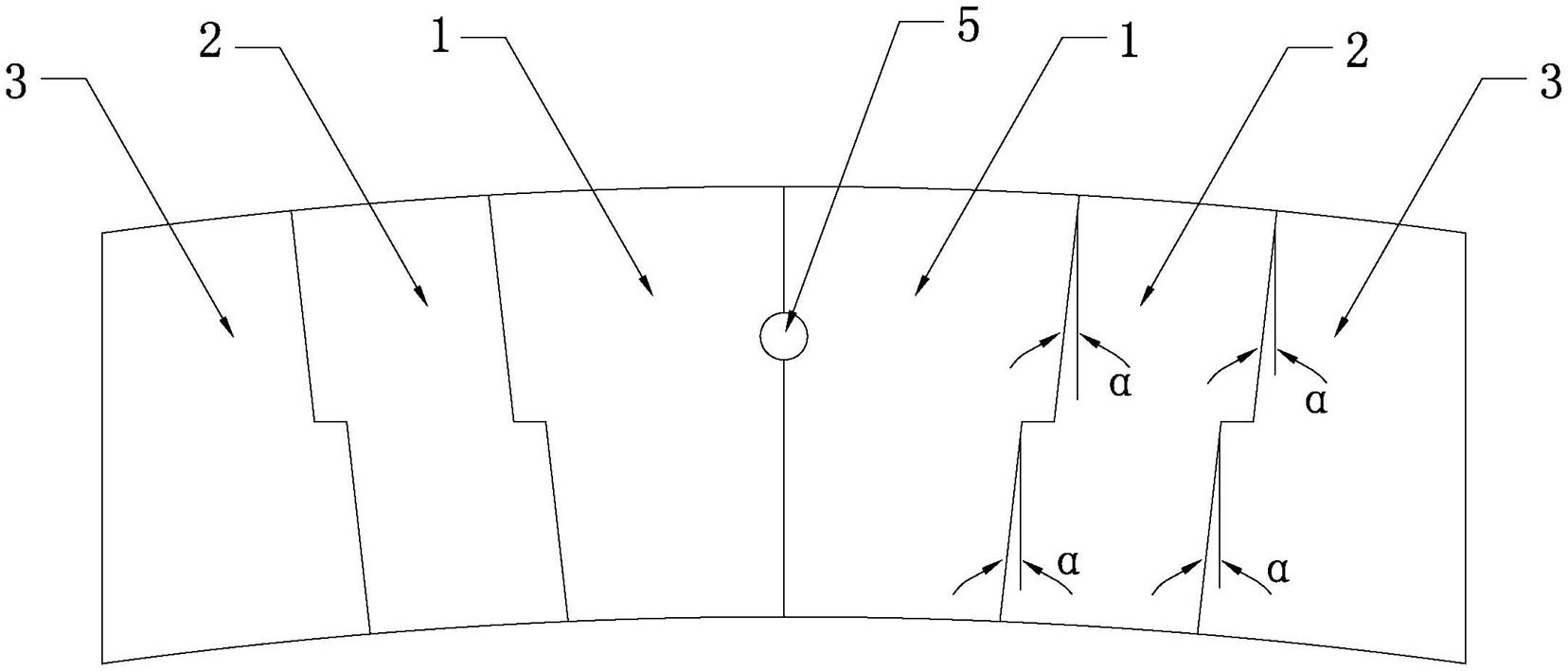

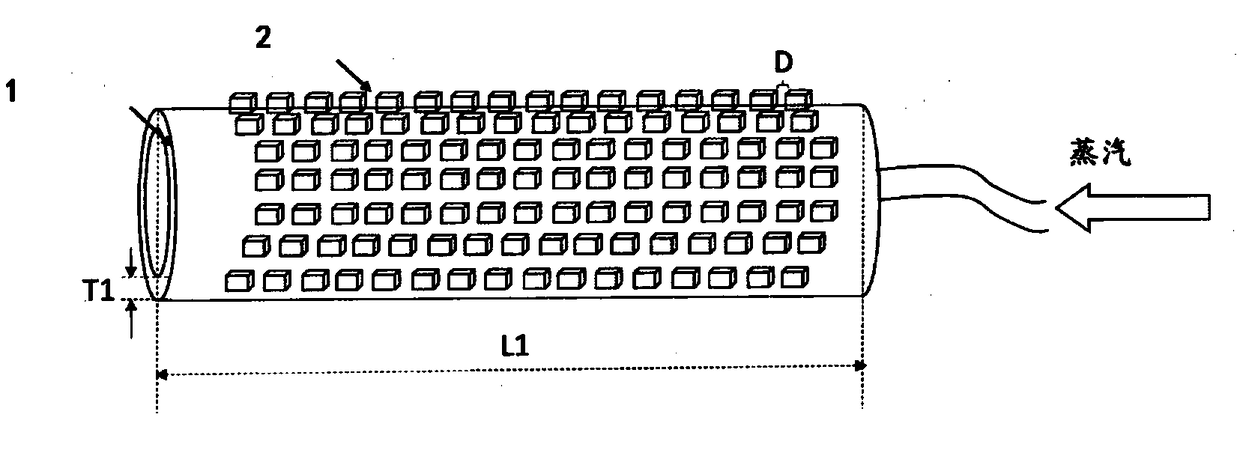

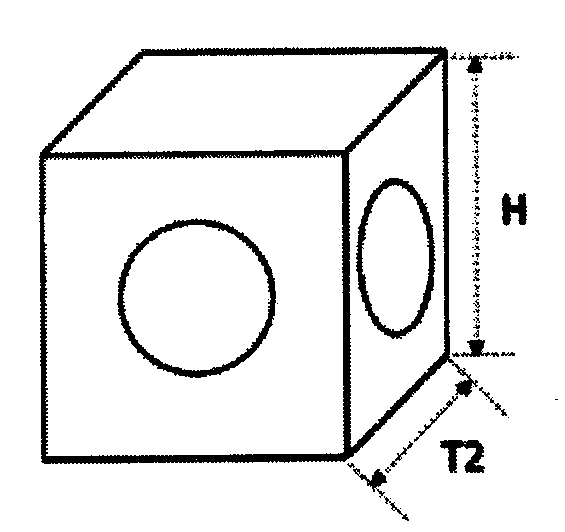

Kiln body arched beam in high-temperature area of pushed slab kiln with nitrogen protection

The invention relates to a kiln body arched beam in a high-temperature area of a pushed slab kiln with nitrogen protection. The kiln body arched beam is characterized in that middle arched beam bricks, inner arched beam bricks and outer arched beam bricks are included; a semicircular groove is formed on one junction surface of each middle arched beam brick, and the other junction surface of each middle arched beam brick is an junction surface; the two junction surfaces of each inner arched beam brick are inclined surfaces; one junction surface of each outer arched beam brick is an inclined surface; the oblique angles alpha of the inclined surfaces of the middle arched beam bricks, the inner arched beam bricks and the outer arched beam bricks range from 3 degrees to 10 degrees; mutually corresponding intermeshing steps are arranged on the inclined surfaces of the middle arched beam bricks, the inner arched beam bricks and the outer arched beam bricks respectively; the middle arched beam bricks, the inner arched beam bricks and the outer arched beam bricks are installed in bilateral symmetry; the semicircular grooves of the two middle arched beam bricks constitute an insertion hole; and a pin column is arranged in the insertion hole. The kiln body arched beam has the advantages of low possibility of loosening, less maintenance and repair, convenience in maintenance and repair and improved production efficiency.

Owner:JIANGYIN CHANGYUAN MASCH MFG CO LTD

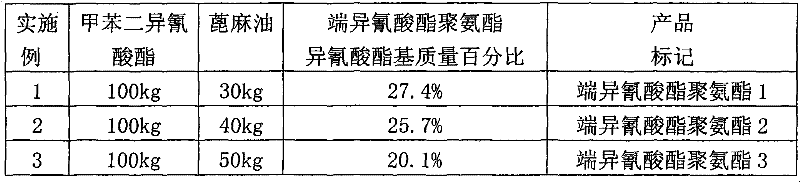

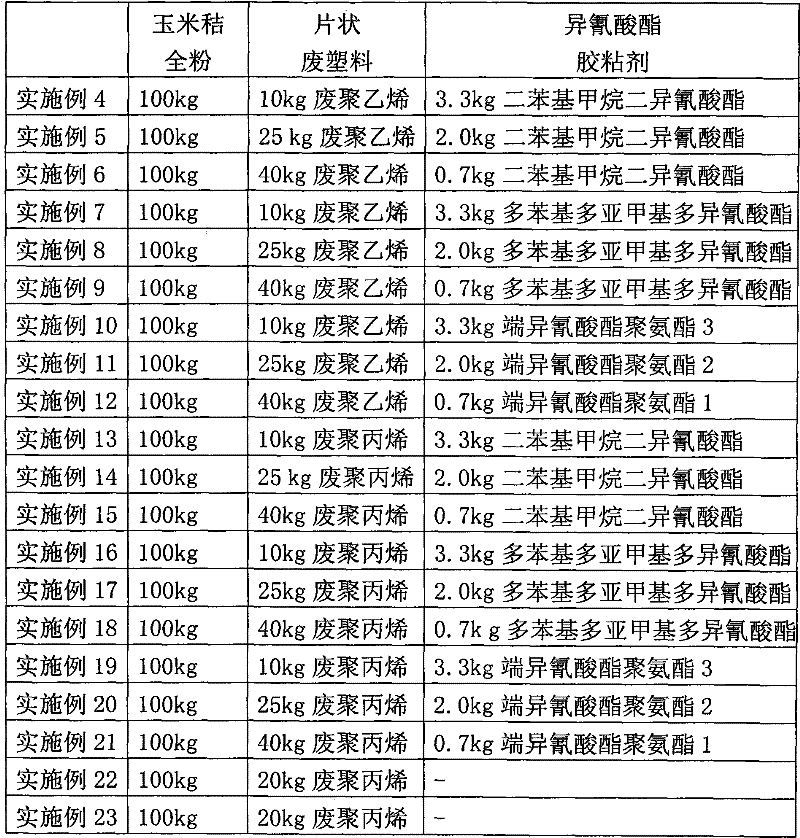

Preparation method for corn stalk/recycling waste plastic pencil

InactiveCN102248839ANo glue phenomenonMeet usage habitsNon-propelling pencilsNib holdersAdhesiveImpurity

The invention discloses a preparation method for a corn stalk / recycling waste plastic pencil. The preparation method for the corn stalk / recycling waste plastic pencil is characterized by comprising the following steps of: screening sands, pebbles and metallic sold impurities out of waste plastics, and grinding; airing corn stalks, drying, smashing and sieving; mixing the dried corn stalk whole powder and platy waste plastic crushed materials at a high speed, spraying an isocyanate adhesive, stirring and blending; and filling the blended materials subjected to adhesive spraying into a pencil mould press, hot-pressing, feeding a pencil core, cold-pressing, and painting on the outer surface for decoration. The pencil prepared by the method has natural appearance similar to that of wood; a pencil holder has high combination fastness; and the corn stalks and the waste plastics are used for replacing the wood, and raw material resources in China are abundant and has low prices, so that the preparation method has extremely important significance for environment protection in China.

Owner:匡赞辉

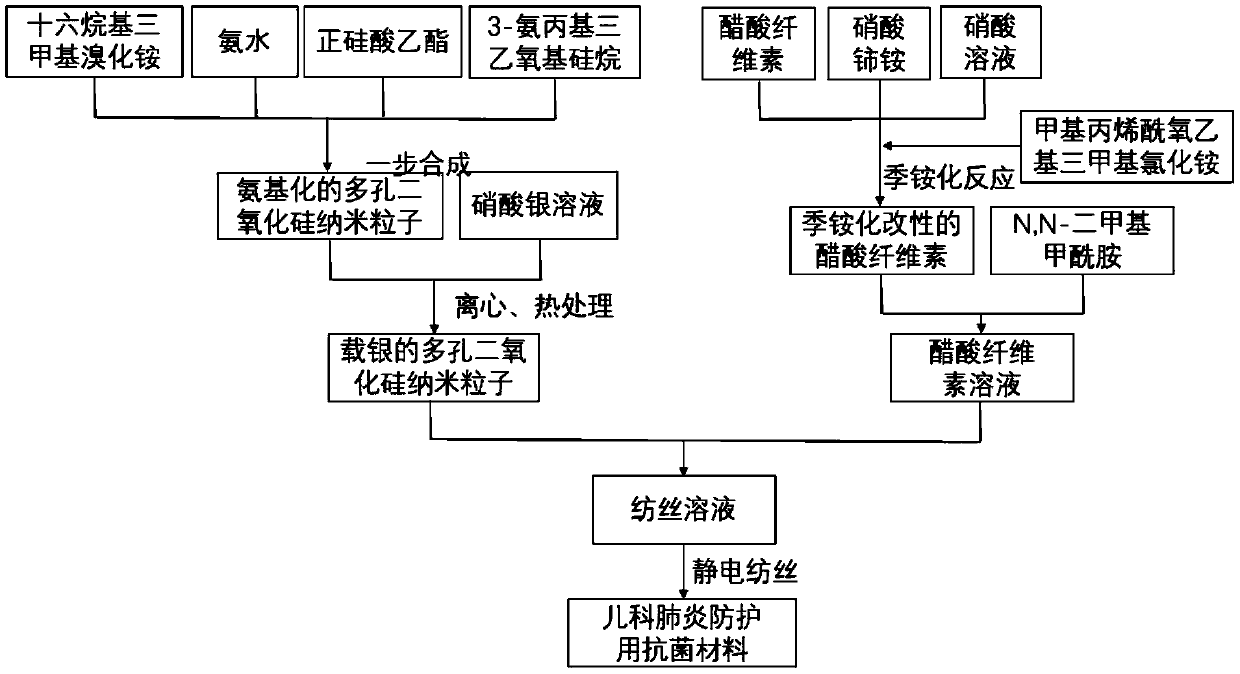

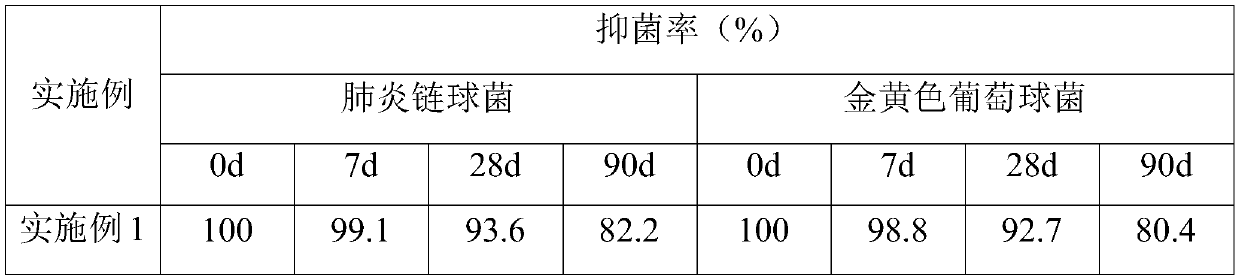

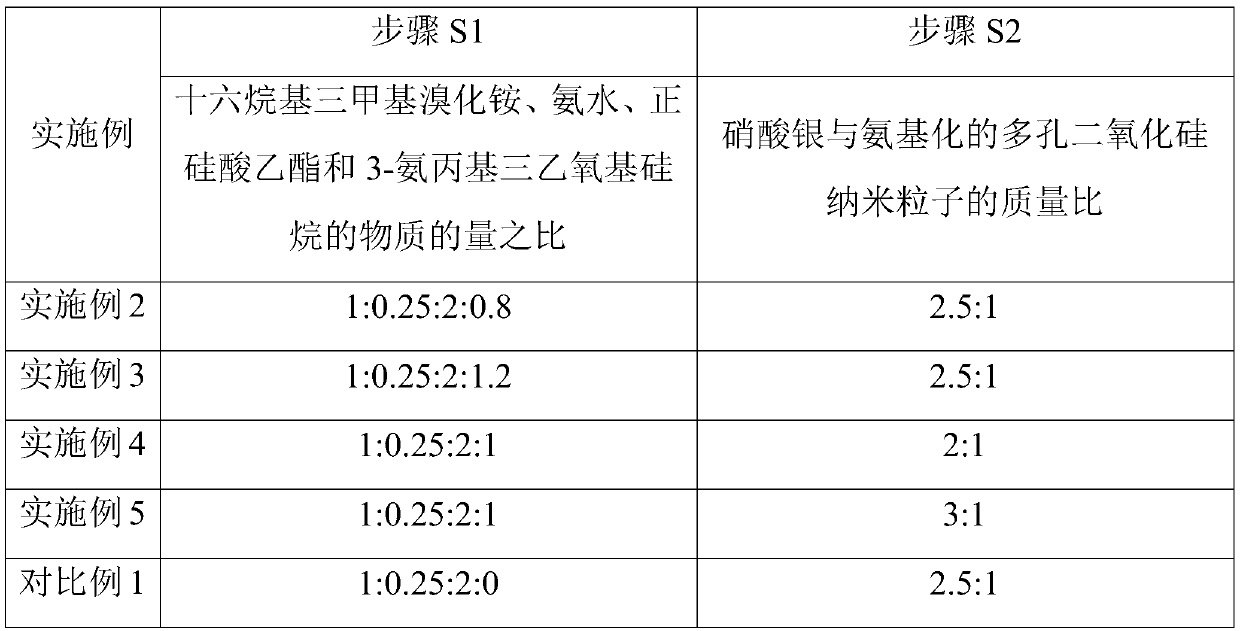

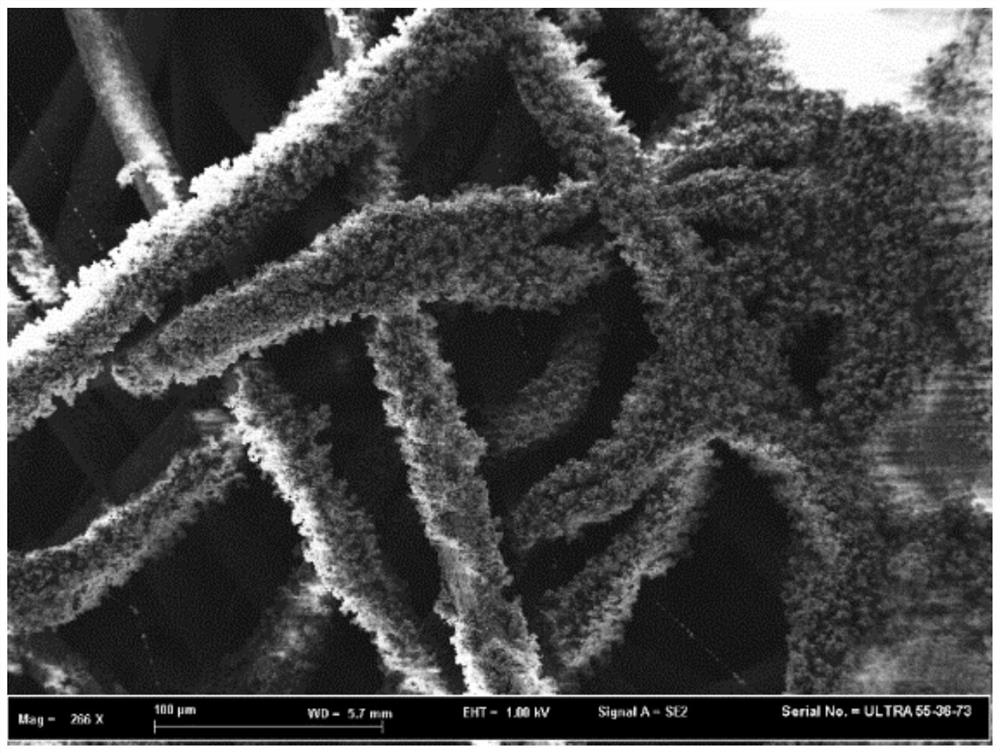

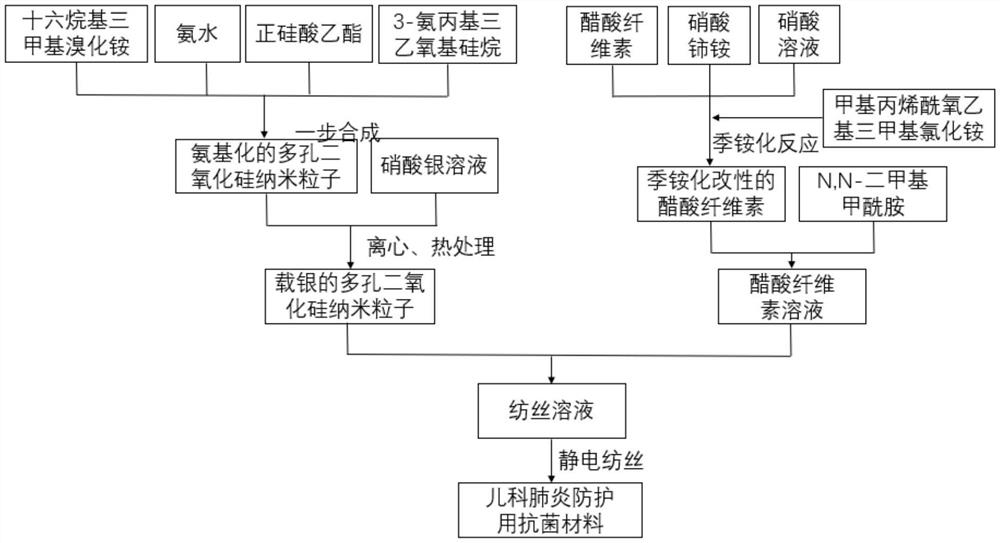

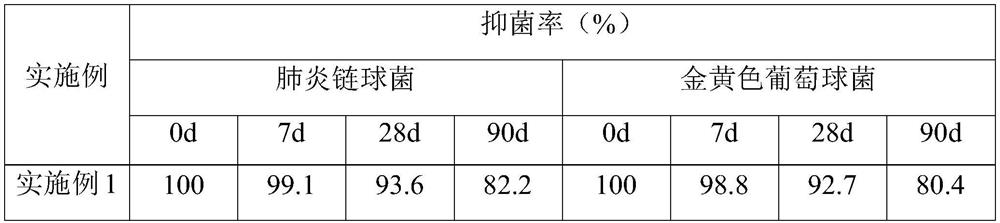

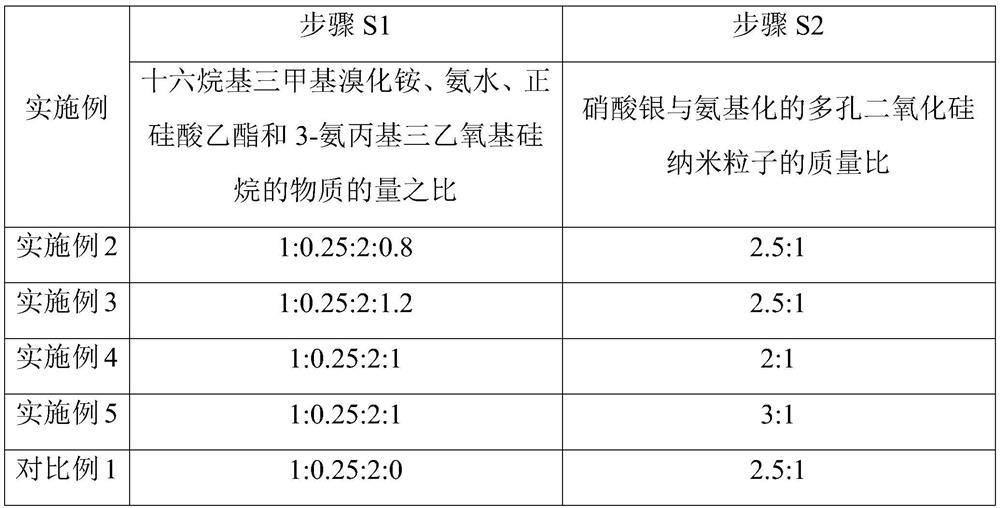

Antibacterial material for pediatric pneumonia protection and manufacturing method thereof

InactiveCN111235661AGood antibacterial propertiesSafe and long-lasting antibacterial effectArtificial filaments from cellulose derivativesArtifical filament manufacturePediatric departmentModified cellulose

The invention discloses an antibacterial material for pediatric pneumonia protection and a manufacturing method thereof. Aminated porous silicon dioxide nanoparticles are prepared and modified by silver ions, the silver-loaded porous silicon dioxide nanoparticles are embedded in quaternized modified cellulose acetate, and the antibacterial material for pediatric pneumonia protection is manufactured through an electrostatic spinning technology. In this way, abundant amino groups in the aminated porous silicon dioxide nanoparticles can be used as the active sites, and tight complexing of the silver ions is realized; and by utilizing a large amount of quaternary ammonium groups grafted on the cellulose acetate and the nano silver, the release rate of silver is reduced on the basis of ensuringthe antibacterial effect, so that the prepared antibacterial material has excellent antibacterial performance and safe and long-acting antibacterial effect. The manufacturing method of the antibacterial material for the pediatric pneumonia protection provided by the invention is easy to operate, high in controllability, capable of meeting the requirements of practical application and relatively high in application value.

Owner:HENAN PROVINCE HOSPITAL OF TCM THE SECOND AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

Antibacterial fiber, preparation method of antibacterial fiber and antibacterial product

ActiveCN113802205AStrong combination fastnessNot easy to fall offMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberElectrospinning

The invention relates to a preparation method of antibacterial fiber. The method comprises the following steps of providing a PVA aqueous solution, wherein the mass fraction of PVA in the PVA aqueous solution is 8-15%; adding nano TiO2 particles and a dispersing agent into the PVA aqueous solution, and performing ultrasonic dispersion to obtain a spinning solution, wherein the mass ratio of the PVA aqueous solution to the nano TiO2 particles ranges from (100: 1) to (100: 15), and the absolute value of the Zeta potential of the spinning solution ranges from 10 mV to 40 mV; and performing electrostatic spinning on the spinning solution to obtain the antibacterial fiber. The invention also relates to the antibacterial fiber prepared by the preparation method and an antibacterial product prepared from the antibacterial fiber. The preparation process is simple, the obtained antibacterial fiber has excellent antibacterial performance, meanwhile, the nano TiO2 particles are not prone to falling off, and the antibacterial rate is reduced by not more than 5% after 50 times of cyclic washing, so that spun products, filtering materials, packaging materials, medicine and health materials and other antibacterial products made from the antibacterial fiber have excellent antibacterial and bacteriostatic performance, and the effect is lasting.

Owner:宁波航天米瑞科技有限公司

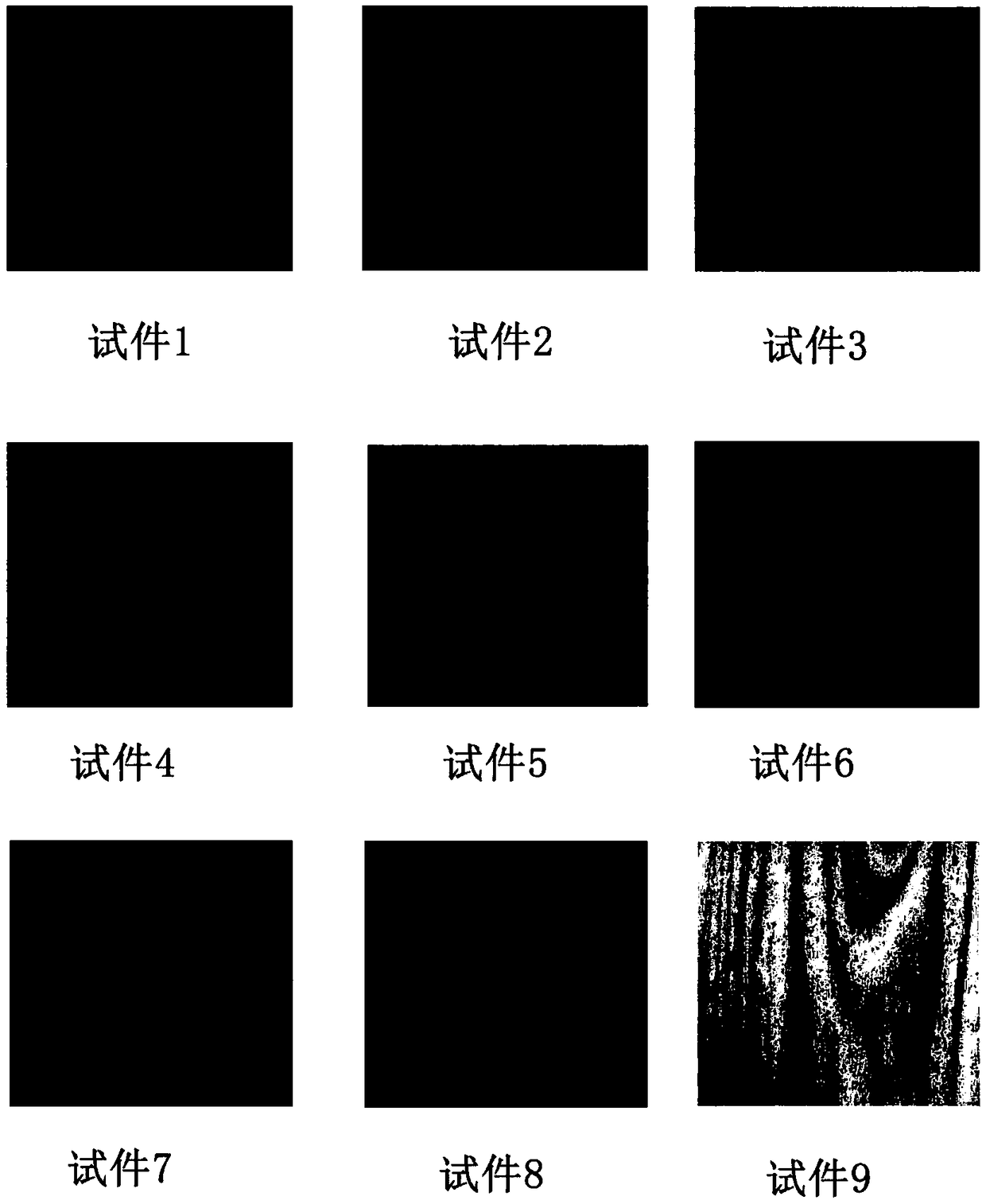

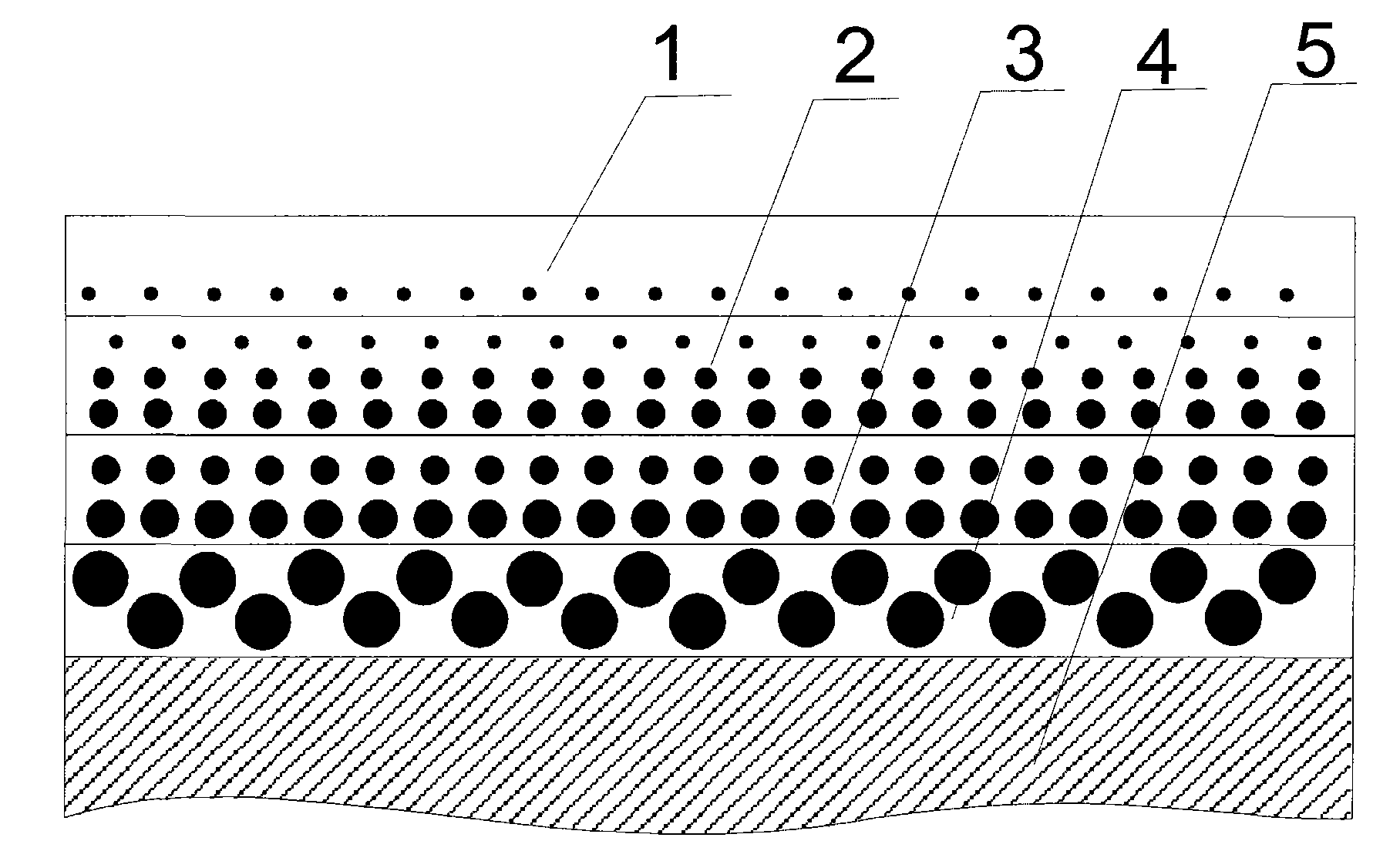

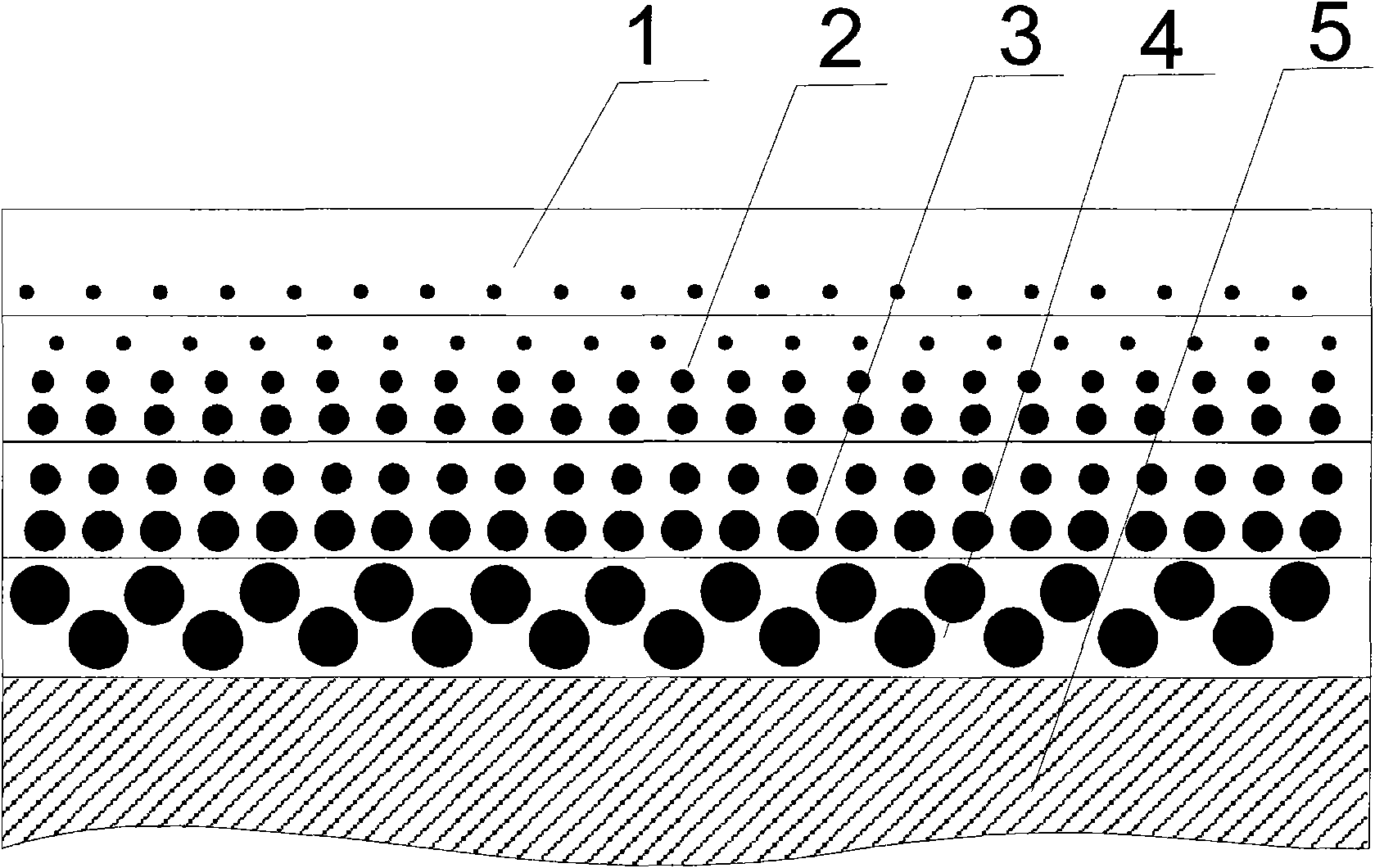

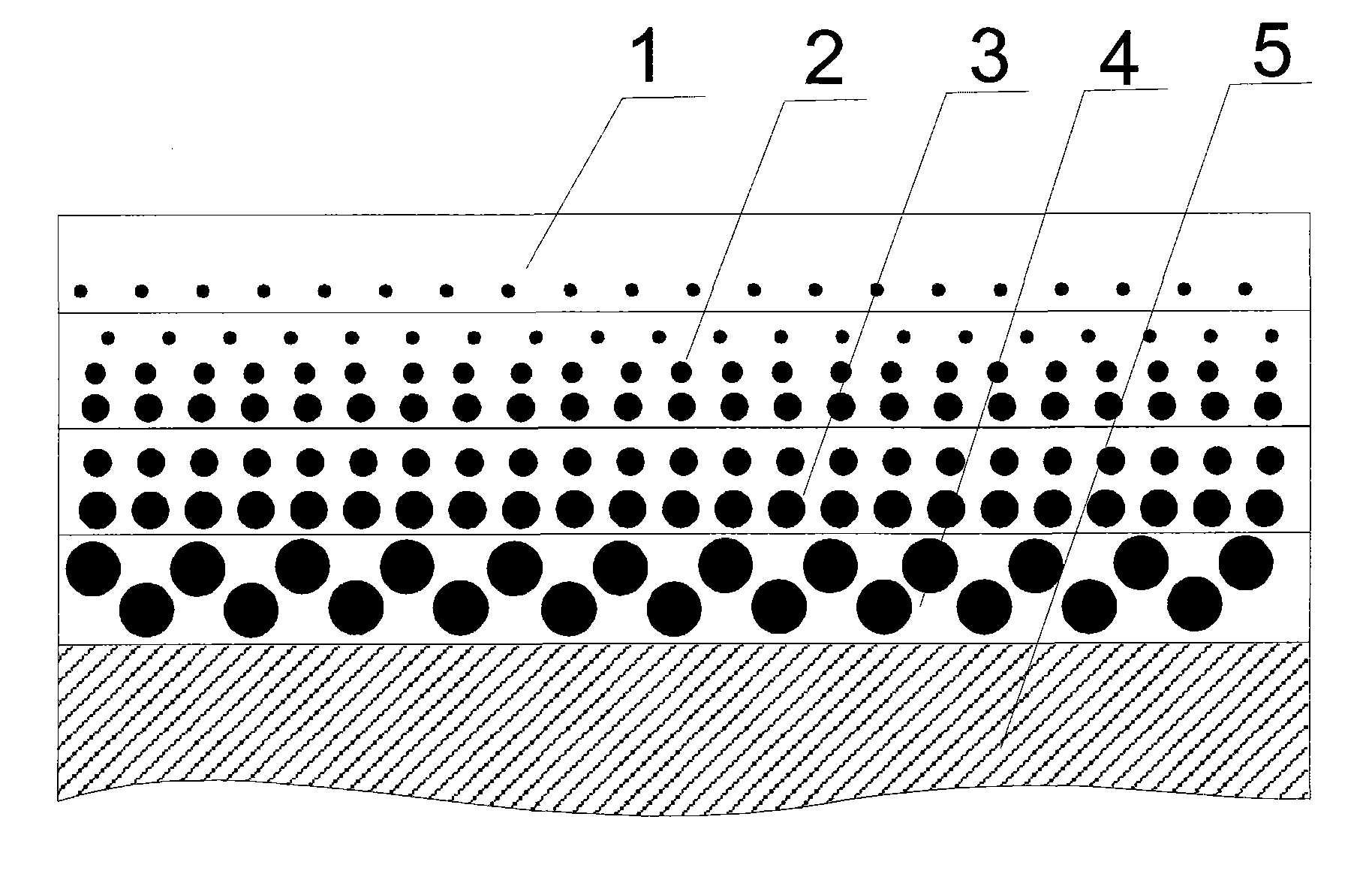

Film-coated radiation-cured bright abrasive paper and preparation method thereof

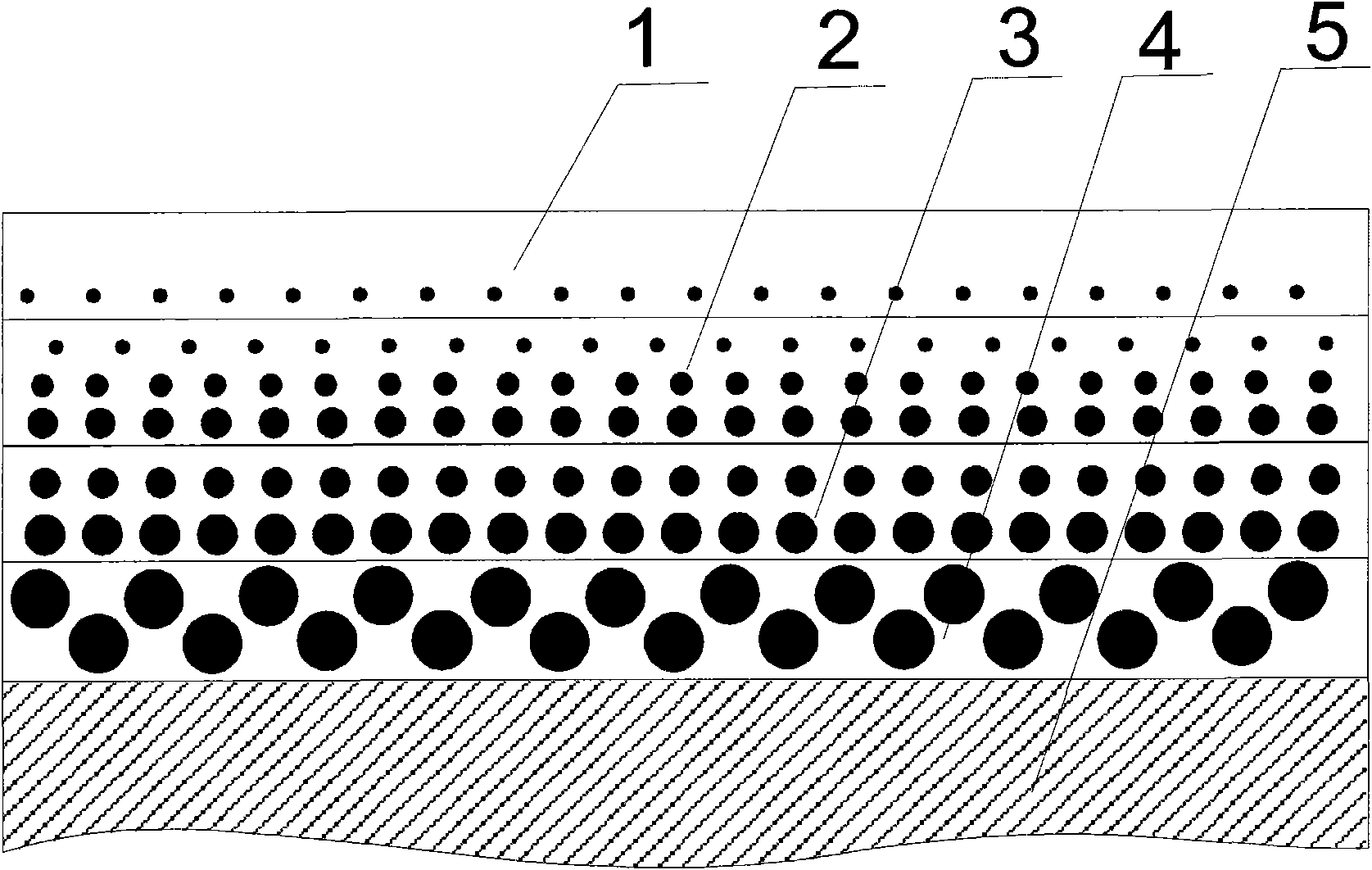

PendingCN111270560AStrong combination fastnessHigh brightness and glossSpecial paperPaper/cardboardVolatile organic compoundPrepolymer

The invention discloses film-coated radiation-cured bright abrasive paper and a preparation method of the film-coated radiation-cured bright abrasive paper. The paper comprises a paper base material,an adhesive layer, an evaporation layer, a frosted layer, a film layer and a surface coating, wherein the frosted layer is prepared from a frosted coating added with organic frosted particles; the frosted coating is prepared from the following components in parts by weight: 20-70 parts of a prepolymer, 20-70 parts of an active diluent, 1.0-20.0 parts of organic frosted particles, 0-5.0 parts of aphotoinitiator and 1.0-5.0 parts of an auxiliary agent. By means of the technical scheme, the paper has bright bright crystal effect, strong visual impact effect, visual impression of frosted and gravel, smooth surface, low energy consumption, zero emission of volatile organic compounds in the technological process, and environmental protection.

Owner:YANTAI BOYUAN TECH MATERIALS

Special epoxy anticorrosive antibacterial powder coating for valve fire protection and preparation method thereof

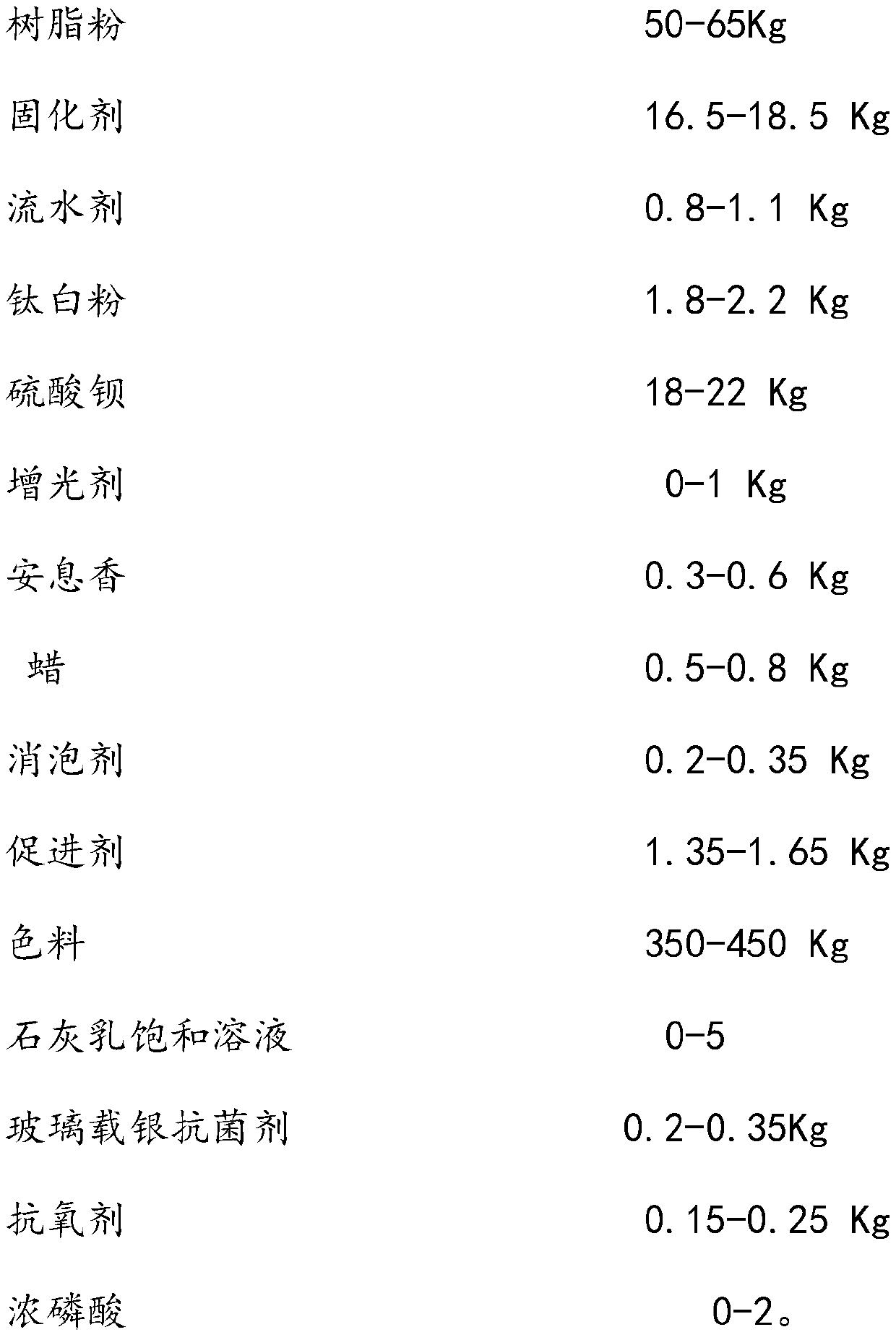

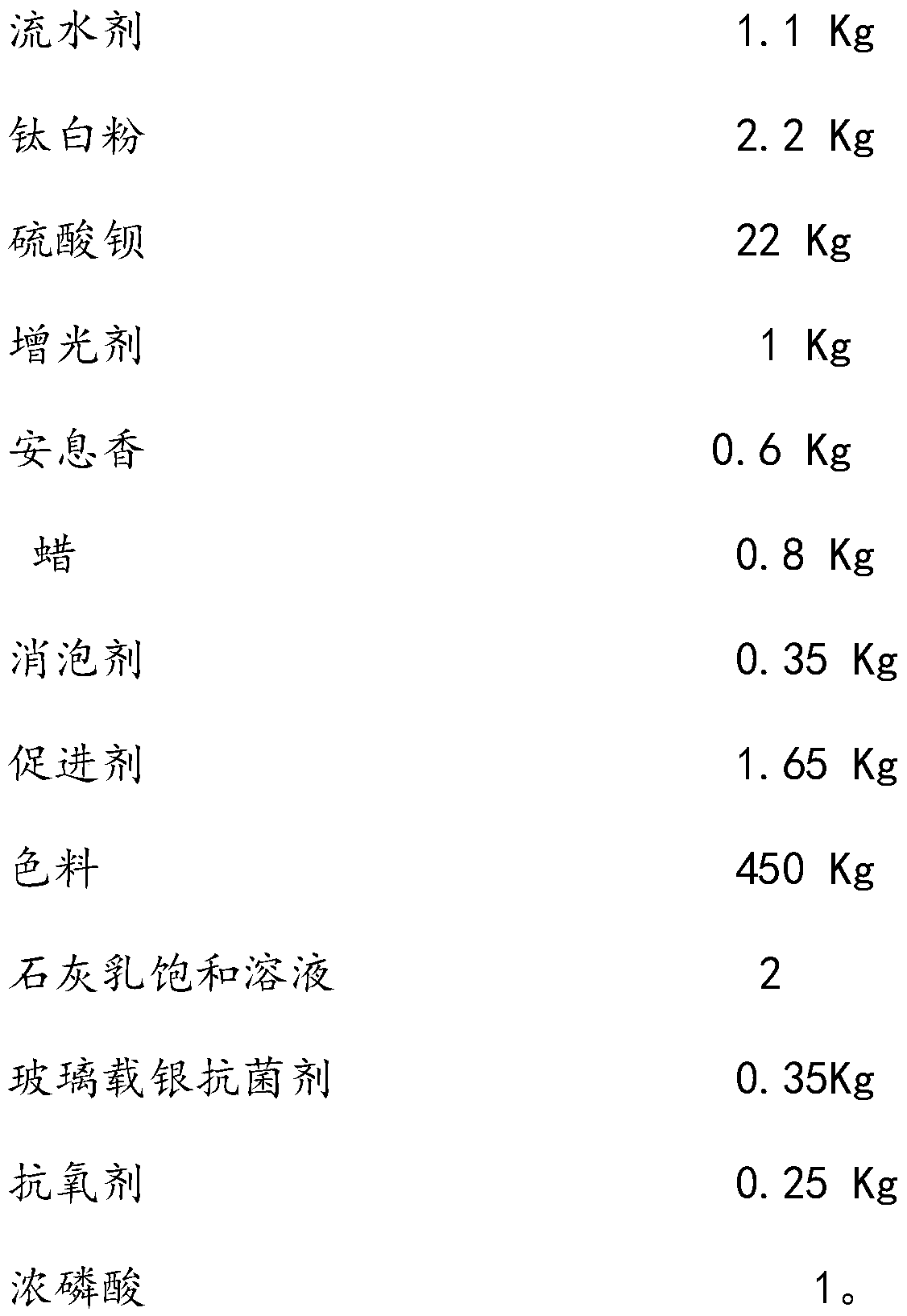

InactiveCN111484775AImprove liquidityUniform flow stateAntifouling/underwater paintsPaints with biocidesPolymer scienceO-Phosphoric Acid

The invention provides special epoxy anticorrosive antibacterial powder for valve fire protection and a preparation method thereof. The preparation method comprises the following steps: adding 50-65Kgof resin powder; 16.5 to 18.5 Kg of a curing agent; 0.8 to 1.1 Kg of a flowing water agent; 1.8 to 2.2 Kg of titanium dioxide; 18 to 22Kg of barium sulfate; 0 to 1Kg of gloss enhancer; 0.3 to 0.6 Kgof benzoin; 0.5 to 0.8 kg of wax, 0.2 to 0.35 kg of a defoaming agent, 1.35 to 1.65Kg of an accelerant, 350 to 450Kg of a pigment, 0.2 to 0.35Kg of a glass silver-loaded antibacterial agent, 0.15 to 0.25 kg of an antioxidant and 0 to 2Kg of concentrated phosphoric acid and mixing the above components at a high speed to form powder; adding 0-5Kg of lime milk saturated solution during high-speed mixing to obtain a mixture; carrying out a melting reaction at 96 + / -3 DEG C by using a screw extruder to extrude a mucilage glue-like body, rolling the mucilage glue-like body into continuous sheets with the thickness of 1-1.5 mm, cooling, rolling the sheets into fragments, grinding the fragments into powder by using a high-speed flour mill, screening, and determining the particle size to obtain theantibacterial and anticorrosive powder coating.

Owner:福建佳辉塑粉有限公司

A kind of air filter material capable of releasing negative ions and preparation method thereof

ActiveCN106621571BIncrease concentrationFacilitated releaseDispersed particle filtrationFilament/thread formingAir filterNanofiber

Owner:DONGHUA UNIV

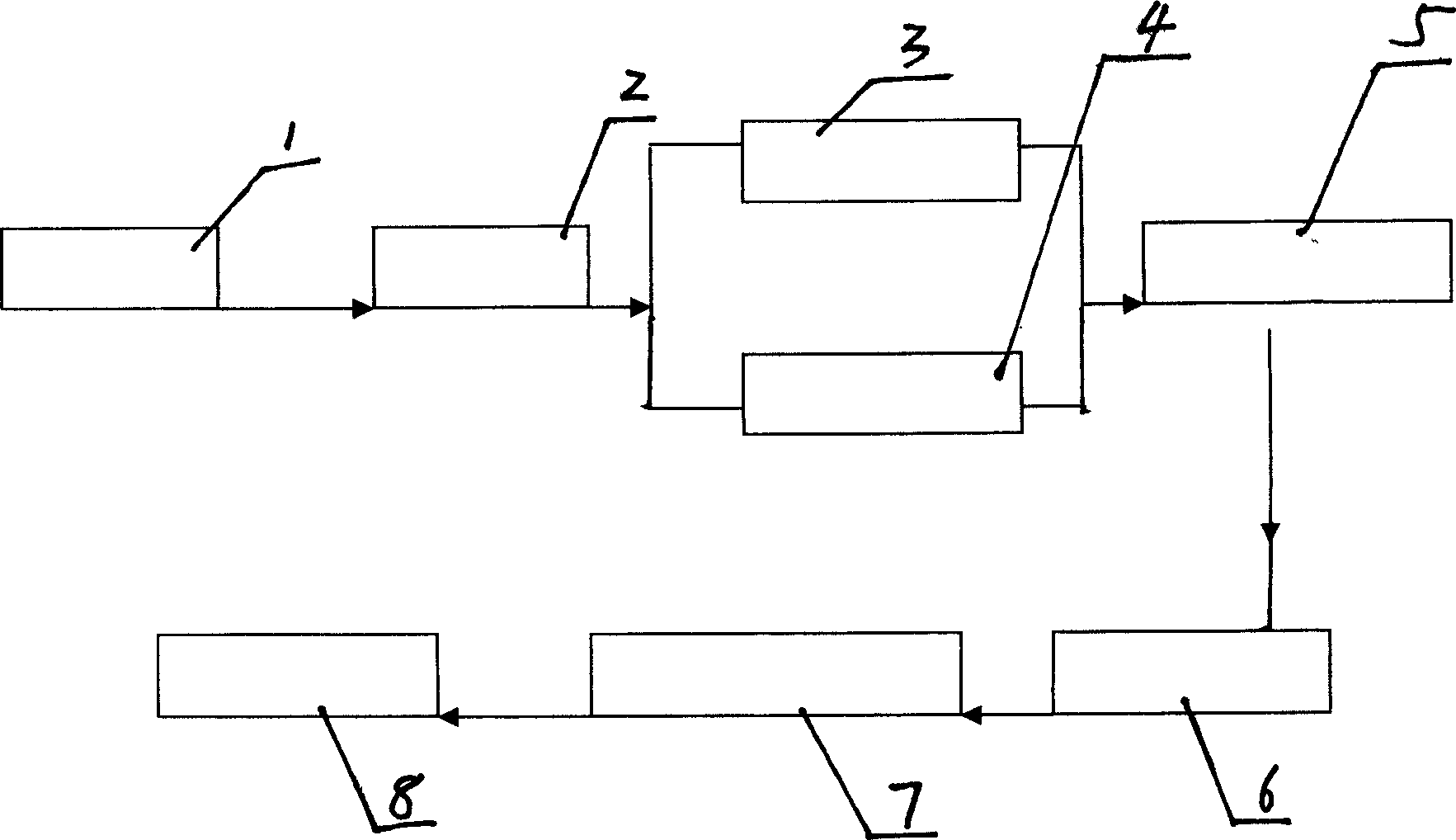

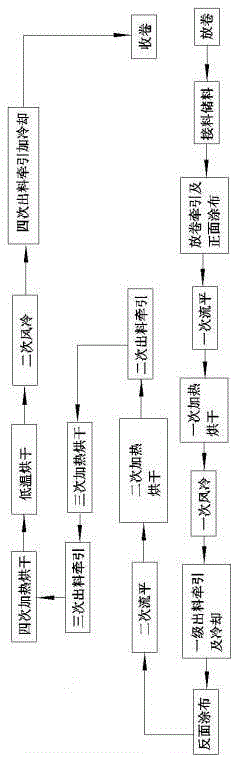

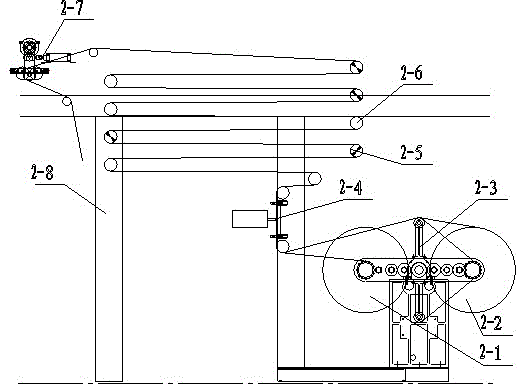

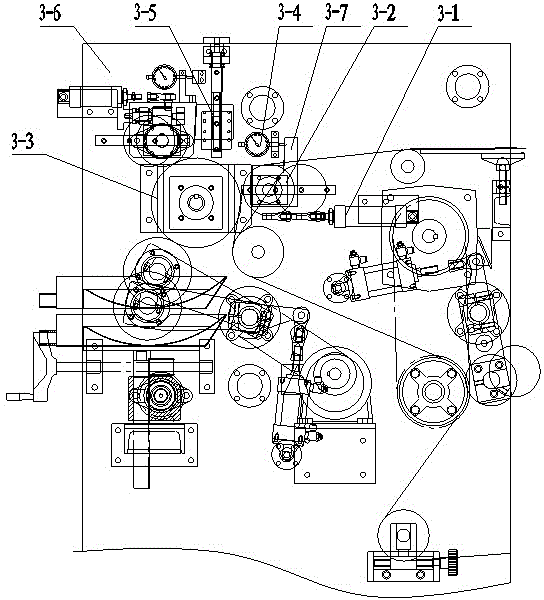

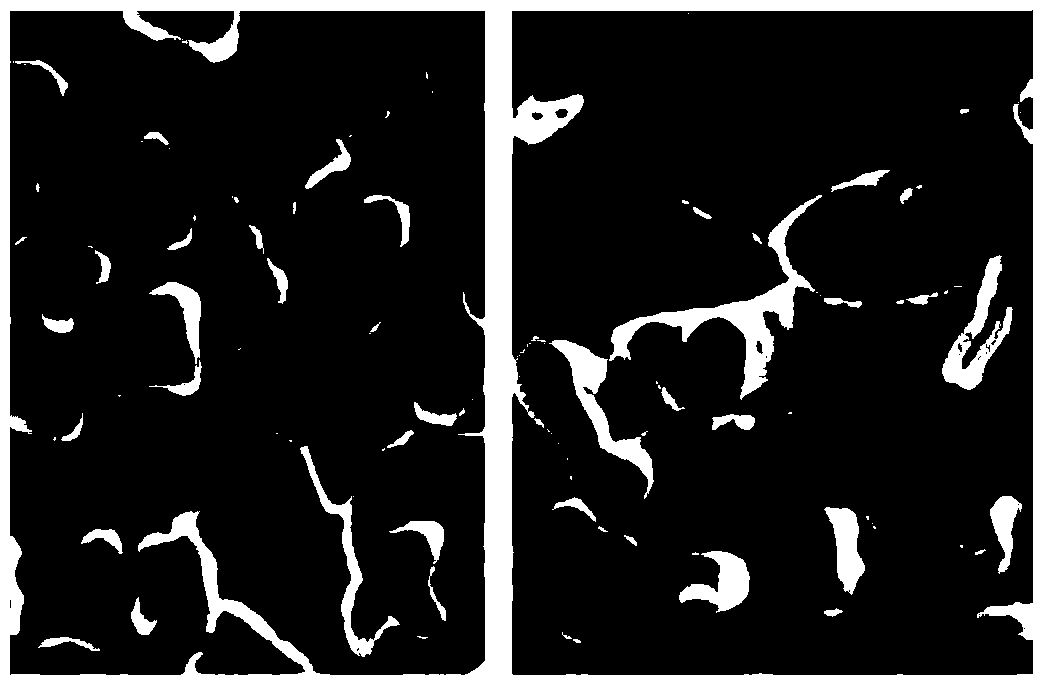

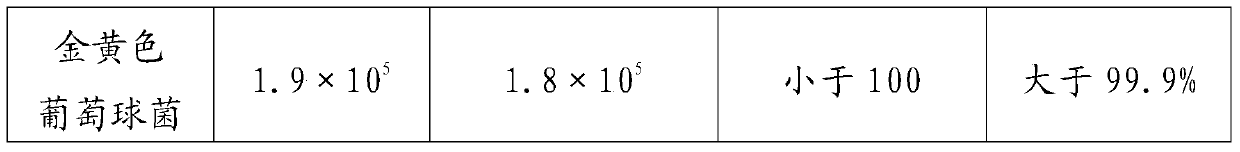

Production process of solar cell back film

ActiveCN103107241BReduce wasteReduce consumptionFinal product manufactureSemiconductor devicesState of artEngineering

The invention provides a manufacturing technique of a solar cell back film. The manufacturing technique of the solar cell back film comprises the following steps: after a material roll is unreeled, material receiving and storing are carried out to a material film, and then unreeling traction and front coating are carried out to the material film out of the material receiving and storing; primary leveling, primary heating and drying and first air cooling are sequentially carried out to the material film after the front coating, and then primary discharging traction and cooling are further carried out; secondary leveling, secondary heating and drying are sequentially carried out to the material film after back side coating is carried out to the cooled material, and then secondary discharging traction is carried out; and triple heating and drying, triple discharging traction, quartic heating and drying, low temperature drying, secondary air cooling, quartic discharging traction and cooling are sequentially carried out to the material film after the secondary discharging traction, and finally rolling up is carried out. Compared with the prior art, the manufacturing technique of the solar cell back film soles problems generated in a solar cell back film producing process, and improves quality of products.

Owner:山东城际轨道交通科技股份有限公司

A kind of fiber fabric and preparation method thereof

ActiveCN104975364BImprove breathabilityLarge outer surface areaBiocideMonocomponent polyurethanes artificial filamentFiberPolymer science

The invention relates to a fiber fabric with good antibacterial and moisture absorption and perspiration properties, at least a part of the fibers of which contain copper, and the copper is added to the fibers during the spinning process. The invention also relates to a method for the preparation of a fibrous fabric comprising the step of adding copper powder to at least a portion of the fibers used in the fabric, wherein said copper powder is mixed with fibers or polymer masterbatches in molten state. The fiber of the fiber fabric of the present invention has an X-shaped cross-section, which has a larger surface tension than ordinary fibers, and can form a plurality of tiny drainage and ventilation channels to improve the water absorption and drainage and air permeability of the fiber fabric; the present invention In the spinning stage, the copper element has been implanted into the fiber, and it is evenly and tightly combined with the fiber, which can improve the bactericidal effect, and the copper element can be kept for a long time, and it can still have good antibacterial and deodorizing effects after repeated washing.

Owner:PRIDEWOOD INT

Nano wave adsorption compound coating composition and its preparation and spraying method thereof

InactiveCN1263811CStrong surface bonding fastnessStrong combination fastnessRadiation-absorbing paintsNano siliconN-Butanol

Owner:西安华捷科技发展有限责任公司

Sterilizing and virus-killing liquid containing nano short fibers and preparation method thereof

The invention relates to a sterilizing and virus-killing liquid containing nano short fibers and a preparation method thereof. The sterilizing and virus-killing liquid containing the nano short fiberscomprises a dispersion medium and the nano short fibers dispersed in the dispersion medium, wherein the surfaces of the nano short fibers are covered with a sterilizing and virus-killing substance and a binder, or the sterilizing and virus-killing liquid containing the nano short fibers further contains lysozyme and a dispersing agent. The preparation method comprises the steps of firstly, preparing a nanofiber membrane of which the surfaces of nanofibers are partially covered with a sterilizing and virus-killing substance and a binder by taking the sterilizing and virus-killing substance, the binder and a polymer X as raw materials, then smashing fibers in the nanofiber membrane into nano short fibers, and finally, mixing the nano short fibers with a dispersion medium, lysozyme and a dispersing agent to prepare the sterilizing and virus-killing liquid containing the nano short fibers. The method disclosed by the invention is simple, and the prepared sterilizing and virus-killing liquid containing the nano short fibers is uniform in dispersion, capable of sterilizing and killing viruses for a long time, safe, non-toxic and harmless to a human body.

Owner:上海迅江科技有限公司 +1

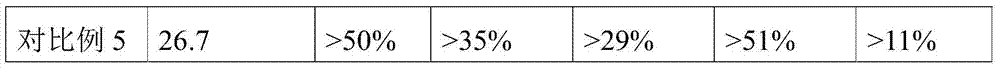

Broad-spectrum antibacterial and antiviral textile based on graft copolymerization of double-long-chain ionic liquid structural monomer and preparation method of broad-spectrum antibacterial and antiviral textile

PendingCN114875667AStrong combination fastnessExcellent washing resistanceBiochemical fibre treatmentAbrasion resistant fibresAnti bacterialDouble bond

The invention relates to a broad-spectrum antibacterial and antiviral textile based on double-long-chain ionic liquid structure monomer graft copolymerization, which comprises a textile and at least one organic monomer, the organic monomer is grafted and copolymerized onto the textile, the organic monomer is an organic monomer containing a double-long-chain ionic liquid structure, the organic monomer is represented by a general formula, wherein A is an organic group containing a carbon-carbon double bond, C is a cationic group of the ionic liquid, X is an organic group or an organic chain segment connecting A and C through a covalent bond, B1 and B2 are hydrophobic chain segments connected with C through covalent bonds respectively, and D is an anionic group of the ionic liquid. The invention also relates to a preparation method of the broad-spectrum antibacterial and antiviral textile. According to the broad-spectrum antibacterial and antiviral textile disclosed by the invention, functional groups with antibacterial and antiviral effects are firmly combined to the textile in a covalent bond manner, so that the broad-spectrum antibacterial and antiviral textile has excellent washing resistance and abrasion resistance and is lasting in function.

Owner:水木聚力接枝新技术(深圳)有限责任公司

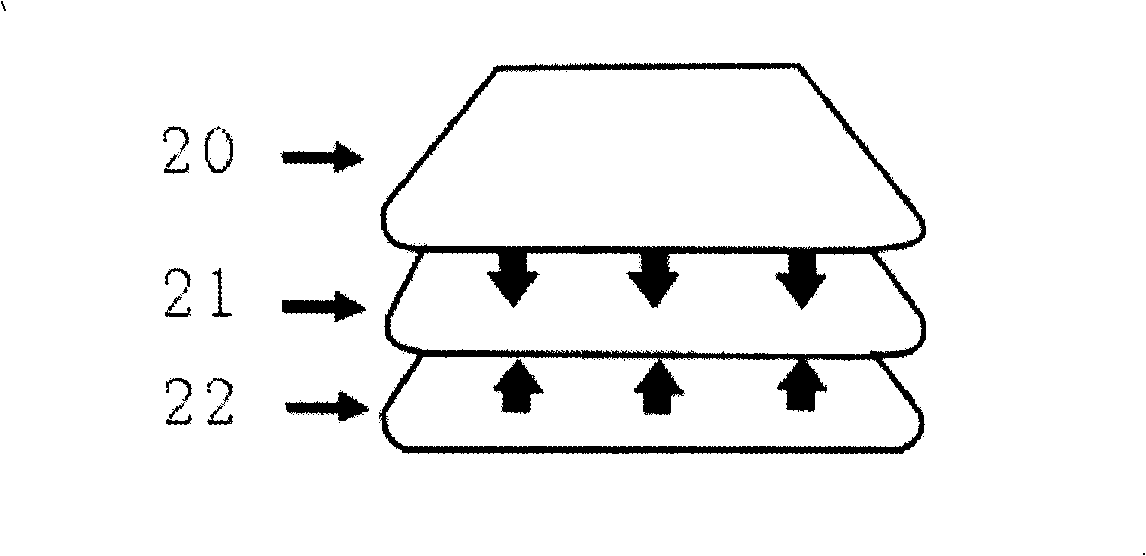

Spotlight display high-brightness reflection optical lens protecting adhesive film

InactiveCN101604032BCorrosion resistanceElectrically insulatingSynthetic resin layered productsPolyester coatingsPolyesterPolyethylene terephthalate

The invention discloses a spotlight display high-brightness reflection optical lens protecting adhesive film which comprises a surface layer, a middle main film and a bottom layer. The surface layer is a polyethylene layer, the bottom layer is a polyethylene layer, and the middle main film comprises an upper layer, a middle layer and a lower layer, wherein the upper layer is a polyethylene terephthalate layer, the lower layer is a polyethylene terephthalate layer, and the middle layer is a polyester paint layer. The protecting adhesive film achieves the effects of optical transmittance, clearpicture and screen brightness increase in the light transmission aspect. When a backlight of a screen is turned on, contents on the screen can be clearly viewed through the protecting adhesive film; when the backlight of the screen is turned off, the protecting adhesive film can generate a mirror effect with high quality, and a user can clearly view a scene reflected by the protecting adhesive film like looking into a mirror.

Owner:梁晓斌

Selective composite coating for absorbing solar light and thermal

InactiveCN101769649AGood weather resistanceAvoid affecting service lifeSolar heat devicesVacuum evaporation coatingCompound aSolar light

The invention discloses a selective composite coating for absorbing solar light and thermal which belongs to field of solar energy equipment, particularly, relates to a selective absorbing coating which is used on the surface of the flat-plate solar collector and is used for absorbing and utilizing solar energy. The selective composite coating for absorbing solar light and thermal is formed by compounding a plurality of layers of metal and non-metal, the selective solar energy is attached on a metal flat plate; the characteristics are as follows: the attachment sequence of the coating on the metal flat plate is as follows: a bottom layer, a titanium-oxygen-titanium absorbing layer, and a silica emitting layer, wherein, the titanium-oxygen-titanium absorbing layer is made through at least two reactive sputtering processes. The invention provides a selective absorbing film with excellent selective absorption characteristic of solar energy and firm film, which is provided with high binding strength, good weatherability, as well as high production efficiency in production.

Owner:SHENZHEN PROSUNPRO SOLAR ENERGY

A kind of discoloration agent and discoloration method of wood chemical discoloration induced by copper ion

ActiveCN109531746BBeautiful colorClear textureWood treatment detailsWood impregnation detailsCopper chlorideActive agent

The invention discloses a color-changing agent for inducing chemical discoloration of wood by copper ions and a color-changing method thereof. The color-changing agent comprises the following components in parts by mass, 10 to 50 parts of copper chloride, 1 to 5 parts of a fixing agent, 10 to 100 parts of a surfactant, and 800 to 950 parts of water; and the color-changing agent is applied to a wood single board and then dried to complete the discoloration of the wood. The method utilizes the color-changing agent containing copper chloride to induce a chemical discoloration reaction of molecules in the wood, and the color penetration degree of the wood is high after discoloration, the colors displayed after chemical discoloration are naturally beautiful, the texture is clearer, and the layering is stronger. In addition, the method also has the characteristics that the color-changing method is simple in operation, and the processing process is more environmentally friendly.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Antibacterial material for pediatric pneumonia protection and manufacturing method thereof

InactiveCN111235661BEffective protectionImprove antibacterial propertiesArtificial filaments from cellulose derivativesArtifical filament manufactureCellulose acetateSilver ion

The invention discloses an antibacterial material for pediatric pneumonia protection and a manufacturing method thereof. Aminated porous silicon dioxide nanoparticles are prepared and modified by silver ions, the silver-loaded porous silicon dioxide nanoparticles are embedded in quaternized modified cellulose acetate, and the antibacterial material for pediatric pneumonia protection is manufactured through an electrostatic spinning technology. In this way, abundant amino groups in the aminated porous silicon dioxide nanoparticles can be used as the active sites, and tight complexing of the silver ions is realized; and by utilizing a large amount of quaternary ammonium groups grafted on the cellulose acetate and the nano silver, the release rate of silver is reduced on the basis of ensuringthe antibacterial effect, so that the prepared antibacterial material has excellent antibacterial performance and safe and long-acting antibacterial effect. The manufacturing method of the antibacterial material for the pediatric pneumonia protection provided by the invention is easy to operate, high in controllability, capable of meeting the requirements of practical application and relatively high in application value.

Owner:HENAN PROVINCE HOSPITAL OF TCM THE SECOND AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

Resist agent for blue calico

InactiveCN102127874BLittle impact on purityStrong combination fastnessDyeing processPolymer sciencePolyvinyl alcohol

The invention relates to the technical field of blue calico production and manufacture, in particular to a resist agent for blue calico, aiming to provide a resist agent for blue calico, being simple to make and process and having high adhesive rate. The invention adopts the technical scheme that the resist agent for blue calico comprises quicklime, soybean meal, polyvinyl alcohol and penetrant. The invention has the advantages of simpleness in preparation and processing, less influence by raw material purity, high adhesive rate, good adsorption property and strong bonding firmness with cotton cloth, and the blue calico made by the resist agent can be normally used after being aired, wherein the airing time is shortened from 7 days to18h.

Owner:滨州技师学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com