Antistatic protective film

An anti-static and protective film technology, applied in conductive coatings, coatings, etc., can solve the problems of long service life of anti-static protective film, affecting use, increasing surface resistance value, etc., to improve the spreading performance, not easy to break, reduce the surface The effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

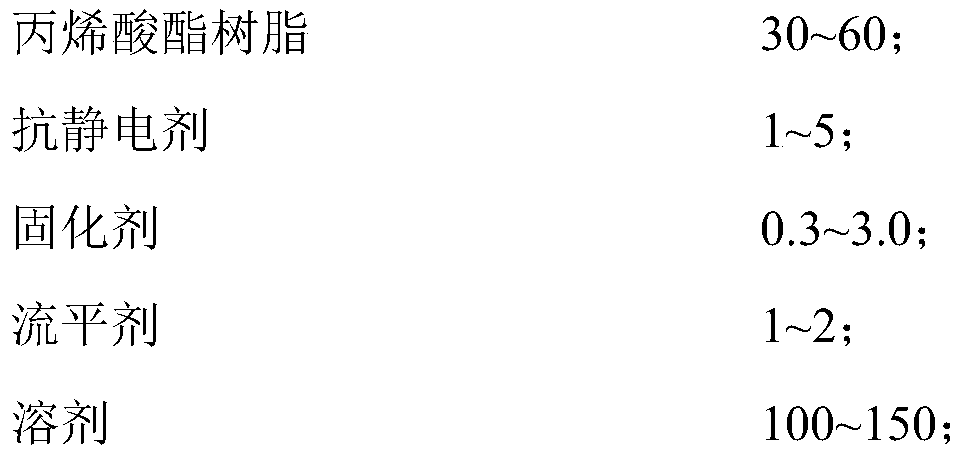

Method used

Image

Examples

Embodiment 1

[0035] Weigh 6g vinyltrimethoxysilane, 14g trifluoroethyl methacrylate, 30g methyl methacrylate, 5g lauryl acrylate, 15g ethyl acrylate, 10g stearyl methacrylate, 20g acrylic acid, at 75 Polymerize for 3.5 hours under the condition of ℃, then cool down the synthesized resin to 50℃ and then discharge to obtain acrylate resin.

[0036] Weigh 30g of the above acrylate resin, 0.6g Daycon TC1SR, 0.4g LS-2002N, 0.3g hexamethylolmelamine resin, 0.4g BYK346, 0.4g BYK306, 0.2g Deqian 837, 25g isopropanol and 75g deionized water , mixed evenly to obtain an antistatic coating liquid, which is coated on an optical-grade polyester film and dried to obtain an antistatic protective film.

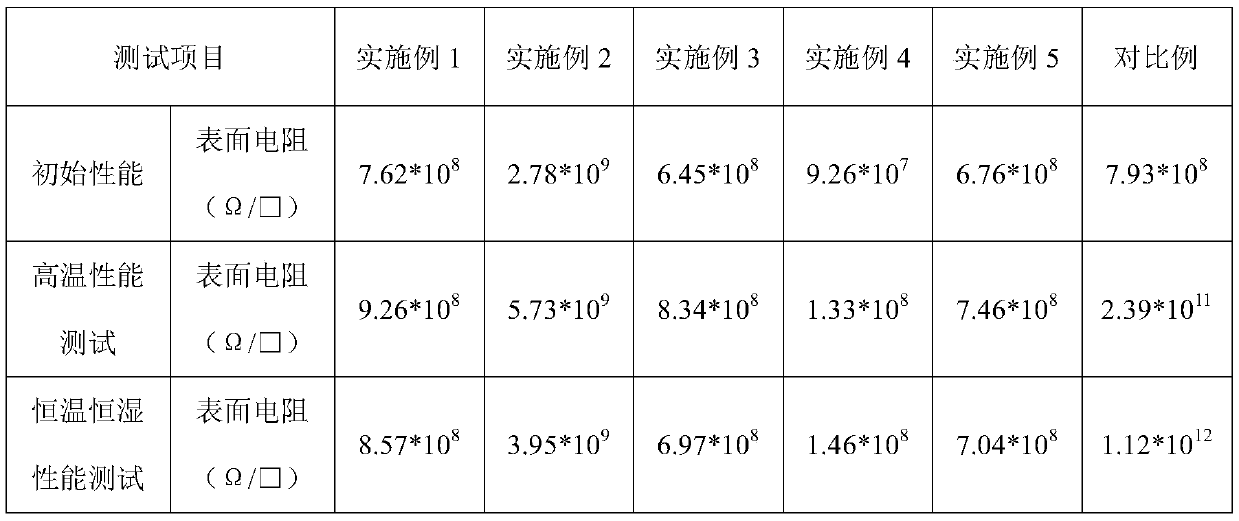

[0037] After measuring the resistance of the antistatic protective film, put it into an electric heating constant temperature blast drying oven with a temperature of 80°C for 500 hours, and a constant temperature and humidity box with a temperature of 60°C and a humidity of 90%RH for 500 hours, and take it...

Embodiment 2

[0040] Weigh 3.7g γ-methacryloxypropyltrimethoxysilane, 12.3g vinyltrimethoxysilane, 0.6g hexafluorobutyl methacrylate, 3.4g trifluoroethyl methacrylate, 5g methacrylic acid Methyl ester, 5g styrene, 5g vinyl acetate, 40g ethyl acrylate, 10g acrylic acid, 5g methacrylic acid, 5g diacetone acrylamide, 5g hydroxyethyl acrylate, polymerized at 75°C for 3.5 hours, and then synthesized After the resin is cooled to 50°C, it is discharged to obtain an acrylate resin.

[0041] Weigh 60g of the above acrylate resin and 2g of Daycon TC1SR), 2g of 90076-65-61, 1g of 919-16-4, 1.8g of hexamethylolmelamine resin, 1.2g of methyl etherified melamine resin, 1g of BYK346, 0.5g of BYK306 , 0.5g Deqian 495, 80g isopropanol, 32.5g n-propanol and 37.5g deionized water, mixed evenly to obtain an antistatic coating solution, which is coated on an optical grade polyester film and dried to obtain Antistatic protective film.

[0042] After measuring the resistance of the antistatic protective film, p...

Embodiment 3

[0045] Weigh 1.2g of γ-methacryloxypropyltrimethoxysilane, 4g of vinyltrimethoxysilane, 0.8g of vinyltris(2-methoxyethoxy)silane, 1.29g of hexafluorobutyl methacrylate ester, 4.3g trifluoroethyl methacrylate, 0.41g dodecafluoroheptyl acrylate, 10g methyl methacrylate, 5g styrene, 10g vinyl acetate, 25g lauryl acrylate, 25g ethyl acrylate, 5g acrylic acid, 2g of methacrylic acid and 3g of methylolacrylamide were polymerized at 75°C for 3.5 hours, and then the temperature of the synthesized resin was lowered to 50°C and discharged to obtain an acrylate resin.

[0046] Weigh 45g of the above acrylate resin, 2g of Daycon TC1SR, 1g of 90076-65-6, 0.6g of hexamethylolmelamine resin, 1g of methyl etherified melamine resin, 0.6g of BYK306, 0.7g of Deqian 837, 0.2g of Deqian 495 , 40g of isopropanol and 80g of deionized water were mixed uniformly to obtain an antistatic coating solution, which was coated on an optical-grade polyester film and dried to obtain an antistatic protective fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com