Special epoxy anticorrosive antibacterial powder coating for valve fire protection and preparation method thereof

An anti-corrosion and anti-bacterial powder coating technology, applied in powder coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problem of low tensile strength and surface hardness of mixtures, low thermal conductivity, low heat distortion temperature, blockage of valves for fire protection, etc. problems, to achieve the effect of improving product stability, good fluidity, and uniform flow state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

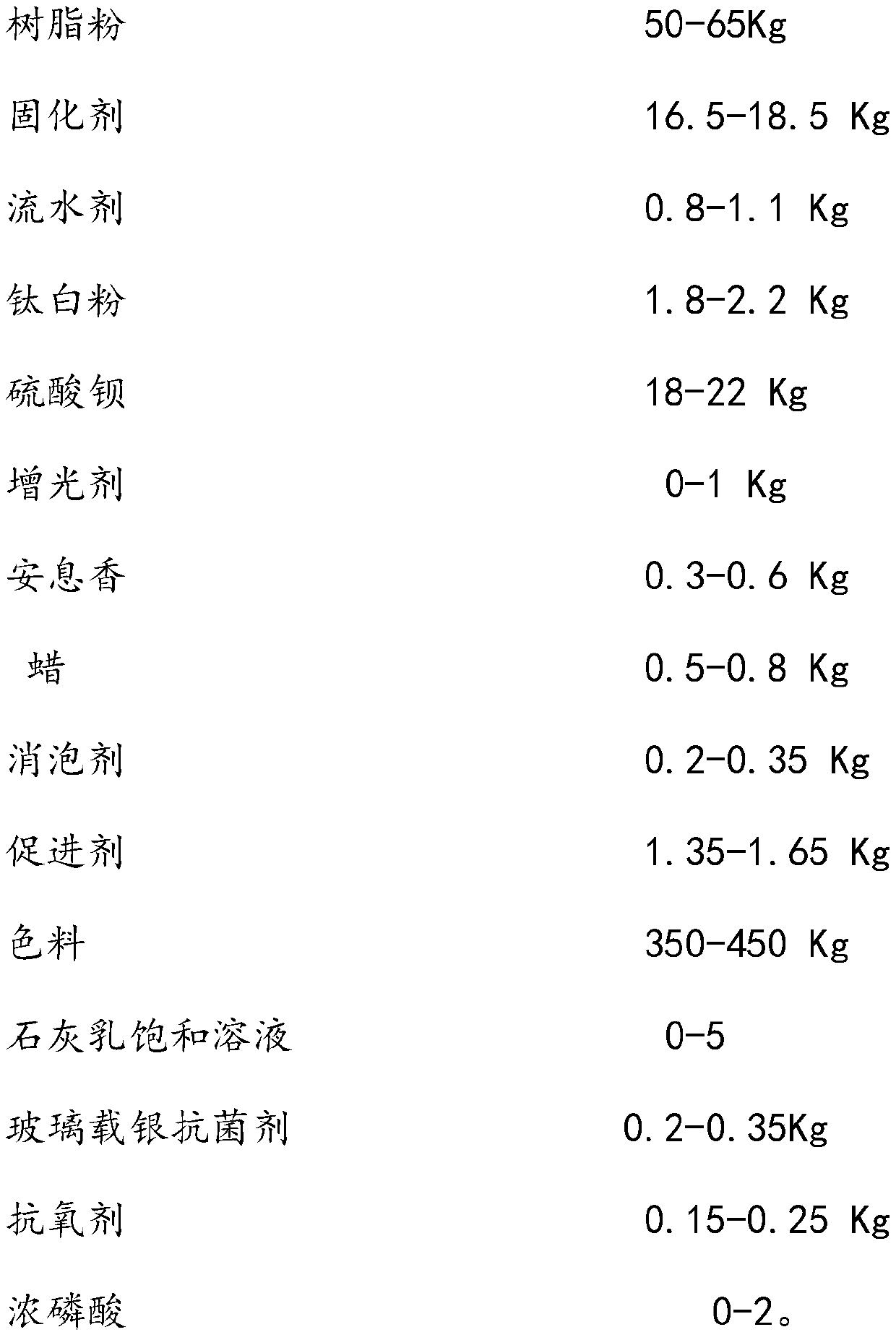

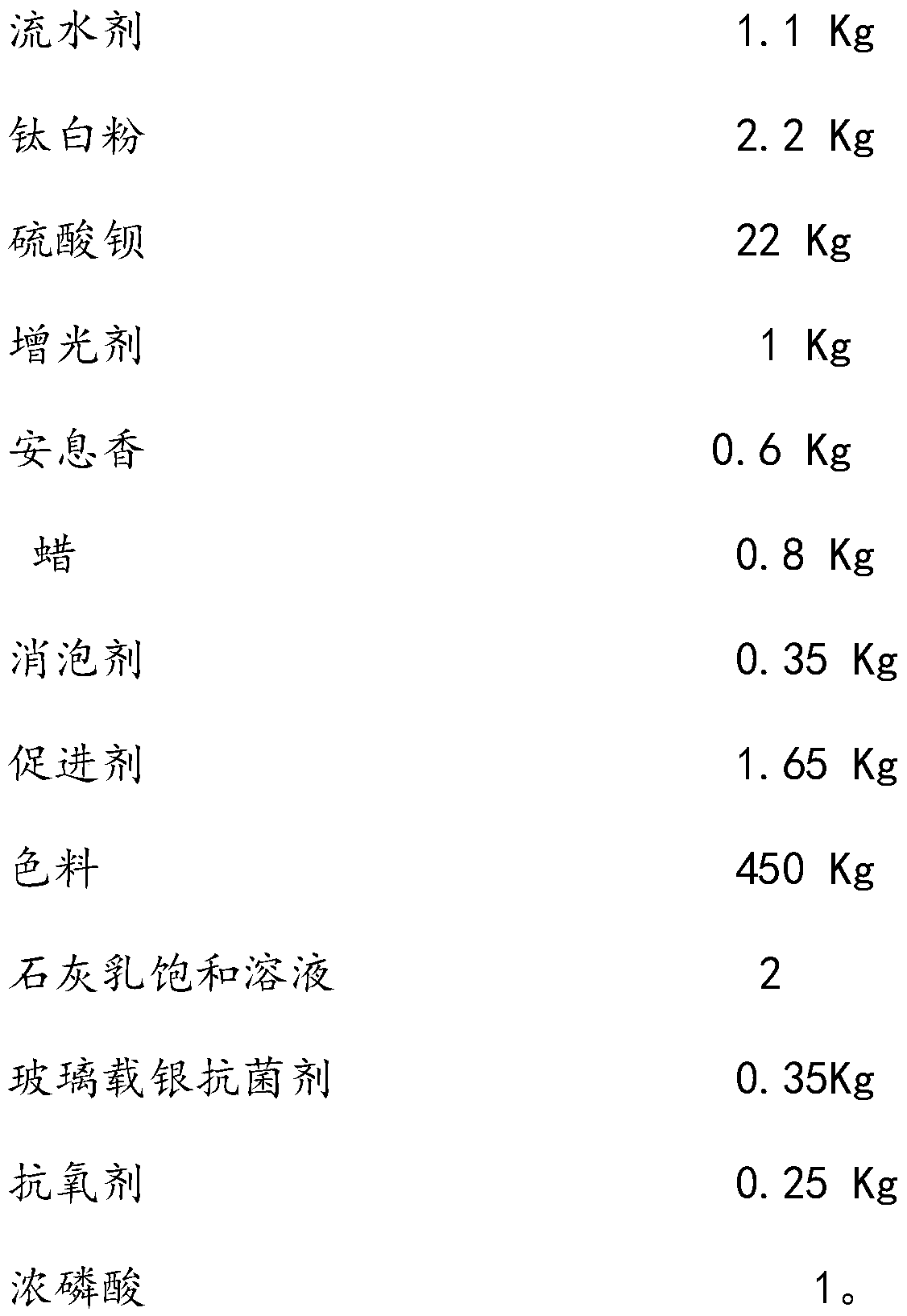

[0025] A special epoxy anti-corrosion and anti-bacterial powder coating for valve fire protection is made of the following raw materials in parts by weight: 65Kg of polyethylene resin powder, 18.5Kg of curing agent, 1.1Kg of water-flowing agent, 2.2Kg of titanium dioxide, 22Kg of barium sulfate, 1Kg brightening agent, 0.6Kg benzoin, 0.8Kg wax, 0.35Kg defoamer, 1.65Kg accelerator, 0.35Kg glass-loaded silver antibacterial agent, 0.25Kg tris[2.4-di-tert-butylphenyl] Phosphite (168) antioxidant and 1Kg of concentrated phosphoric acid, 450Kg of pigment, 2Kg of milk of lime saturated solution.

[0026] The leveling agent includes the following materials in parts by weight: 1-3 parts of polyacrylic resin, 0.2 parts of concentrated phosphoric acid, 10 parts of silicon micropowder, 1.8 parts of coconut oil, and 1.5 parts of microcrystalline cellulose.

[0027] The defoamer is composed of one or more of methylpolysiloxane, vanillin, chitosan and monoglyceride in any mixing ratio.

[00...

Embodiment 2

[0033] A special epoxy anti-corrosion and anti-bacterial powder coating for valve fire protection, made of the following raw materials in parts by weight: 60Kg of epoxy resin powder, 18Kg of curing agent, 1Kg of running water agent, 2Kg of titanium dioxide, 20Kg of barium sulfate, 1Kg of lightening agent, 0.5Kg benzoin, 0.5Kg wax, 0.3Kg defoamer, 1.5Kg accelerator, 0.3g glass-loaded silver antibacterial agent, 0.2Kg 2,5-ditert-butylhydroquinone antioxidant Agent DTBHQ and 2Kg of concentrated phosphoric acid, 400Kg of pigment, 5Kg of milk of lime saturated solution.

[0034] The leveling agent includes the following materials in parts by weight: 1-3 parts of polyacrylic resin, 0.2 parts of concentrated phosphoric acid, 10 parts of silicon micropowder, 1 part of coconut oil, and 1.2 parts of microcrystalline cellulose.

[0035] The defoamer is composed of one or more of methylpolysiloxane, vanillin, chitosan and monoglyceride in any mixing ratio.

[0036]The components of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com