An antibacterial textile product and a preparing method thereof

A technology of antibacterial textiles and textiles, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of weak combination fastness between antibacterial functional groups/particles and textiles, limited range of antibacterial types, and few reports of anti-drug-resistant bacteria, etc. Achieve the effects of easy promotion, low cost and strong combination fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

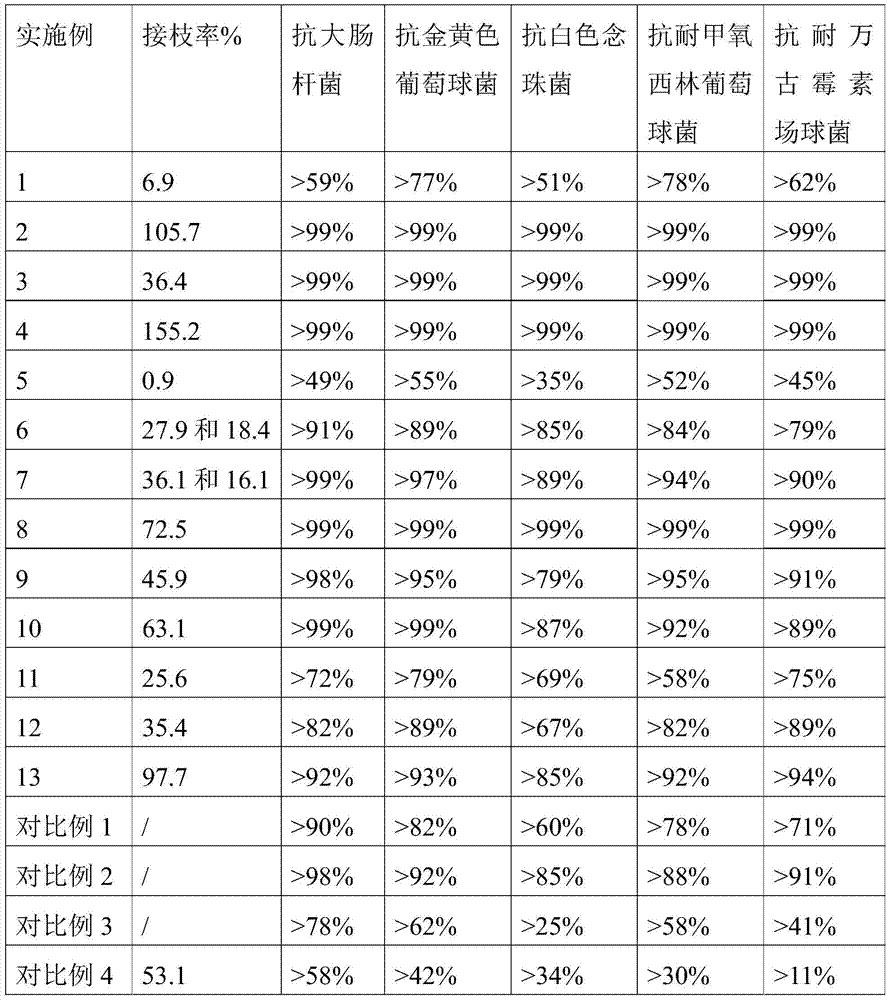

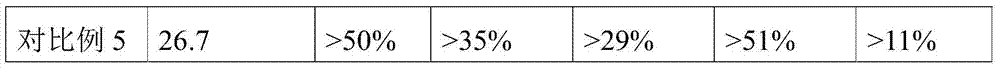

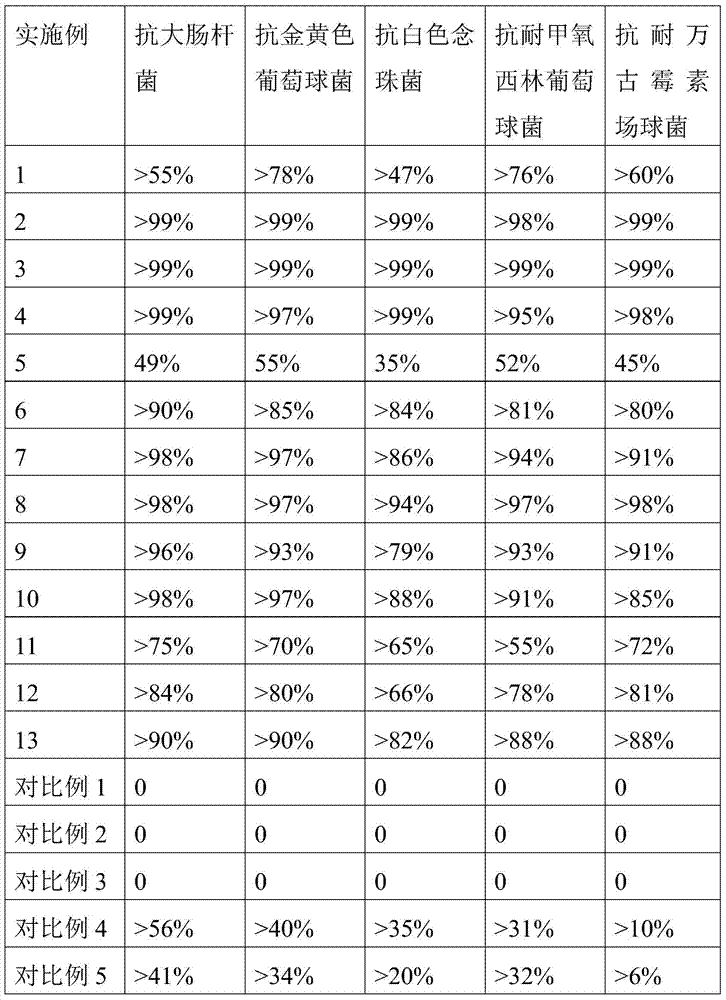

Examples

Embodiment 1

[0033] Example 1: Preparation of Polyester Fabric UV Initiated Solution Grafting [Acrylic Ethyltrimethylamine] Tetrafluoroboric Acid

[0034] Cut the polyester fabric to an appropriate size, soak it in the acetone solution of benzophenone for 20 minutes, then take out the polyester fabric, and volatilize the acetone in a ventilated place, so that the benzophenone is evenly dispersed on the surface of the polyester fabric. Subsequently, a 10% aqueous solution of [ethyltrimethylamine acrylate] tetrafluoroboric acid was sprayed on the surface of the polyester fabric. Transfer the polyester fabric to a sealable quartz container, pass nitrogen gas to remove oxygen for 20 minutes, seal it, and irradiate it under a UV lamp with a wavelength of 256nm to initiate graft polymerization reaction, and pass oxygen to terminate the reaction after 30 minutes.

[0035] The grafting rate of [ethyltrimethylamine acrylate] tetrafluoroboric acid on the polyester fabric measured by weighing method ...

Embodiment 2

[0036] Example 2: Preparation of silk fabric chemically initiated emulsion grafting [1-ethyl-3,3'-bis(1-vinylimidazole)]disulfate

[0037] Toluene is used as the dispersed phase, sorbitan stearate is used as the emulsifier, and [1-ethyl-3,3'-bis(1-vinylimidazole)]dihydrogen disulfate is configured under high-shear stirring Water-in-oil emulsion of salt in toluene. Soak 5×5cm silk cloth in the emulsion, add potassium persulfate as an initiator, pass nitrogen to remove oxygen for 20 minutes, seal the container, heat to 60°C to initiate graft polymerization reaction, and react for 5 hours, pass oxygen to terminate the reaction .

[0038] The grafting rate of [1-ethyl-3,3'-bis(1-vinylimidazole)]disulfate on silk fabrics was determined to be 105.7% by weighing method.

Embodiment 3

[0039] Example 3: Preparation of cotton co-radiation body grafted 1-butyl-3-vinylimidazolium chloride salt

[0040] Cut the pure cotton cloth into a suitable size, apply 1-butyl-3-vinylimidazolium chloride evenly on the surface of the cotton cloth by padding, place the cotton cloth in an irradiation tube, blow nitrogen gas to remove oxygen for 20 minutes, and seal it , irradiated with 50 kGy of cobalt-60 source gamma rays at room temperature. The irradiated cotton cloth was extracted with water in a Soxhlet extractor for 48 hours to remove unreacted monomers and homopolymers, dried and weighed.

[0041] The grafting rate of 1-butyl-3-vinylimidazolium chloride on pure cotton cloth was measured by weighing method to be 36.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com