Antibacterial fiber, preparation method of antibacterial fiber and antibacterial product

An antibacterial fiber and aqueous solution technology, applied in the chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., can solve the problems of insufficient particle loading, uneven particle size, and insufficient loading, and achieve excellent antibacterial and bacteriostatic properties. , Combined with strong fastness and lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

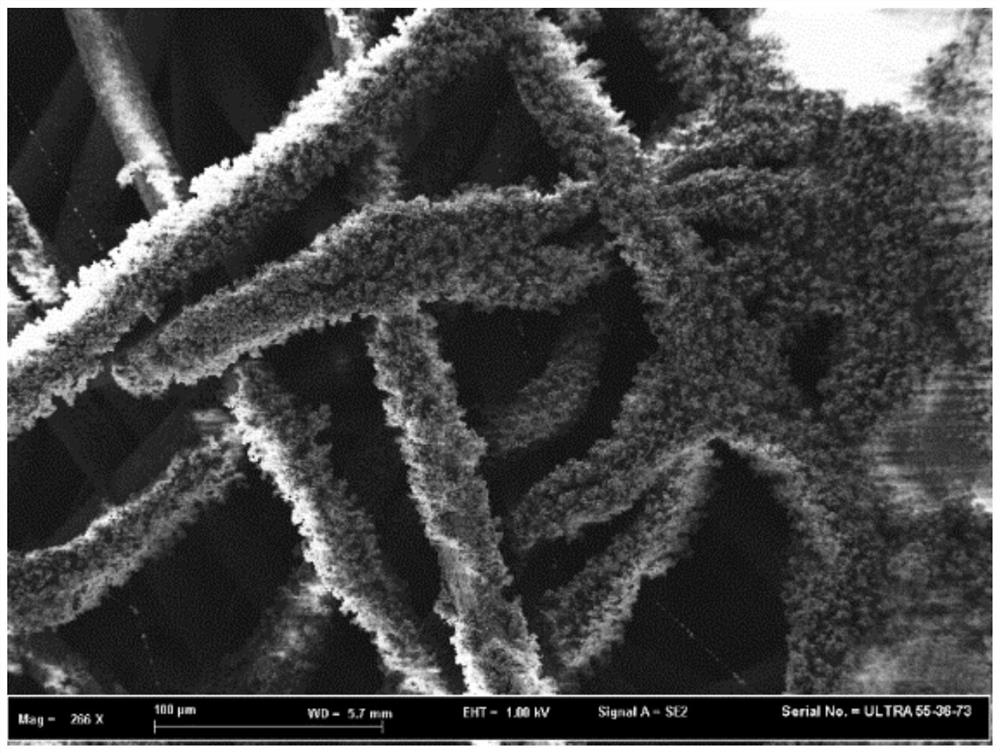

Image

Examples

preparation example Construction

[0024] The preparation method of the antibacterial fiber provided by the present invention comprises the following steps:

[0025] S1, providing a PVA aqueous solution, wherein the mass fraction of PVA in the PVA aqueous solution is 8%-15%;

[0026] S2, adding nano titanium dioxide particles and a dispersant to the PVA aqueous solution, and performing ultrasonic dispersion to obtain a spinning solution, wherein the mass ratio of the PVA aqueous solution to the nano titanium dioxide particles is 100:1-100:15, The absolute value of the Zeta potential of the spinning solution is 10mV-40mV;

[0027] S3, performing electrospinning on the spinning solution to obtain antibacterial fibers.

[0028] In step S1, the mass fraction of PVA in the PVA aqueous solution (polyvinyl alcohol aqueous solution) is further preferably 10%-12%.

[0029] In step S2, PVA aqueous solution and nano-TiO 2 When the particles are used to prepare the spinning solution, due to the nano-TiO in the spinning ...

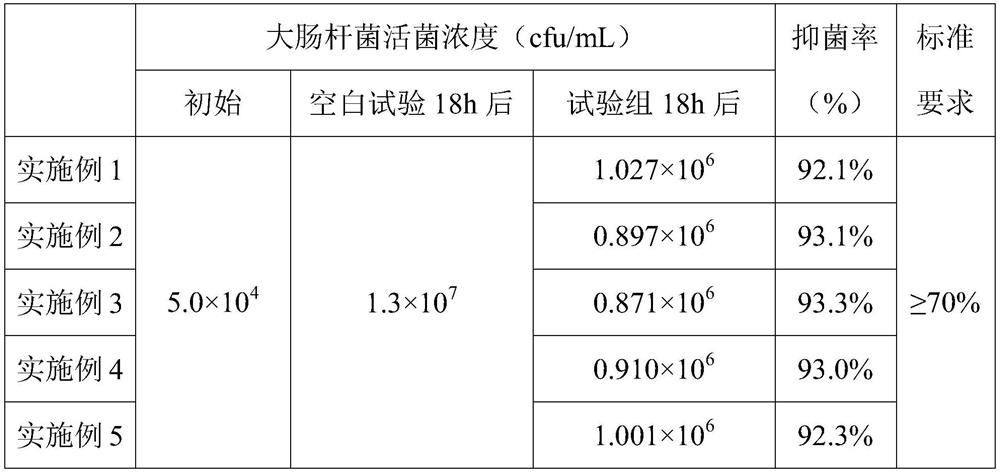

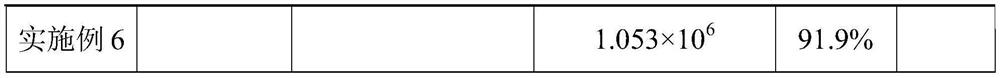

Embodiment 1

[0043] Prepare 100 parts by weight of a PVA aqueous solution with a mass fraction of 8%, add 5 parts by weight of nano titanium dioxide particles with a particle size of 20 nm and 0.005 parts by weight of stearic acid, and carry out ultrasonic dispersion at a frequency of 30KHz to obtain the absolute value of Zeta potential 15mV of spinning solution.

[0044]Electrospin the spinning solution. In electrospinning, the advancing speed is 0.3mL / h, the receiving distance is 12cm, the voltage is 10KV and is 1.25 times the mass fraction, the spinning needle is connected to the positive electrode, and the receiving end is connected to the negative electrode. The ultra-fine denier polyester fiber fabric is used as the receiving substrate, and after electrospinning is completed, it is naturally dried at room temperature to obtain antibacterial fibers.

Embodiment 2

[0046] Prepare 100 parts by weight of PVA aqueous solution with a mass fraction of 10%, add 10 parts by weight of nano titanium dioxide particles with a particle size of 15 nm and 0.04 parts by weight of stearic acid, and carry out ultrasonic dispersion at a frequency of 30KHz to obtain the absolute value of Zeta potential 20mV of spinning solution.

[0047] Electrospin the spinning solution. In electrospinning, the advancing speed is 0.5mL / h, the receiving distance is 13cm, the voltage is 13KV and 1.3 times the mass fraction, the spinning needle is connected to the positive electrode, and the receiving end is connected to the negative electrode. The ultra-fine denier polyester fiber fabric is used as the receiving substrate, and after electrospinning is completed, it is naturally dried at room temperature to obtain antibacterial fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com