Production process of solar cell back film

A technology of solar cells and production processes, applied in the direction of circuits, electrical components, and final product manufacturing, to achieve the effects of reasonable design, low friction coefficient, and low investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] For the research and development of the solar cell industry, corresponding special equipment is produced according to the process flow for double-sided coating of the protective film of the solar cell silicon wafer backplane.

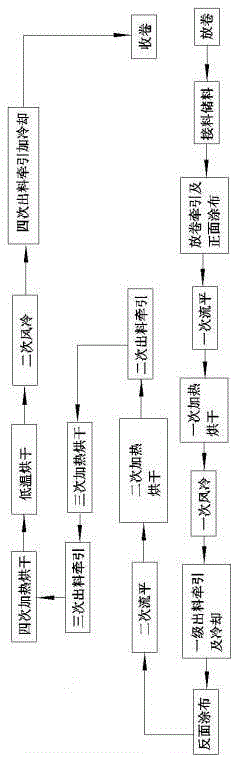

[0027] The workflow is as follows:

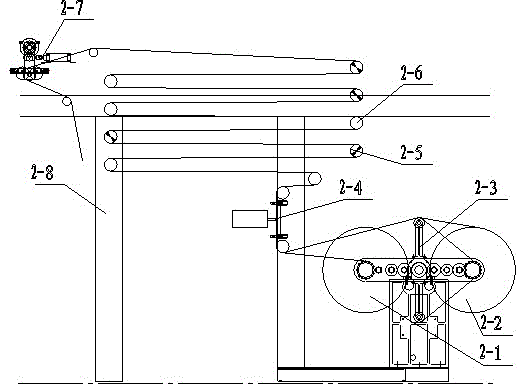

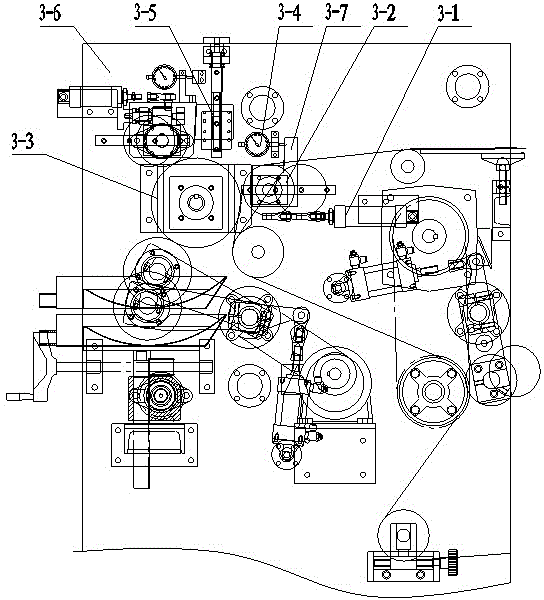

[0028] Unwinding device (located at the right end of the machine, double-station rotation, electric feeder) → receiving and storing device (located on the left side of unwinding, pneumatic storage mechanism, ultrasonic receiving device) → unwinding traction and front coating device (Located on the left side of the material receiving and storage device, the pressure roller has anti-static function) → Primary leveling device (located on the left side of the front coating, using a guide roller and glass conveying method, using infrared light waves to heat to improve coating leveling Efficiency, increase coating adhesion fastness) → Primary heating drying device (located on the left side of the primary leveling section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com