Film-coated radiation-cured bright abrasive paper and preparation method thereof

A radiation curing and frosting technology, applied in the field of decorative materials, packaging and printing materials, can solve the problems of uneven surface of frosted or matte effect layer, weak visual impact effect, poor folding resistance and tensile resistance, etc. Rough, strong visual impact, strong combination fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

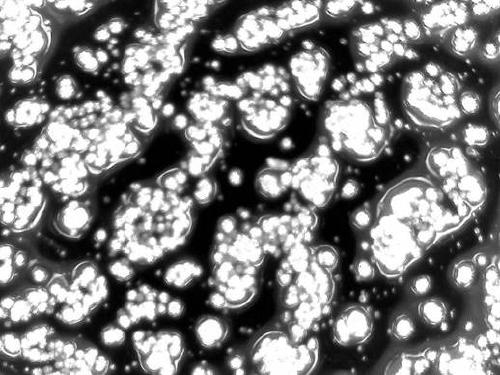

[0053] The present invention also provides the preparation method of the above-mentioned radiation-cured film-coated bright frosted paper, which is special in that: firstly prepare the above-mentioned frosted paint containing organic frosted particles, then carry out surface treatment on the film, and then apply the frosted paint on the film and use It is cured by radiation, and then the film is vacuum evaporated, and then the film with the frosted layer is compounded with the paper substrate through the film coating process, and finally the product is obtained by coating. The specific process includes: batching - film corona - film coating - vacuum evaporation - compounding - coating treatment - finished product.

[0054] Furthermore, the process can be optimized, and the specific process steps are as follows:

[0055] Ingredients: first add the prepolymer and active diluent into the container by weight percentage, control the stirring speed at 200-500rpm, and stir for 5-10mi...

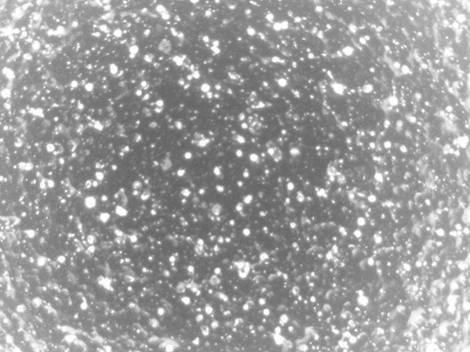

Embodiment 1

[0064] In this example, the electron beam radiation curing process is used to prepare radiation-cured coated glossy frosted paper, and the paper substrate-225g coated composite white cardboard, the film layer-15μPET transfer base film, the frosted layer-electron beam cured frosted coating, bonding Agent layer-polyacrylic adhesive, top coat-waterborne polyurethane top coat, vapor deposition layer-aluminum vapor deposition layer were prepared.

[0065] Step 1: Ingredients

[0066] First, add 35 parts of difunctional polyester acrylate, 35 parts of difunctional urethane acrylate, 10 parts of dicyclopentyloxyethyl acrylate, and 15 parts of neopentyl glycol dipropoxylated diacrylate into the container , control the stirring speed at 200-500rpm, stir for 5-10min; then add 1.0 parts of polyethylene micropowder with a particle size of 5-20μm into the container, control the stirring speed at 800-1000rpm, stir for 10-20min; then add 0.5 parts of defoamer , 2.0 parts of wetting agent, a...

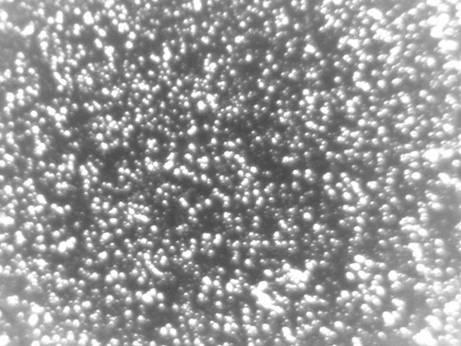

Embodiment 2

[0078] This example adopts the electron beam radiation curing process to prepare radiation-cured coated glossy matte paper, including: paper substrate-225g coated composite white cardboard, film layer-22 μ BOPP film, matte layer-electron beam cured matte coating, adhesive Layer-polyacrylic adhesive, top coat-waterborne polyurethane top coat, vapor deposition layer-aluminum vapor deposition layer.

[0079] Step 1: Ingredients

[0080] First, 25 parts of difunctional polyether acrylate, 20 parts of difunctional epoxy acrylate, 10 parts of methyl methacrylate, 10 parts of ethoxy ethyl acrylate, 10 parts of tripropylene glycol diacrylate, 10 parts Add tetraethylene glycol diacrylate into the container, control the stirring speed at 200-500rpm, and stir for 5-10min; then add 10 parts of polypropylene micropowder with a particle size of 5-20μm into the container, and control the stirring speed at 800-1000rpm , stir for 10-20min; then add 1.0 parts of defoamer, 2.0 parts of wetting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com