Preparation method of novel pencil

A pencil, a new type of technology, applied in non-propelled pencils, pen holders, printing, etc., can solve the problems of user pollution, undisclosed adhesive properties, pencil holder bonding strength, and unexplained adhesive content, etc., to achieve low prices and huge raw material resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

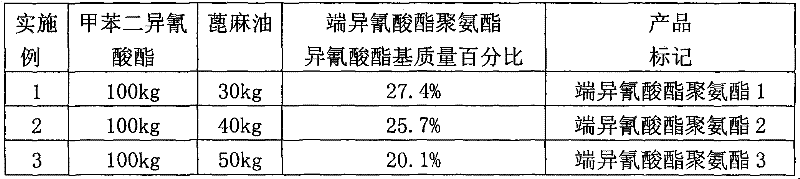

[0033] Preparation of isocyanate-terminated polyurethane: Add toluene diisocyanate and castor oil into the reaction kettle, heat to 70-85°C, keep warm for 180min, cool, and discharge;

[0034] The performance tests of the raw materials and products used in Examples 1 to 3 are shown in Table 1.

[0035] Table 1

[0036]

Embodiment 4~21

[0038] Sieve the recycled waste plastics to remove sand, stones and metal solid impurities, and then grind them into smaller than 1cm 2 flakes, spare;

[0039] Drying the rice straw, drying until the water content is less than 15%, pulverizing, sieving, collecting the rice straw powder with a particle size of less than 40 mesh, and sealing it for later use;

[0040] Add the dry rice straw powder and flake waste plastic fragments into a high-speed mixer, then spray the isocyanate adhesive under high pressure, stir and blend at room temperature for 10 minutes, and obtain the spray adhesive blend;

[0041] Fill the spray glue blend into the pencil molding machine, heat press, feed the pen core, cold press, and paint the exterior;

[0042] The detailed raw materials and consumption of each embodiment are shown in Table 2

[0043] Table 2

[0044]

[0045] Example 6

[0046] Note: the preparation method of isocyanate-terminated polyurethane 1 is shown in Exam...

Embodiment 2

[0048] See Example 3 for the preparation method of isocyanate-terminated polyurethane 3.

[0049] The agricultural residue rice straw / waste plastic pencil that embodiment 4~21 makes, detects the binding fastness of pen holder according to the light industry standard QB / T2774-2006 of the People's Republic of China: the pencil that makes is immersed in (30 ± 2) ℃ of Under the water surface for 1 hour, after taking it out, turn the two ends of the pen holder reversely, and there is no phenomenon of glue opening on the pen holder, which has reached the standard for the fastness of the pen holder specified in QB / T2774-2006; In line with people's usage habits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com