Patents

Literature

45results about How to "Save replacement time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

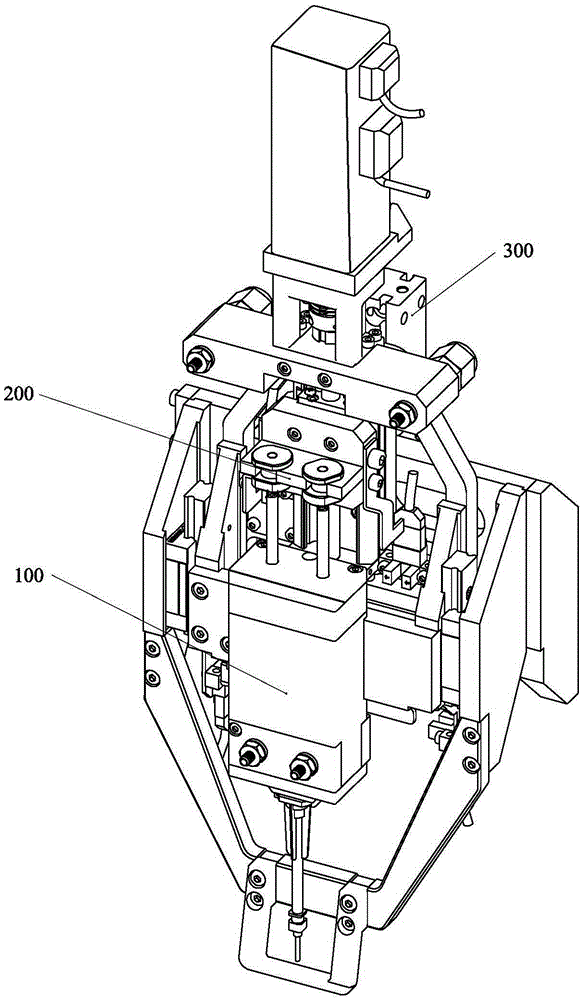

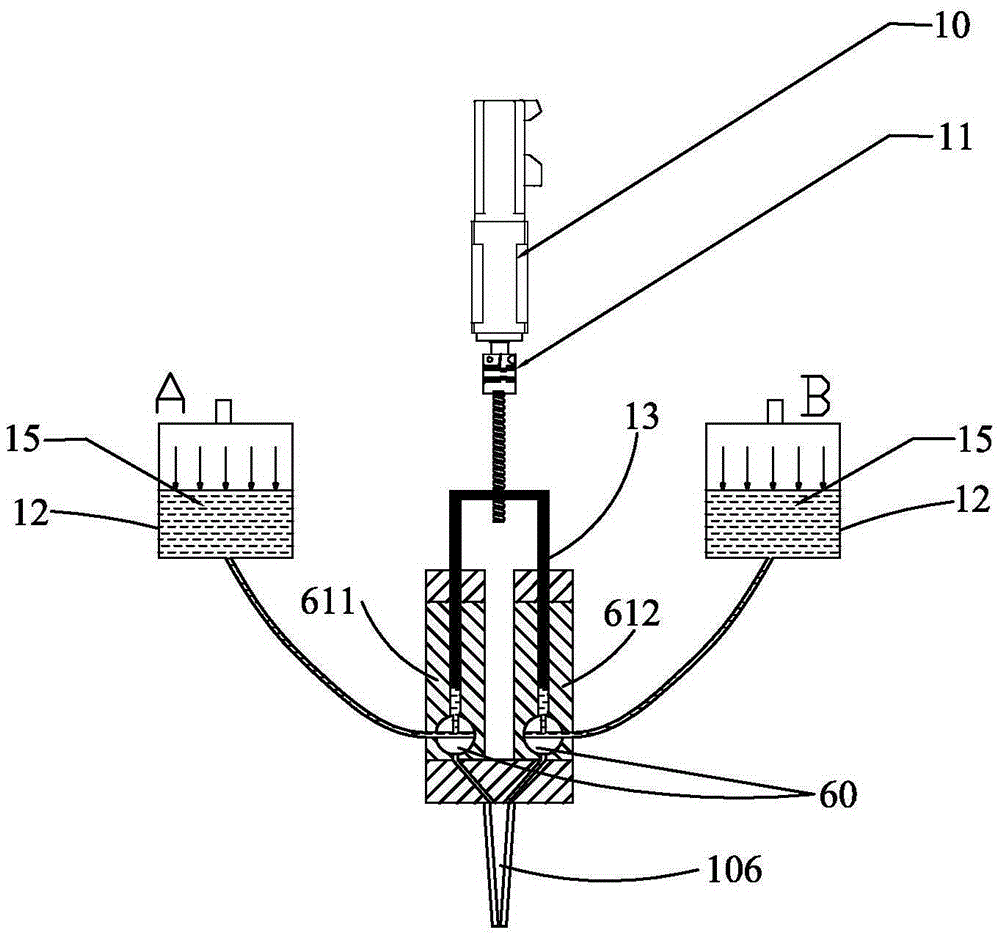

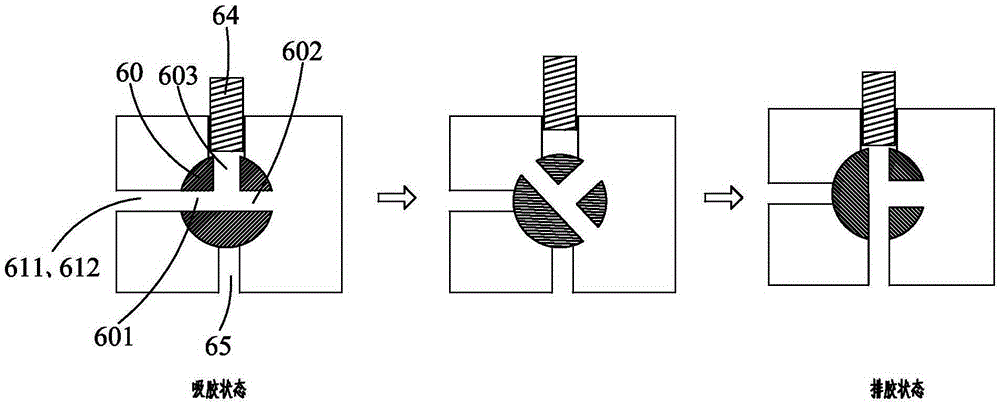

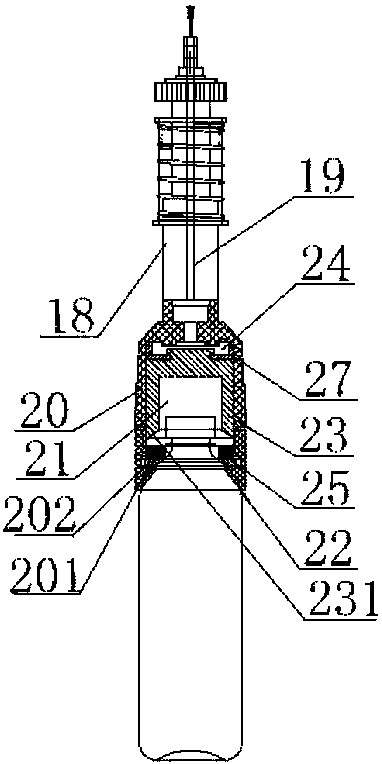

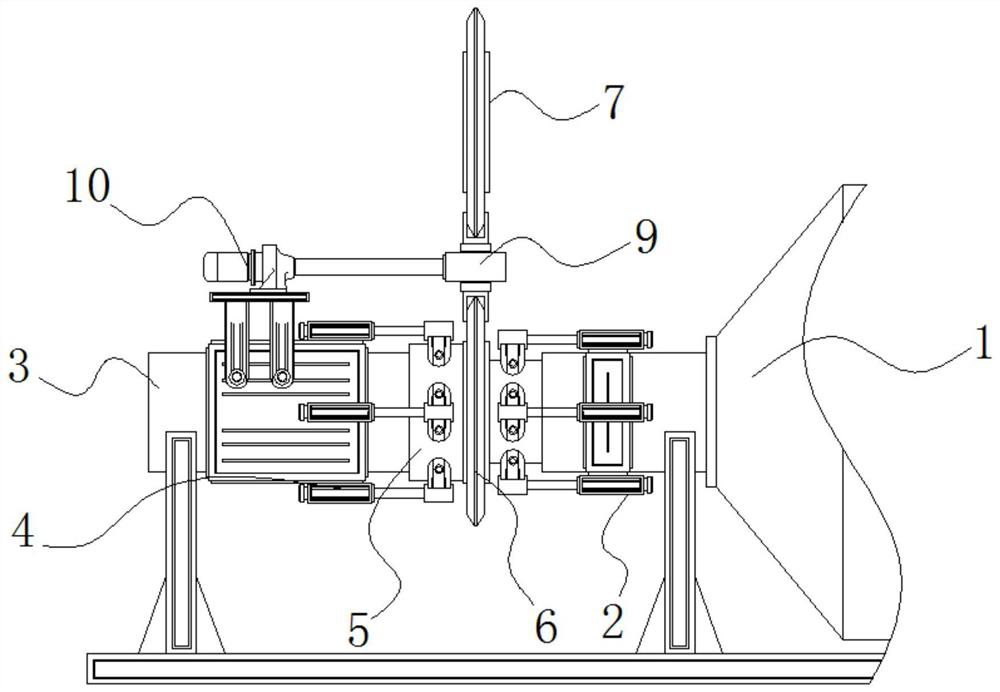

A and B glue dispenser

InactiveCN105381931AEasy to installEasy maintenanceLiquid surface applicatorsCoatingsElectric machineryEngineering

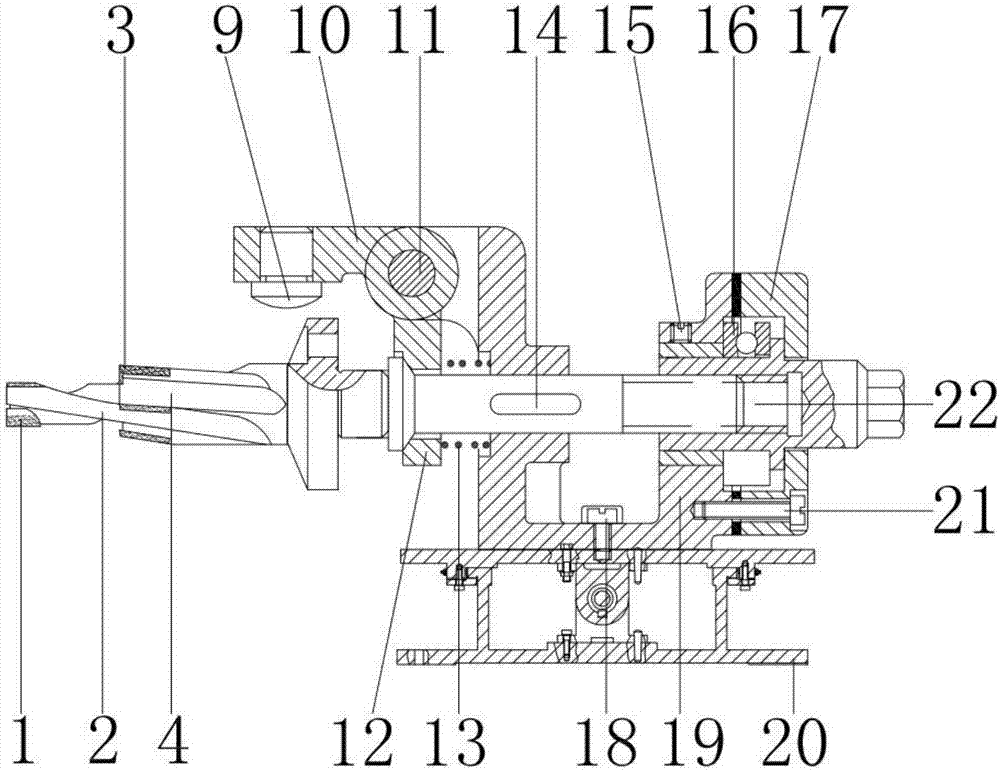

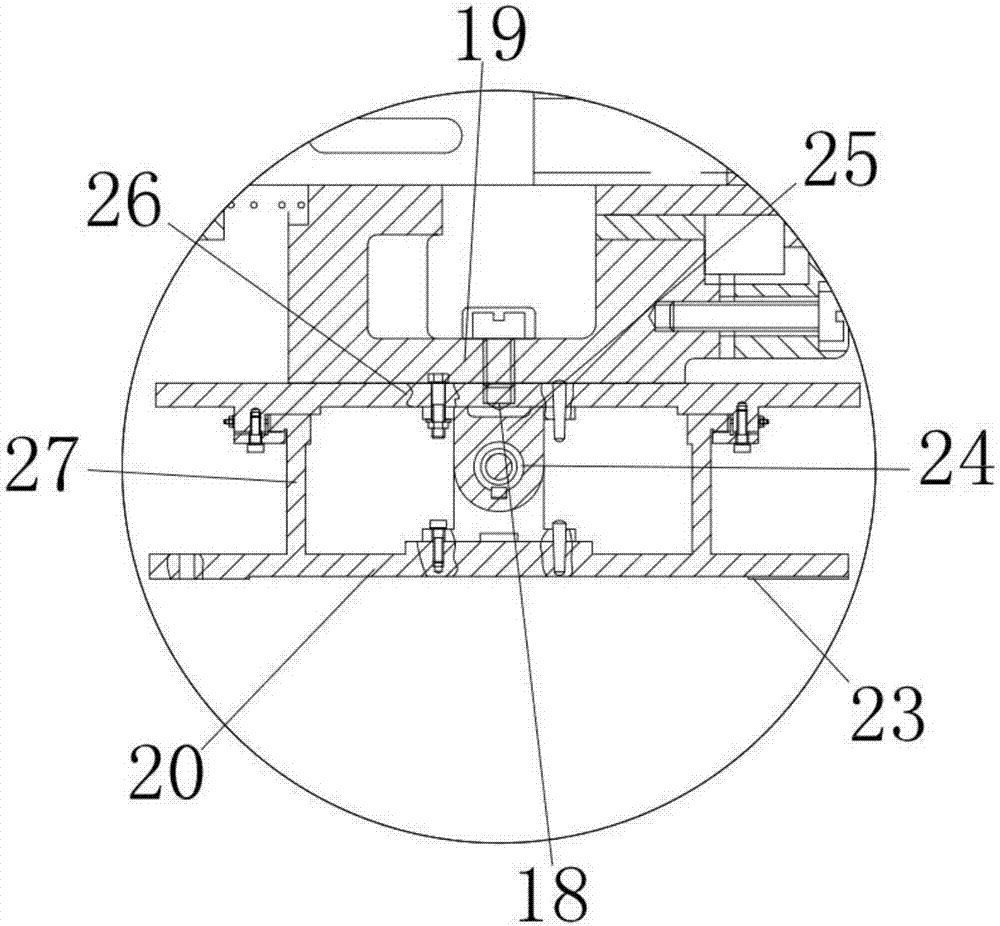

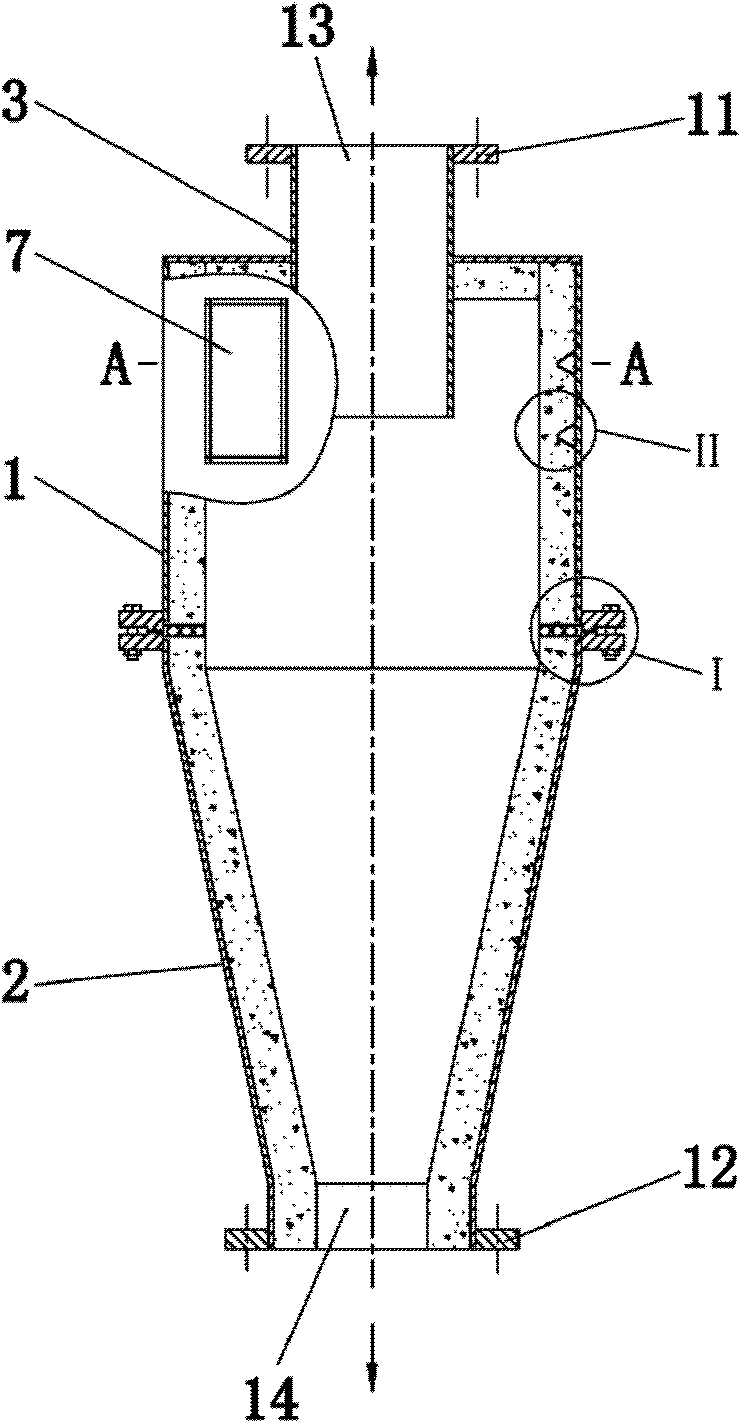

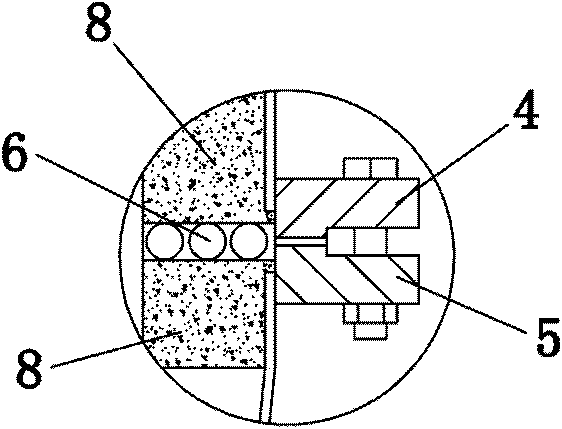

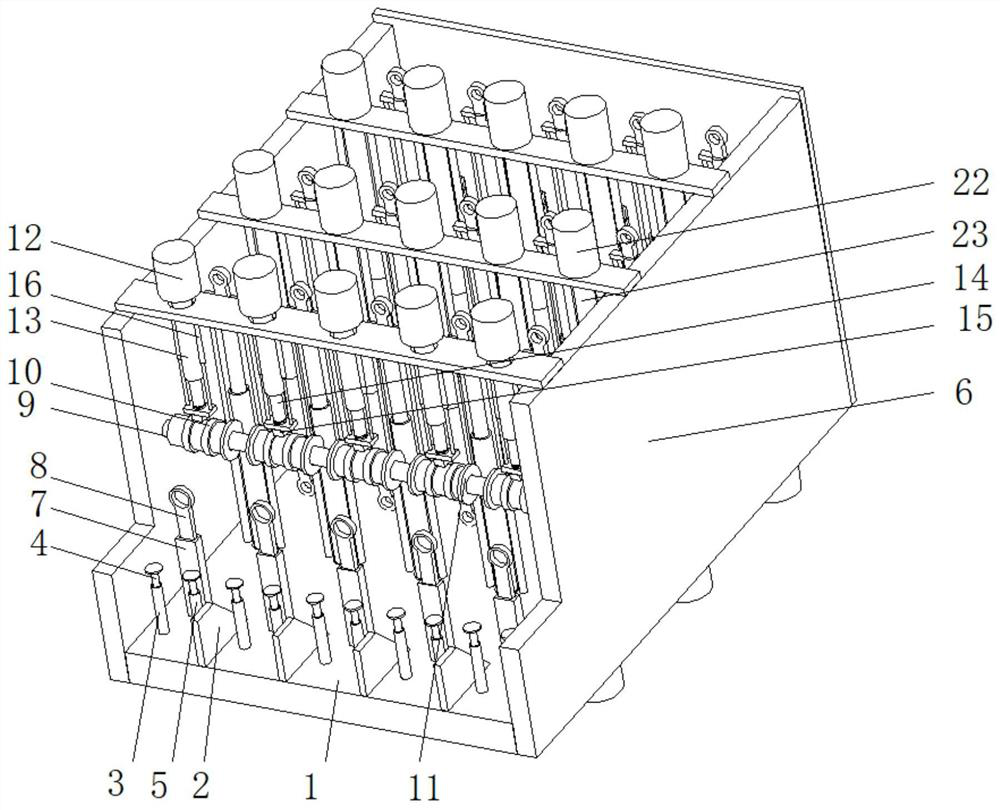

The invention discloses an A and B glue dispenser. The A and B glue dispenser comprises a set of plunger type glue dispensing valve feeding and discharging A and B glue continuously, a set of glue pushing mechanism precisely controlling glue amount and a set of mechanism capable of rapidly replacing glue mixing pipes and a glue dispensing needle head. Different mixing proportions of the A and B glue can be obtained by changing the diameter of a piston rod through the plunger type glue dispensing valve. The plunger type glue dispensing valve can be connected with big glue barrels and continuous glue dispensing is achieved without changing glue pipes. The glue pushing mechanism drives a lead screw to push a piston through a stepping or servo motor, and precise glue ranking control is achieved. When the glue mixing pipes and the glue dispensing needle head need to be replaced, the needle head replacing mechanism can separate the glue mixing pipes from the needle head, and the needle head position after replacement is not needed to be recalibrated.

Owner:KUNSHAN XUNTAO PRECISION MACHINERY

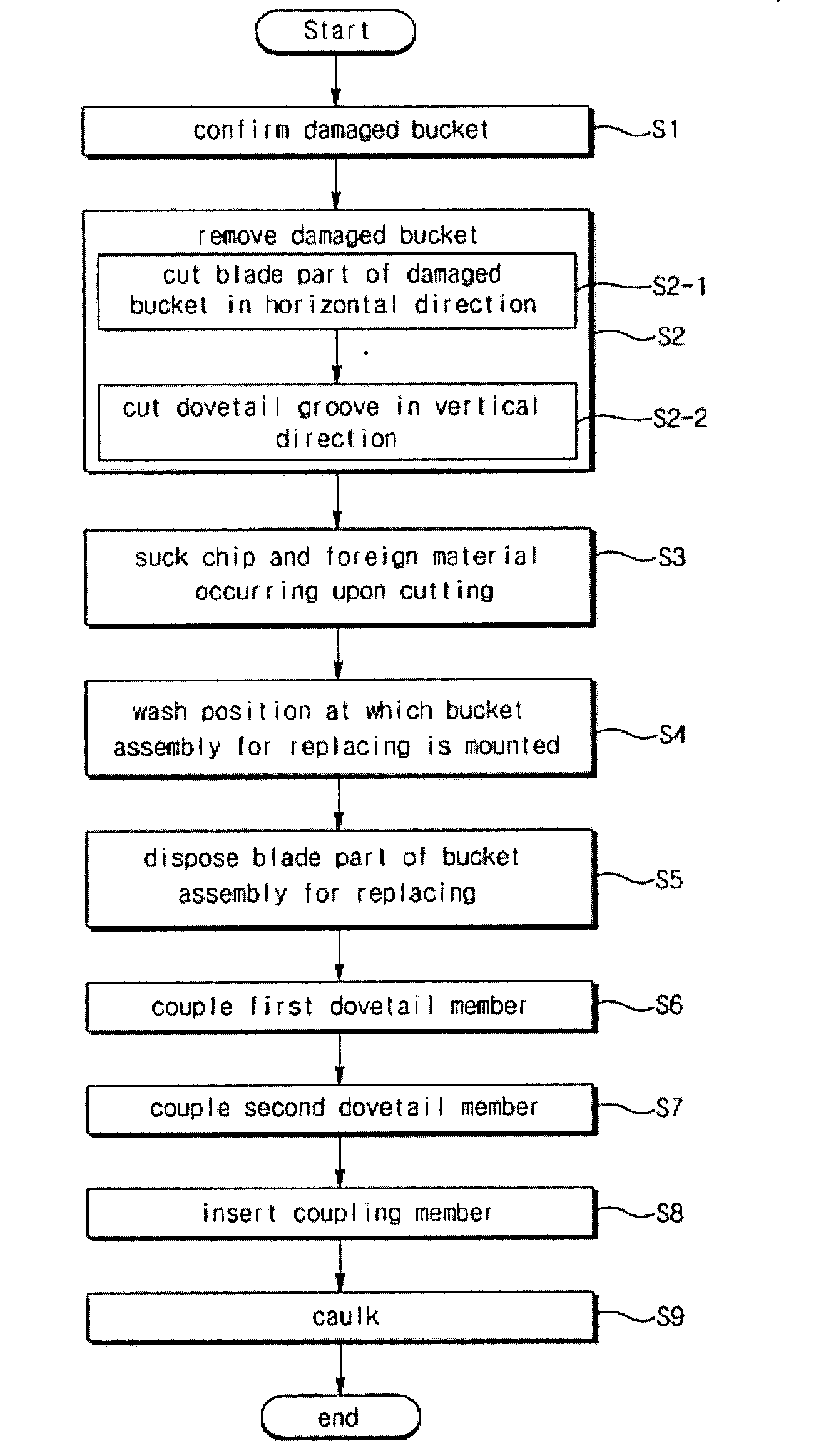

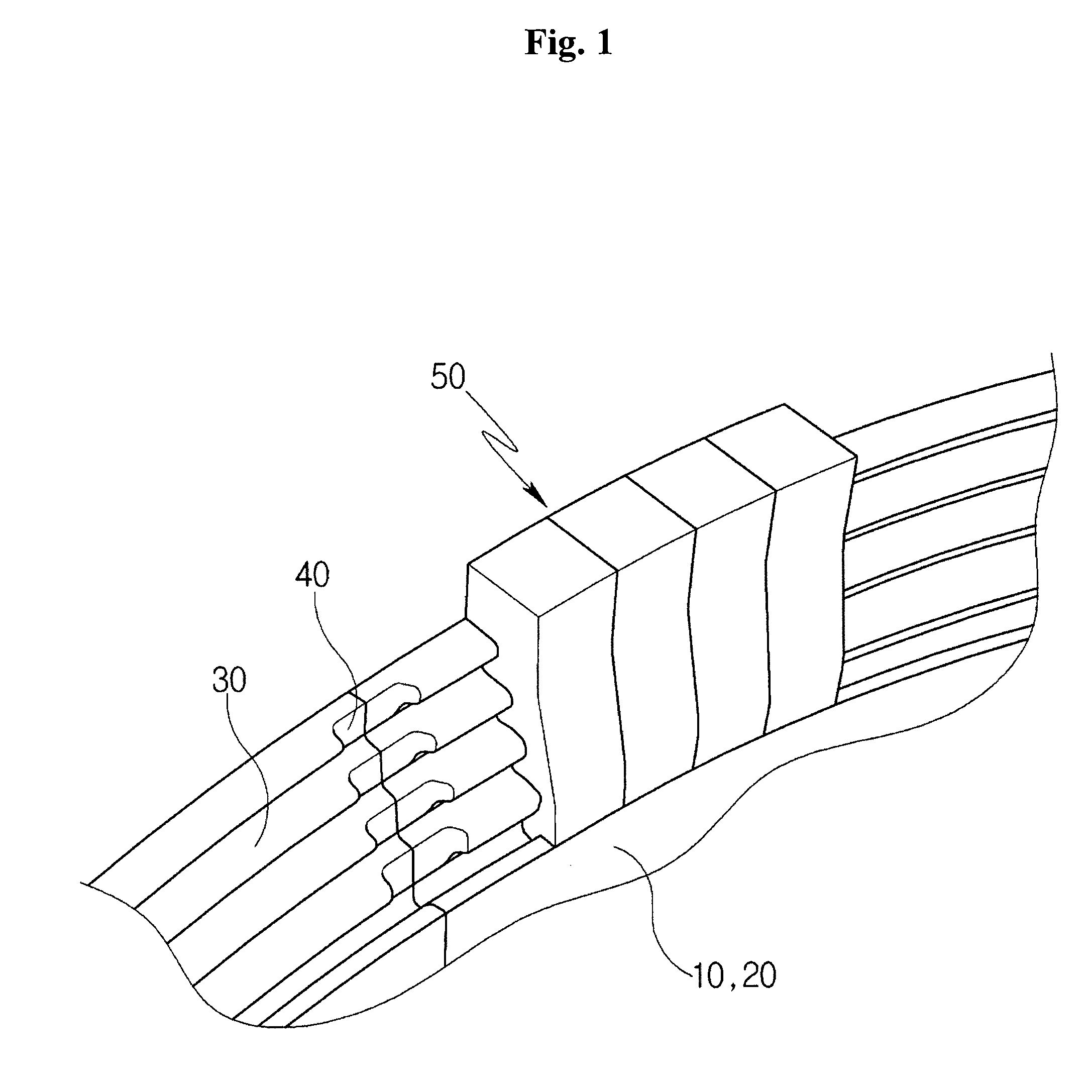

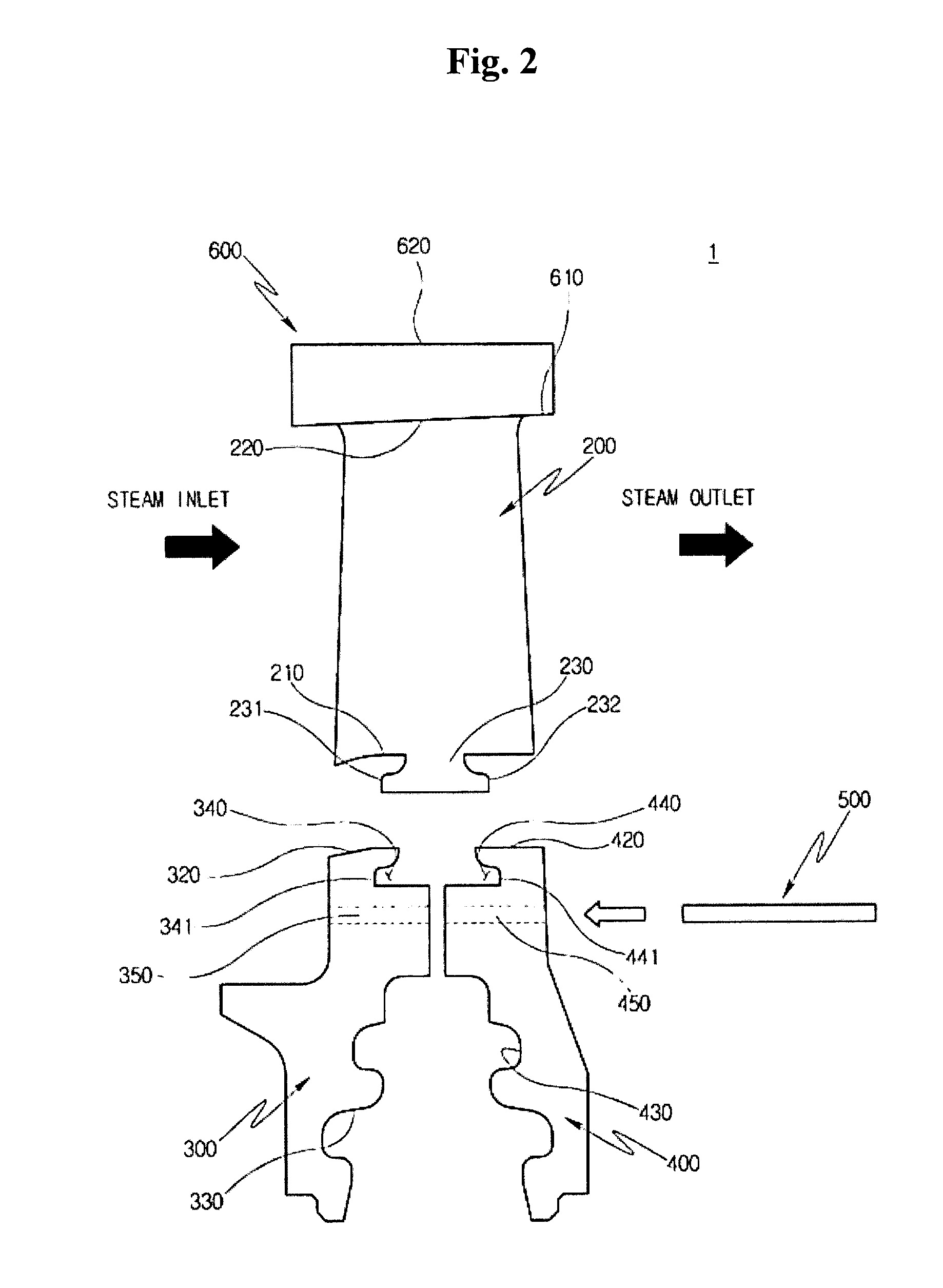

Bucket assembly for replacing old bucket provided with turbine and method for replacing the same

ActiveUS20160186569A1Save replacement timeReduce replacement costsPropellersPump componentsEngineeringTurbine

A bucket assembly for replacing an old bucket is provided with a turbine and a method for replacing the same. The bucket to be replaced is removed and then the bucket assembly configured of a blade part, first and second dovetail members, and a coupling member is simply assembled in a male dovetail, without sequentially disassembling the already installed buckets though a notch opening upon replacing the damaged bucket among the already installed buckets in a tangential entry type dovetail, thereby shortening replacement time and replacement costs of the bucket assembly and preventing a secondary damage occurring to the rotor or the rotor wheel during the disassembling process.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

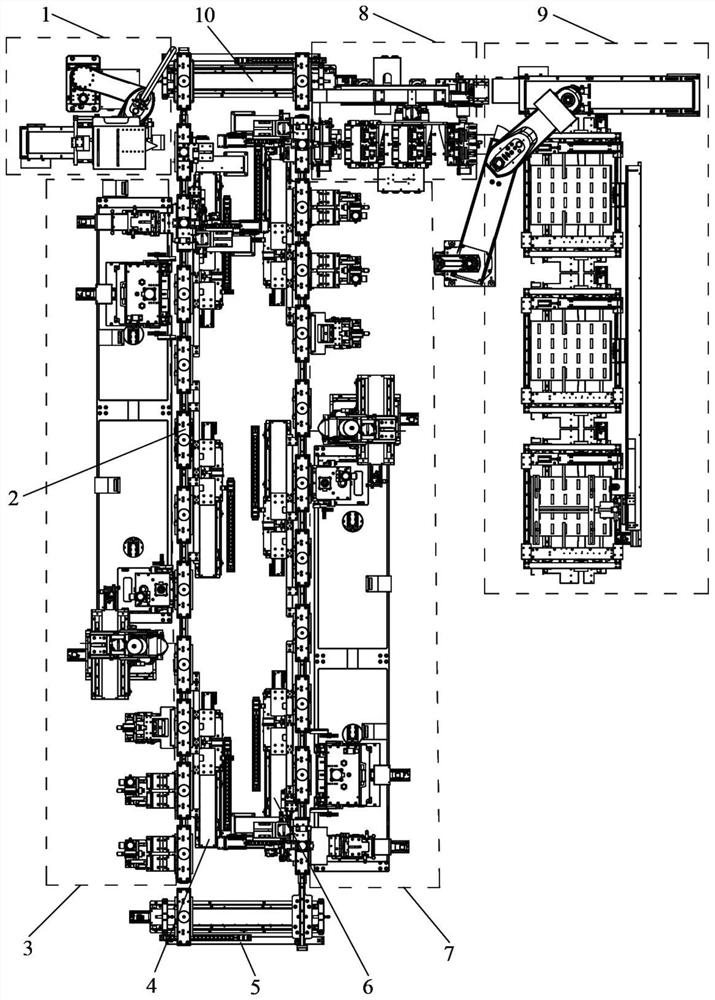

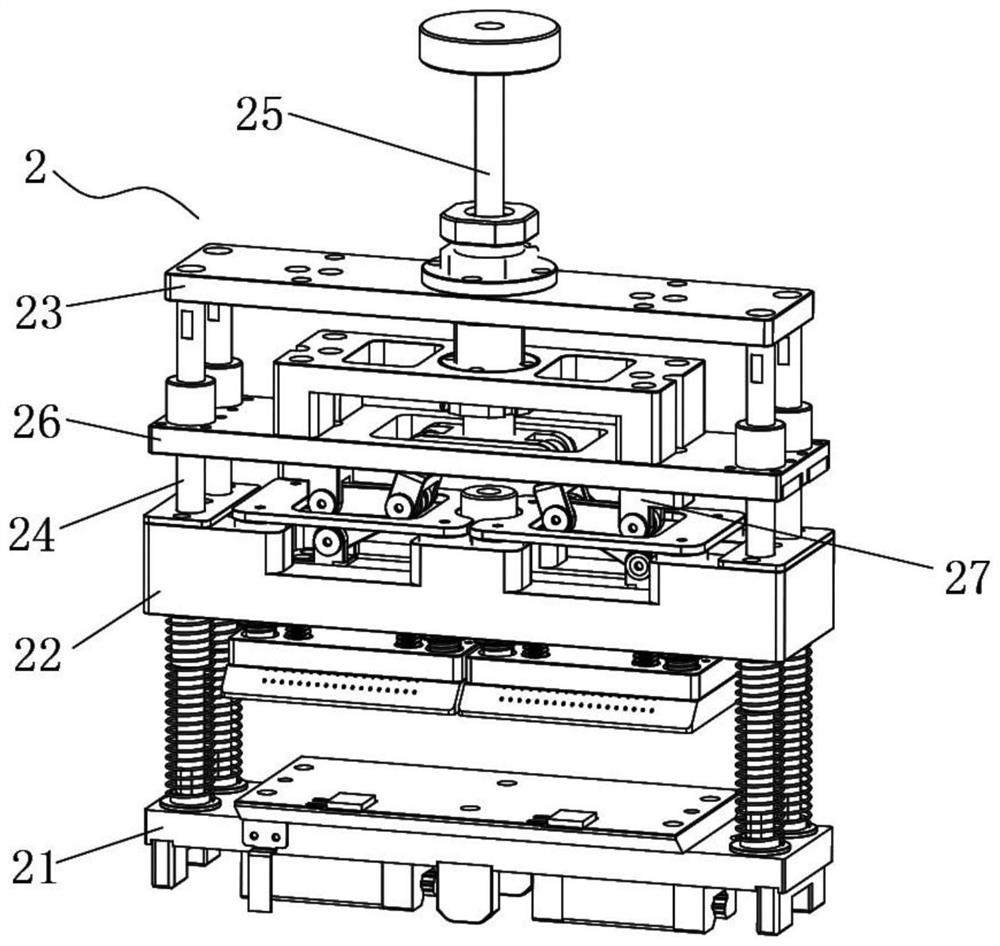

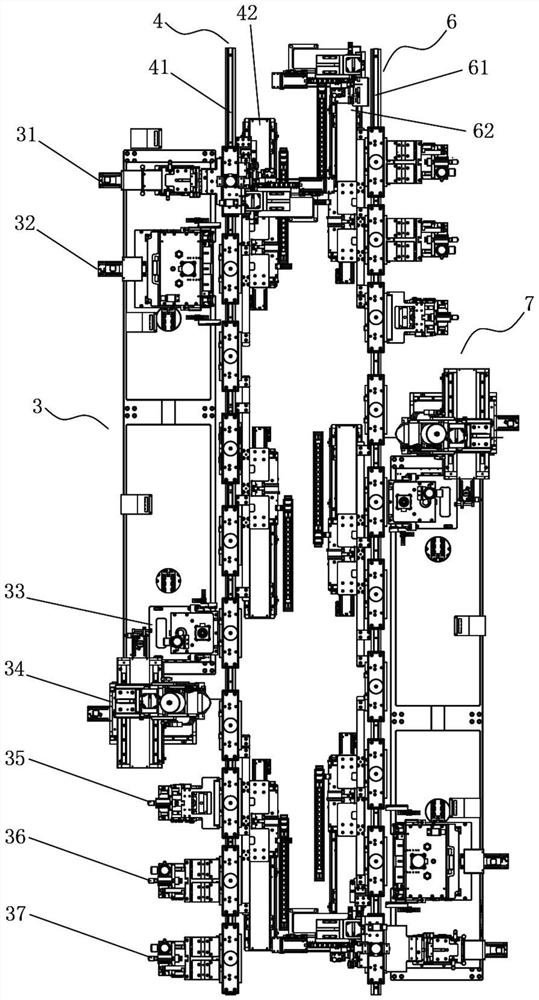

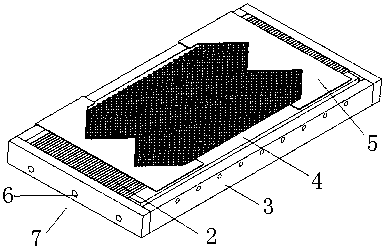

Lithium battery shaping equipment

ActiveCN111786027AImprove shaping efficiencyQuality assuranceAssembling battery machinesFinal product manufactureEngineeringTransfer mechanism

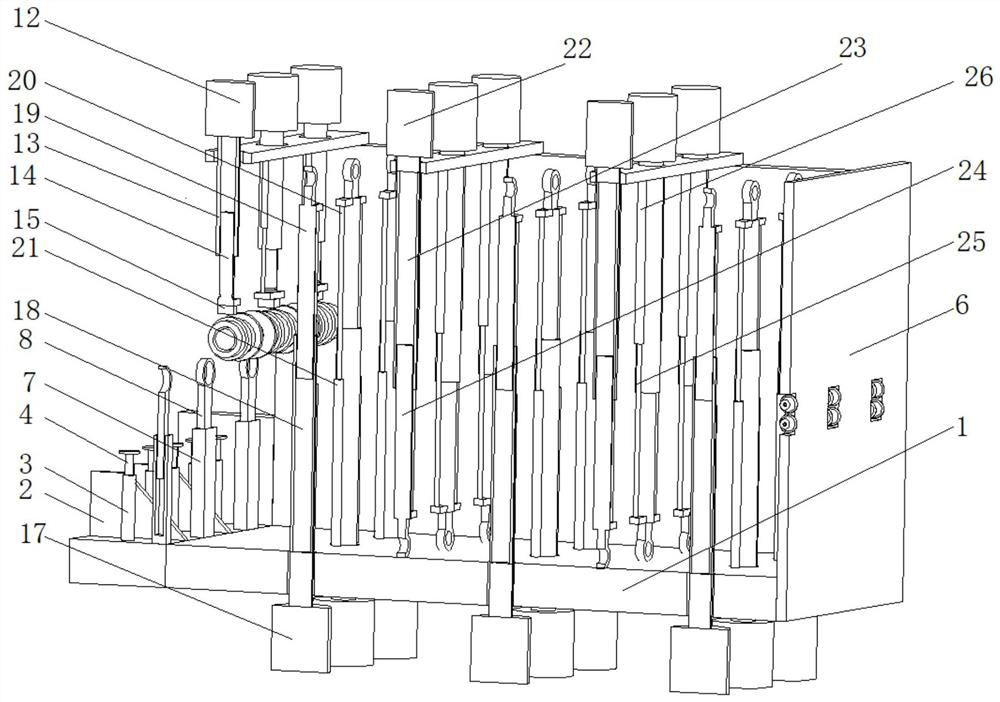

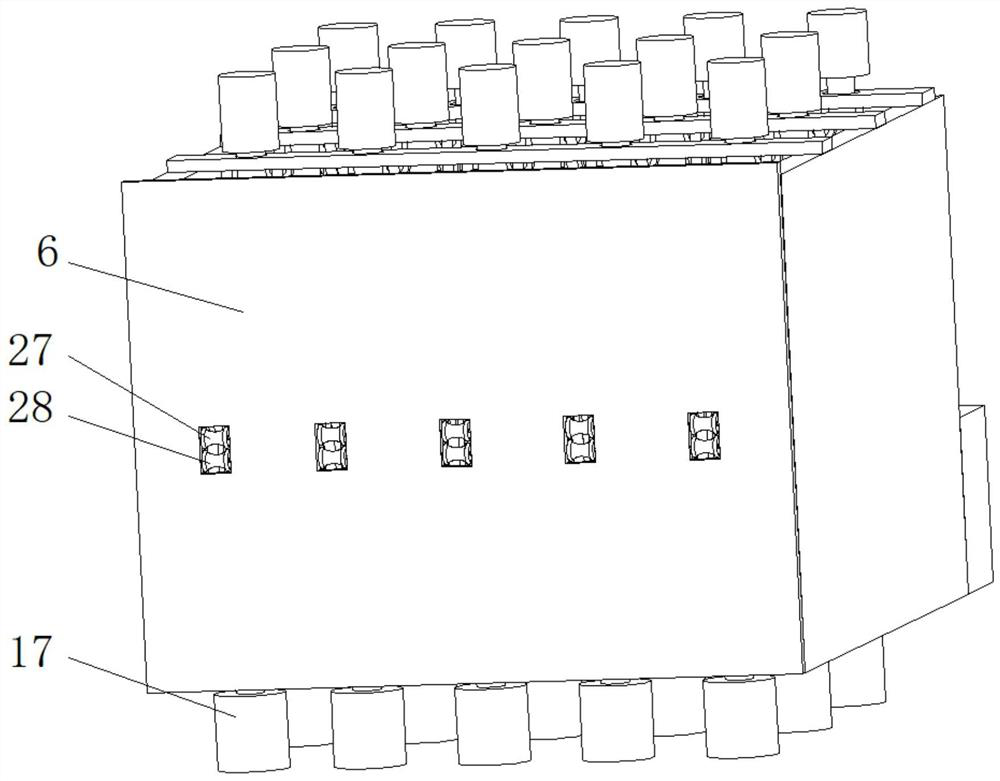

The invention provides lithium battery shaping equipment. The lithium battery shaping equipment comprises a feeding mechanism, a left shaping mechanism, a right shaping mechanism, a left conveying mechanism, a right conveying mechanism, a front clamp transfer mechanism, a rear clamp transfer mechanism, a fine shaping mechanism, a discharging mechanism and a plurality of battery cell clamps, wherein the left conveying mechanism and the right conveying mechanism are distributed in parallel left and right; the front clamp transfer mechanism is connected to the front ends of the left conveying mechanism and the right conveying mechanism, the rear clamp transfer mechanism is connected to the rear ends of the left conveying mechanism and the right conveying mechanism, and the battery cell clampsare circularly conveyed on the left conveying mechanism, the rear clamp transfer mechanism, the right conveying mechanism and the front clamp transfer mechanism. The feeding mechanism and the left shaping mechanism are arranged on the left side of the left conveying mechanism from front to back. The full-automatic battery cell shaping machine has the beneficial effects that the automation of eachshaping process of a battery cell is realized, the production efficiency is improved, and the production stability can be ensured.

Owner:东莞市爱康智能技术有限公司

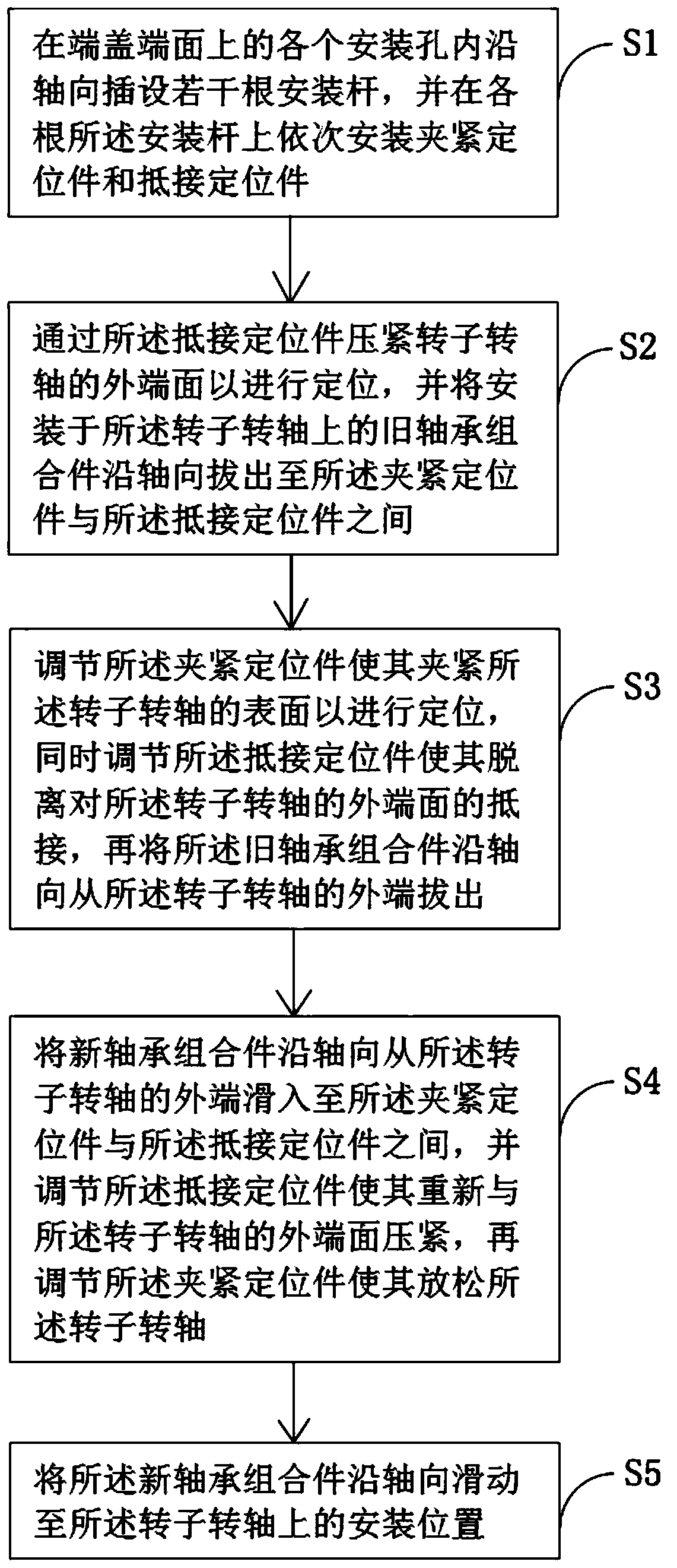

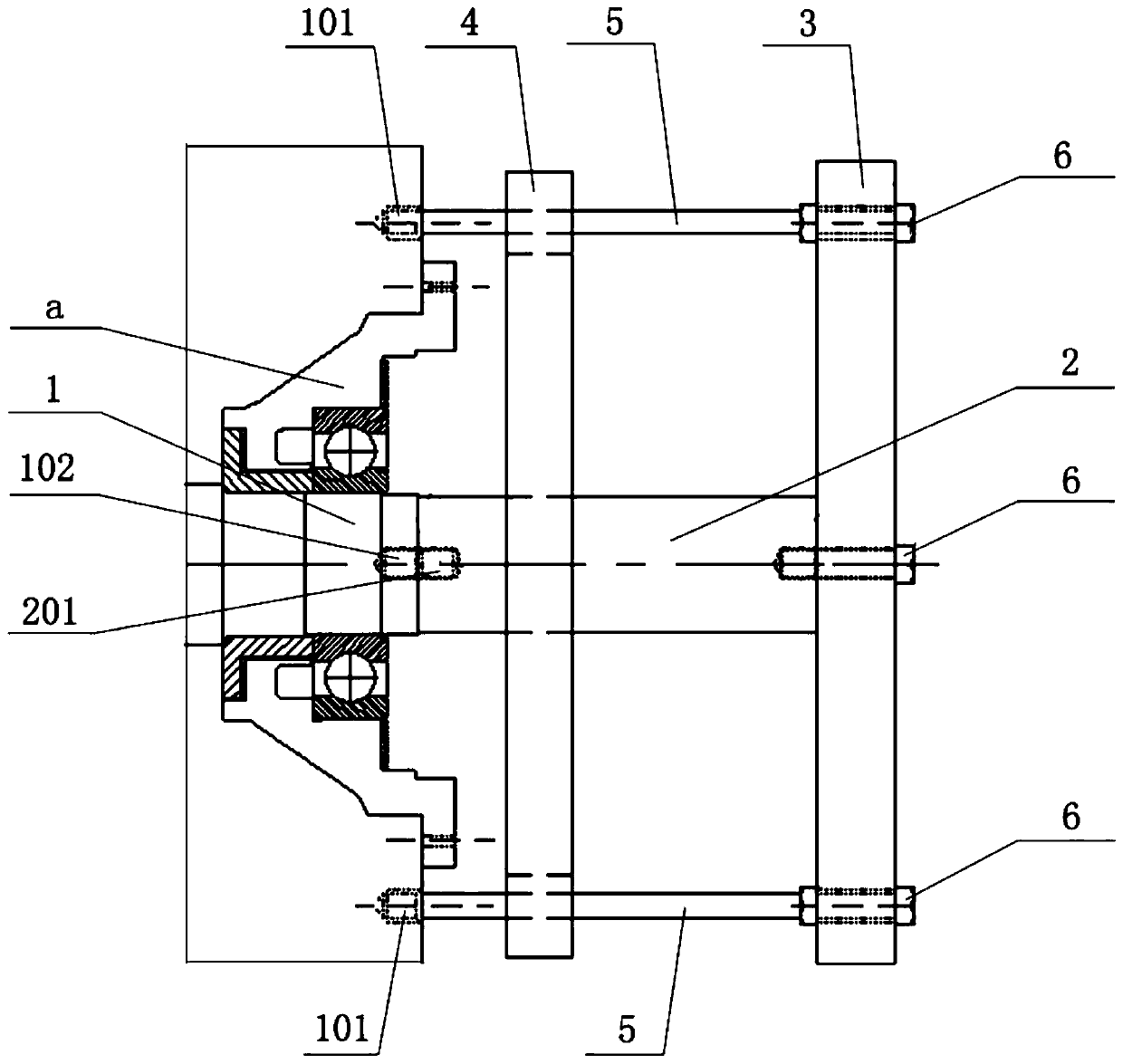

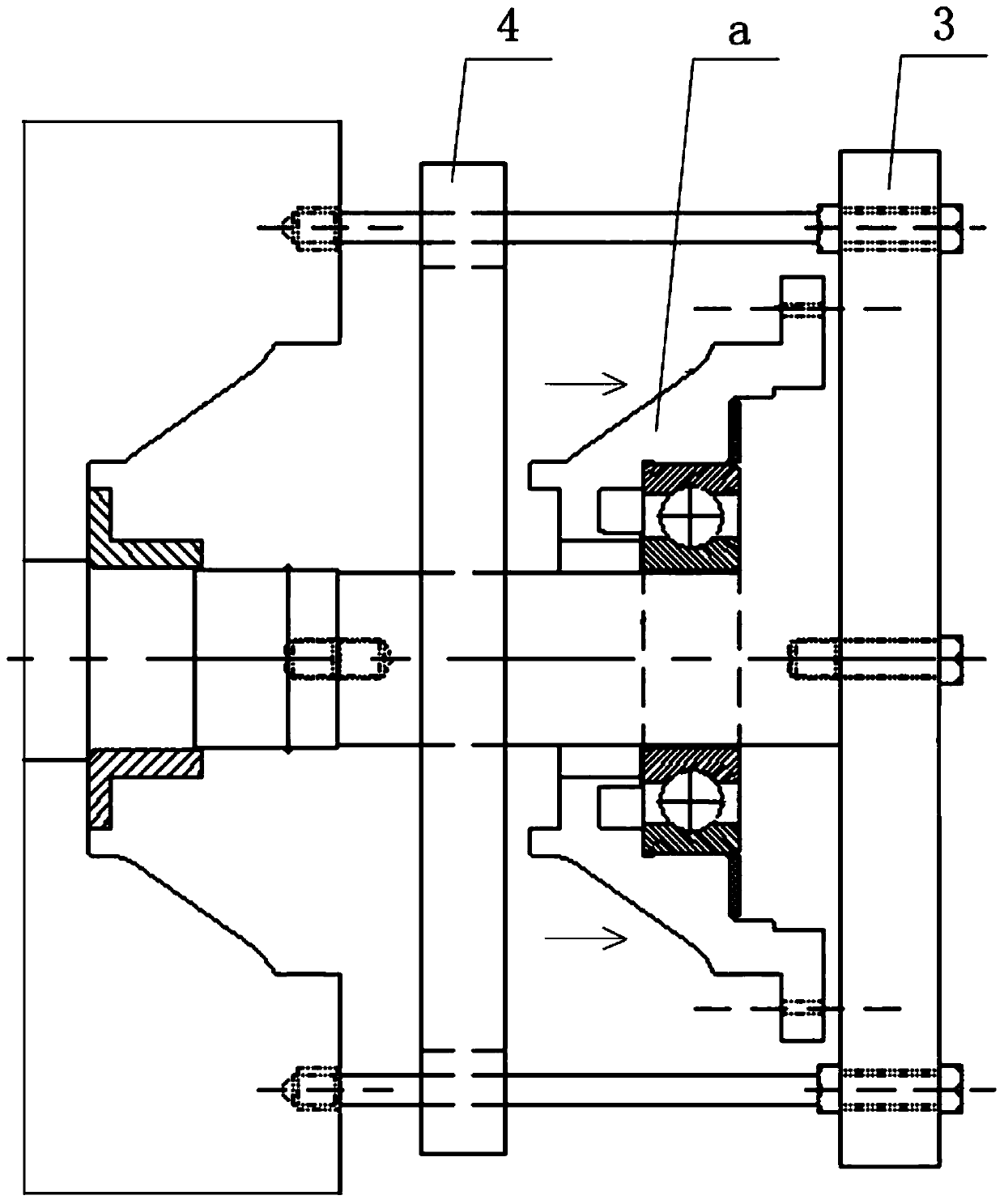

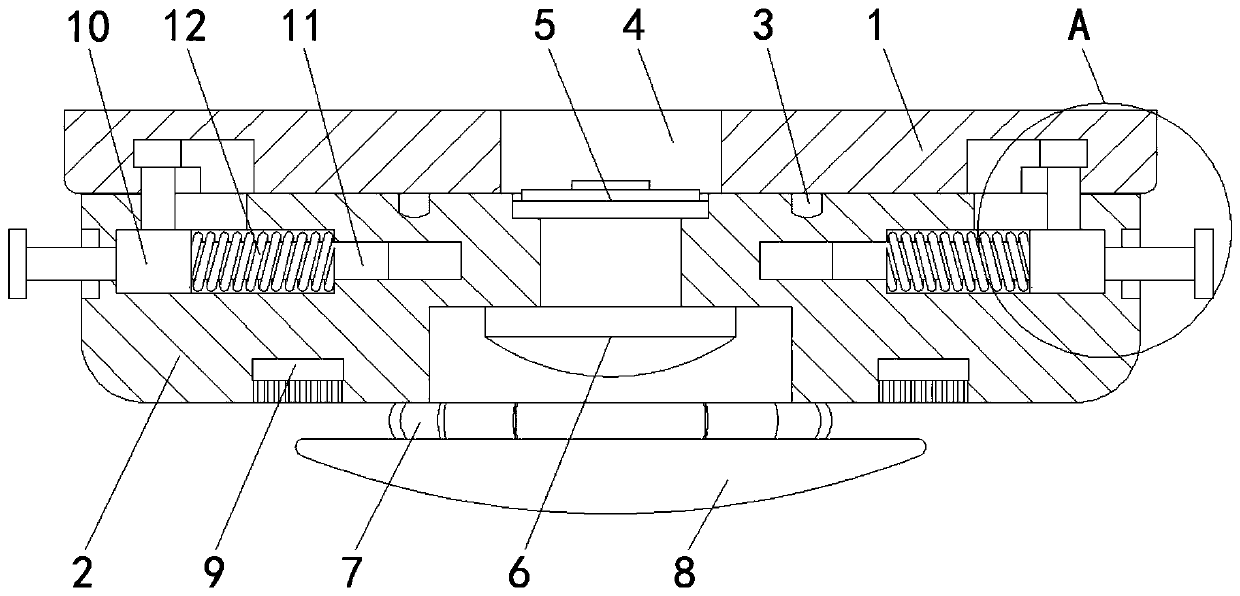

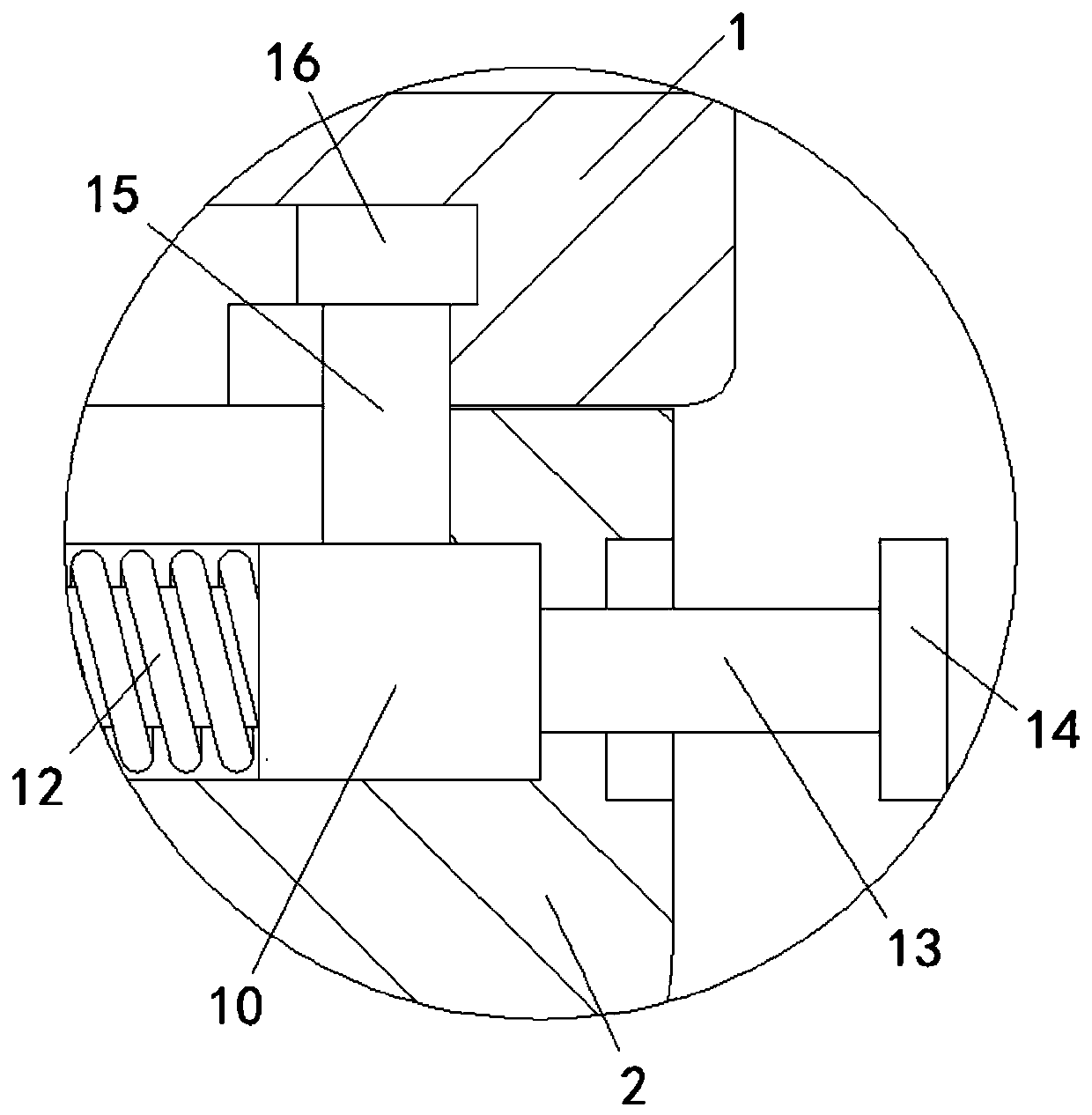

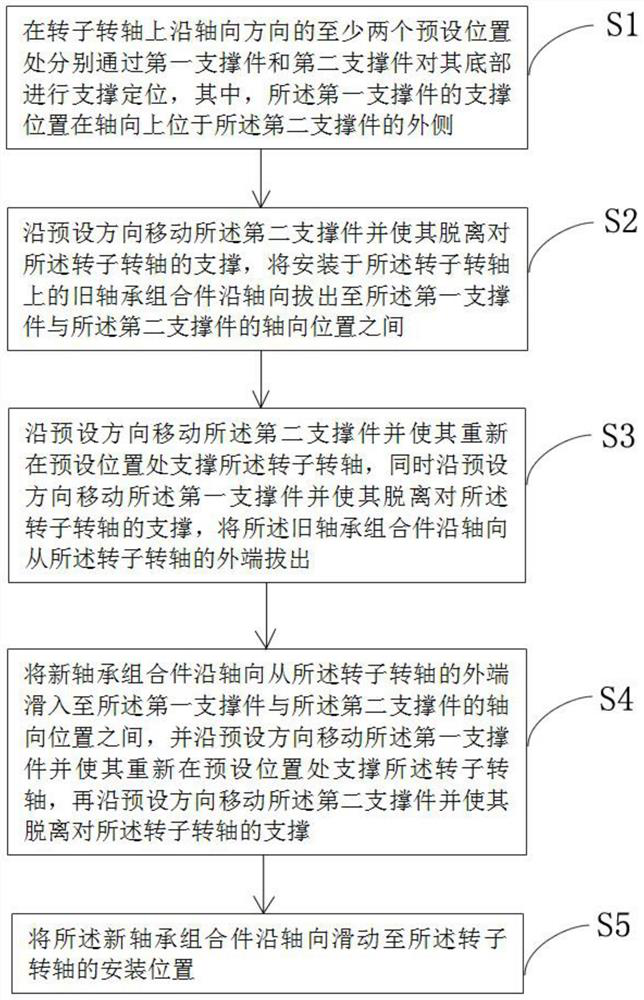

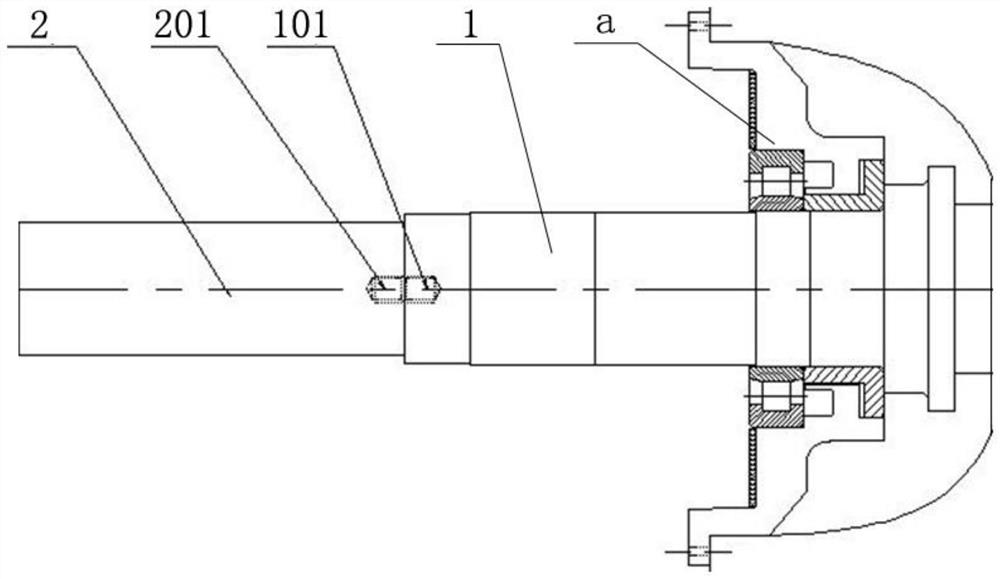

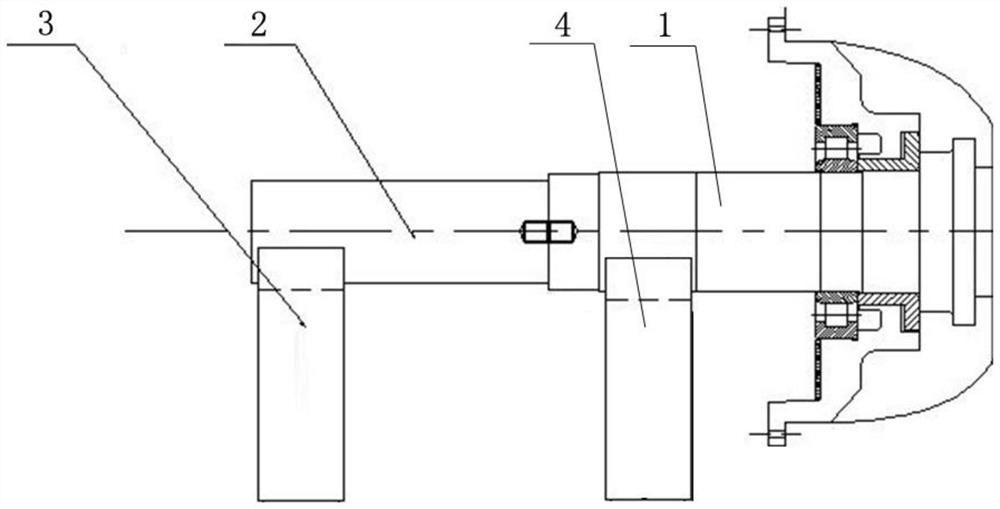

Method for disassembling and assembling motor bearing without disassembly

ActiveCN110829745AEnough room to slideAvoid displacementBearing repair/replacementShaft repair/replacementClassical mechanicsElectric machinery

The invention discloses a method for disassembling and assembling a motor bearing without disassembly, which comprises the steps of inserting a mounting rod on the end surface of an end cover, and sequentially mounting a clamping positioning member and an abutting positioning member; pressing the outer end surface of a rotor rotating shaft through the abutting positioning member for positioning, and pulling out an old bearing assembly in the axial direction; adjusting the clamping positioning member to clamp the rotor rotating shaft for positioning, adjusting the abutting positioning member toenable the abutting positioning member to release the pressing for the rotor rotating shaft, and pulling out the old bearing assembly from the outer end of the rotor rotating shaft in the axial direction; sliding a new bearing assembly into the space between the clamping positioning member and the abutting positioning member from the outer end of the rotor rotating shaft in the axial direction, adjusting the abutting positioning member to enable the abutting positioning member to press the outer end surface of the rotor rotating shaft again, and then adjusting the clamping positioning memberto loosen the rotor rotating shaft; and sliding the new bearing assembly to a mounting position on the rotor rotating shaft in the axial direction. According to the invention, the disassembly-free disassembly and replacement of the motor bearing can be achieved, the disassembly and replacement efficiency is improved, and rotor displacement in the disassembly and replacement process is avoided.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

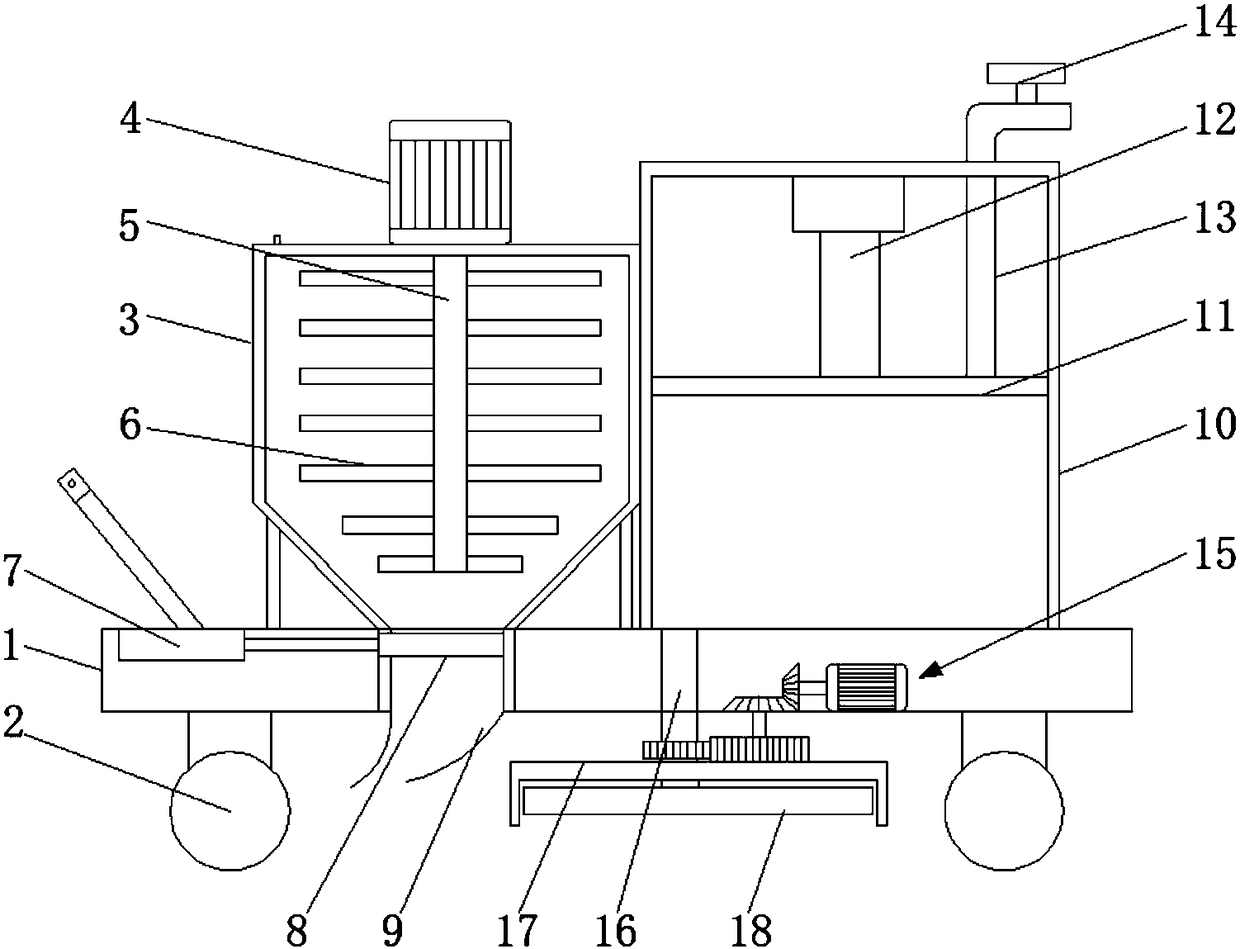

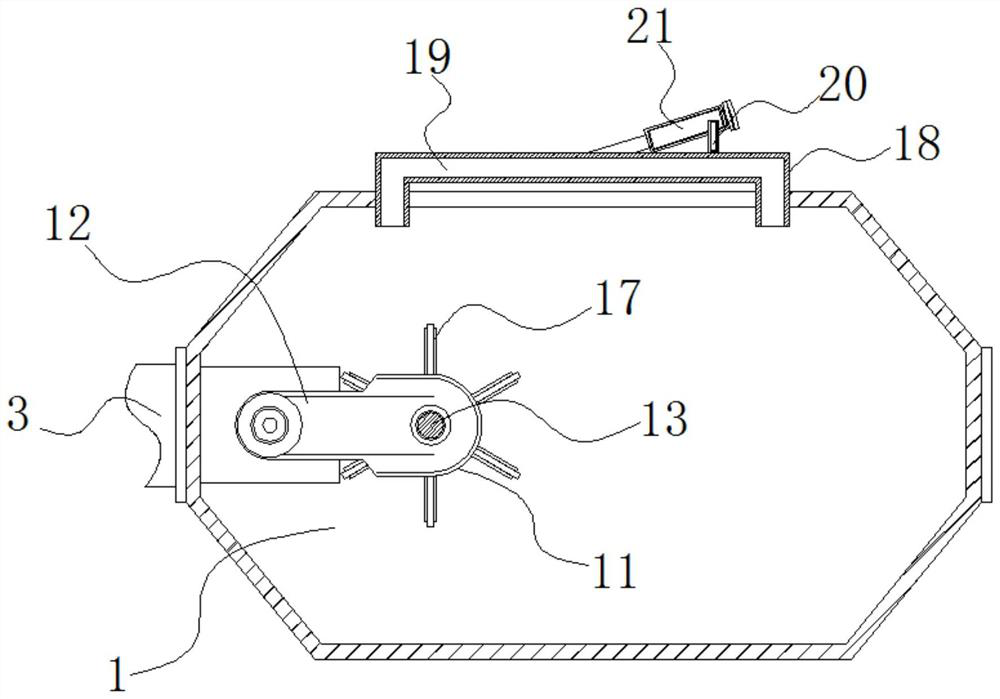

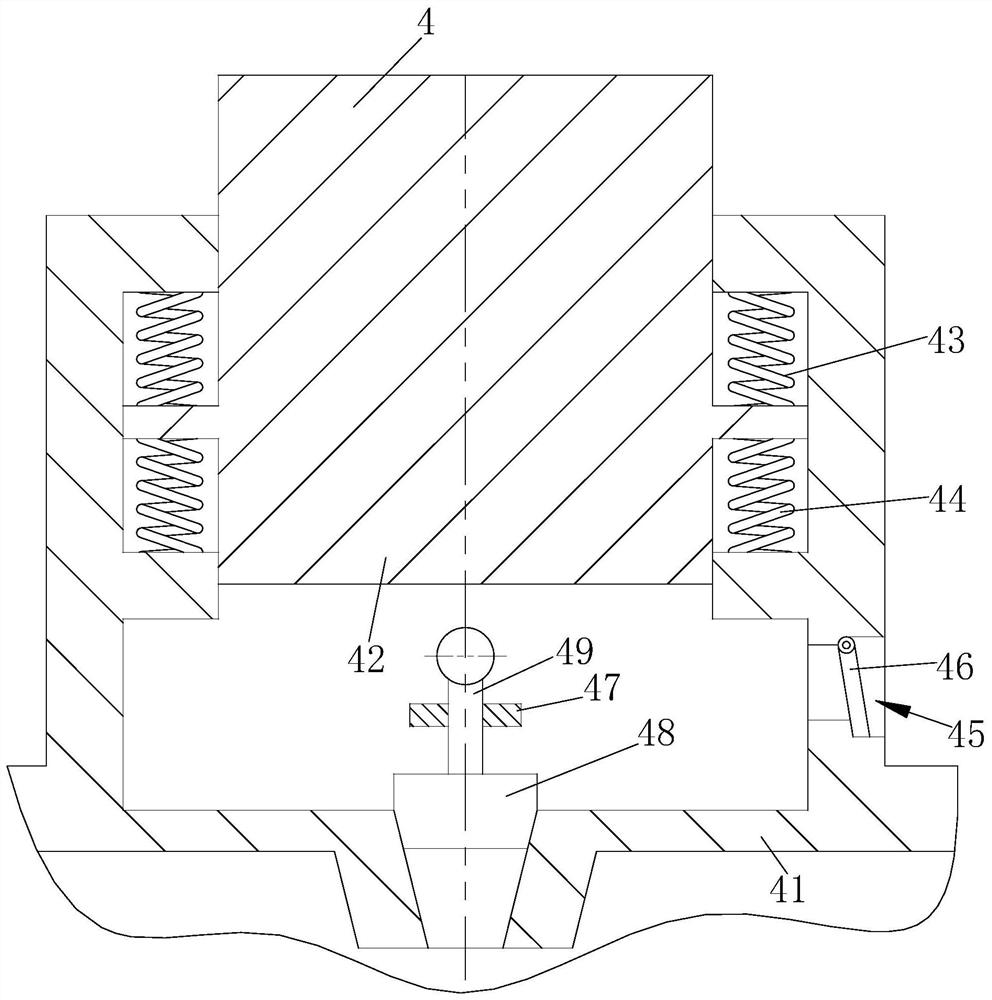

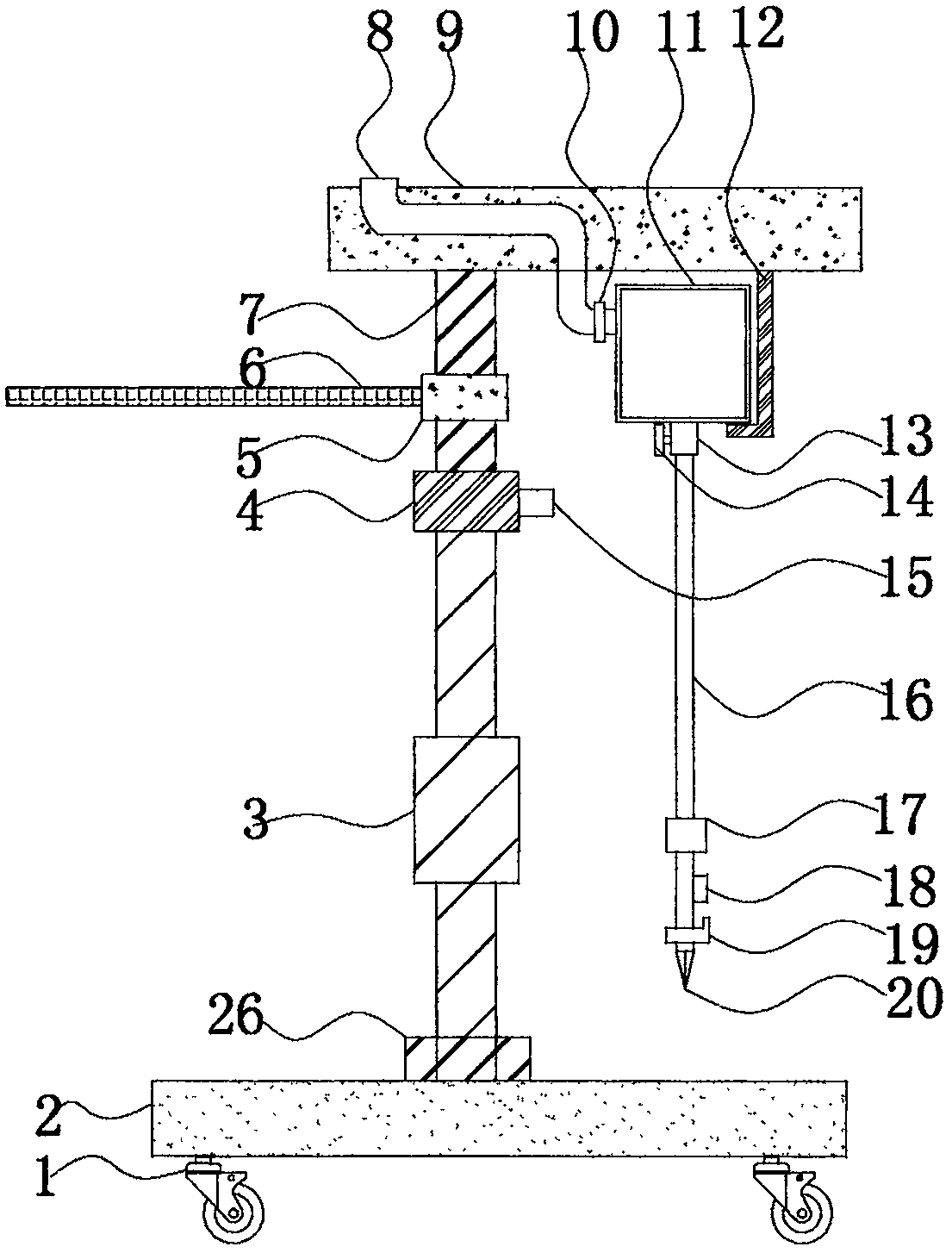

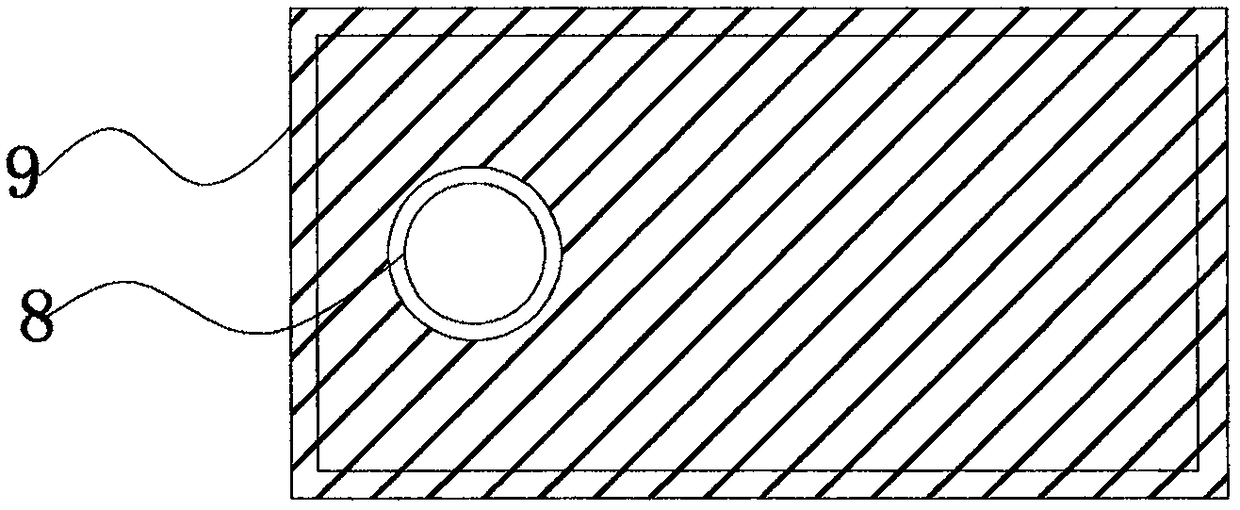

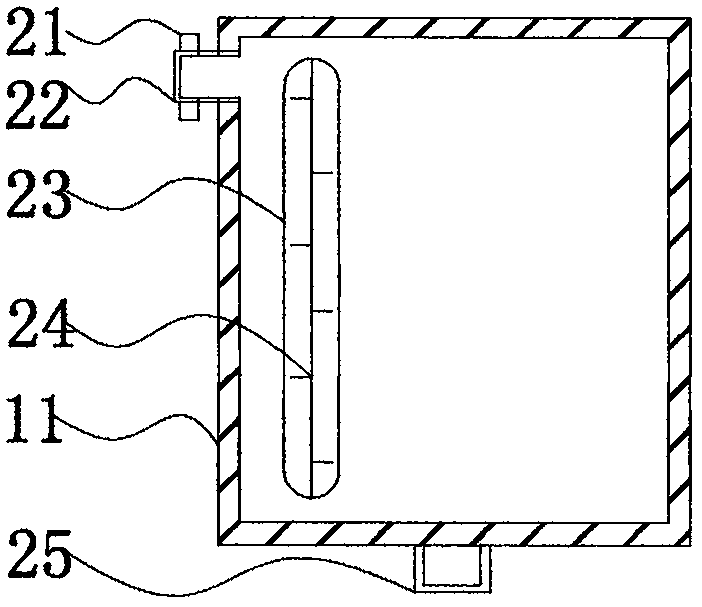

Fertilizing device for agricultural use

InactiveCN108551825AAvoid conversionIncrease profitFertiliser distributersPressurised distribution of liquid fertiliserAgricultural engineeringFunnel shape

The invention discloses a fertilizing device for agricultural use. The fertilizing device for agricultural use comprises a pedestal, a solid material box and a liquid material box; universal wheels are fixedly arranged at the four corners of the bottom end of the pedestal through supporting legs; the solid material box and the liquid material box are fixed on the pedestal; the solid material box is arranged on the left side of the liquid material box; a stirring device is arranged in the solid material box; the stirring device comprises a stirring motor, a stirring rod and a stirring paddle; the upper end of the solid material box adopts a cuboid structure and the lower end of the solid material box adopts a funnel-shaped structure; the bottom end of the solid material box is provided witha discharging port in the pedestal; and a first electric telescopic rod is fixedly arranged at the top end of the internal part of the pedestal on the left side of the discharging port. The fertilizing device for agricultural planting is provided with the solid material box and the liquid material box so as to perform fertilizing utilization on different types of fertilizer and save the use costof various fertilizing device, and performs rotary spraying in a retaining disk so as to prevent a discharging spray head from being blocked and realize uniform spraying.

Owner:NANAN WENFA ELECTRONICS TECH CO LTD

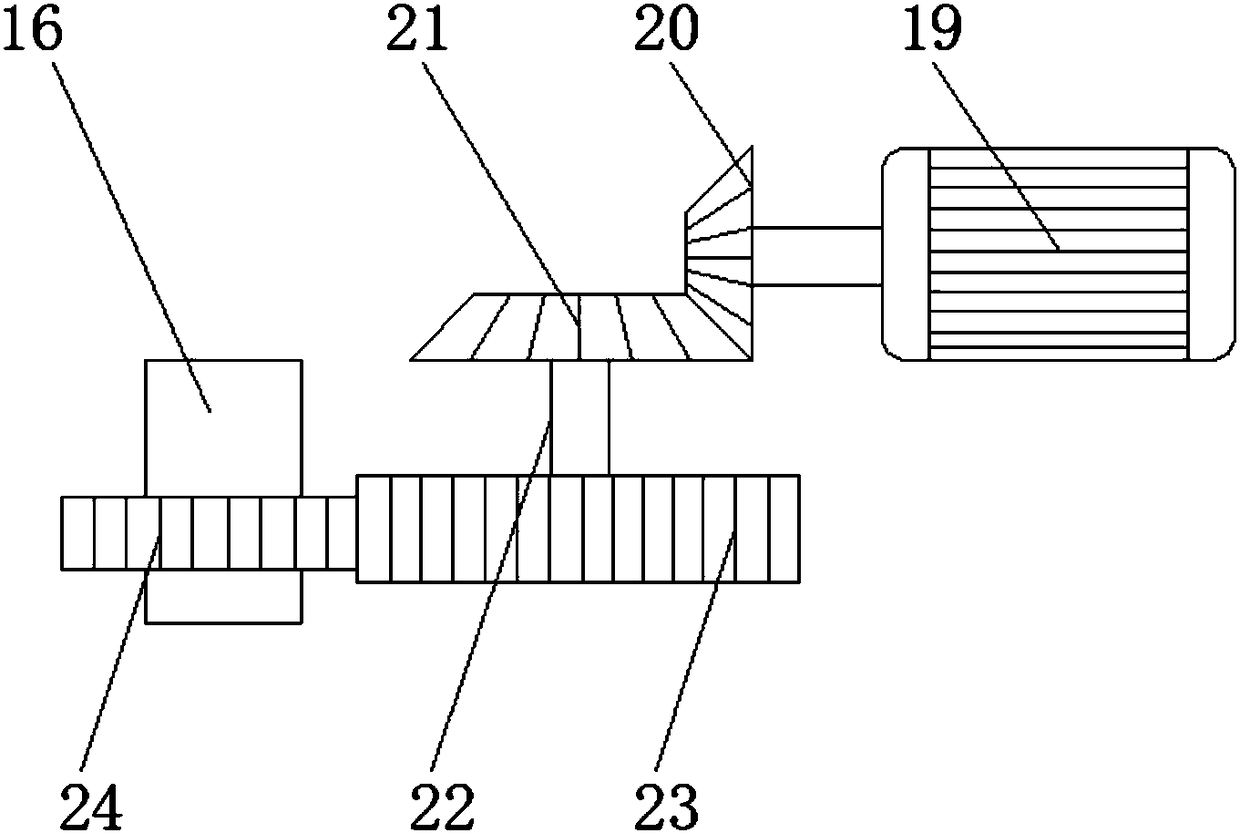

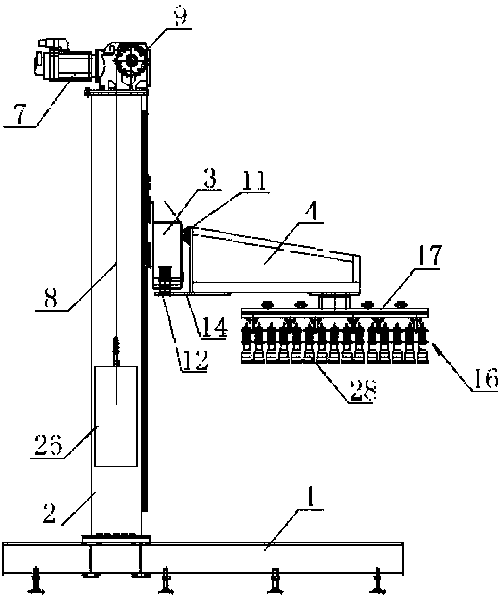

Bottle filling manipulator

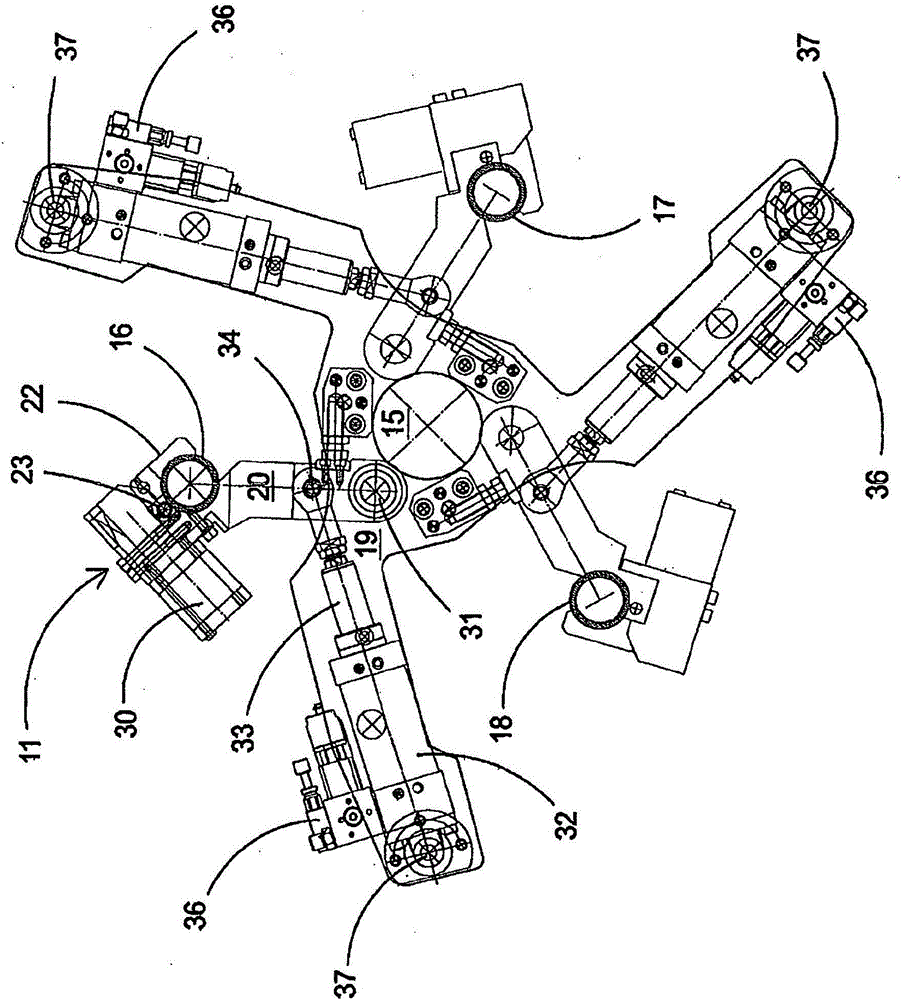

InactiveCN109455336AGuaranteed uptimeAccurate motion positioningPackaging bottlesElectric machineryEngineering

The present invention discloses a bottle filling manipulator, and the bottle filling manipulator is characterized by adopting a bottle taking mode that a piston is extruded by compressed air so as toextrude an O-shaped spring inwards and clamp a bottle mouth, and thus the bottle filling manipulator is suitable for various bottle types; the bottle filling manipulator is simple and reliable in structure and users do not need to frequently replace clamping jaws according to different bottle types, thereby greatly saving replacement and installation time and improving production efficiency; through servo synchronization of a lifting servo motor and a displacement servo motor, movement and positioning of a packing and bottle taking mechanism is able to be accurately realized, and a bottle taking manipulator runs stably and reliably in a bottle taking and packing process.

Owner:常州市邹区蔬菜产业发展有限公司

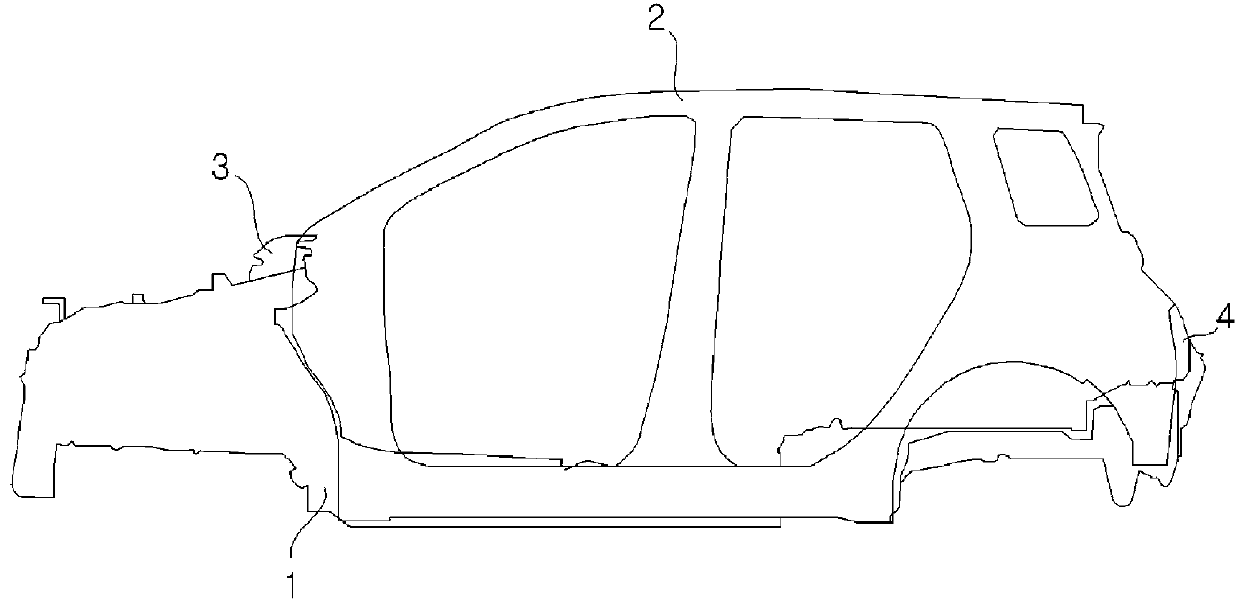

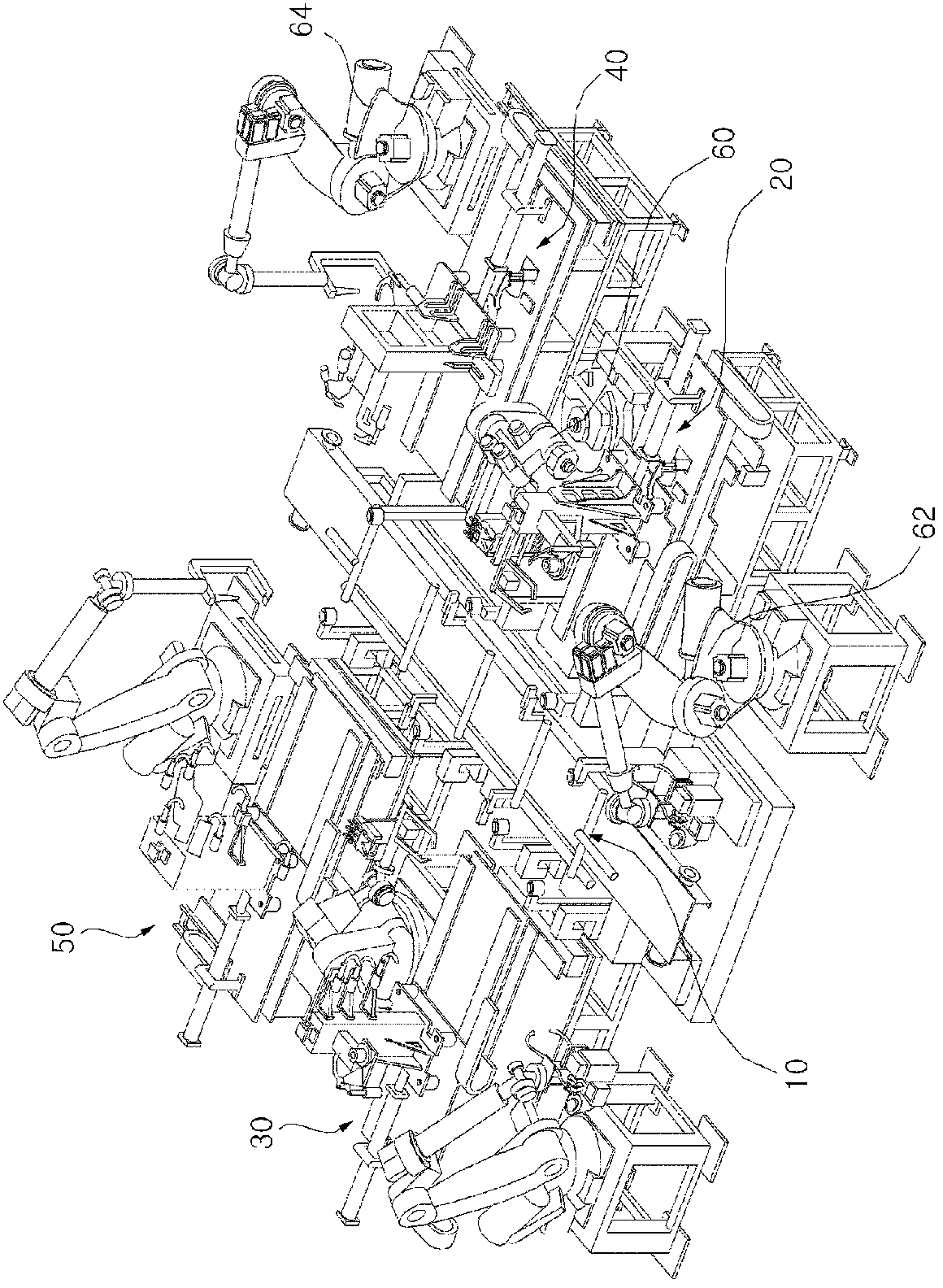

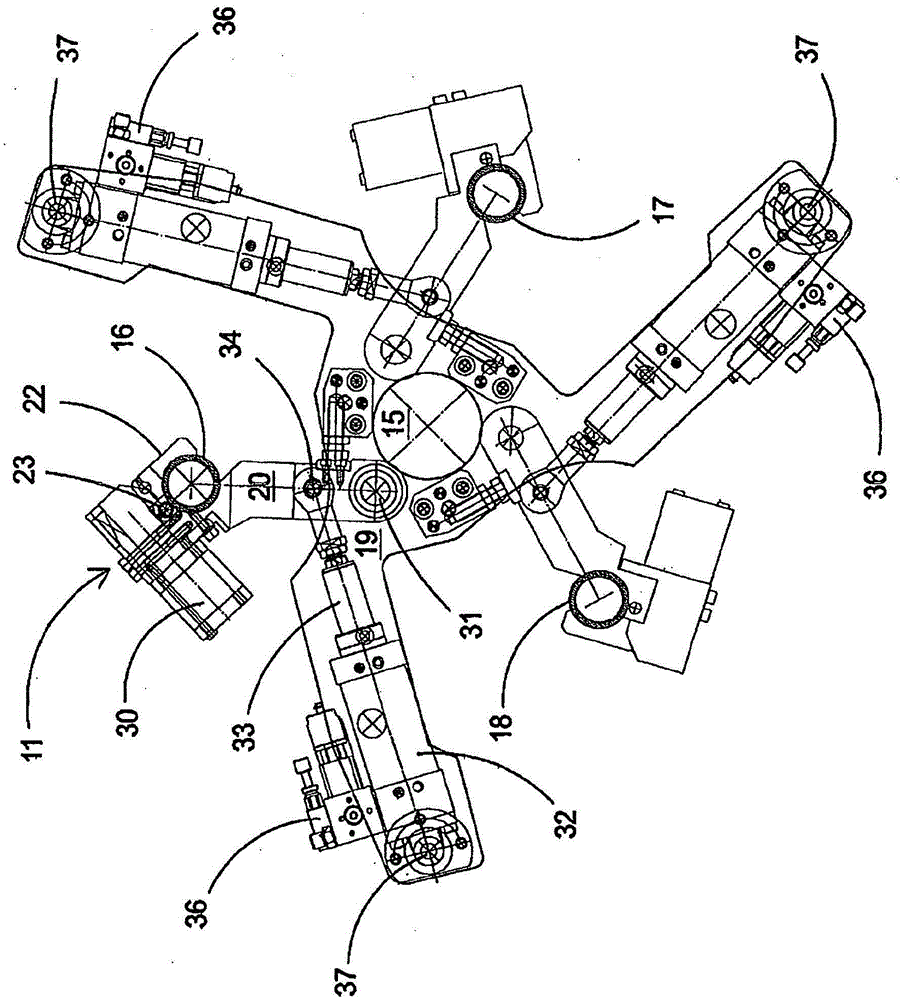

Vehicle body assembly apparatus

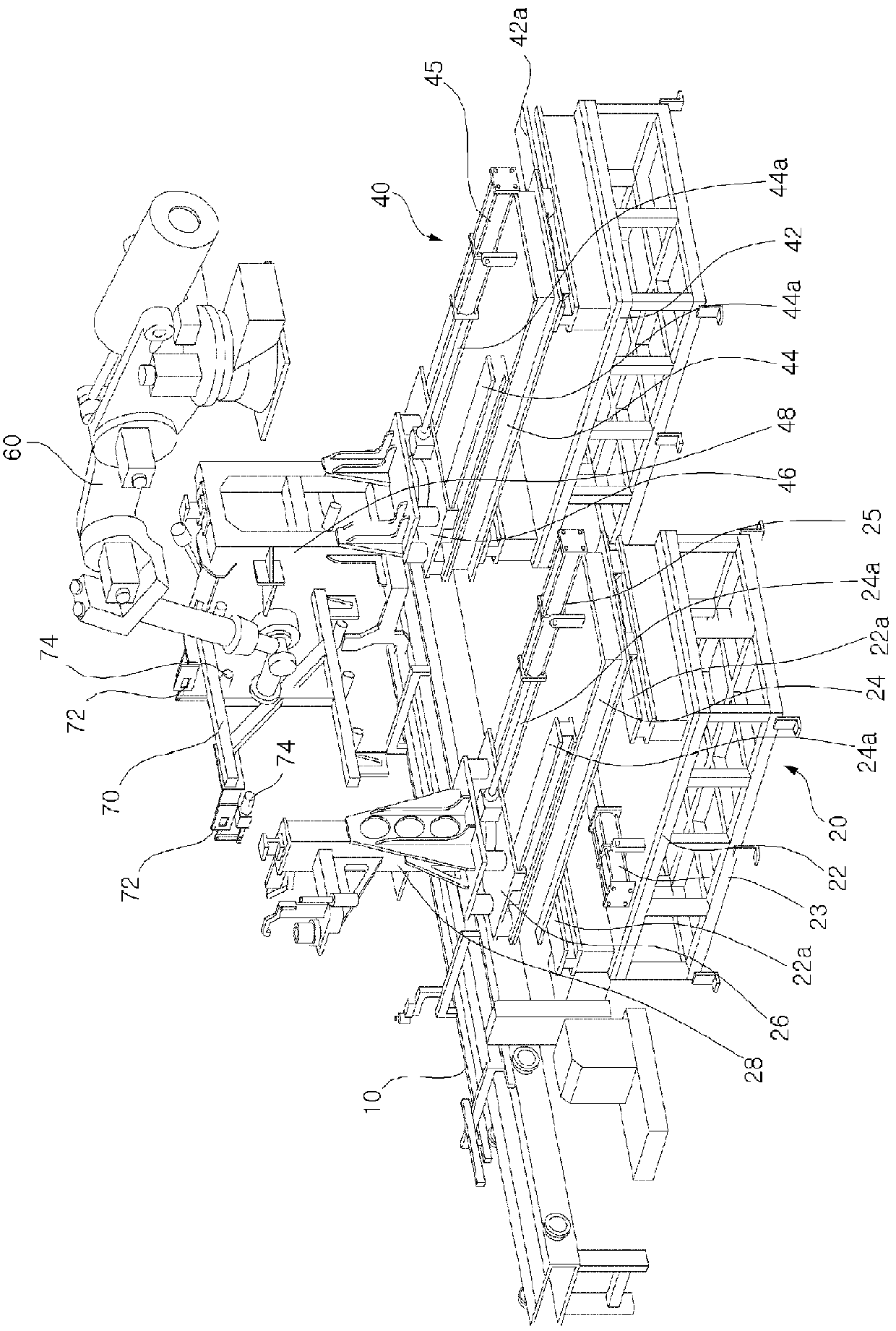

InactiveCN103313908AEasy to replaceSmall sizeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

Provided is a vehicle body assembly apparatus, the weight of which is reduced to enable the easy replacement of a jig, and which can be used in various types of vehicles. The vehicle body assembly apparatus according to one embodiment of the present invention comprises: a front jig unit which fixes a front portion of a side body so as to couple the side body to a side surface of an underbody; and a rear jig unit which fixes a rear portion of the side body, wherein the front jig unit and the rear jig unit can be respectively adjusted relative to one other so as to adjust the distance therebetween.

Owner:LG ELECTRONICS INC

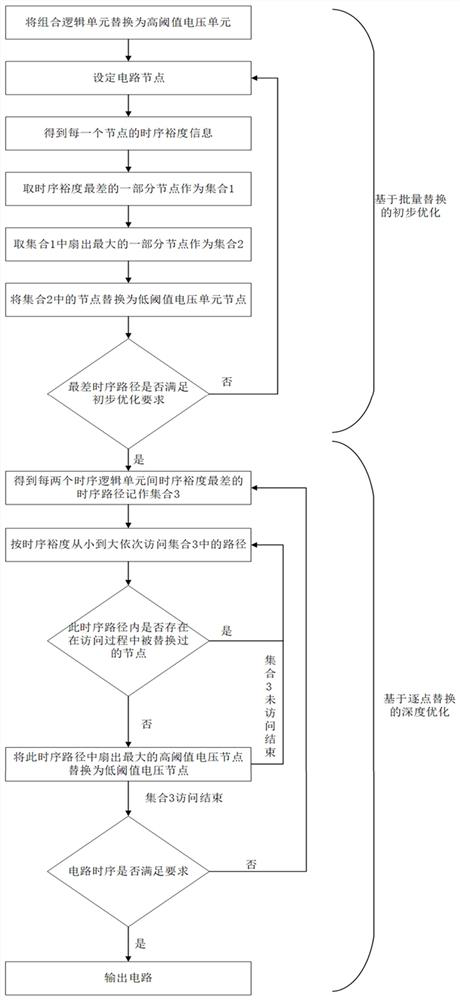

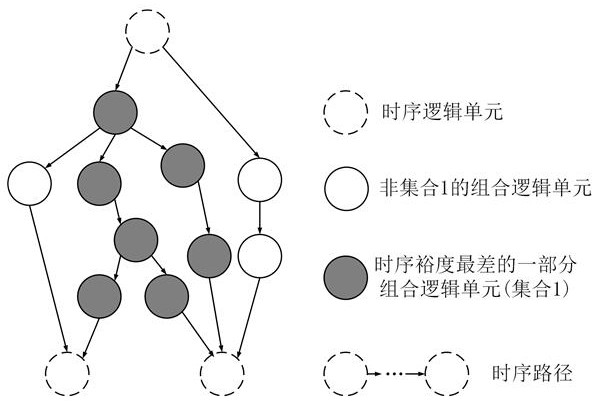

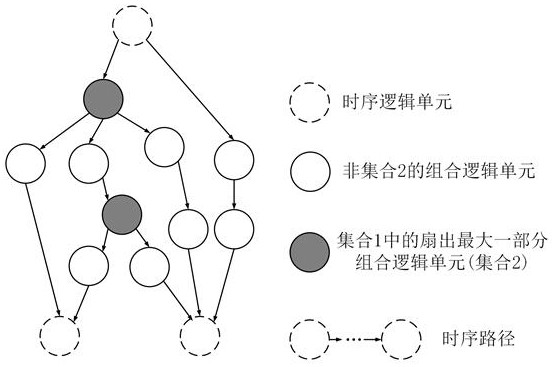

Step-by-step multi-threshold voltage unit distribution method based on time sequence margin and time sequence path

ActiveCN112183003ASave replacement timeImprove convenienceEnergy efficient computingComputer aided designDistribution methodHemt circuits

The invention discloses a step-by-step multi-threshold voltage unit distribution method based on unit time sequence margin and a unit time sequence path, and belongs to the technical field of low power consumption of integrated circuit design. The method comprises two steps, namely, preliminary optimization based on batch replacement and deep optimization based on point-by-point replacement. According to the preliminary optimization based on batch replacement, the part, with the maximum fan-out, of the part of nodes with the worst time sequence margin in the circuit is replaced with a low threshold voltage unit in batch, and multiple rounds of iteration are carried out. According to deep optimization based on point-by-point replacement, a unit in each violated time sequence path in each round of replacement circuit is optimized, and iteration is carried out until the circuit time sequence meets the requirement. According to the method, nodes needing to be traversed in depth optimization are effectively reduced through preliminary optimization based on batch replacement, and then it is ensured that the circuit time sequence meets the requirement through depth optimization based on point-by-point replacement.

Owner:ZHEJIANG UNIV

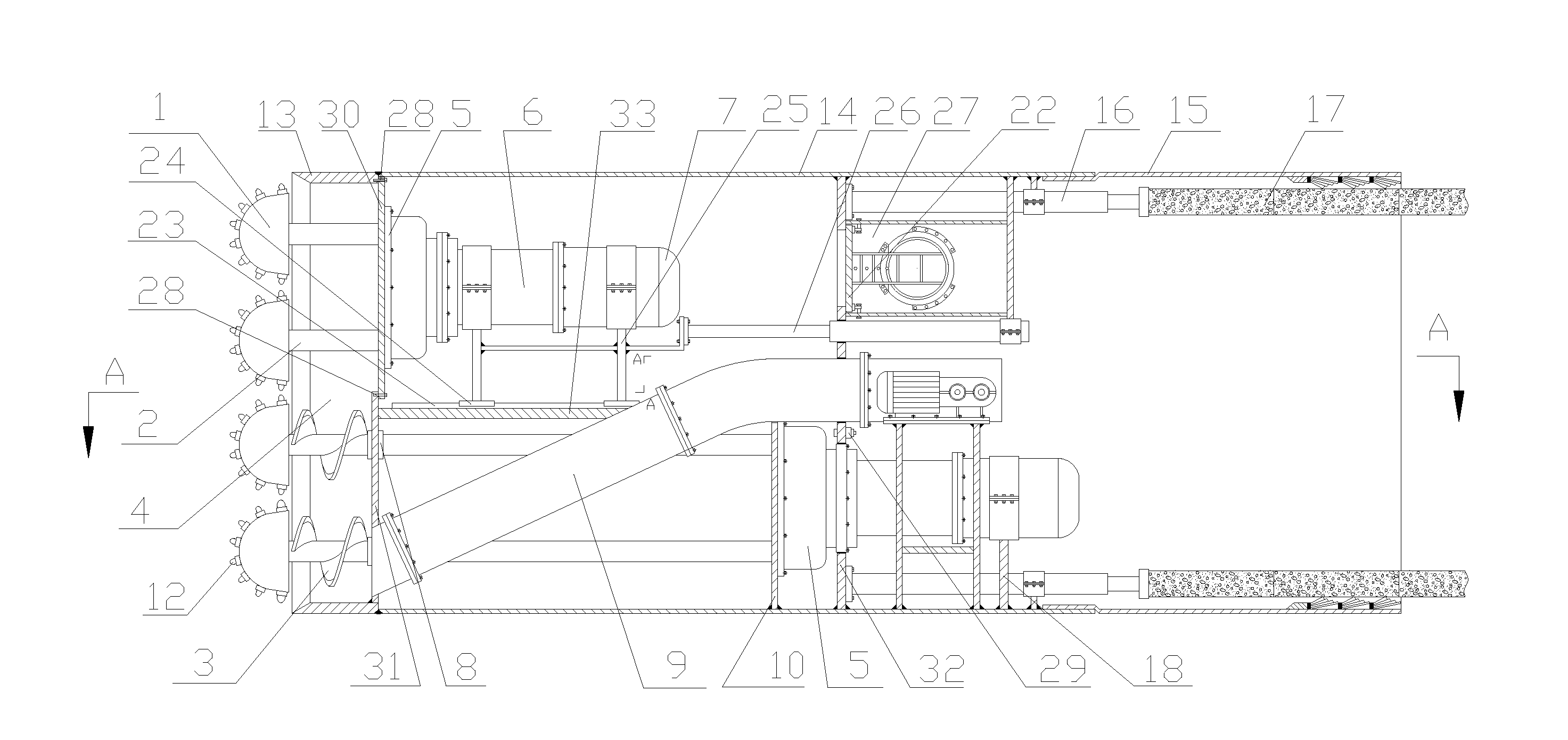

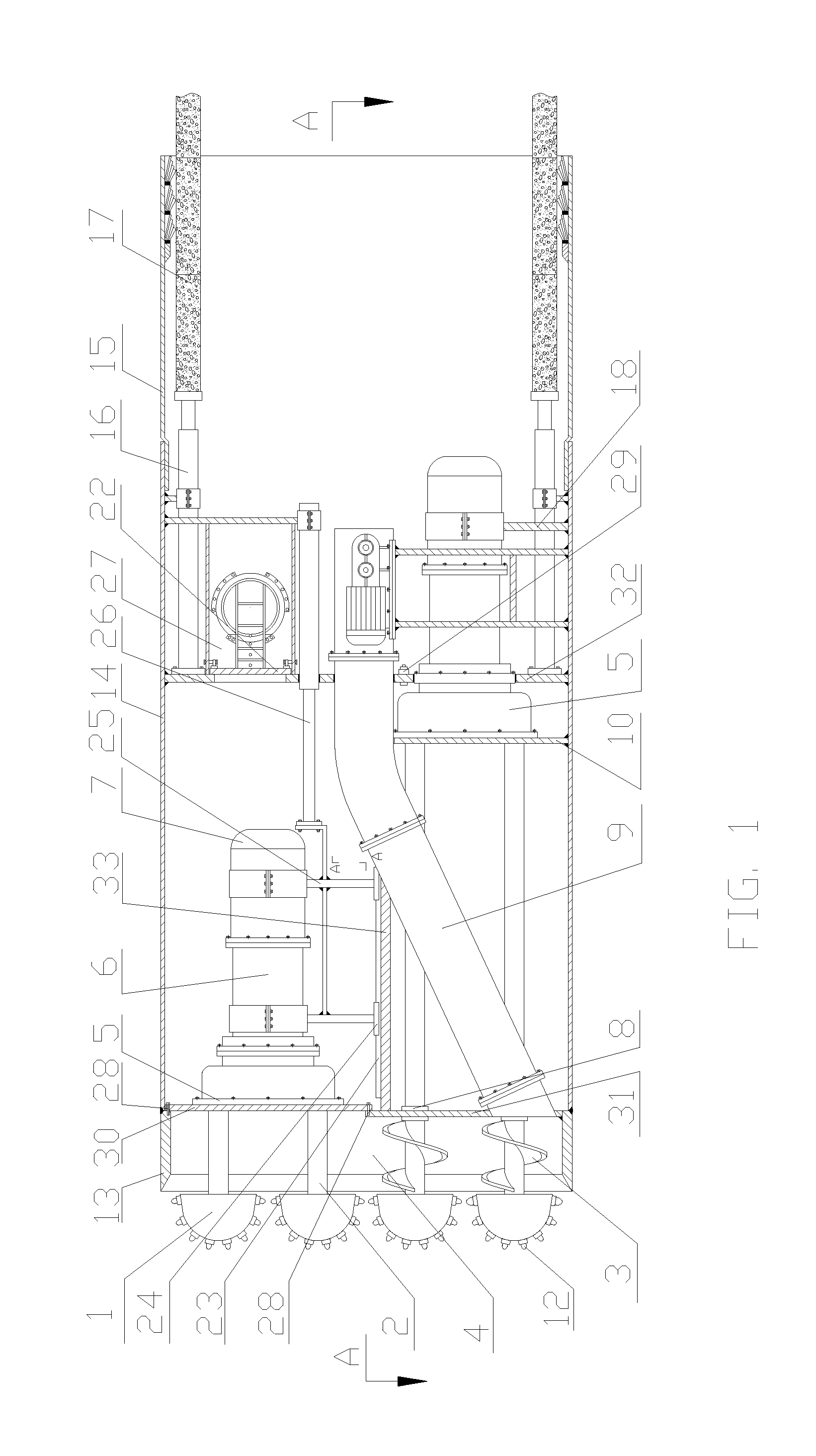

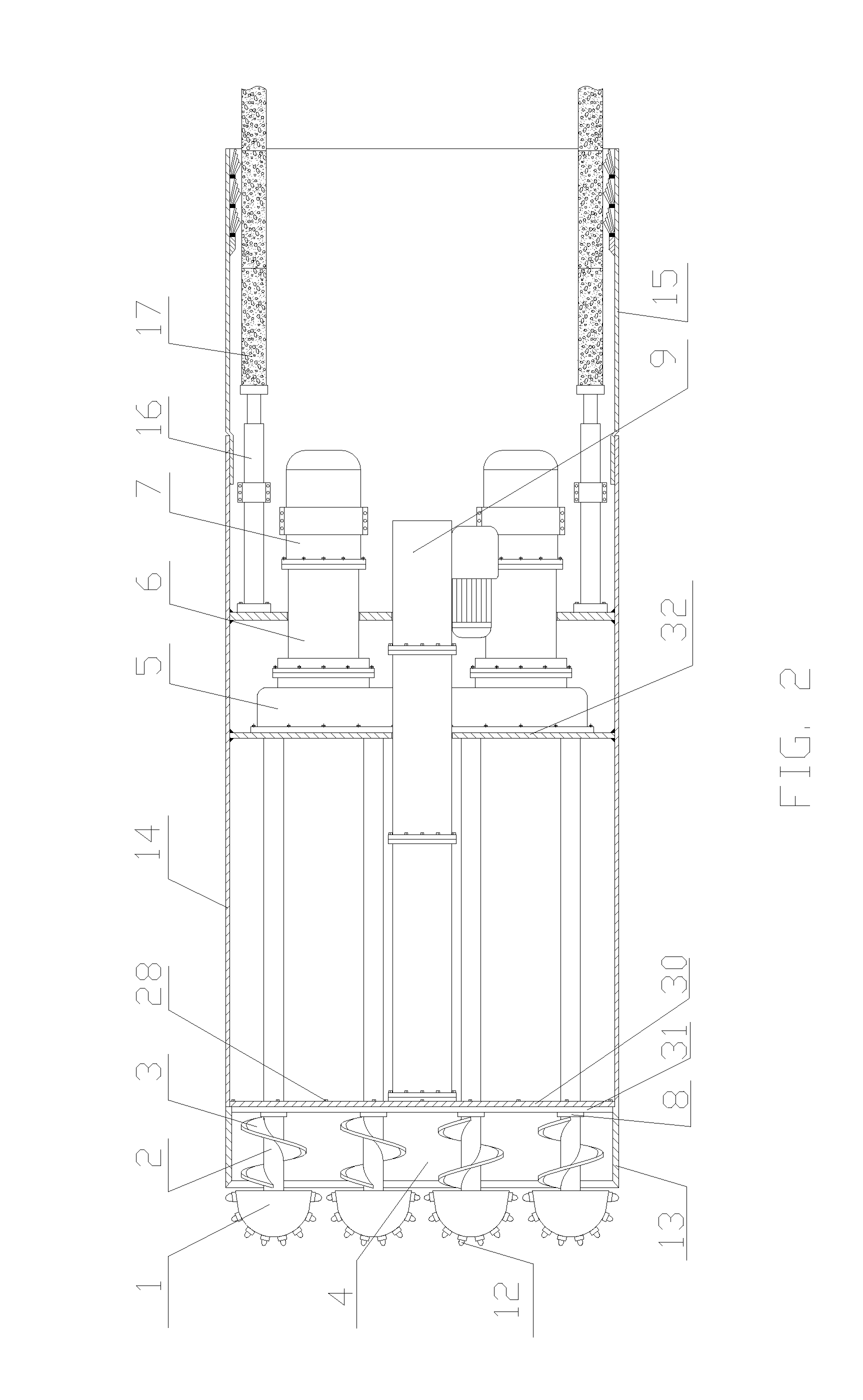

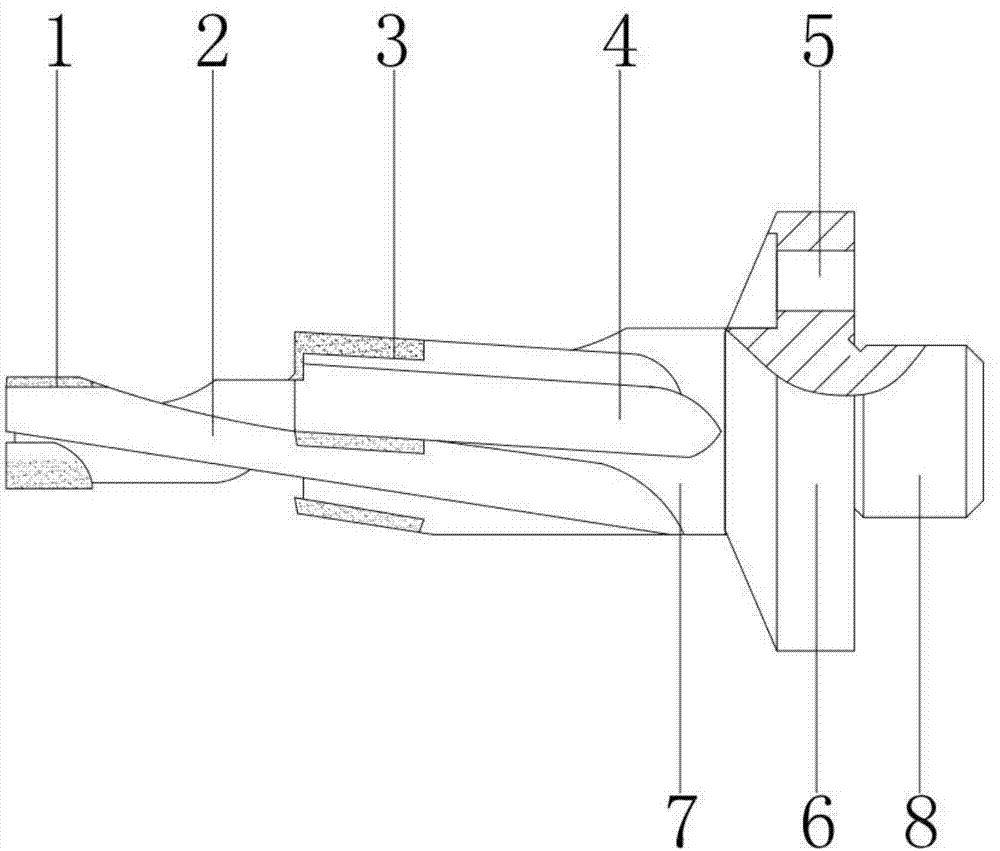

Earth Pressure Balance Shield Machine without Cutter Disk

ActiveUS20150042146A1Prevent rotationPrevent movementMine roof supportsTunnelsTransfer caseReduction drive

An EPB shield machine without disc cutter, which includes a partition unit formed by a moveable partition member (30) and a stationary partition member (31), a front shield unit (13) including a cutting unit (1) with cutting head (11) and cutting teeth (12), a shaft member (2) connected to the cutting head (11) and a power transmission unit formed by a transfer case (5), a reducer (6) and a driving motor (7). In the power transmission unit at an upper portion of the machine, the transfer case (5) is fixedly to the moveable partition member (30), a sliding arrangement supports the reducer (6) and the driving motor (7), which are connected to the transfer case (5, and a telescopic cylinder (26) is connected to the sliding arrangement. The machine has advantages of high cutting efficiency, balanced service life, high directional construability and high adaptability to tunnel cross section.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Bar milling cutter

The invention discloses a bar milling cutter. A convex cutter is included; a cutter groove is formed in the inner wall of the convex cutter; the outer wall of the cutter groove is connected with the inner wall of the convex cutter; a flat cutter is arranged on the outer side of the cutter groove; a material guiding groove is formed in the outer wall of the flat cutter; the outer wall of the material guiding groove is connected with the inner wall of the flat cutter; and a cutter body is arranged on the inner wall of the material guiding groove. According to the bar milling cutter, due to cooperation among the convex cutter, the cutter groove, the flat cutter and the material guiding groove, under the effects of an impeller, a notch and a hole channel of a machined workpiece are machined bythe convex cutter, and cut down fragments can be brought out by the cutter groove during cutter retracting; in order to prevent tripping of a cutter handle in a high-speed rotating state, a clampingarm is pressed downwards to fix a sleeve, and therefore the defects that a tool bit of a traditional bar milling cutter cannot be fast replaced, and tool bit connection is not stable can be overcome,the machining steps are simplified, the overhauling and replacing time is saved for an operator, the work difficulty is reduced for the operator, the work fatigue of the operator is overcome, and thebar milling cutter is applicable to application and popularization.

Owner:常州丹姆德工具制造有限公司

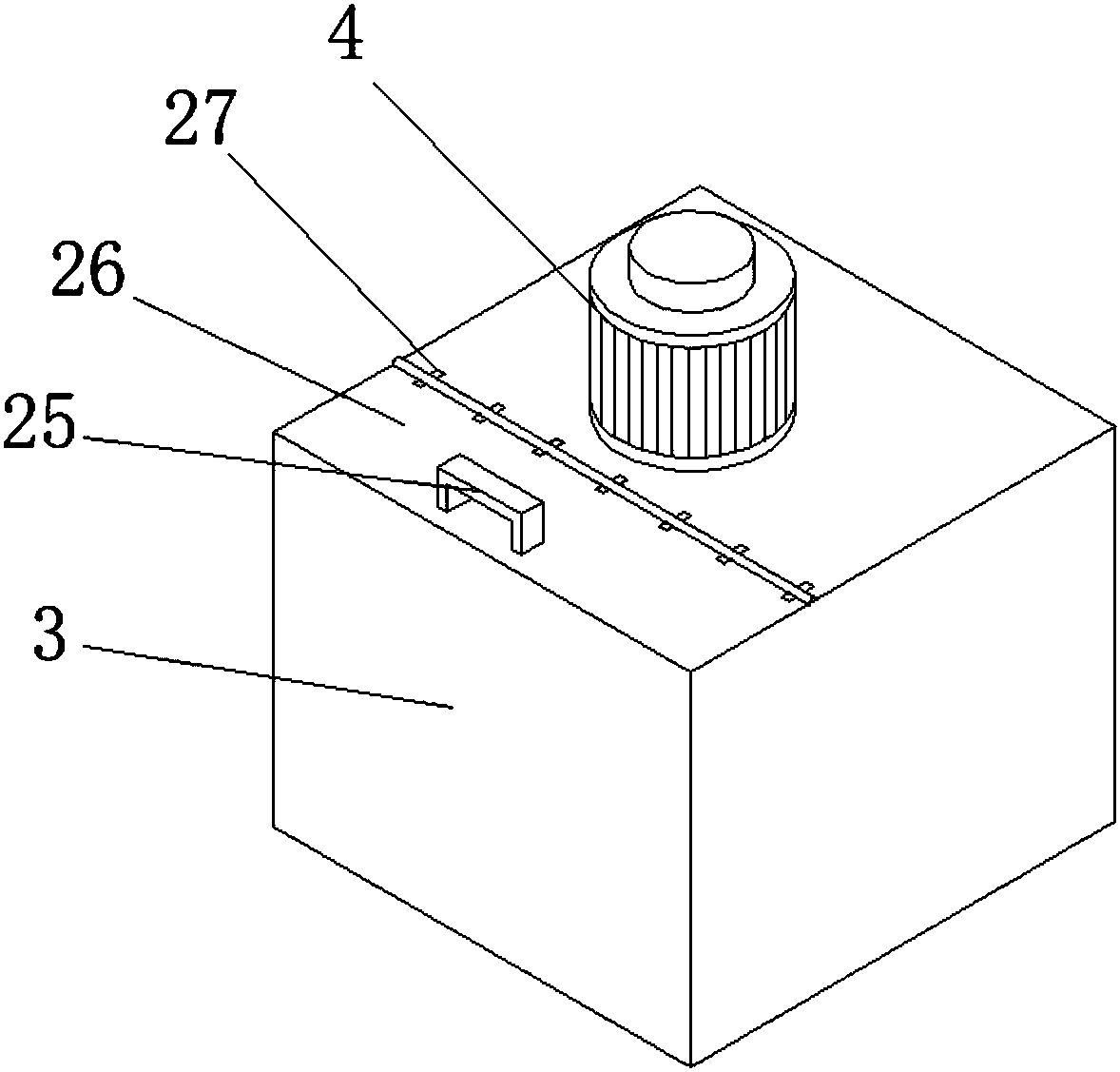

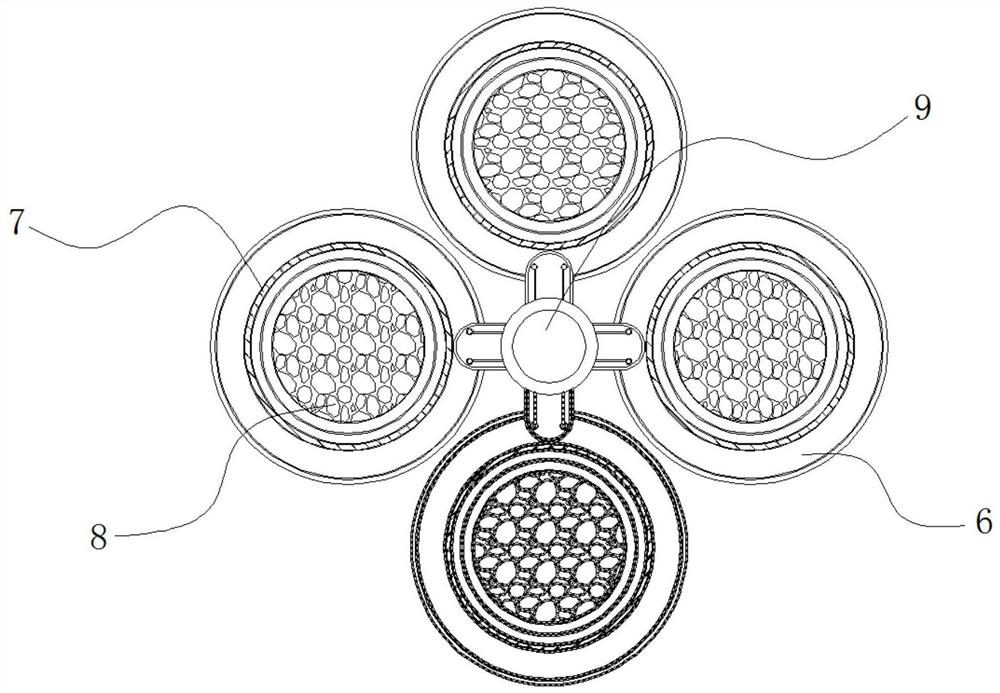

Cyclone separator for ecological oil

InactiveCN102179319AReduce maintenance rateSave replacement timeReversed direction vortexCyclonePulp and paper industry

The invention relates to a cyclone separator for ecological oil, which consists of a cylinder body positioned on the upper half part, and a tapered cylinder and a wearable layer positioned on the lower half part; a cyclone inlet is formed on the side surface of the cylinder body; the side wall of the cyclone inlet is tangential to the inner wall of the wearable layer; an air outlet is formed on the upper part of the cylinder body; a discharging port is formed on the lower part of the tapered cylinder; the separator is formed by connecting the two sections of the cylinder body and the tapered cylinder; a plurality of pins are arranged inside the wearable layer; the upper part of the cylinder body is provided with an air outlet cylinder; the air outlet is positioned on the exposed part of the air outlet cylinder; the lower end of the air outlet cylinder positioned inside the cylinder body is provided with a filter screen. The cyclone separator for ecological oil can save the replacement time and the lifting cost; the inner wall of the separator has high wearability and impact resistance; and the service life is long.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Efficient catalytic combustion equipment for waste gas treatment

PendingCN112013408AImprove cooling effectSpeed up circulationGas treatmentDispersed particle separationActivated carbonPtru catalyst

The invention discloses efficient catalytic combustion equipment for waste gas treatment, and relating to the technical field of waste gas treatment. The equipment specifically comprises a combustionbox, a catalyst efficient mixing assembly and an oxygen supplementing mechanism. The left side of the combustion box is connected with an air inlet pipe adsorption assembly. One side of a spring telescopic rod is connected with a tubular clamping piece. Grooves are formed in the surfaces of two sides of an activated carbon clamping plate, an activated carbon plate is embedded into the activated carbon clamping plate, a replacement motor is connected to the left end of a replacement rotating shaft, the catalyst efficient mixing assembly is arranged in a combustion box, and an oxygen supplementing mechanism is arranged at the top of the combustion box. According to the efficient catalytic combustion equipment for the waste gas treatment, a saturated activated carbon plate can be rapidly replaced, a plurality of activated carbon plates can be replaced at a time, replacement time can be shortened, it is guaranteed that normal operation of the equipment is not delayed, meanwhile, time for workers to replace the activated carbon plates is greatly prolonged, and working pressure of the workers is reduced.

Owner:苏州山禾环保科技有限公司

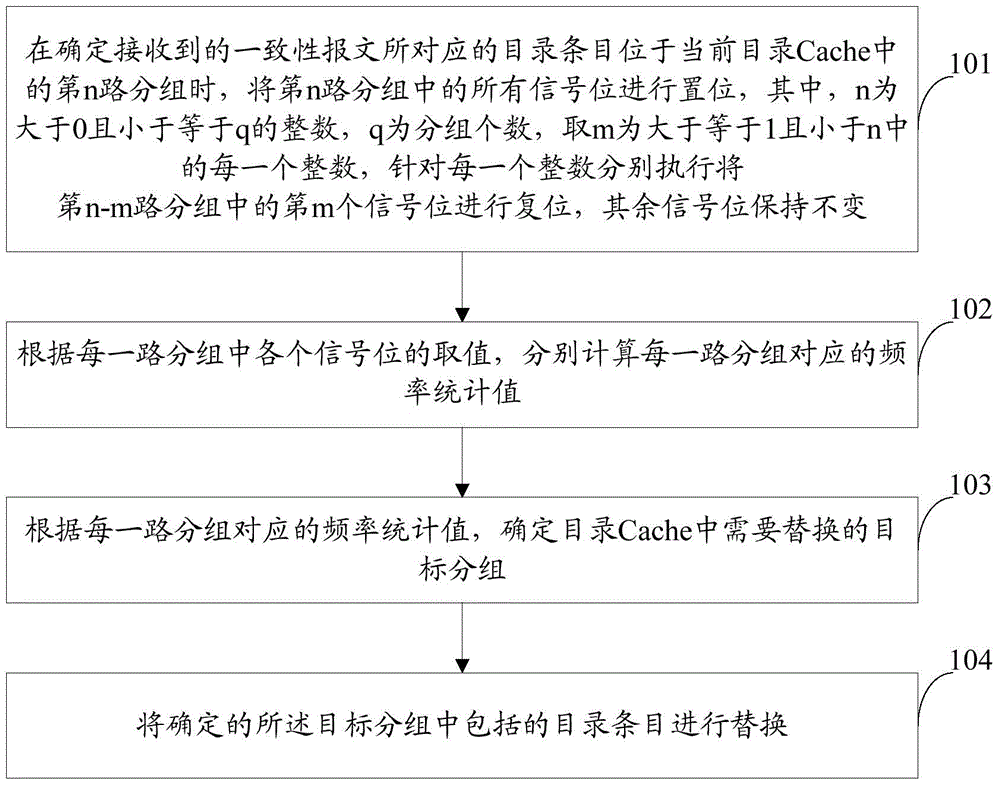

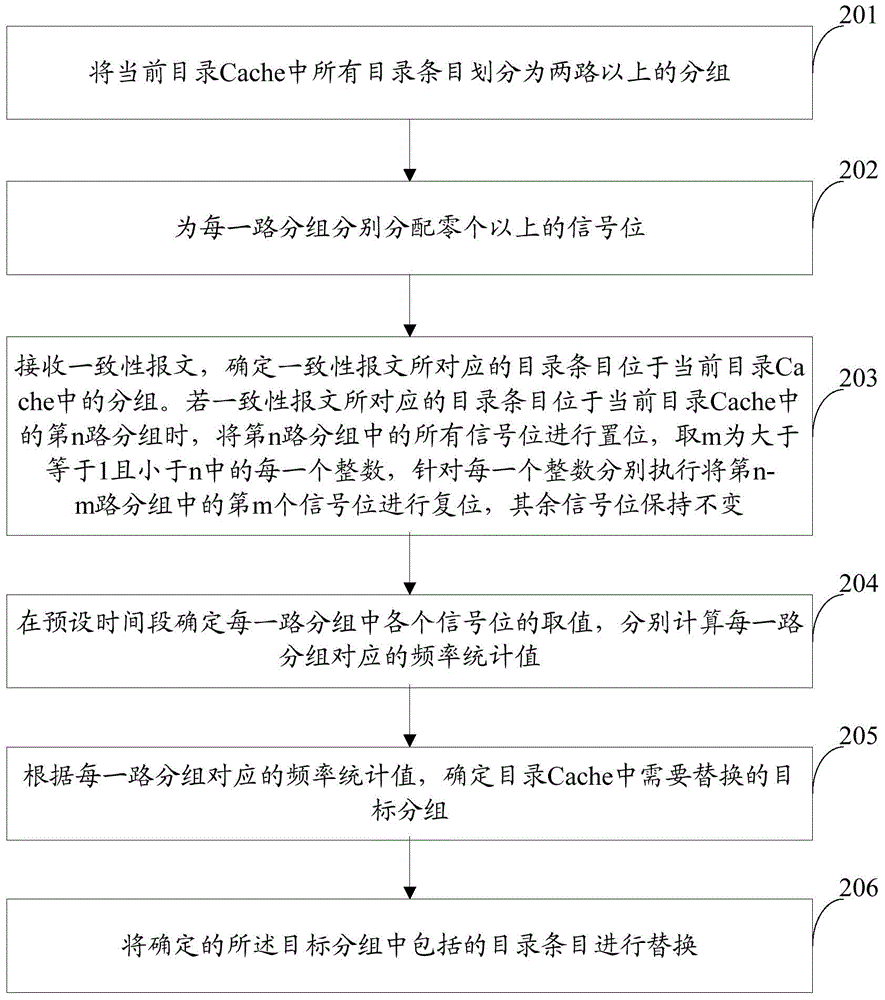

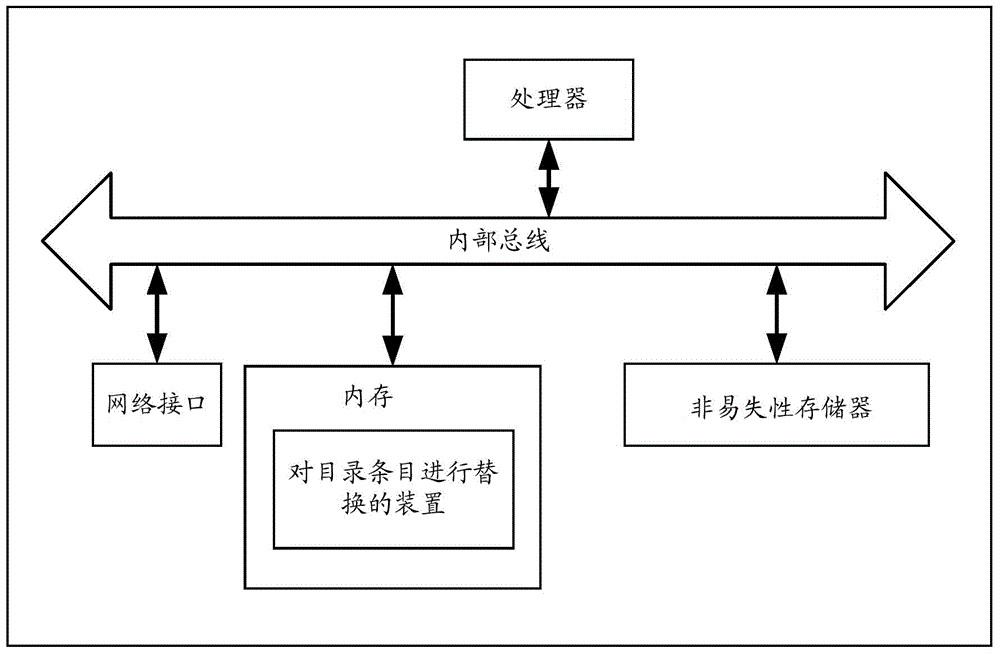

Method and device for replacing contents items

ActiveCN104484288ASave replacement timeSave resourcesMemory adressing/allocation/relocationAlgorithmComputer engineering

The invention provides a method and a device for replacing contents items. All the contents items in a current contents Cache are divided into more than two paths of groups, and more than zero signal bit is distributed for each path of group. The method comprises the following steps of when determining that the contents items of a received consistency message are located in the nth path of group in the current contents Cache, setting all the signal bits in the nth path of group; selecting m which is an integer among integers being more than or equal to 1 and less than n and respectively resetting an mth signal bit in the (n-m)th path of group aiming at each integer; keeping the residual signal bits unchanged; respectively calculating a frequency statistic value corresponding to each path of group according to a value of each signal bit in each path of group; determining a target group needing to be replaced in the current contents Cache according to the frequency statistic value corresponding to each path of group; replacing the contents items in the determined target group. By virtue of the method and the device for replacing contents items, the system resource is saved.

Owner:SHANDONG LANGCHAO YUNTOU INFORMATION TECH CO LTD

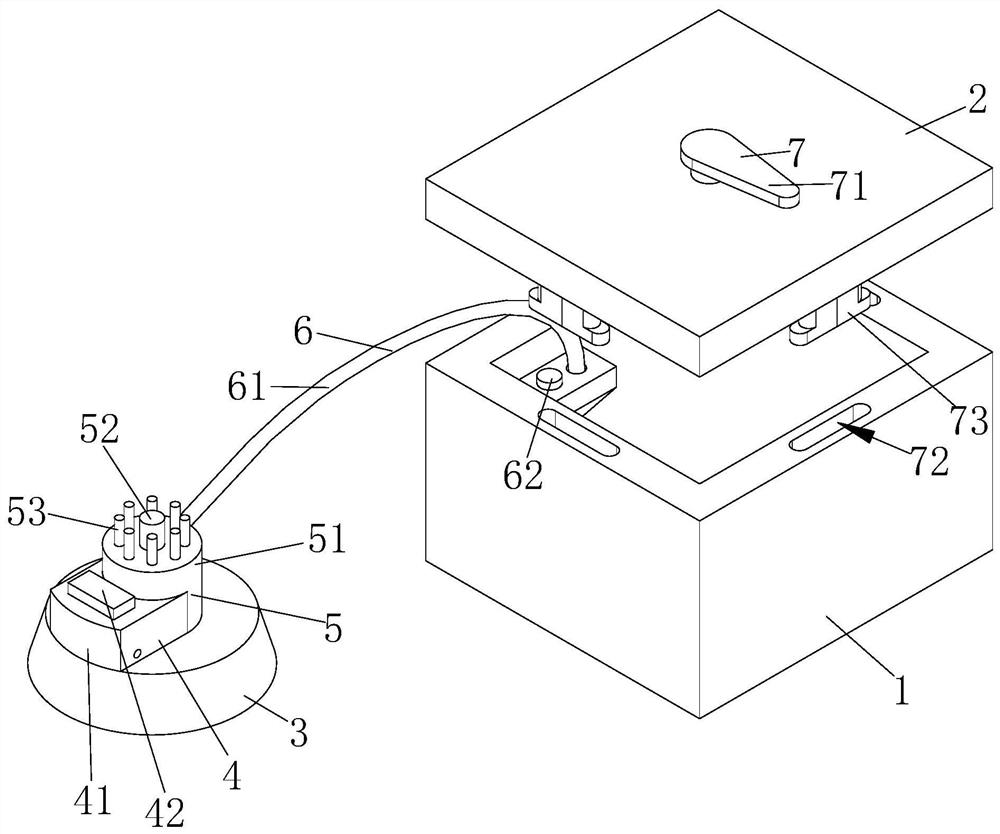

Telescopic temperature sensing probe convenient to adjust

The invention relates to the field of temperature sensing probes, in particular to a telescopic temperature sensing probe convenient to adjust, which comprises a main body, an upper cover, a sucker, afixing mechanism, a contact mechanism, a telescopic mechanism, a sealing mechanism and a quick change mechanism, through the arrangement of the fixing mechanism, the telescopic temperature sensing probe can be timely transferred to a new position to be fixed according to needs of a user, the using effect of the device is improved through simple and rapid operation, through the arrangement of thecontact mechanism, temperature sensing probes of different measurement intervals can be used according to needs, the user can conveniently obtain accurate temperature data, and through the arrangementof the quick change mechanism, the probe with the abraded surface after long-term use can be quickly replaced, the influence on the work progress and the data accuracy is avoided, the replacement time is saved, the cable can be effectively stored and released through the arrangement of the telescopic mechanism, the winding and the space occupation of the cable are avoided, and through the arrangement of the sealing mechanism. mechanisms such as suckers which do not need to work can be stored in the main body, so that the working space is saved.

Owner:杭州墙镪科技有限公司

Household wireless intelligent smoke alarm mechanism

InactiveCN110189497AEasy to replaceEasy maintenanceFire alarm smoke/gas actuationEngineeringWireless

The invention relates to the technical field of intelligent fire fighting and discloses a household wireless intelligent smoke alarm mechanism, comprising a mounting plate, wherein a shell is movablymounted at the bottom of the mounting plate; sealing rings extending into the interior of the shell are fixedly mounted at the bottom of the mounting plate; a wire inlet hole is set in the mounting plate; a wiring board located below the wire inlet hole is fixedly mounted on the top of the shell; a smoke sensor is fixedly mounted in the shell; connection blocks located below the smoke sensor are fixedly mounted at the bottom of the shell; a protection block is fixedly mounted at the bottom of the connection blocks; buzzing sheets are fixedly mounted in the shell; two movable blocks are movablymounted in the shell; and stabilization rods are fixedly mounted at mutually close sides of the two movable blocks. The household wireless intelligent smoke alarm mechanism is simple in operation andis convenient for a user to replace and overhaul. Replacement and overhaul time is effectively reduced.

Owner:YANCHENG UNIV SCI & TECH PARK CO LTD

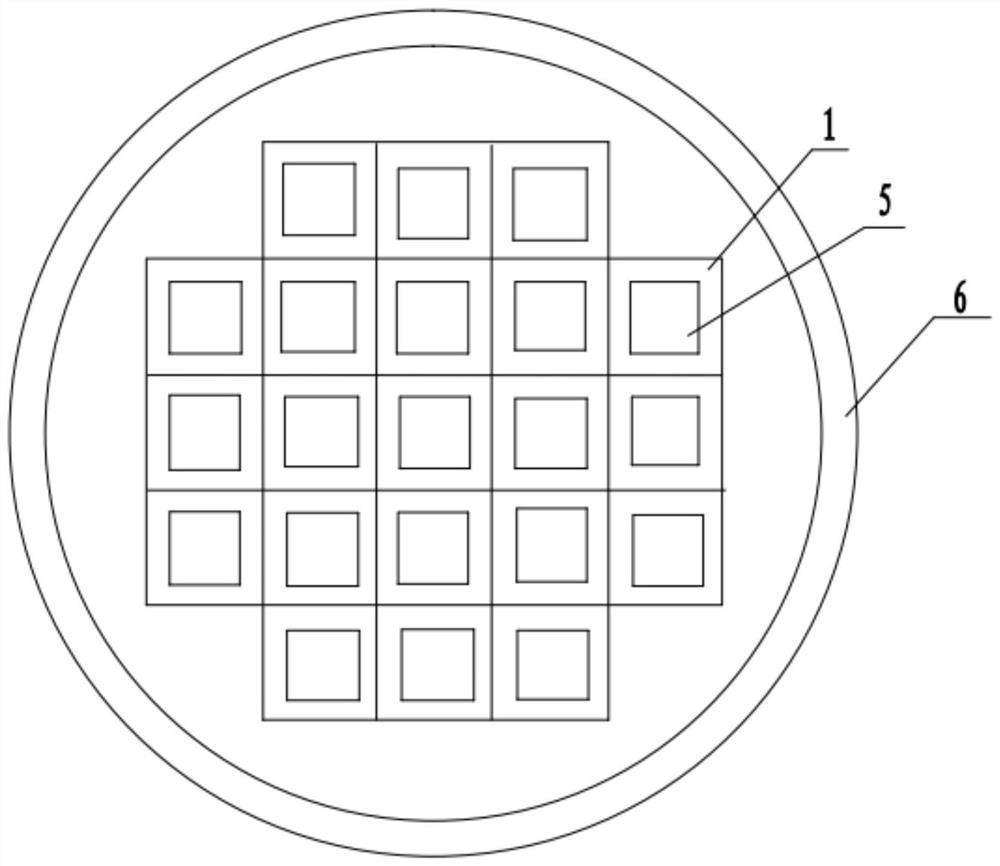

Array-type combined electrode used for dense group hole electrosparking and preparation method thereof

ActiveCN108372334AExact combinationGuaranteed positioning accuracyElectrical-based machining electrodesManufacturing technologyAlloy

The invention relates to an array-type combined electrode used for dense group hole electrosparking and a preparation method thereof. Aiming at the defects that as for an existing electrode manufacturing technology, the difficulty is large, the efficiency is low, the cost is high, and the electromachining quality and efficiency are difficult to guarantee, by breaking through the key technologies such as extrusion forming manufacturing of standard single electrodes, design of array-type electrode moulds and rapid tightening and disassembling of electrodes, the array-type combined electrode usedfor dense group hole electrosparking and capable of being rapidly assembled and disassembled and flexibly combined and the preparation method thereof are provided. The preparation method comprises the specific implementation steps of design and manufacturing of the standard single electrodes; design and manufacturing of the array-type electrode moulds; design and manufacturing of an electrode base and combined baffles; assembly of a combined electrode tool; assembly of the standard single electrodes; and low-melting-point alloy casting and electrode fixing. The array-type combined electrode used for dense group hole electrosparking and the preparation method thereof have the advantages of low cost, high efficiency, high quality and high reliability, can achieve efficient and high-precision machining of a group hole structure, and meet the machining requirements of products in the military and civilian fields.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Preparation method for co-growth of multiple single crystal diamonds

PendingCN114016005AImprove temperature uniformityImprove deposition yieldPolycrystalline material growthFrom chemically reactive gasesPhysical chemistrySingle crystal growth

The invention discloses a preparation method for co-growth of a plurality of single crystal diamonds. The method comprises the following steps: designing an independent molybdenum support unit for each seed crystal; placing a plurality of independent molybdenum support units loaded with seed crystals on a water-cooling deposition table of CVD equipment, adjusting the positions of different molybdenum support units on the deposition table according to the surface temperature difference of different seed crystals after startup, and adjusting the combination of different seed crystals and the molybdenum support units at the same time, so that the surface temperature difference of various crystals on the deposition table is within a set range; and for the molybdenum support units exceeding the single crystal growth temperature range, the heat dissipation structures on the upper and lower surfaces of the molybdenum supports are corrected or new molybdenum support units are replaced until the temperatures of the seed crystals carried by all the molybdenum supports on the deposition table are within the set single crystal growth temperature range. The molybdenum support units for bearing the seed crystals are independently arranged and can be randomly combined and exchanged on the water-cooling deposition table, so that the positions of the seed crystals can be exchanged as required, the surface temperatures of a plurality of pieces of seed crystals are consistent, and the flexibility and effectiveness of seed crystal temperature adjustment are realized.

Owner:HEBEI PLASMA DIAMOND TECH

Cleaning device for surgery of general surgery department

InactiveCN108310516AEnsure safetyEasy to moveCannulasEnemata/irrigatorsSurgical operationEngineering

The invention discloses a cleaning device for surgery of the general surgery department. The device comprises a base, universal wheels are arranged at the lower end of the base, and a fixing block iswelded to the upper end of the base; an electric retractable rod is connected to the upper end of the fixing block, a bearing is arranged at the tail end of the electric retractable rod, and a connection column is welded to the outer side of the upper end of the bearing; a fixing clamp is arranged at the side end of the bearing, a spiral sleeve is arranged on the connection column, and a supporting plate is arranged at the side end of the spiral sleeve. The cleaning device is flexible and convenient to move, the up-down height and the left-right direction can also be adjusted at the same time,the operation in the surgery process is facilitated, the device does not need to be replaced and filled manually, the device is directly connected with a standby bottle when it is discovered that corresponding cleaning fluid is insufficient, the corresponding replacement time is greatly shortened, the corresponding working efficiency is improved, it is also guaranteed that the surgery is conducted normally and safely, and the device is compact and reasonable in structural design, high in practicability and suitable for popularization.

Owner:肖春明

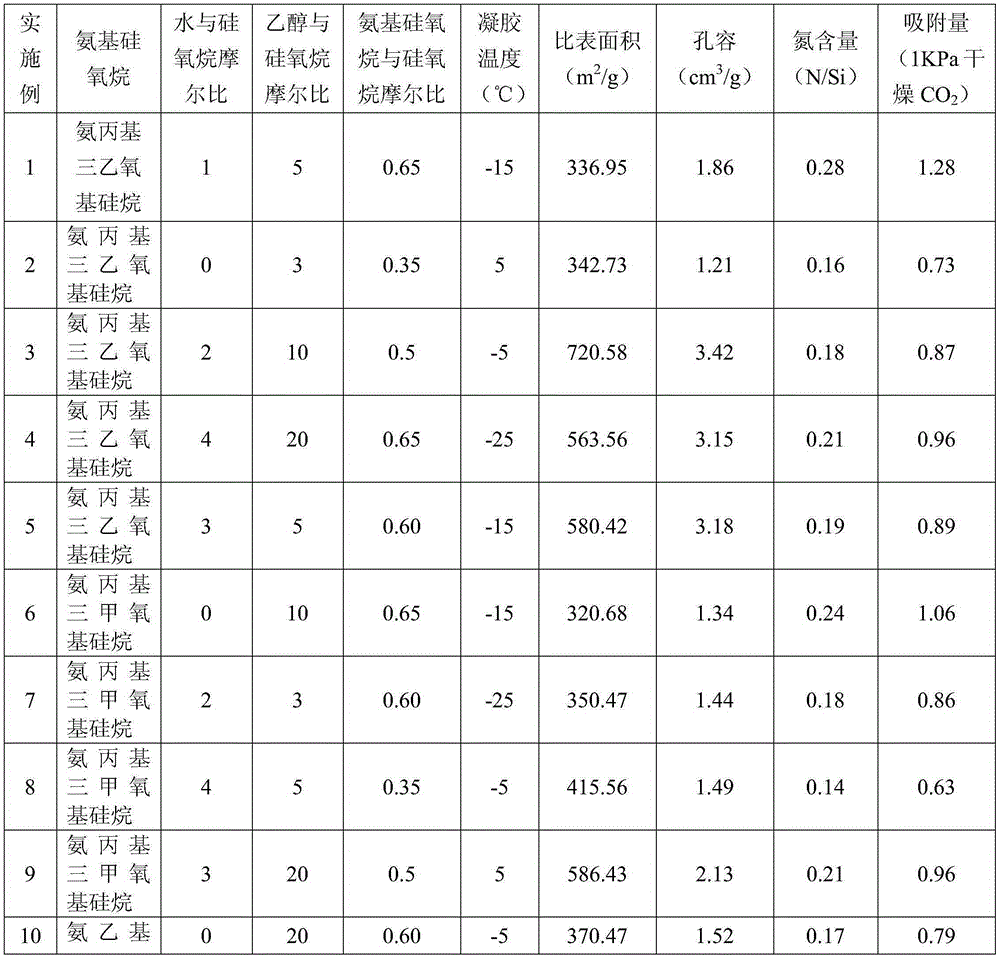

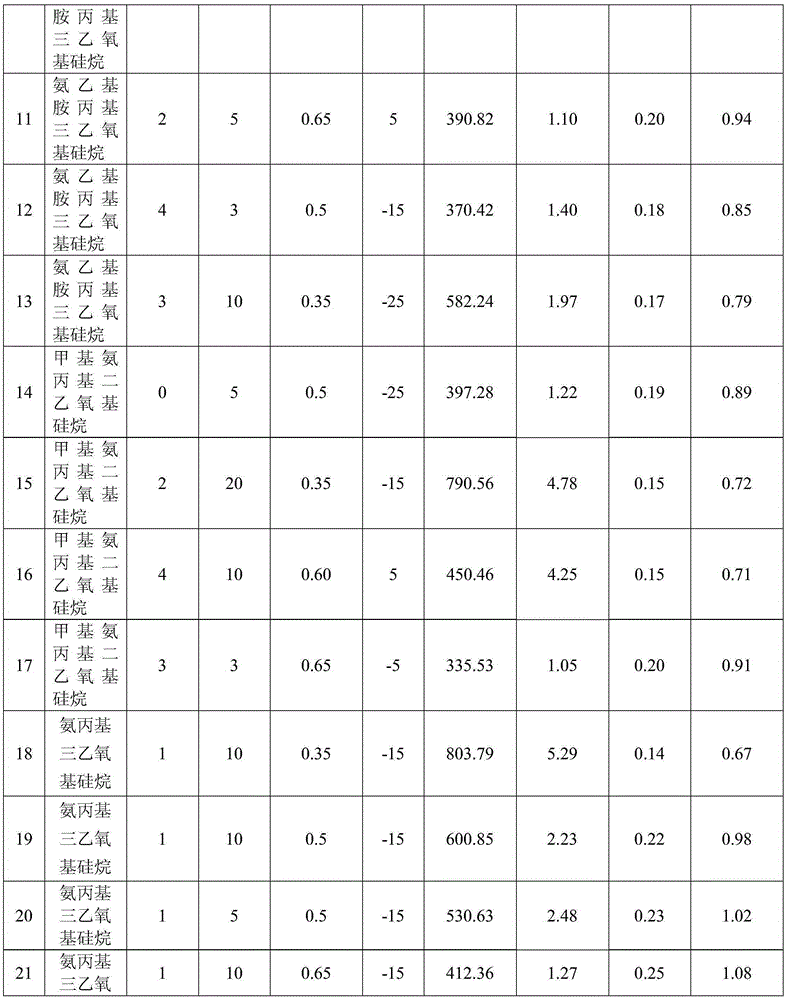

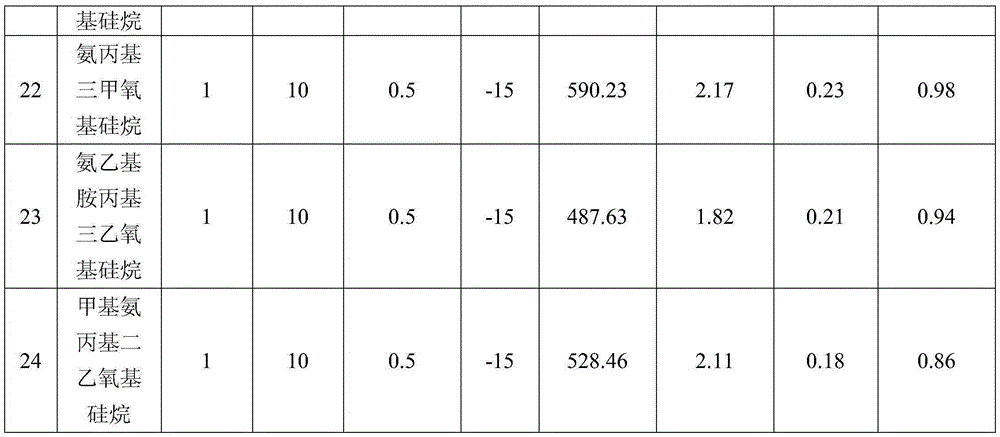

A kind of preparation method of renewable low-concentration CO2 high-efficiency adsorption material

ActiveCN104117343BWell mixedAvoid inhomogeneityOther chemical processesDispersed particle separationSupercritical dryingAminosilochrome

Owner:NAT UNIV OF DEFENSE TECH

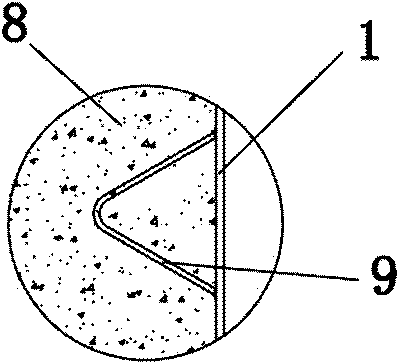

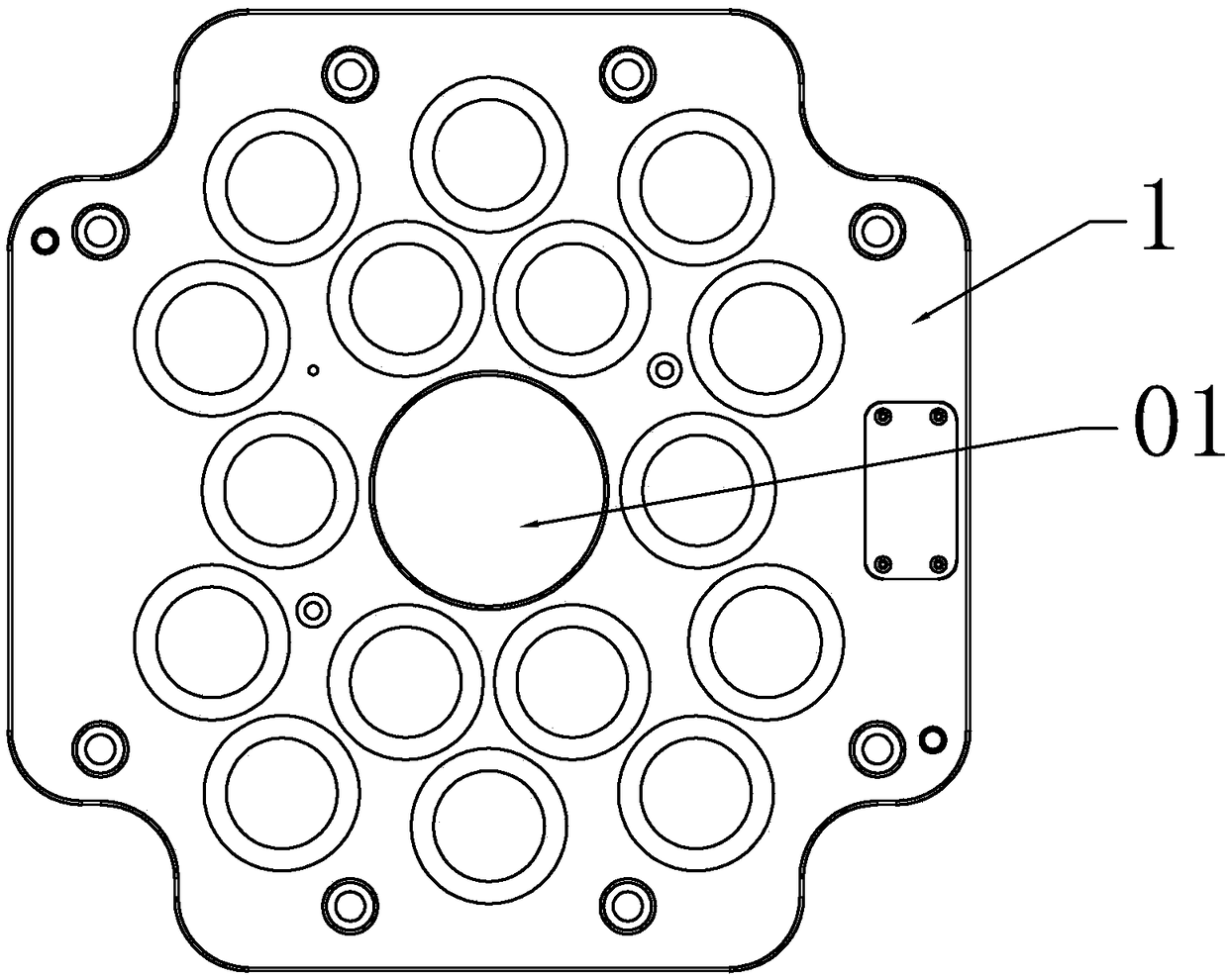

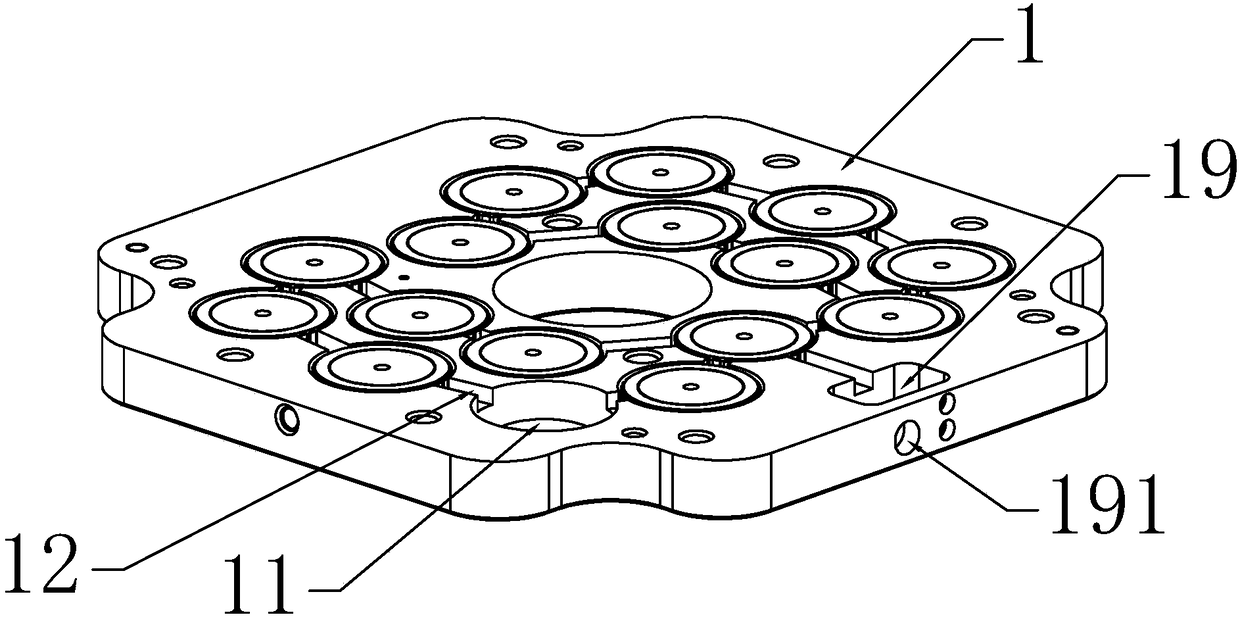

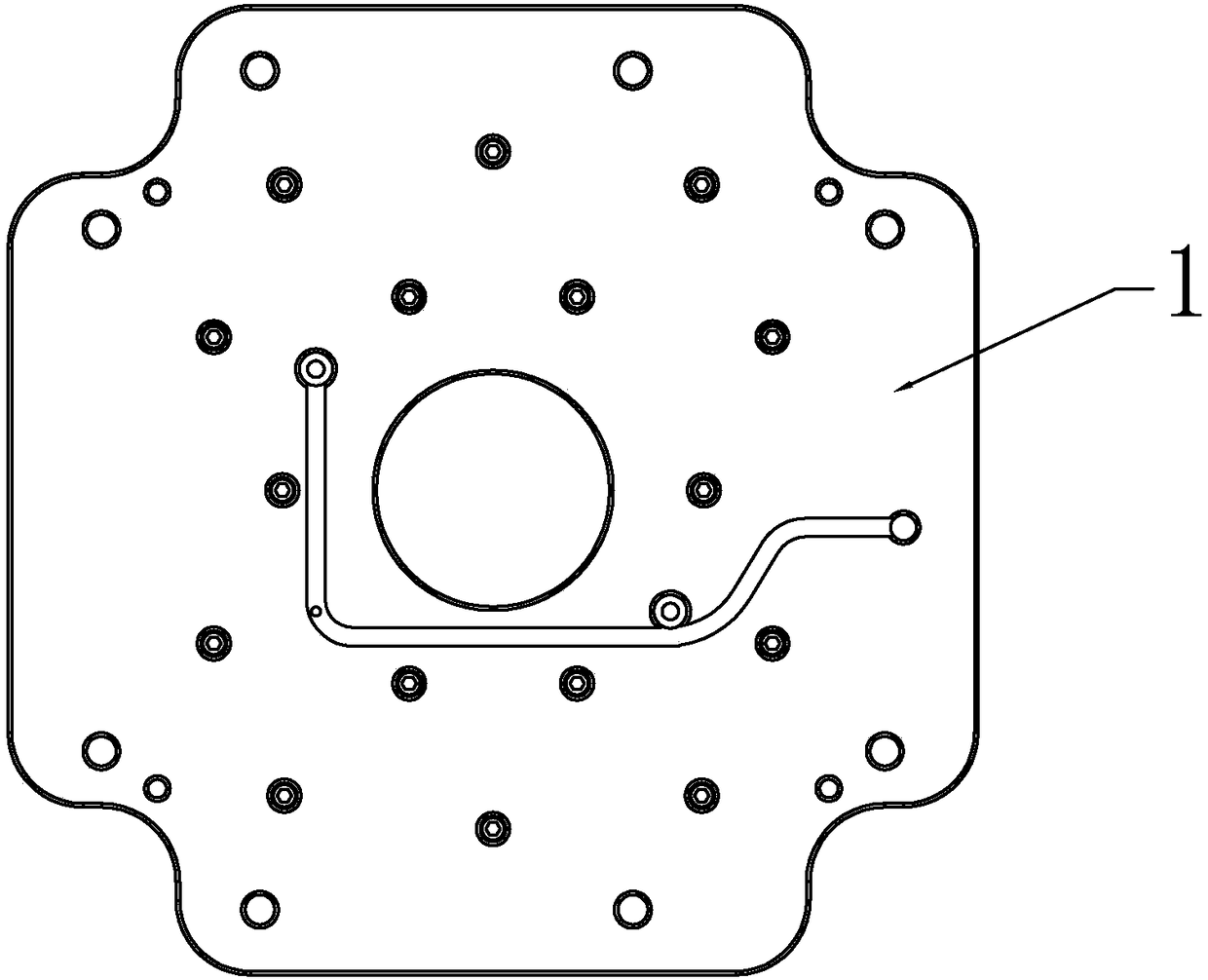

Intelligent electric permanent magnetic chuck

The present invention discloses an intelligent electric permanent magnetic chuck. A plurality of blind die holes which are separated by die walls are arranged in a template, a lead gap is arranged onthe top of the die wall, a column which is arranged in the middle of the bottom of each blind die hole is connected with the template, a surrounding groove surrounding the column is arranged between the column and the die wall of the blind die hole, the structure of the blind die hole is simple, magnetic elements are arranged in the surrounding grooves in sequence, the surrounding grooves can rapidly check and align NdFeB rings which are formed by connecting a plurality of fan-shaped NdFeB elements. The outside of each NdFeB ring is an N pole, and the inside is an S pole. When the magnetic force is generated, reduced or increased, each NdFeB ring operates independently without mutually magnetic interference, the magnetic field grouping is not in mess, the magnetic field is released and recycled in a vertical circulation mode, the magnetic absorption ability is improved, the surrounding grooves can gather the magnetic force, one magnetic element is arranged in each blind die hole, so that the problem can be found easily, rapid detection and recovery can be realized, the die replacement time and adjustment time are shortened, the production efficiency is improved, and the productioncost is reduced.

Owner:佛山市顺德区盛锵德磁科技有限公司

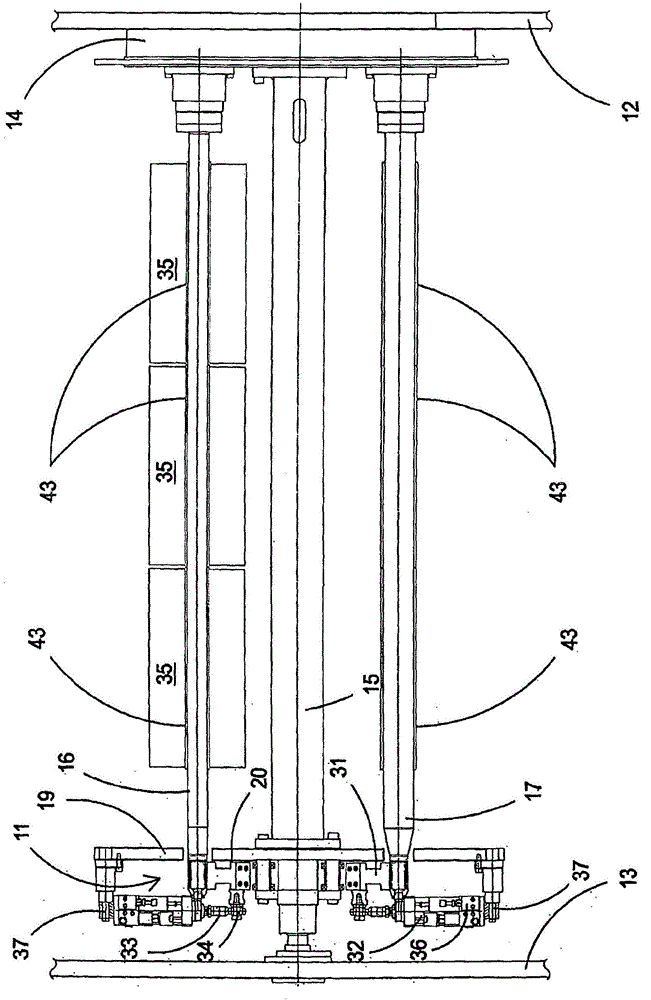

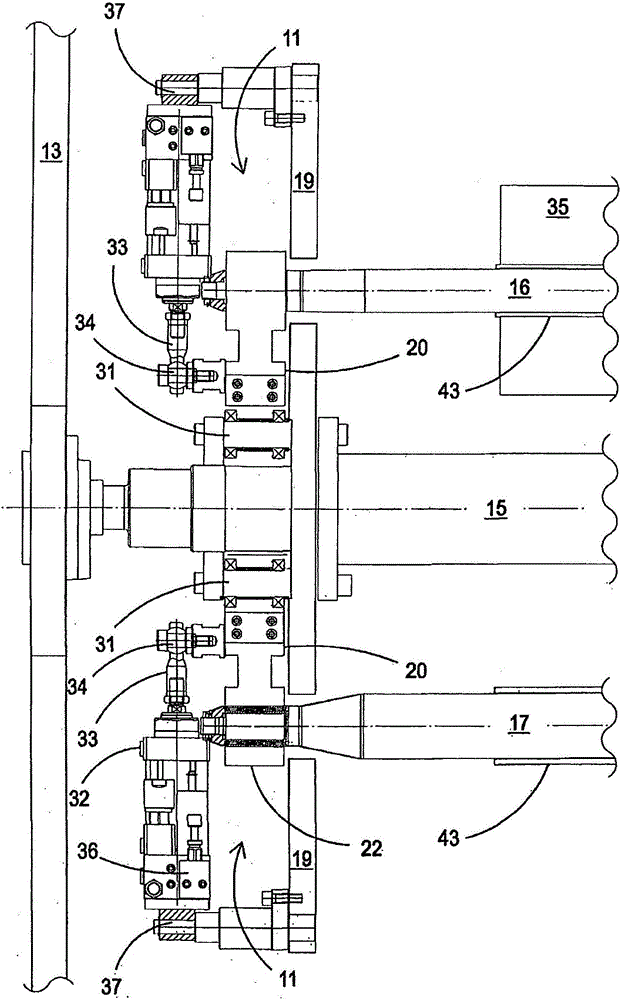

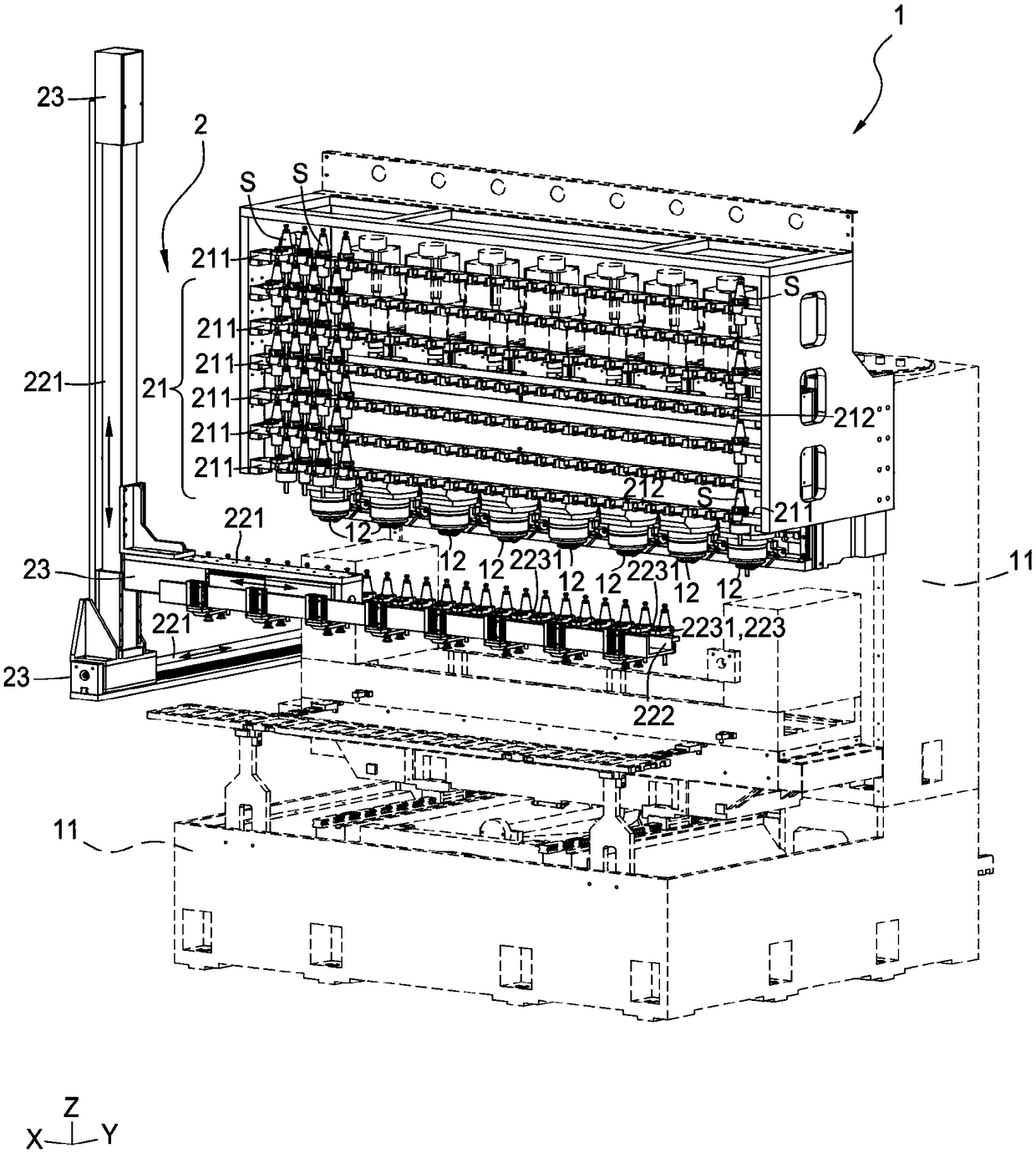

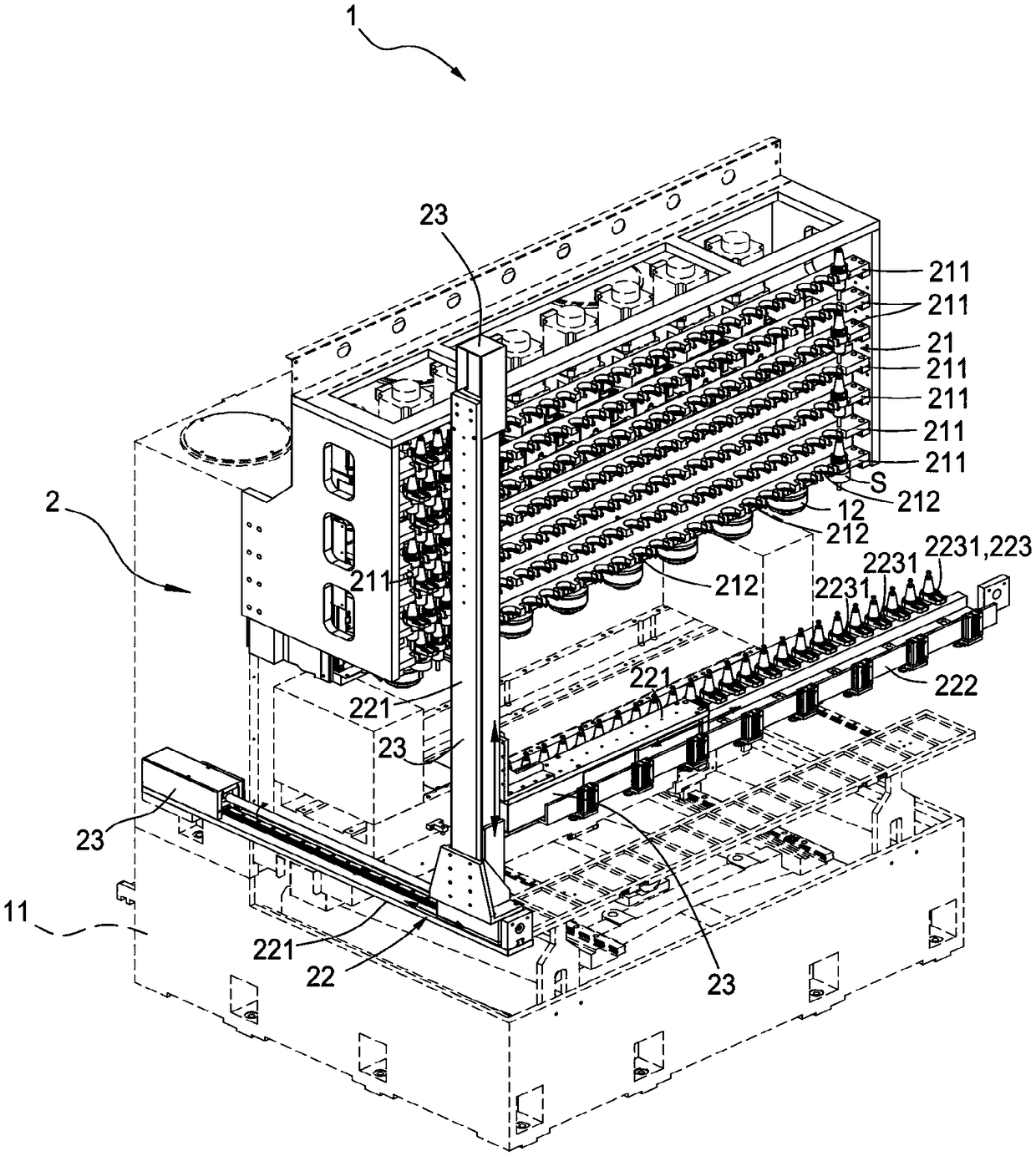

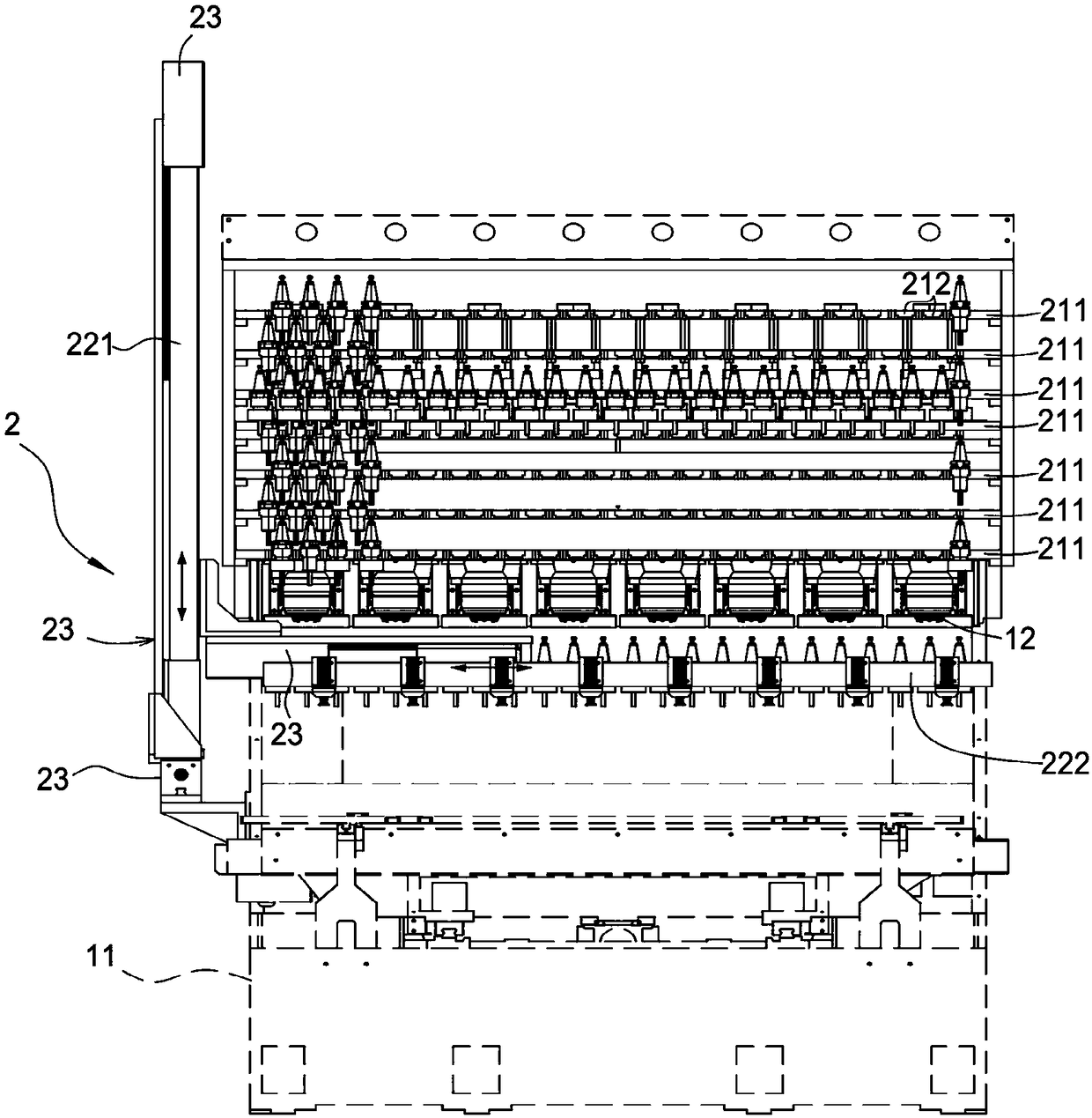

Holding and supporting components for winding mandrels in plastic film winding machines

A holding and support assembly for a winding mandrel in a machine for winding plastic film onto rolls, said machine comprising a winding mandrel positioned between two uprights (12, 13), wherein A first upright (12) carries a rotating plate (14) that cantileverly supports three mandrels (16, 17, 18) and a central shaft (15) that integrally constitute A winding reel, wherein the other end of the central shaft (15) is supported at the second column (13), wherein, corresponding to the free end of the central shaft (15), a star plate (19) is provided, said The star plate has three support arms through each free end of the three mandrels (16, 17, 18) of the corresponding toggle lever mechanism (21, 22, 25) consisting of The actuator (30) is driven and carried on a rod (20) articulated relative to the star plate (19), said rod being in turn driven by another actuator (32) on the corresponding spindle (16, 17 or 18) swings between an operational blocking position for releasing the corresponding mandrel (16, 17, 18) and a rest position.

Owner:COLINES SPA

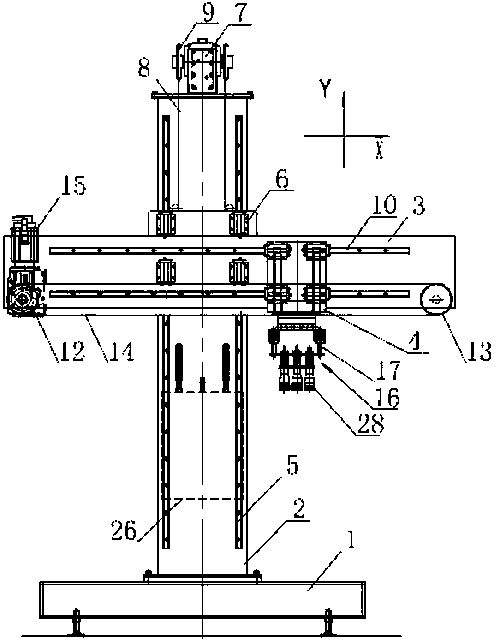

Multi-spindle tool replacement system and method

PendingCN109128954AReduce stepsReduce processing timePositioning apparatusMetal-working holdersThree-dimensional spaceEngineering

The invention relates to a multi-spindle tool replacement system and method. The system is arranged on a multi-spindle machining tool, the multi-spindle machining tool comprises a machine table, and multiple spindles arranged on the machine table, the spindles can be moved to the tool replacing position of a replacement tool, and the multi-spindle tool replacement system comprises a fixed tool rest and a first moving tool rest; the fixed tool rest is provided with multiple rows of rest bodies, and each rest body is provided with multiple tool rest bases allowing tools to be clamped, the firstmoving tool rest comprises a moving mechanism with moving capacity in the three-dimensional space direction and a rod body arranged on the moving mechanism, the rod body is provided with at least onetaking and putting unit, through moving of the rod body, the taking and putting units are linked, and the taking and putting units take or put back the tool arranged on the fixed tool rest. The movingpath of the taking and putting units comprises the corresponding position of all rest bodies of the fixed tool rest, a tool replacement waiting position close to a tool changing position of the multi-spindle machining tool and the tool changing position of the multi-spindle machining tool. The multi-spindle machining occasion can be subjected to tool changing, and personal operation is reduced.

Owner:新代科技(苏州)有限公司

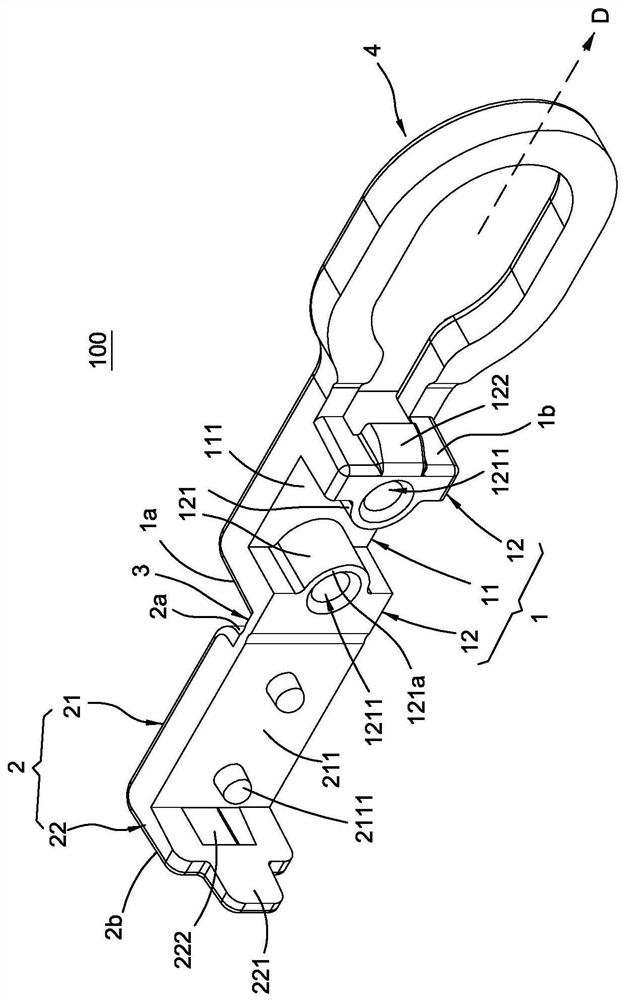

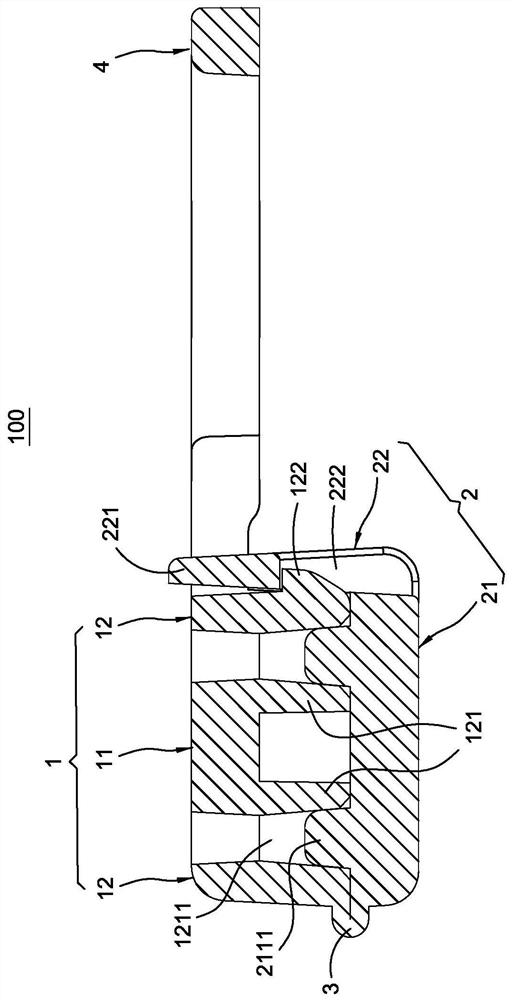

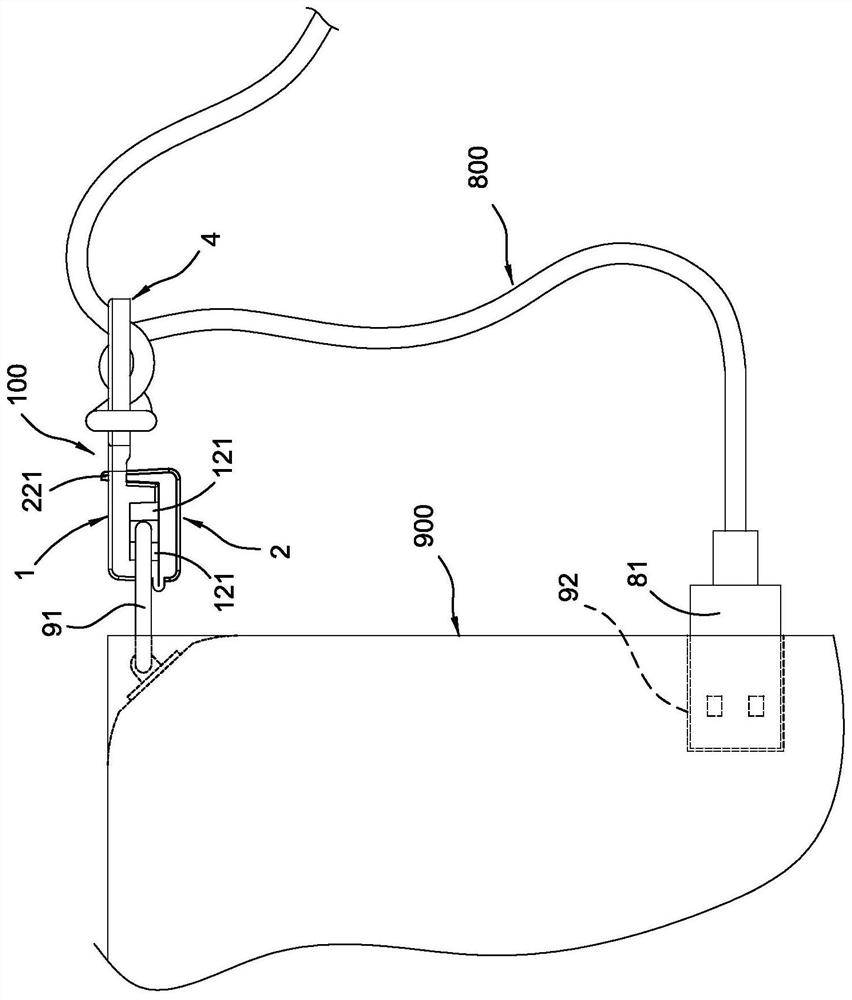

Pull-out prevention structure for cables

ActiveCN111293512BPrevent pulling outEasy to replaceCoupling device detailsComputer periphery connectorsEngineeringStructural engineering

Owner:SHENXUN COMP KUNSHAN +1

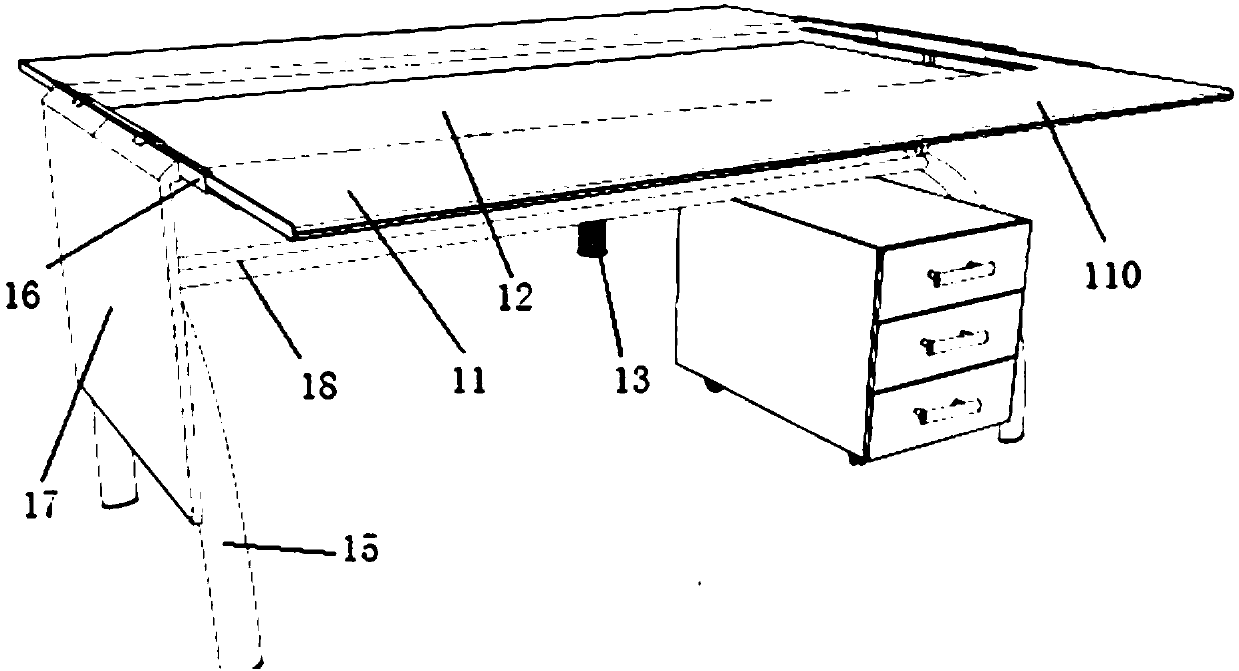

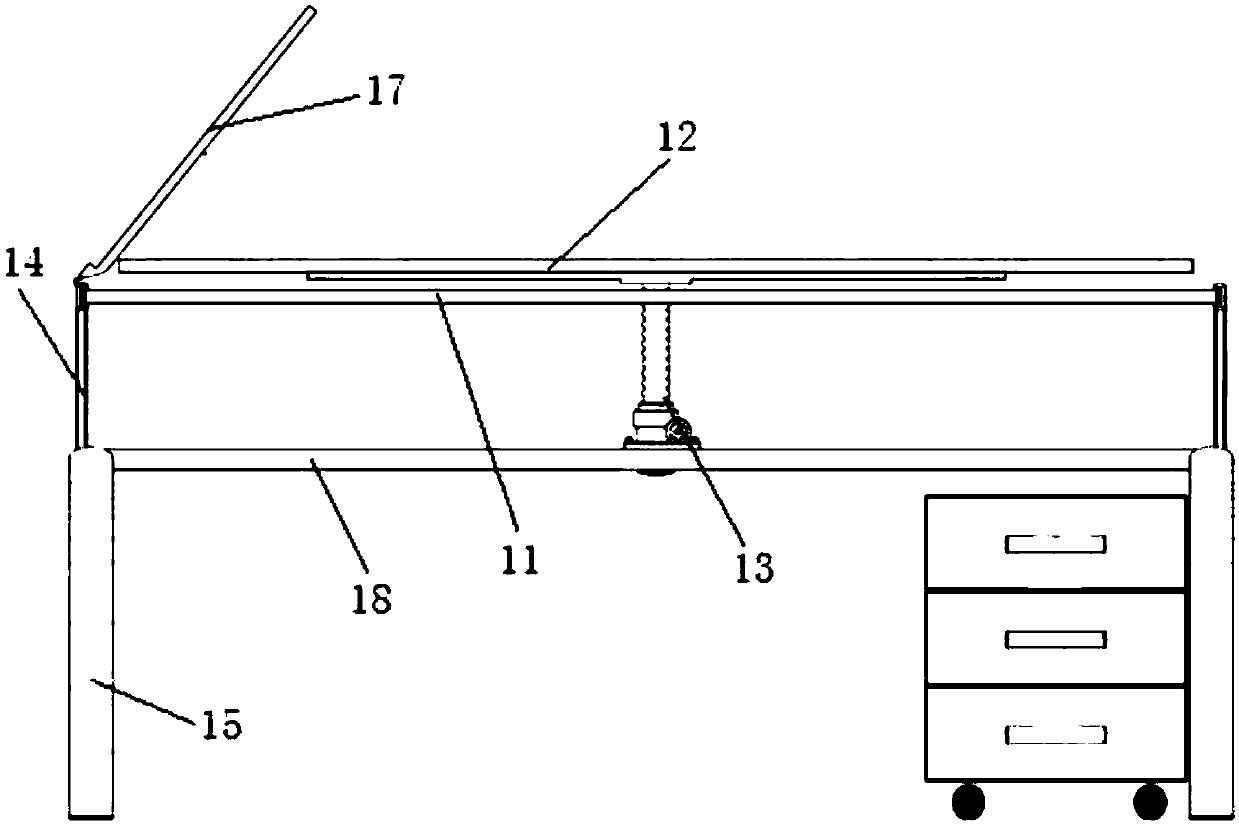

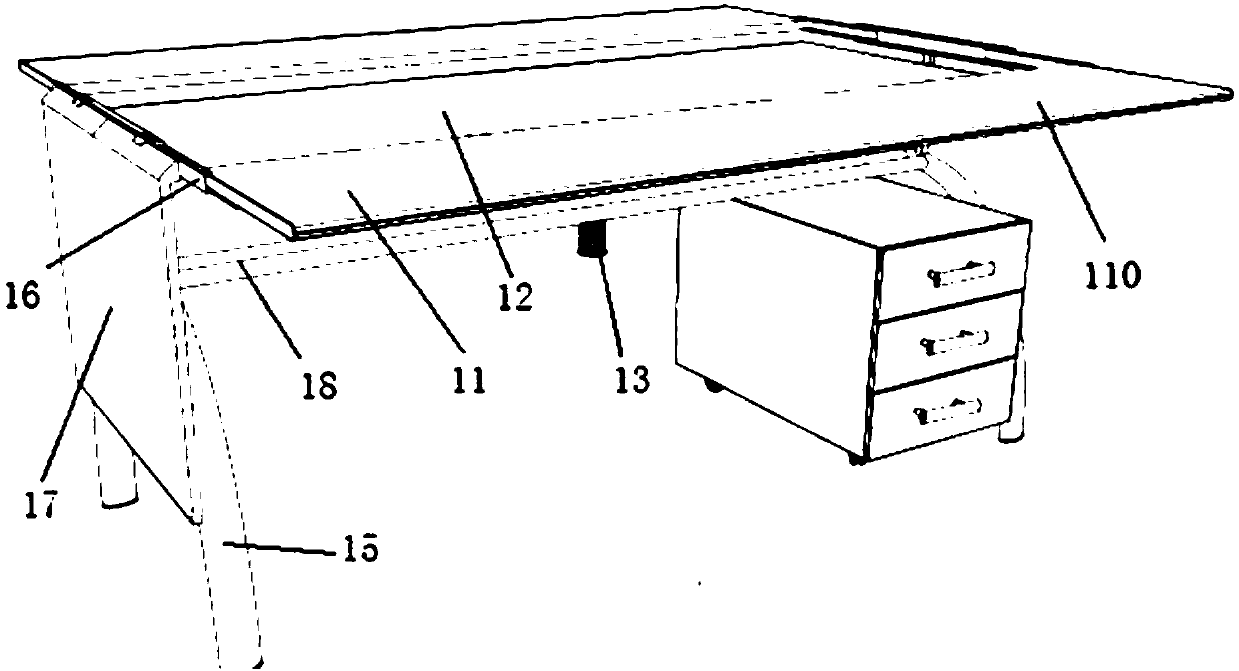

Office table with hidden storage rack

InactiveCN109907480AEasy to operateSave spaceExtensible tablesVariable height tablesEngineeringStructural engineering

The invention discloses an office table with a hidden storage rack. The office table comprises at least two layers of tabletops; the lower-layer tabletop is capable of sliding relative to the upper-layer tabletop; the lower-layer tabletop is capable of completely sliding to the outer side of the upper-layer tabletop; a lifting device is arranged on the upper-layer tabletop. At least two layers oftabletops are arranged, so that the lower-layer tabletop can slide to the outer side of the upper-layer tabletop, and then the upper-layer tabletop can be reduced to the lower side of the lower-layertabletop by the lifting device, the lower-layer tabletop slides to an initial position and then the lower-layer tabletop can be used as a new tabletop, when the new tabletop is required because no space on the upper-layer tabletop is available or guests visit the host.

Owner:李齐

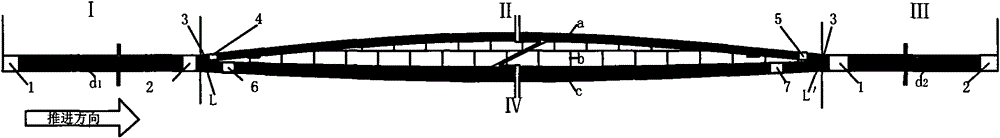

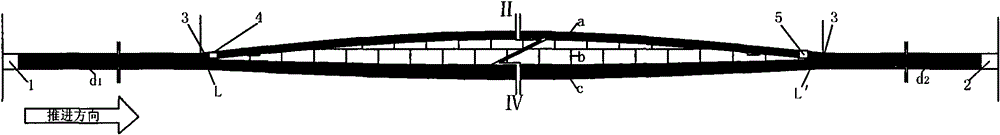

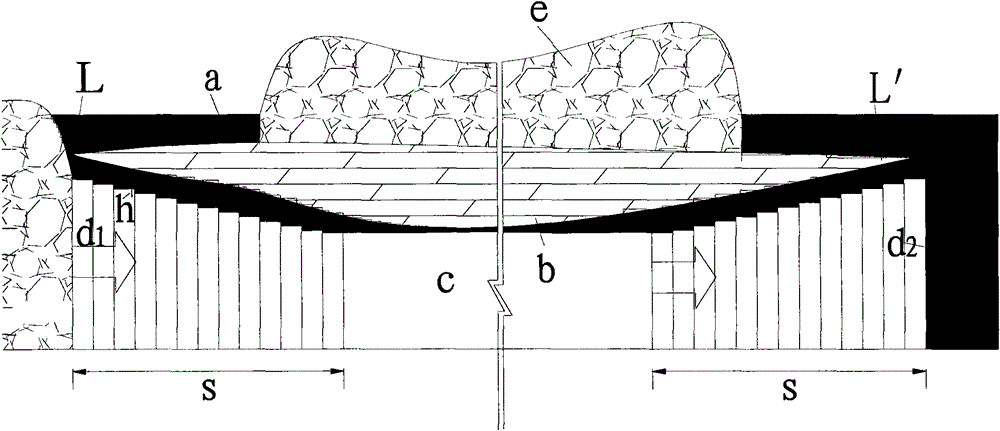

Method for carrying out comprehensive mechanical coal mining and continuous propulsion mining on split and merged coal beds

InactiveCN102061922BPromote recoveryAvoid serious wasteUnderground miningSurface miningSplit linesEngineering

The invention relates to a method for carrying out comprehensive mechanical coal mining and continuous propulsion mining on split and merged coal beds, which is characterized by dividing the whole mining process of the split and merged coal beds into two stages: an actual mining stage of layered coal beds above a split area and an actual mining stage for carrying out continuous propulsion mining on thick coal beds at a merged area and layered coal beds below the split area. A medium thick coal bed hydraulic supportis used for carrying out actual mining on the layered coal beds above the splitarea, and a grand mining high hydraulic support is used for carrying out actual mining on the thick coal beds at the merged area and the layered coal beds below the split area; open-off cut is conducted only once around a split line and a merged line; the mining height of the hydraulic support is required to be both lowered and raised to carry out 'height-differing mining' to realize the comprehensive mechanical coal mining and continuous propulsion mining on coal beds of different thicknesses. By utilizing he method provided by the invention, the number of open-off cuts, finishing cuts and working surfaces for mining the coal beds under such geological conditions can be effectively reduced, the number of standby collar pillars is greatly reduced, the recovery ratio is improved, and benefits of mining the split and merged coal beds are remarkably improved, thus the method provided by the invention has significance in widespread promotion.

Owner:CHINA UNIV OF MINING & TECH

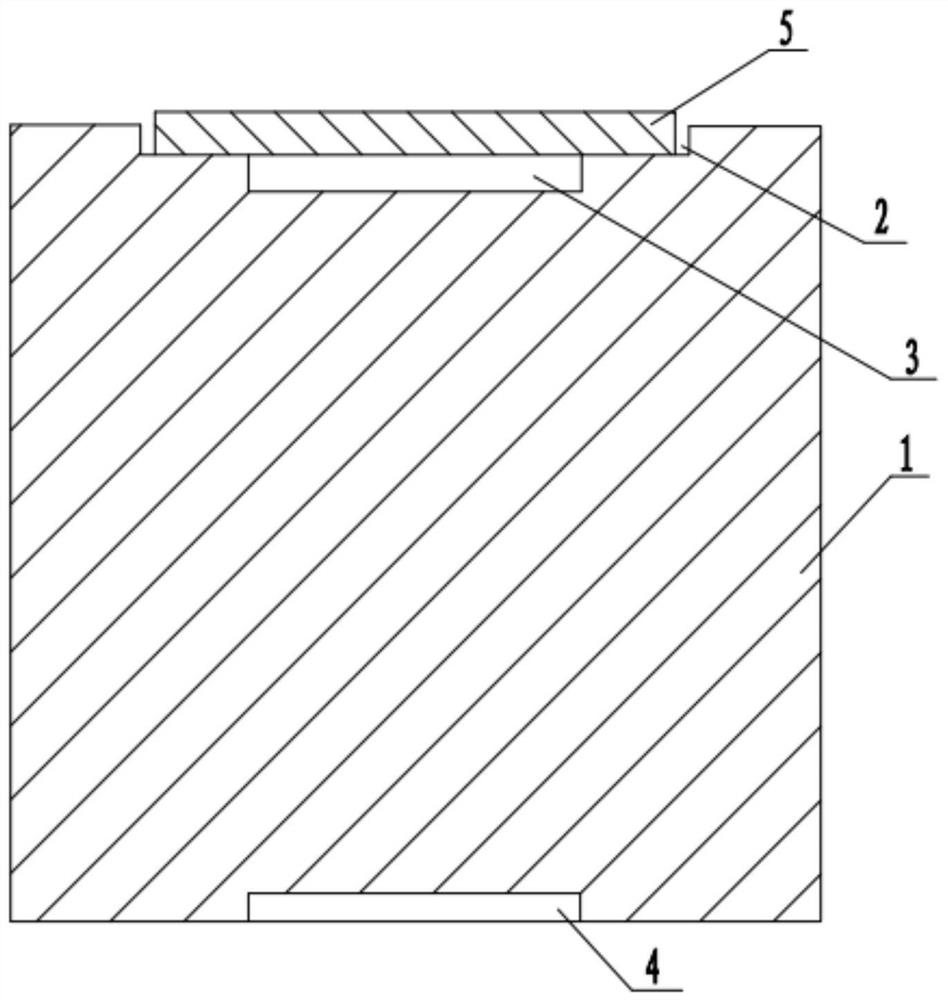

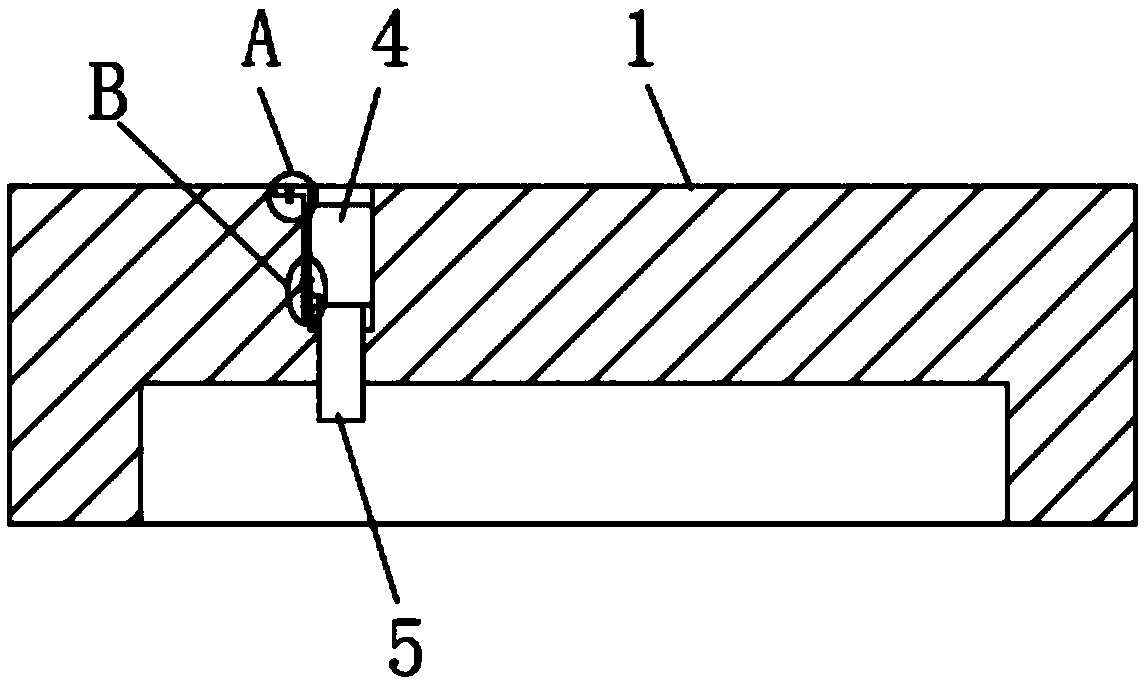

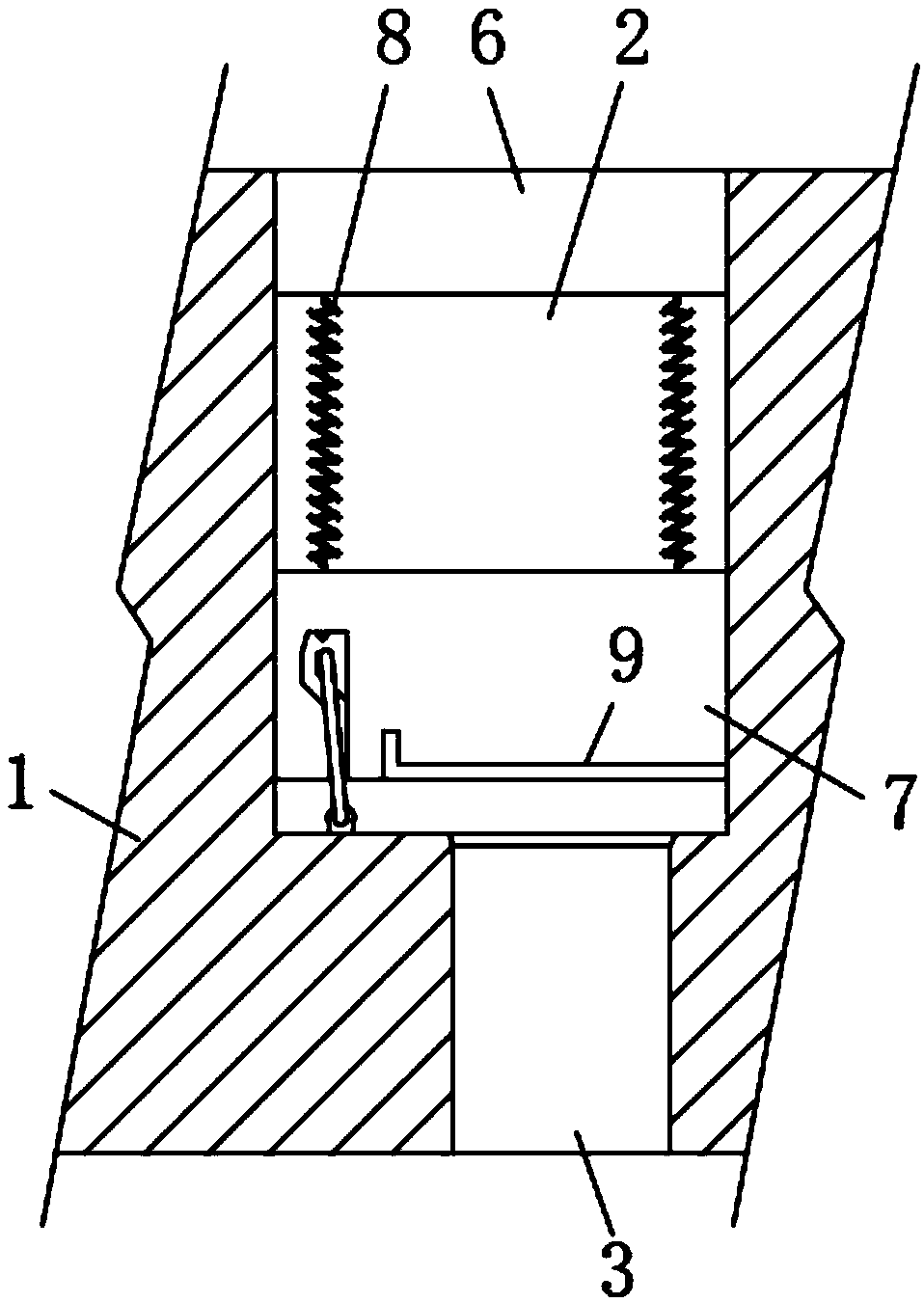

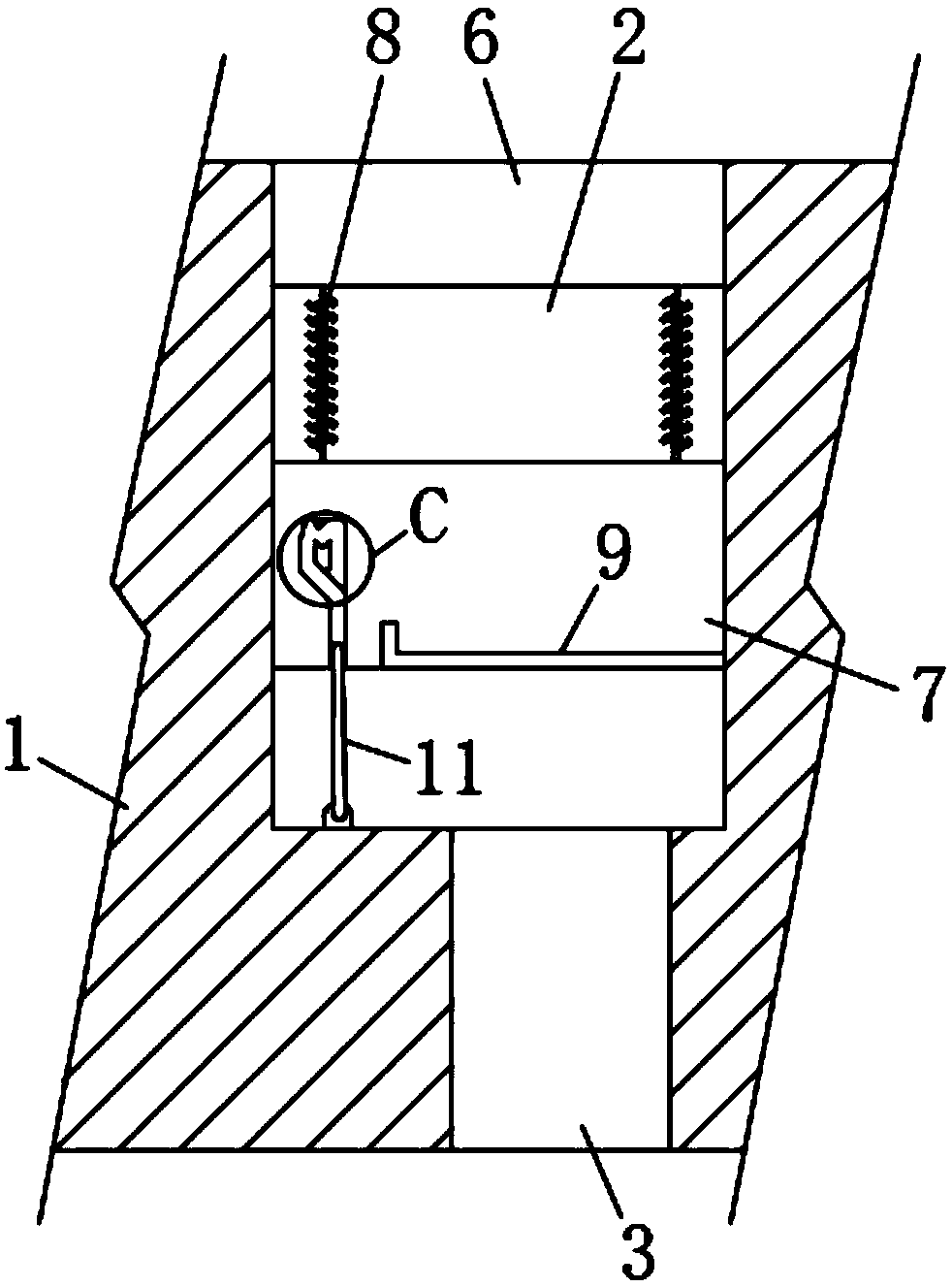

Motor shell expendable mold with insert quick-change structure

ActiveCN109604522AImprove replacement speedSave replacement timeFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention discloses a motor shell expendable mold with an insert quick-change structure. The motor shell expendable mold comprises a mold body, wherein a mold cavity is formed in the bottom wall of the mold body; a mounting slot is formed in the top wall of the mold body, a matching hole is formed in the bottom of the mounting slot, and a fixing block is inserted into the mounting slot; and the bottom of the fixing block is connected to a lug, a movable groove is formed in the inner side wall of one side of the mounting slot, and a tray is arranged in the movable slot. According to the motor shell expendable mold, a detaching and replacing structure of an insert of the motor shell expendable mold is redesigned, when the insert is installed, only the insert needs to be tightly plugged into the matching hole until a clamping hook is clamped on a lap joint so that the insert can be fixed; and when the insert is detached, only the insert needs to be pressed to the bottom again, the clamping hook can be separated from the lap joint, the insert can be popped out under the action of tension springs, then the insert can be quickly taken out, the detaching and replacing speed of the expendable mold insert is greatly improved, and the detaching and replacing time is shortened.

Owner:齐河智谷产业发展有限公司

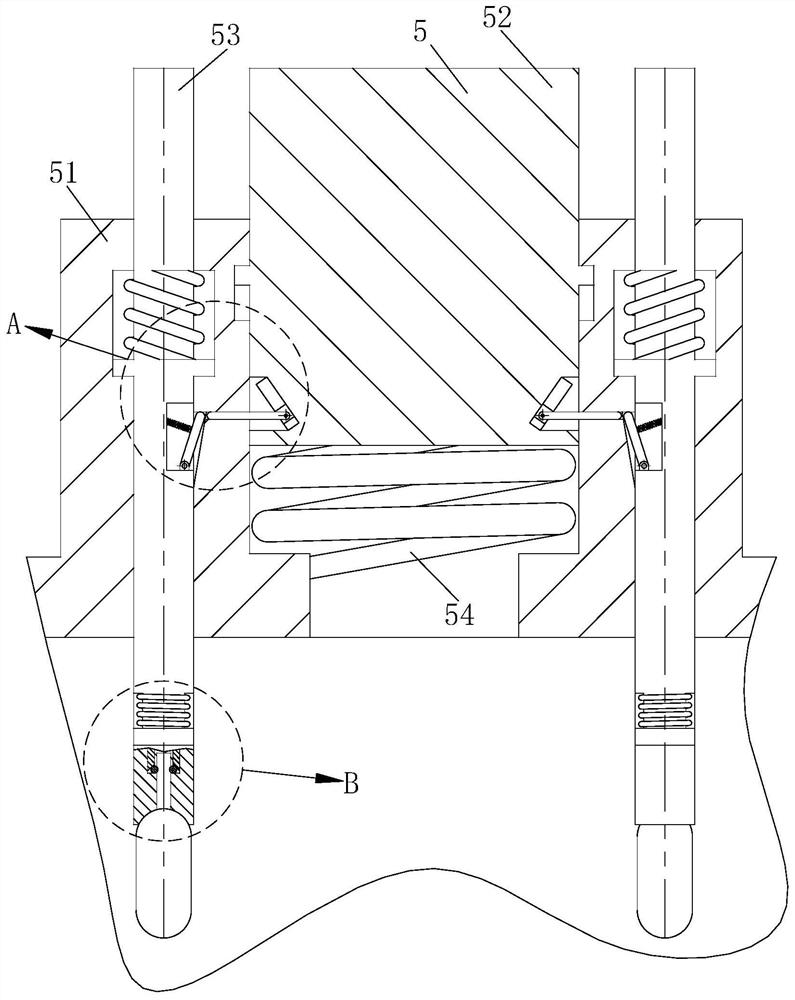

A kind of textile equipment for weaving which is convenient for replacing coils

ActiveCN113184632BEasy to replaceSave replacement timeFilament handlingStructural engineeringMechanical engineering

The invention relates to the technical field of textile equipment, and discloses a textile textile equipment for easy replacement of thread rolls, comprising a support base, the upper part of the support base is fixedly connected with a partition plate, and the upper part of one side of the partition plate is fixed Attach the wired volume to the placement post. The textile equipment for weaving that facilitates the replacement of wire reels installs a wire reel placement column on the upper part of the supporting base of the device to separate different wire reels, and at the same time installs a wire reel placement column and a spare placement column in different sections. When in use, a wire coil is movably socketed on the outside of the wire coil placement column and the spare storage column. After the coil is used, it is convenient to replace the spare wire coil with the original coil, which reduces the replacement time when the coil is disassembled and placed, and increases the efficiency of use.

Owner:淮安一品坊织造有限公司

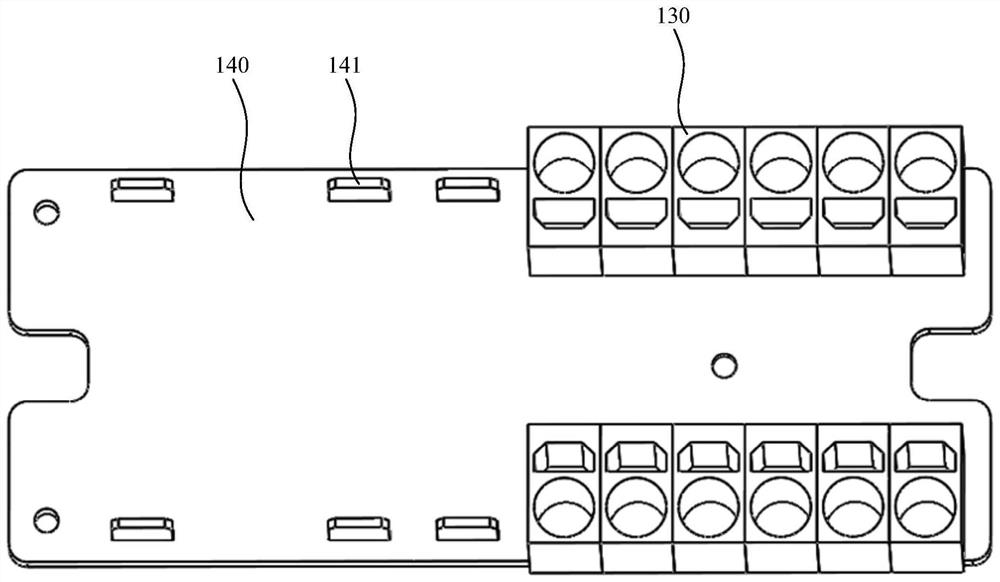

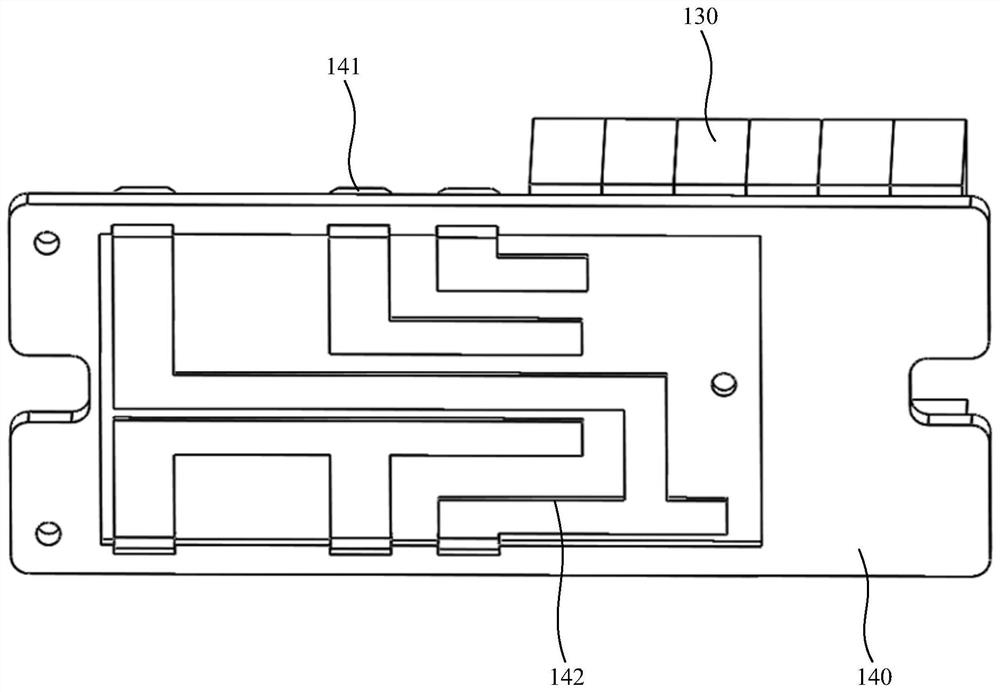

Power distribution box and power distribution system

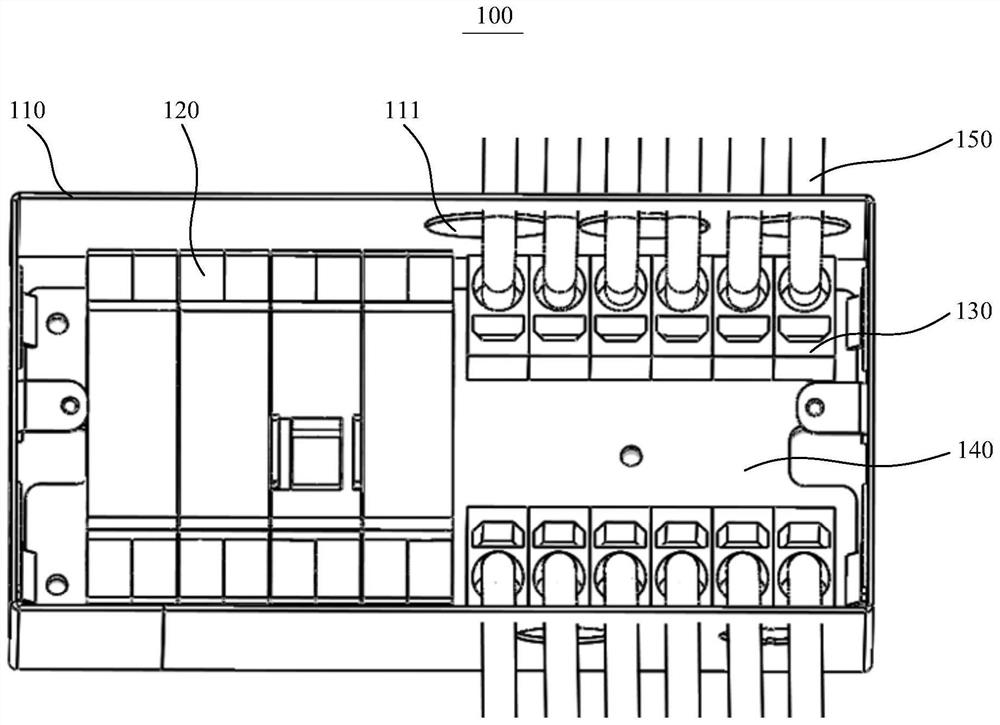

PendingCN114512903AAchieve modularityImprove the level of standardizationBus-bar/wiring layoutsSupervisory desks/panelsBusbarElectrical connection

The invention discloses a power distribution box and a power distribution system, and relates to the technical field of power distribution equipment. The power distribution box comprises a shell, a switch device, a wiring terminal and a busbar, wherein the switch device, the wiring terminal and the busbar are arranged in the shell, and the switch device and the wiring terminal are arranged on the busbar and electrically connected through the busbar in a preset connection relation. According to the distribution box, electrical connection between the switching device and the wiring terminal is realized through the busbar, the switching device and the wiring terminal can be directly installed in the distribution box, a complex wiring link is not needed, the modularization and standardization level is high, and the installation and replacement time is effectively saved.

Owner:SHANGHAI LIANGXIN ELECTRICAL

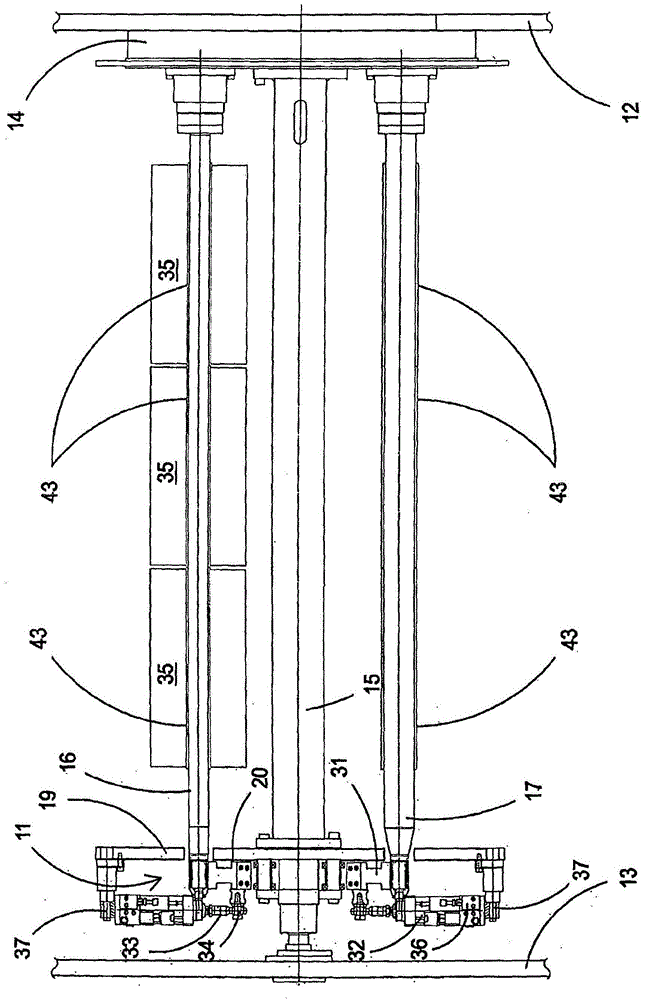

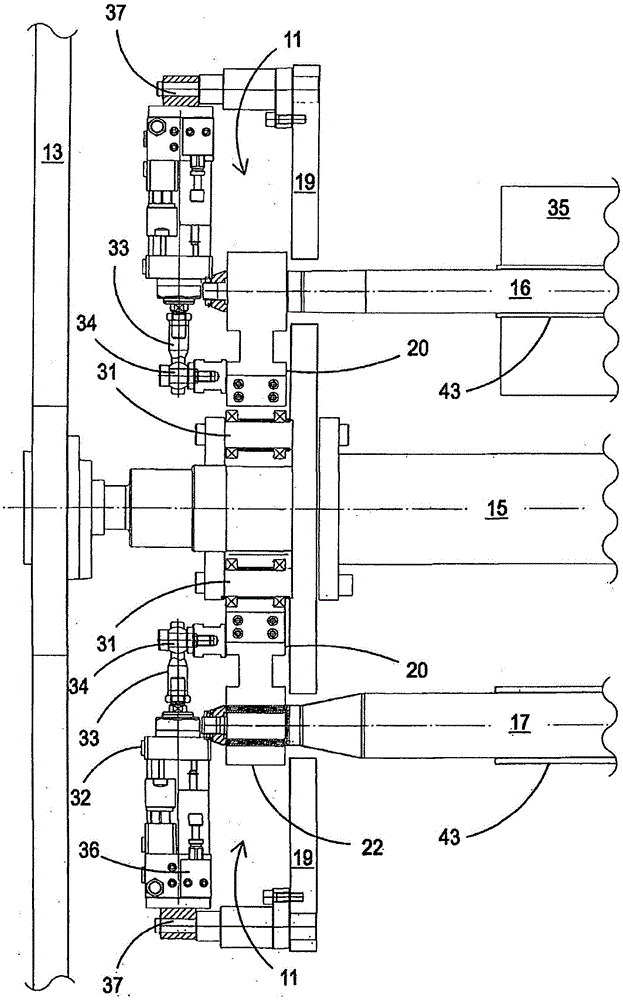

Holding and supporting group of a winding spindle in a plastic film winding machine

ActiveCN105593147AReduce extraction timeSave replacement timeWebs handlingWinding machineRest position

A holding and supporting group of a winding spindle in a machine for winding plastic film onto spools, said machine comprising a winding reel positioned between two uprights (12, 13), wherein a first upright (12) carries a rotating plate (14) which cantilever-supports three spindles (16, 17, 18) and a central shaft (15) which complete the winding reel, wherein the central shaft (15) is supported at the other end at the second upright (13), wherein, in correspondence with a free end of the central shaft (15), there is a star-shaped plate (19) with three supporting arms of each free end of the three spindles (16, 17, 18) through a respective toggle lever mechanism (21, 22, 25) driven by an actuator (30) carried on a lever (20) articulated with respect to the star-shaped plate (19), and in turn caused to oscillate between an operative blocking position of the respective spindle (16, 17 or 18) and a rest position for releasing the respective spindle (16, 17, 18) by means of a further actuator (32).

Owner:COLINES SPA

A process for dismantling and replacing motor bearings without dismantling

ActiveCN110729859BAvoid causingGuaranteed replacement accuracyManufacturing dynamo-electric machinesSupports/enclosures/casingsElectric machineryStructural engineering

The invention discloses a process for dismantling and replacing motor bearings without dismantling, which includes: supporting and positioning the bottom of the rotor shaft through a first support member and a second support member at at least two preset positions along the axial direction; Second support and remove it from support of the rotor shaft, pull out the old bearing assembly between the first support and the second support; move the second support so that it re-supports the rotor shaft while moving the second One support and out of support for the rotor shaft, pull the old bearing assembly off the outer end of the rotor shaft; slide the new bearing assembly in from the outer end of the rotor shaft, and move the first support so that It re-supports the rotor shaft, then moves the second support out of support of the rotor shaft; slides the new bearing assembly axially into place on the rotor shaft. The invention can realize the dismantling-free replacement of the motor bearing, improve the replacement efficiency, and avoid the displacement of the rotor during the replacement process.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com