Cyclone separator for ecological oil

A cyclone separator and ecological oil technology, which is applied to cyclone devices, devices whose axial directions of the cyclone can be reversed, etc., can solve the problems of heavy cyclone separators, long downtime, and high equipment replacement rate, and save energy. The effect of replacing time, enhancing wear resistance and saving hoisting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

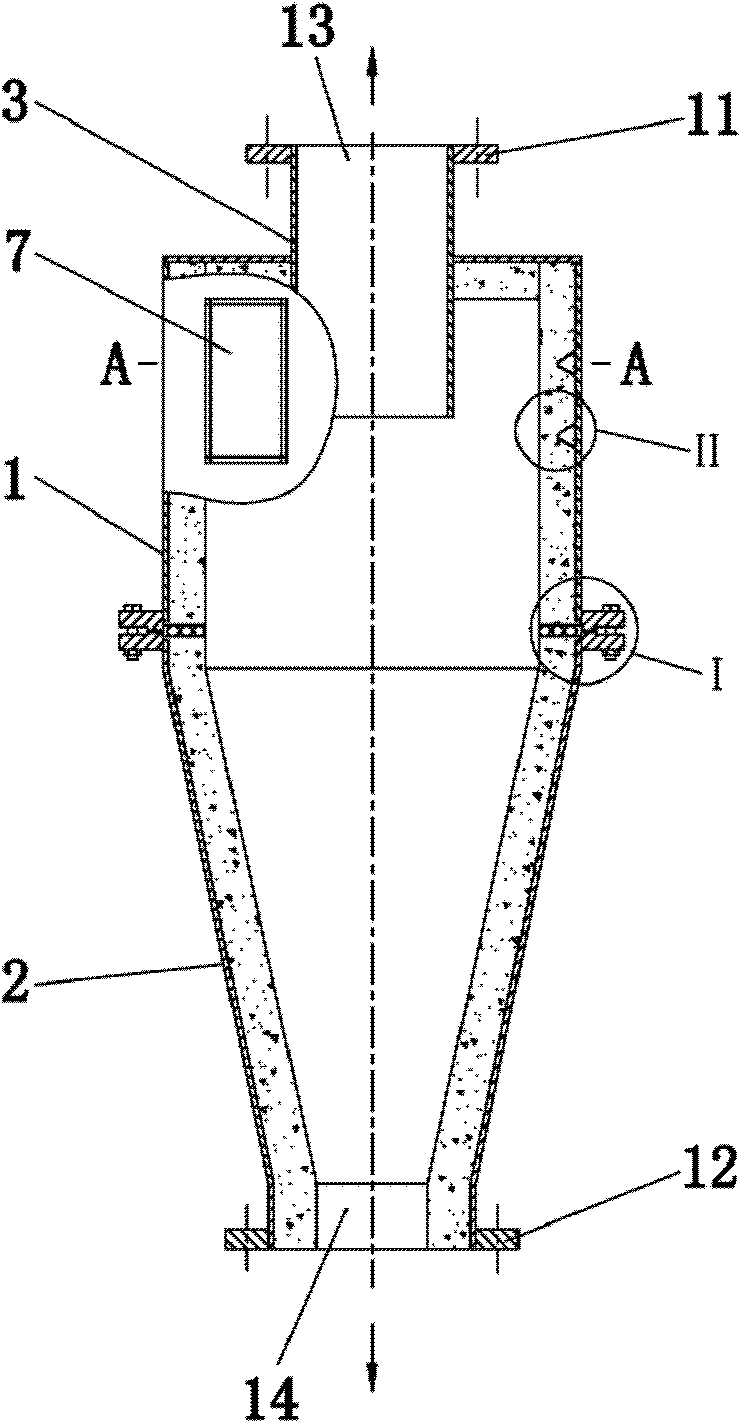

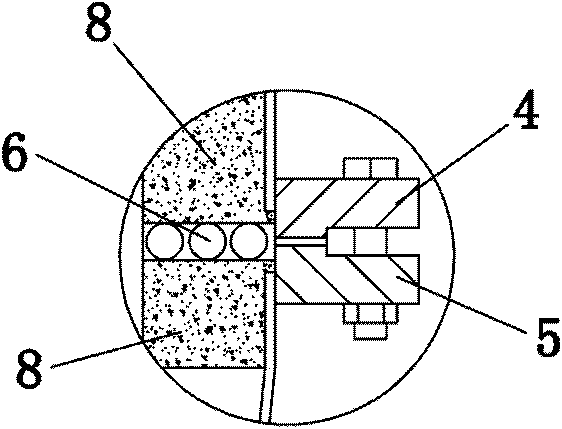

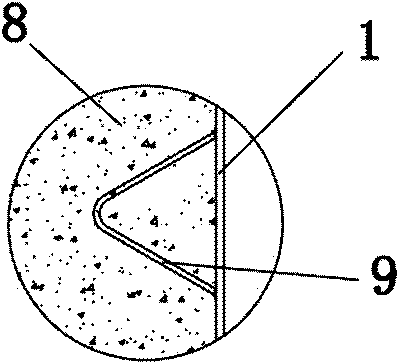

[0016] like figure 1 As shown, the cyclone separator of the present invention is composed of a cylinder body 1, a conical cylinder body 2 and an outlet cylinder 3. The lower end of the cylinder is welded with flange 4, the upper end of the conical cylinder is welded with flange 5, the cylinder 2 and the conical cylinder 2 are connected by bolts through flanges 4 and 5, and the contact between cylinder 1 and conical cylinder 2 The face pad has asbestos 6, such as image 3 , to play a sealing role. The inner walls of the cylindrical body 1 and the conical cylindrical body 2 are provided with a wear-resistant layer 8, and the wear-resistant layer is poured with reinforced steel braze to enhance wear-resistant and refractory materials. The side wall of the cylindrical body 1 is provided with a square cyclone inlet 7, and the side wall of the cyclone inlet is tangent to the inner wall of the wear-resistant layer 8 (such as figure 2 ). The cyclone inlet area of the cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com