Hierarchical-depressurizing oil nozzle manifold

A technology of graded pressure reduction and manifold, which is applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problems of poor pressure regulation effect, unreasonable design, insufficient pressure regulation series, etc. Achieve high cost performance, improve production efficiency and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

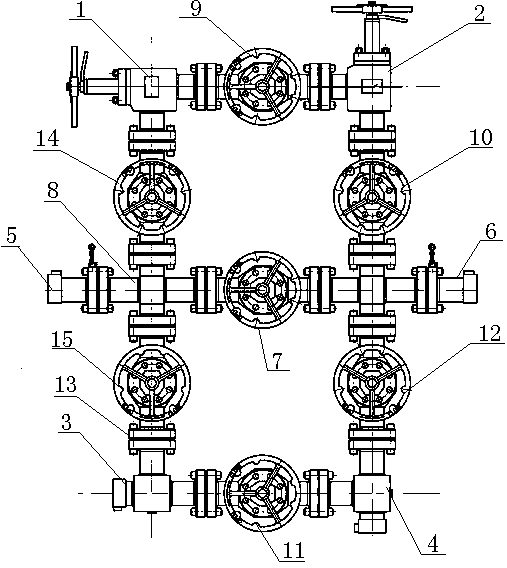

[0014] Example 1, figure 1 describe.

[0015] A graded decompression nozzle manifold, including a manifold pipeline 8, a first adjustable nozzle 1 connected to the manifold pipeline 8 through a first flat gate valve 14, and a first adjustable nozzle 1 connected to the manifold pipeline 8 through a second flat gate valve 15. The first fixed nozzle 3 connected to the manifold pipeline 8, and the first adjustable nozzle 1 and the first fixed nozzle 3 are respectively placed on both sides of the manifold pipeline 8, and are respectively placed on the manifold pipeline The second adjustable oil nozzle 2 and the second fixed oil nozzle 4 on both sides of 8, the second adjustable oil nozzle 2 and the second fixed oil nozzle 4 pass through the third flat gate valve 10, the fourth flat gate valve 12 and the tube respectively. The manifold line 8 is connected; the second adjustable oil nozzle 2 is set on the same side as the first adjustable oil nozzle 1 and placed downstream of th...

Embodiment 2

[0018] Embodiment 2, in conjunction with attached figure 1 describe.

[0019] On the basis of Embodiment 1, the valve pins of the first adjustable oil nozzle 1 and the second adjustable oil nozzle 2 are made of wedge-shaped tungsten carbide.

[0020] The first fixed oil nozzle 3 and the second fixed oil nozzle 4 adopt ceramic oil nozzles.

[0021] The flat gate valve adopts Cameron FL structure, wherein the valve plate is supersonic and adopts imported seals.

[0022] The manifold pipeline 8 is connected with API6A flanges 13 between the independent connectors.

[0023] The inner surface of the manifold pipeline 8 is made of spray-welded tungsten carbide alloy.

[0024] The fluid inlet 5 of the manifold pipeline 8 adopts a 3-1 / 16" fig1502 inlet and a 63-1 / 16" fig1502 outlet for the fluid outlet.

[0025] The optimized process and careful selection of materials in this solution make the technical effect of reducing the manifold pressure better, including but not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com