Preparation method for co-growth of multiple single crystal diamonds

A single crystal diamond, co-growth technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of randomness of seed crystal surface temperature, improve the deposition power density and single crystal deposition efficiency, improve the experimental Efficiency, the effect of improving the uniformity of seed temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

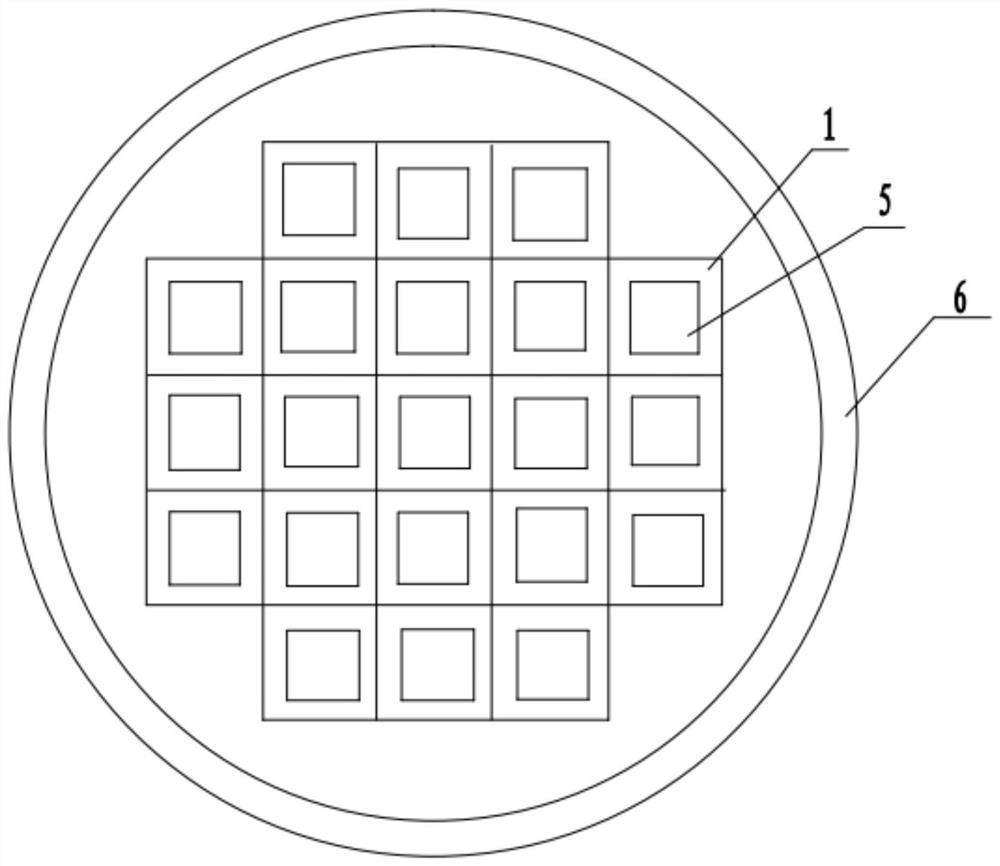

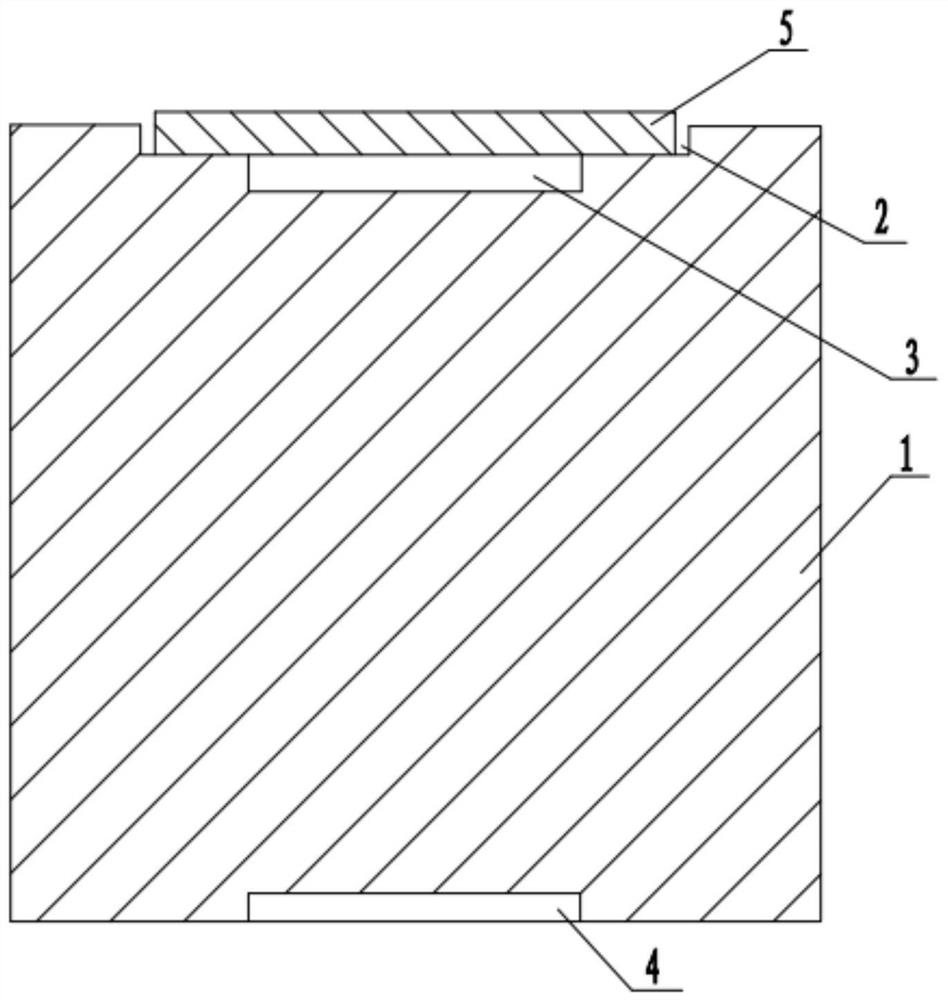

[0029]2.45GHz microwave CVD equipment is used to conduct multi-chip growth experiments of 7mm×7mm seed crystal grown diamonds, and the temperature deviation of various crystals is required to be controlled within the range of 1000±15°C. The specific deposition growth process is:

[0030] Take 21 double-sided polished single crystal diamond seed crystals, the seed crystal side length is 7mm×7mm, and the thickness is 0.5±0.1mm. According to the seed crystal size design and processing such as figure 2 A square free-standing molybdenum holder unit is shown. The side length of the molybdenum support unit is 9mm×9mm, the height of the molybdenum support unit is 8-10mm; the side length of the positioning groove 2 is 7.5×7.5mm, and the depth of the positioning groove 2 is 0.4-0.6mm; the upper temperature adjustment groove 3 and the lower The diameter of the temperature regulating groove 4 is 4.5mm, and the depth is 0.3-0.6mm. The processed 21 independent molybdenum holder units su...

Embodiment 2

[0034] Using 2.45GHz microwave CVD equipment to conduct multi-chip growth experiments of 10mm×10mm seed crystal grown diamonds, it is required that the temperature deviation of various crystals be controlled within the range of 1000±15°C. The specific deposition growth process is:

[0035] Take 16 double-sided polished single-crystal diamond seed crystals, the side length of the seed crystal is 10mm×10mm, and the thickness is 0.5±0.1mm. According to the seed crystal size design and processing such as figure 2 A square free-standing molybdenum holder unit is shown. The side length of the molybdenum support unit is 12mm×12mm, the height of the molybdenum support unit is 8-10mm; the side length of the positioning groove 2 is 10.5×10.5mm, and the depth of the positioning groove 2 is 0.4-0.6mm; the upper temperature adjustment groove 3 and the lower The diameter of the temperature regulating groove 4 is 7mm, and the depth is 0.3-0.6mm. Place the processed 16 independent molybde...

Embodiment 3

[0038] 915MHz microwave CVD equipment is used to conduct multi-chip growth experiments of 10mm×10mm seed crystal grown diamonds, and the temperature deviation of various crystals is required to be controlled within the range of 1000±15°C. The specific deposition growth process is:

[0039] Take 60 double-sided polished single-crystal diamond seed crystals, the side length of the seed crystal is 10mm×10mm, and the thickness is 0.5±0.1mm. According to the seed crystal size design and processing such as figure 2 A square free-standing molybdenum holder unit is shown. The side length of the molybdenum support unit is 12mm×12mm, the height of the molybdenum support unit is 8-10mm; the side length of the positioning groove 2 is 10.5×10.5mm, and the depth of the positioning groove 2 is 0.4-0.6mm; the upper temperature adjustment groove 3 and the lower The diameter of the temperature regulating groove 4 is 7mm, and the depth is 0.3-0.6mm. Place the processed 60 independent molybde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com