Method for carrying out comprehensive mechanical coal mining and continuous propulsion mining on split and merged coal beds

A coal seam and bifurcation technology, which is applied in the field of continuous advancement of coal seam mining, can solve the problems of increasing the number of moving faces, complicated roadway layout, and reducing the recovery rate of coal seams, so as to solve the problem of serious waste of resources, shorten the mining replacement time, The Effect of Raising Coal Seam Recovery Ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

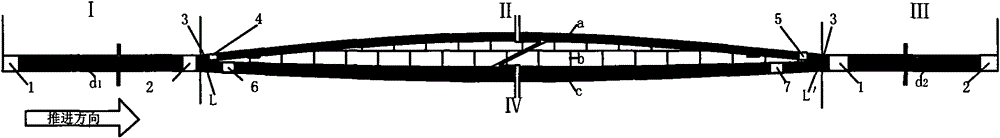

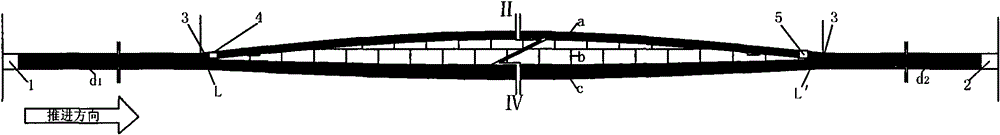

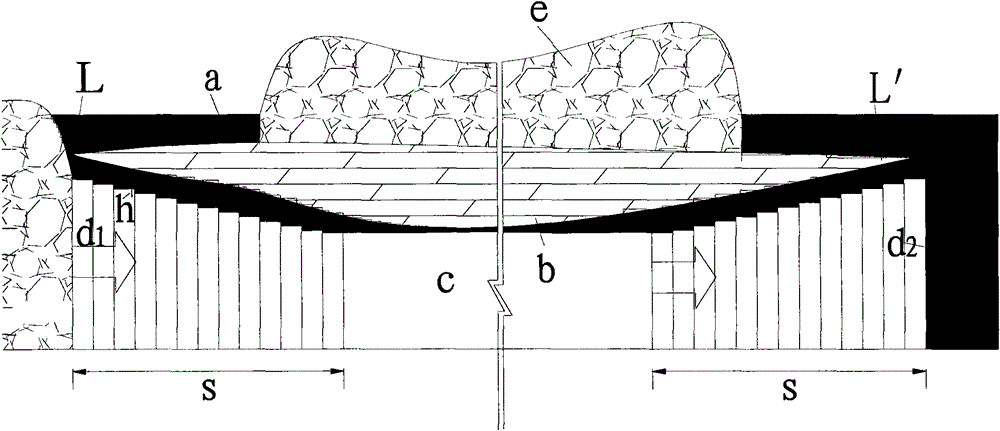

[0021] a. In the layered coal seam a on the bifurcation area, the distance from the bifurcation line L is 8-10m to set up the upper layered coal seam cutting hole 4, install mining equipment, and advance from the upper layered coal seam to the direction of the merging line L', the working face Entering stage II of recovery of upper layered coal seam in bifurcation area:

[0022] b. Stop advancing when the working face advances to a distance of 8-10m from the merging line L', and close the upper layered coal seam in the bifurcation area as eye 5, complete the recovery stage II of the upper layered coal seam in the bifurcation area, and the roof rock layer caving is the goaf e of the stratified coal seam in the bifurcation area;

[0023] c. Open thick coal seam cut hole 1 in the merged area thick coal seam d, install mining equipment, advance in the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com