Intelligent electric permanent magnetic chuck

An electric permanent magnet chuck, intelligent technology, applied in the direction of permanent magnets, circuits, magnets, etc., can solve the problem of not knowing whether there is a problem with the die hole, not being able to judge whether there is magnetism, and the size of the magnetic force cannot be judged, etc., to save mold replacement. And the effect of adjusting time, convenient operation and quick detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

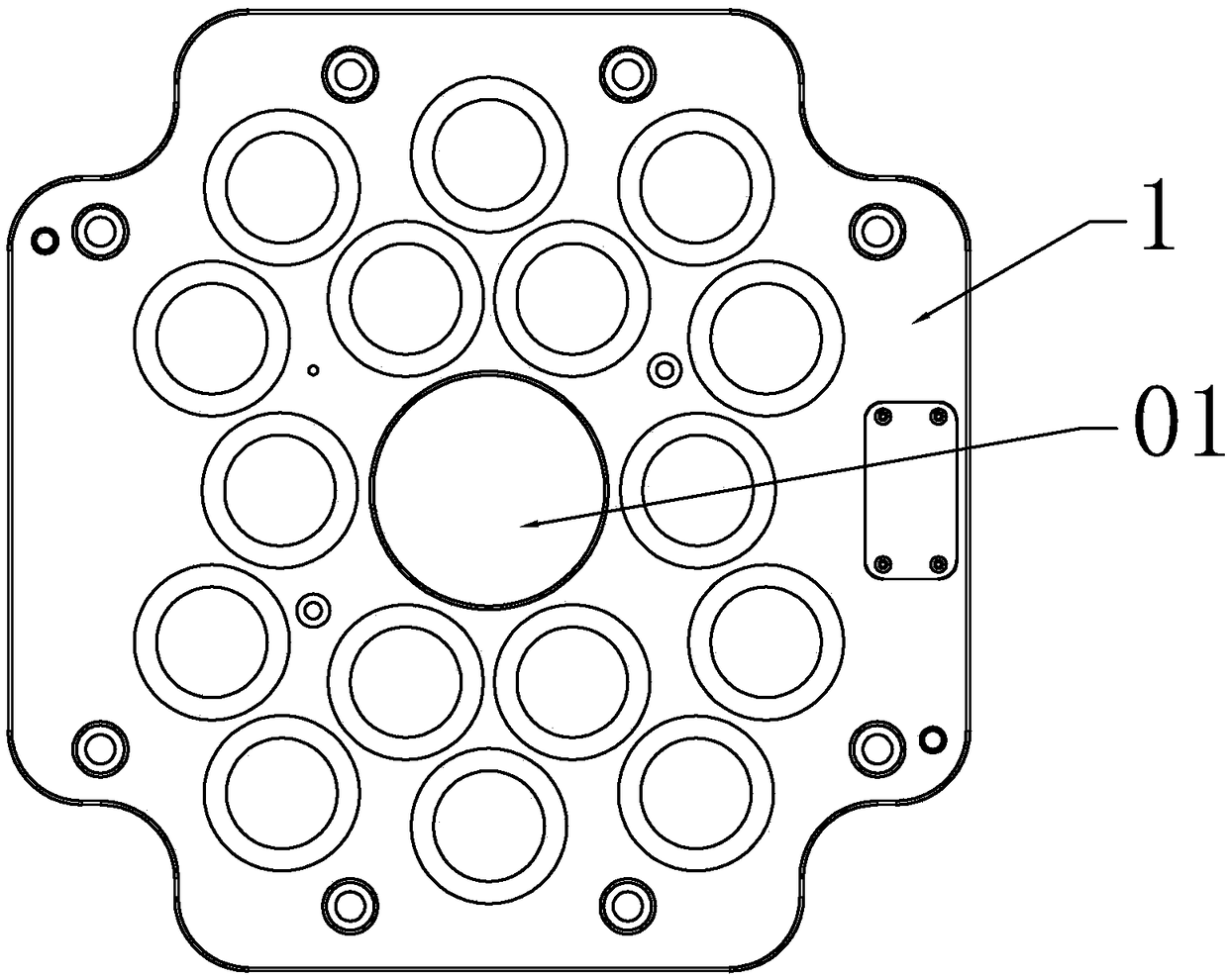

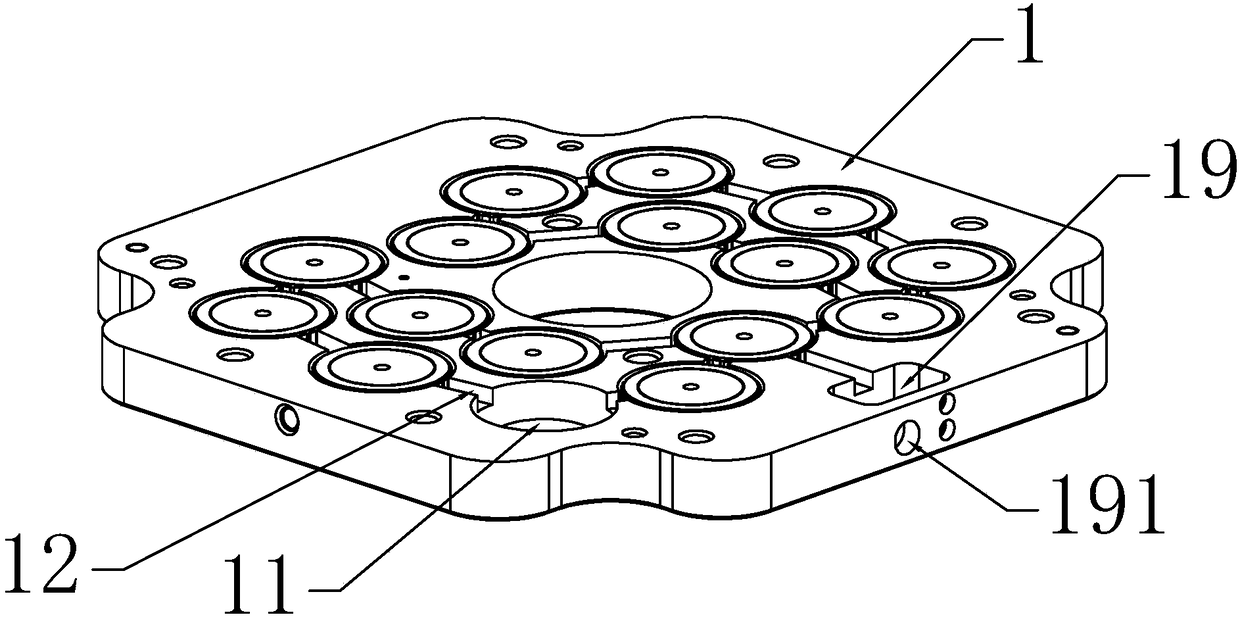

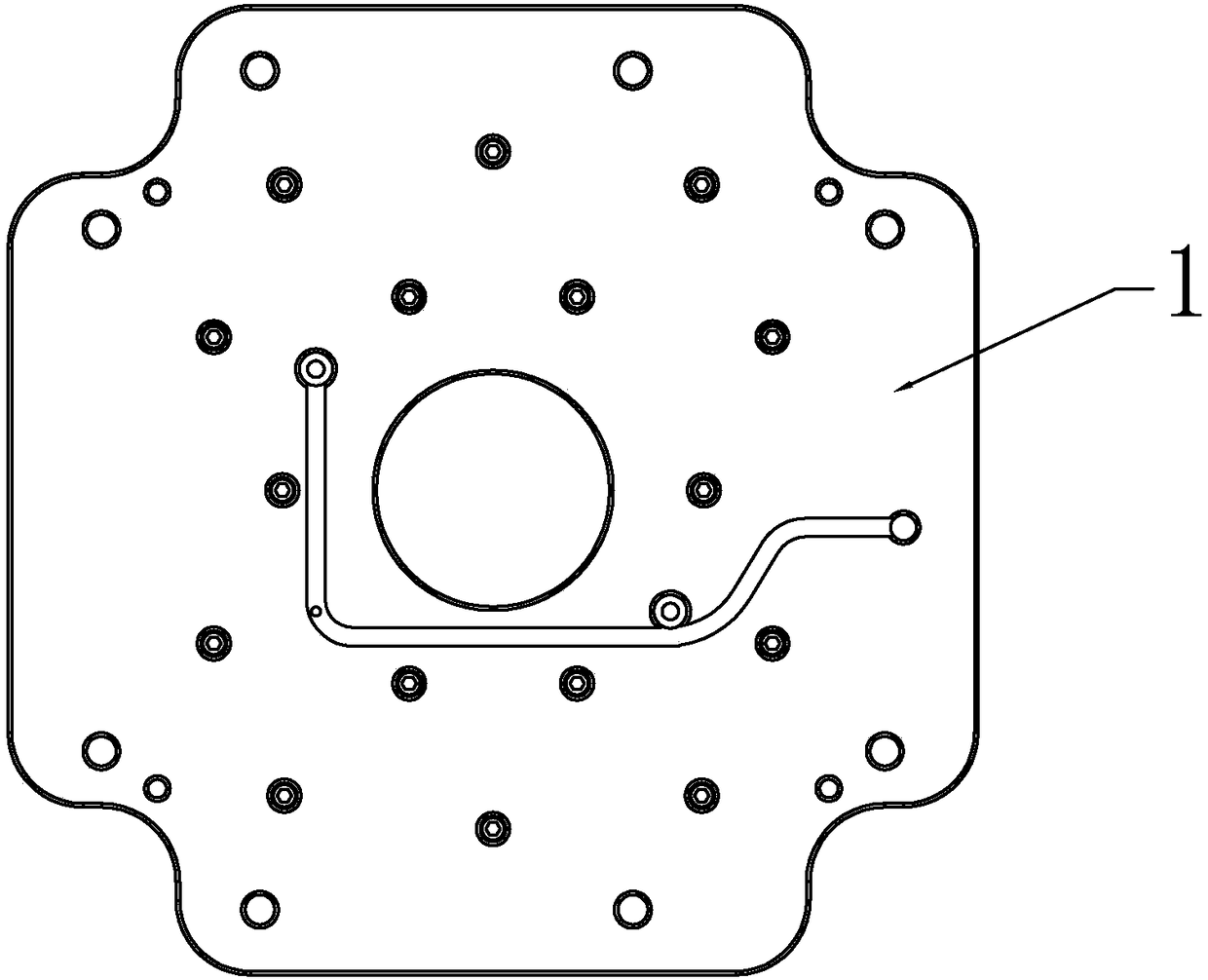

[0029]An intelligent electric permanent magnetic chuck, the electric permanent magnetic chuck device includes a template 1, the reverse side of the template 1 is provided with several blind die holes 11, the top between the blind die holes 11 is provided with a lead gap 12, each blind die hole 11 In the middle of the bottom, there is a cylinder 101 integrated with the template 1, and a surrounding groove 102 surrounding the cylinder 101 is formed between the cylinder 101 and the mold wall of the blind mold hole 11; the cylinder 101 is covered with a magnetic detection coil 103, the magnetic detection coil 103 is fixed on the groove bottom surrounding the groove 102; a NdFeB ring 104 is set on the cylinder 101, and a NdFeB ring 104, the magnetic detection coil 103 and the blind mold hole 11 mold wall are set with a Anti-magnetic interference snare 105, anti-magnetic interference snare 105 is to prevent the magnetic field lines (magnetic field) between the die holes from spreadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com