Patents

Literature

123results about How to "Low level of operation required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

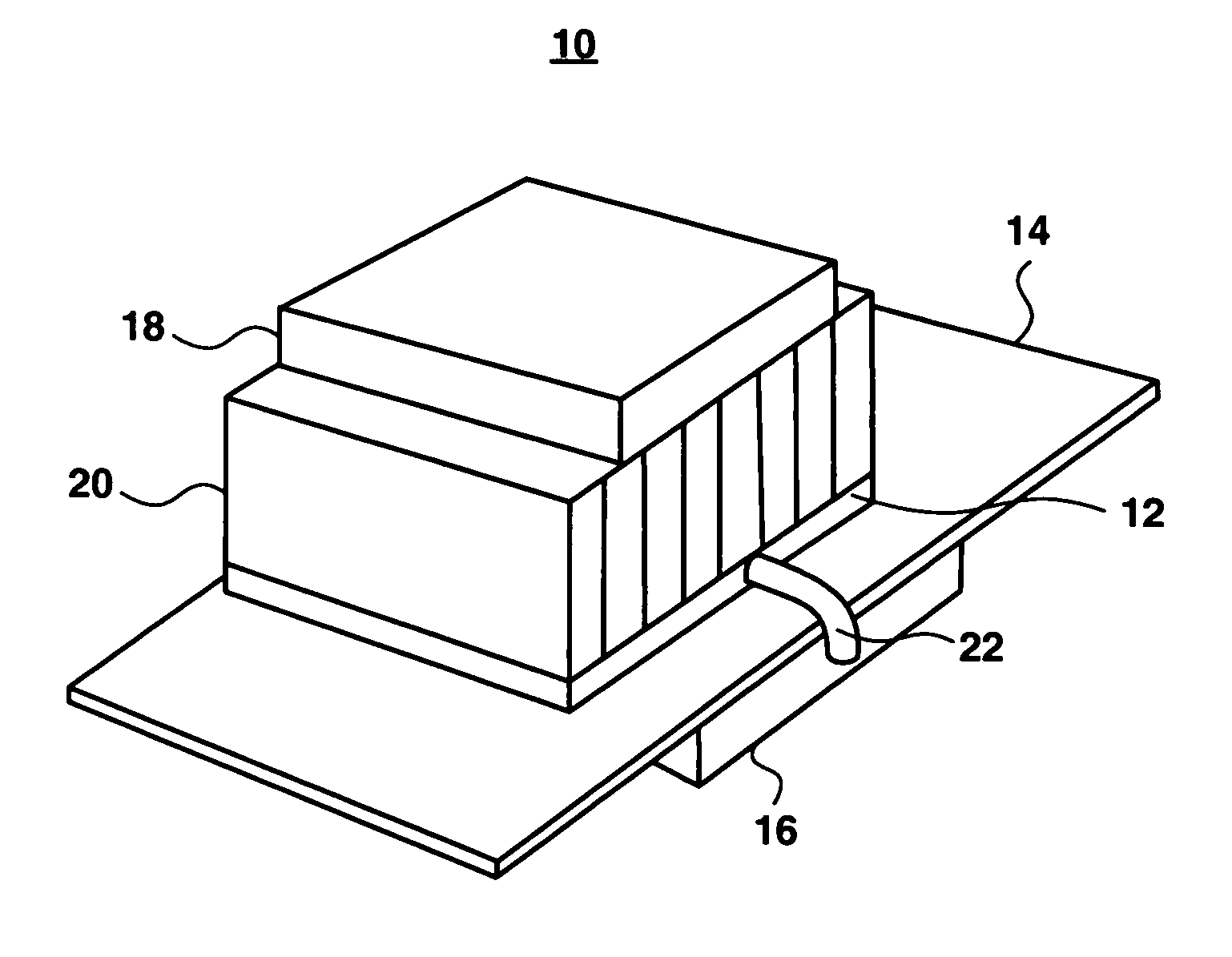

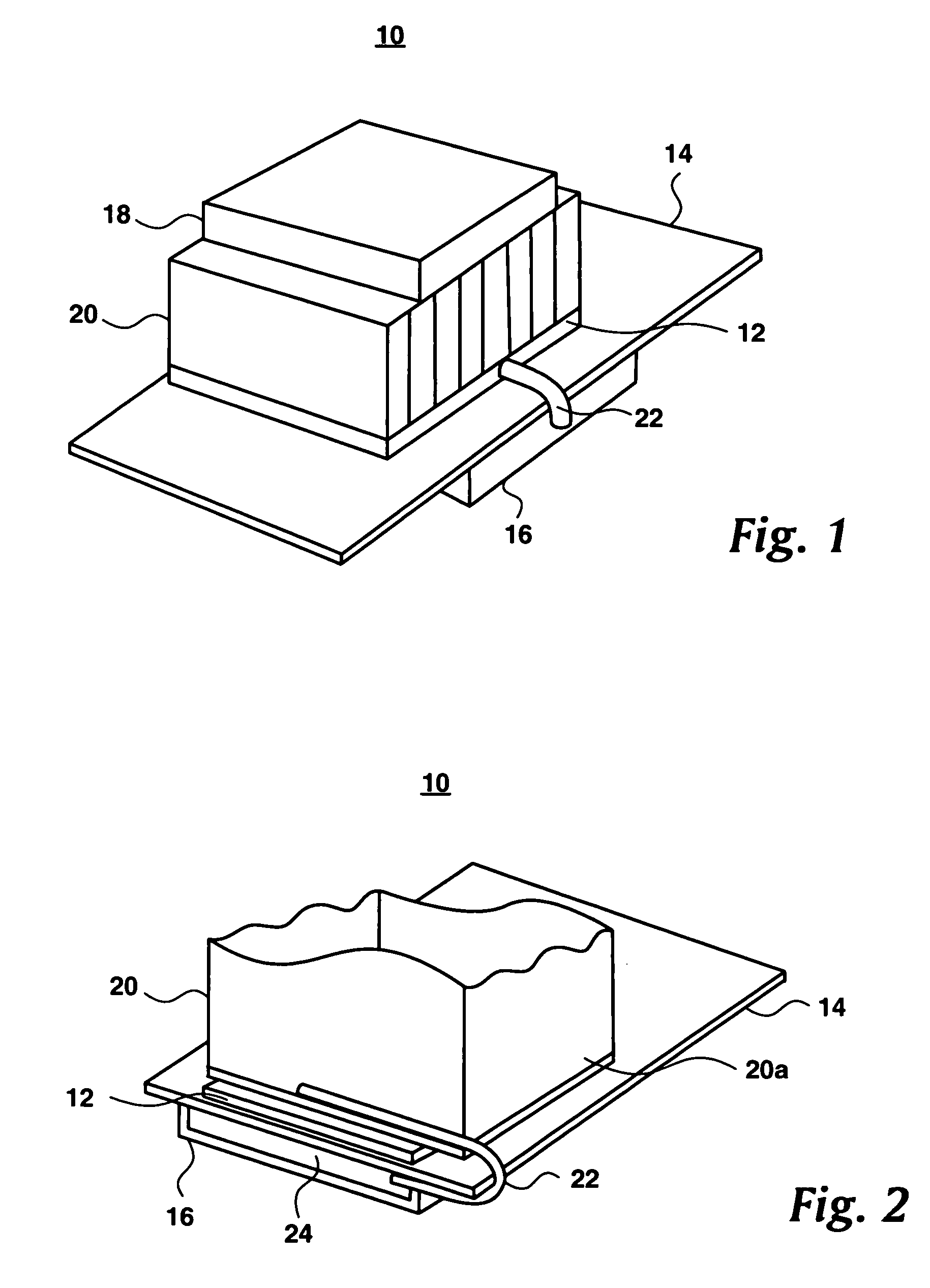

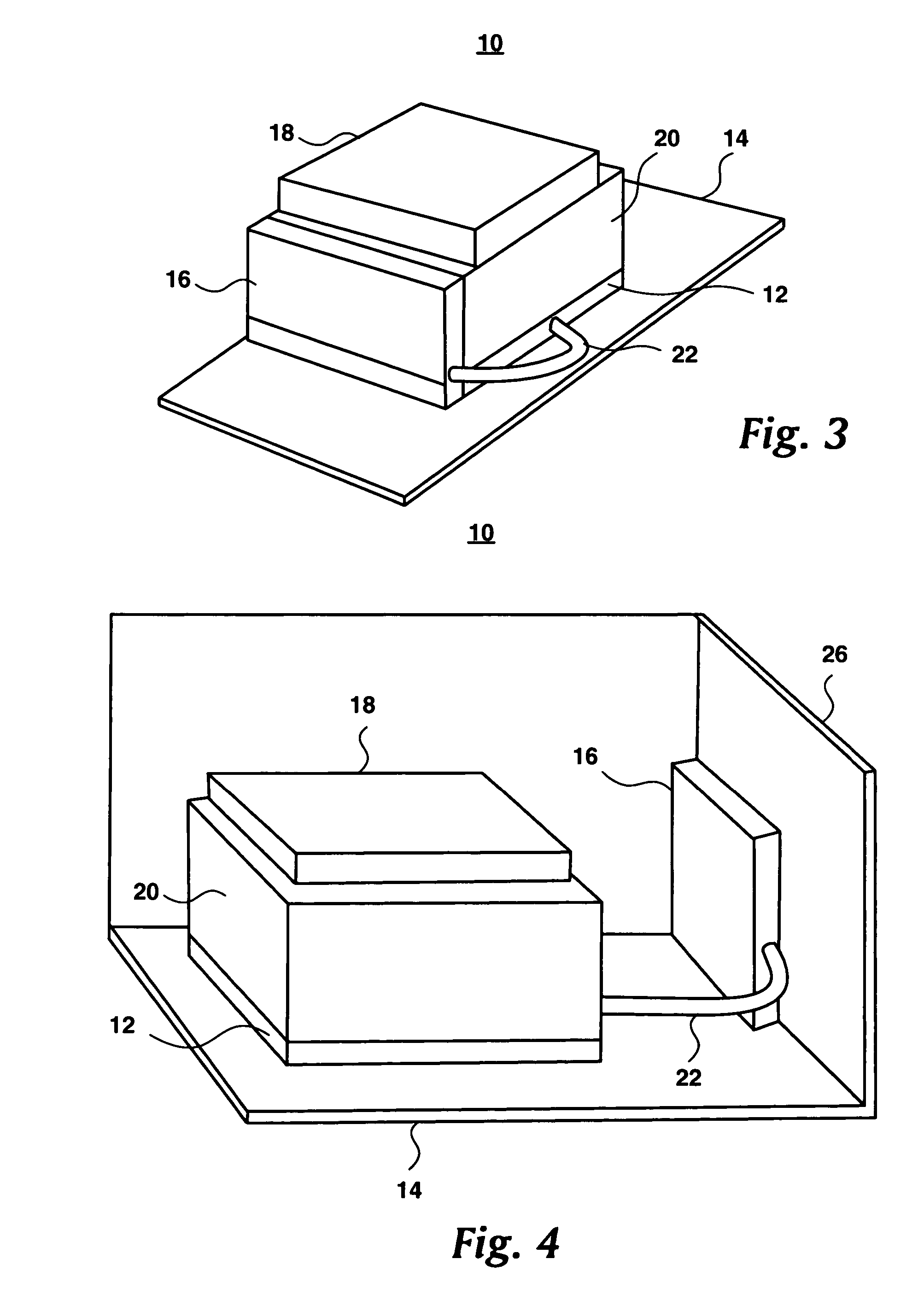

Acoustic and thermal energy management system

ActiveUS7116555B2Reduce usageReducing the acoustic signature of the electronic deviceDigital data processing detailsSemiconductor/solid-state device detailsThermal energyAcoustic energy

An acoustic and thermal energy management system and method comprising a microprocessor and a thermal mass positioned at a distance from the microprocessor, the microprocessor and thermal mass being thermally connected to the microprocessor in a manner to transfer thermal energy from the microprocessor to the thermal mass. The acoustic and thermal energy management system transferring heat from the microprocessor to a thermal mass for dissipation reducing the level of heat at the microprocessor, thereby limiting the operation of or the operation level of a fan.

Owner:INT BUSINESS MASCH CORP

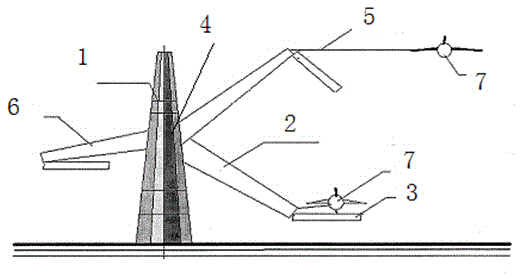

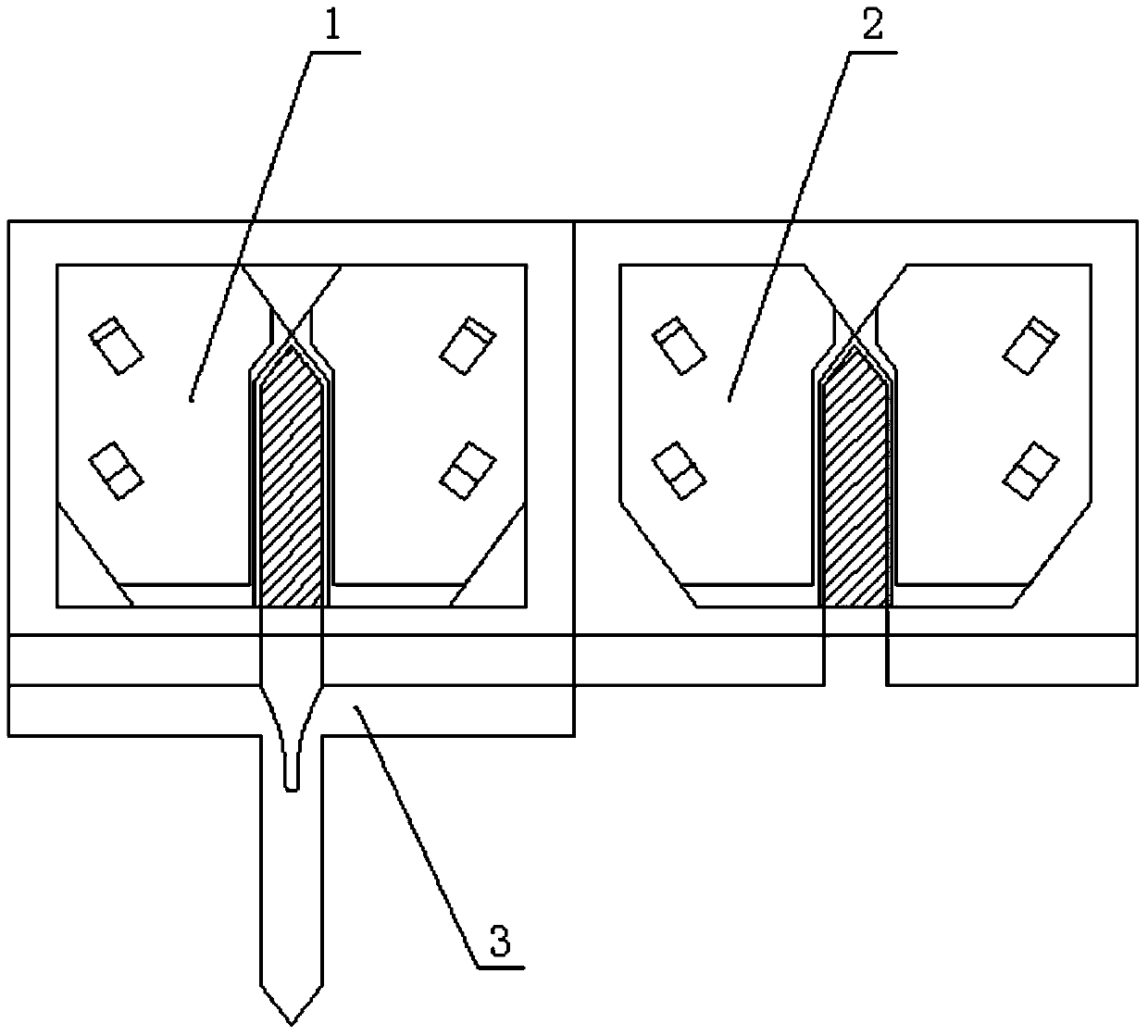

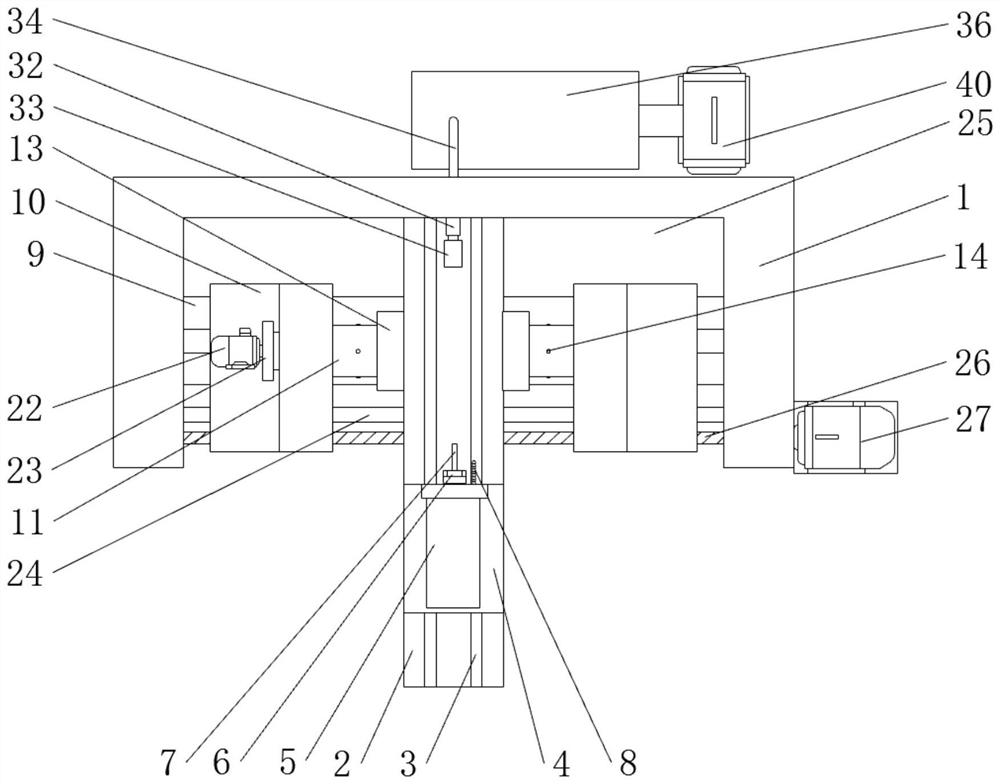

Device for launching and landing aircrafts

InactiveCN104058100AImprove people's livelihoodStrong defenseArresting gearLaunching/towing gearRotational axisFlight vehicle

The invention discloses a device for launching and landing aircrafts. The device comprises a fixedly arranged rotary launching tower, wherein a rotating shaft is arranged at the middle part of the rotary launching tower; a group of rotating arms extending outwards is arranged on the rotating shaft, one end of each rotating arm is hinged to the rotating shaft, and a bearing platform capable of adjusting an angle of inclination is arranged at the extending end of each rotating arm; telescopic flexible elastic ropes matched with the aircrafts are arranged at the extending ends of the rotating arms. The device adopts a brand-new launching and landing manner for the aircrafts, and a large-area runway is not needed, so that a heavy investment is saved; a plurality of aircrafts can be launched at the same during launching, so that the time is reduced compared with the time used during conventionally successive launching; the device is high in controllability and high in reliability, and the requirement for the operant level of navigating mates of the aircrafts is low.

Owner:杨举 +1

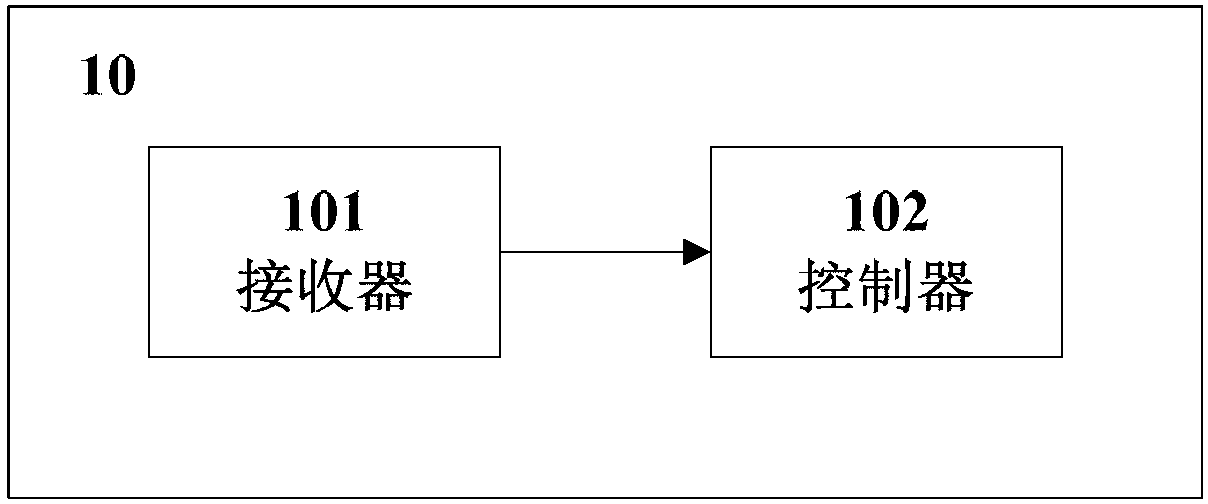

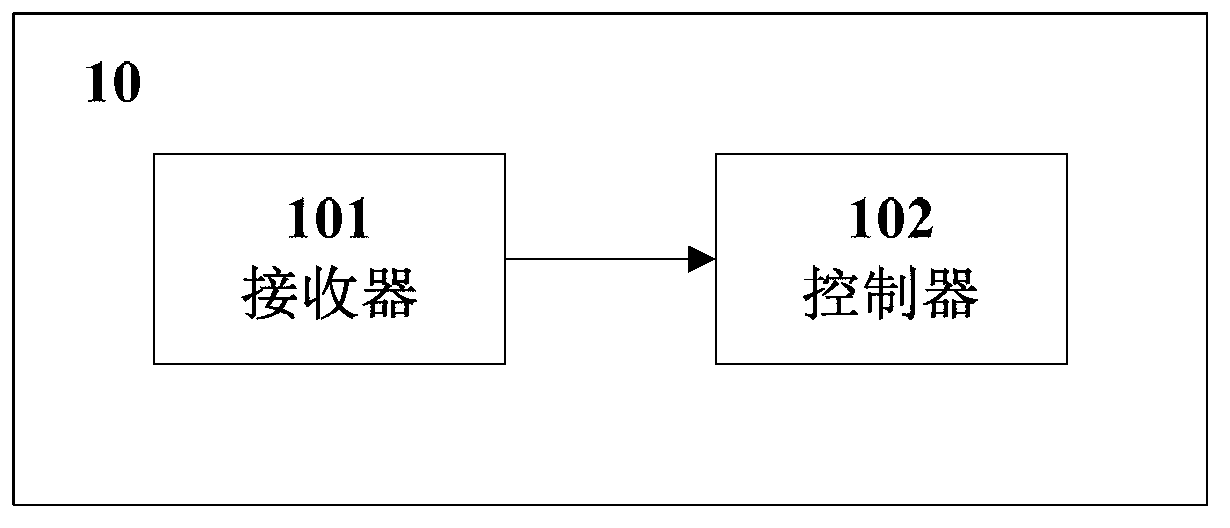

Intelligent arm support control device, system and method and engineering machine

ActiveCN103309352AReduce workloadLow level of operation requiredTarget-seeking controlBuilding material handlingCoordinate changeEngineering

The invention discloses an intelligent arm support control device, system and method and an engineering machine. An arm support comprises multiple connected arm sections. The intelligent arm support control device comprises a receiver and a controller. The receiver is used for receiving a current dip angle of each arm section and a current coordinate and a target coordinate of the tail end of the arm support. The controller is connected with the receiver and is used for confirming the expected coordinate change quantity of the tail end of the arm support according to the current coordinate and the target coordinate of the tail end of the arm support, changing the sequence and maximum allowable values of the dip angles changed for each time according to the expected coordinate change quantity, calculating the current dip angle of each arm section and preset dip angles, and dip angle change quantity of arm sections required to be adjusted and adjusting corresponding arm sections according to the dip angle change quantity. By adopting the technical scheme and after the target coordinate of the tail end of the arm support is set, the arm support can be automatically unfolded to be in a posture corresponding to the target coordinate, manual intervention is not required, the working amount of a machinist is decreased, the requirements for operating level and experiences of the machinist are reduced, and the working efficiency is improved.

Owner:ZOOMLION HEAVY IND CO LTD

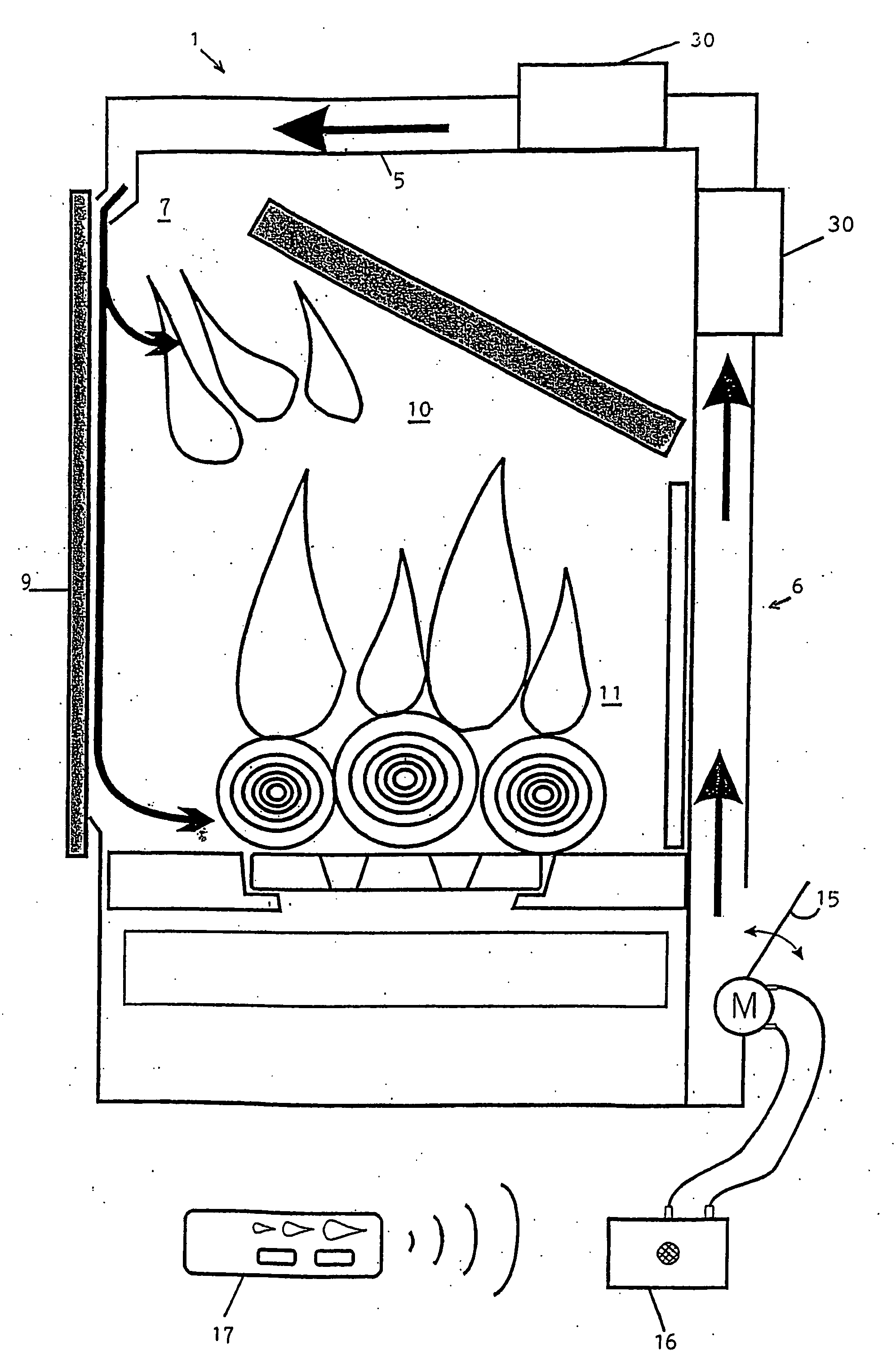

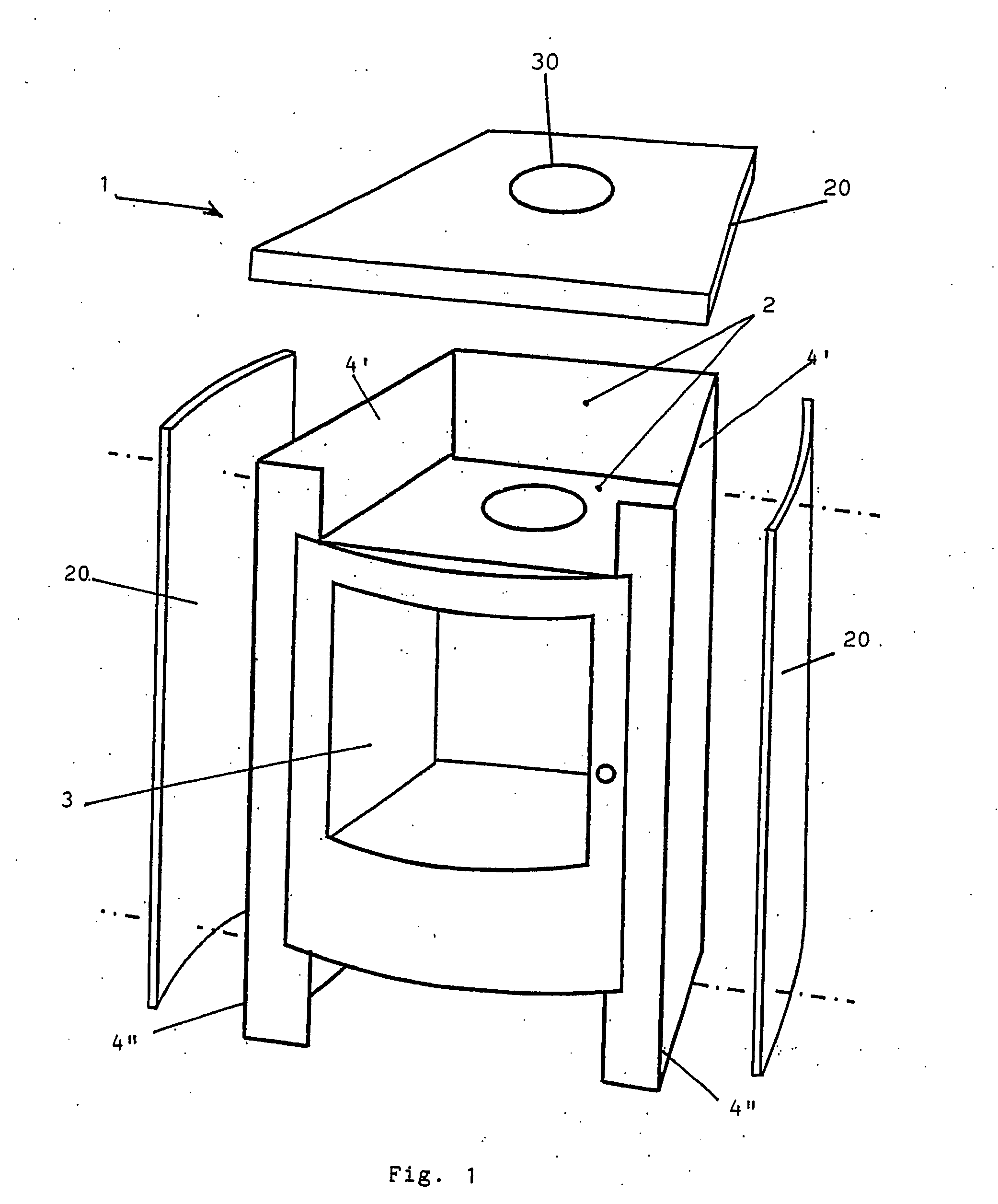

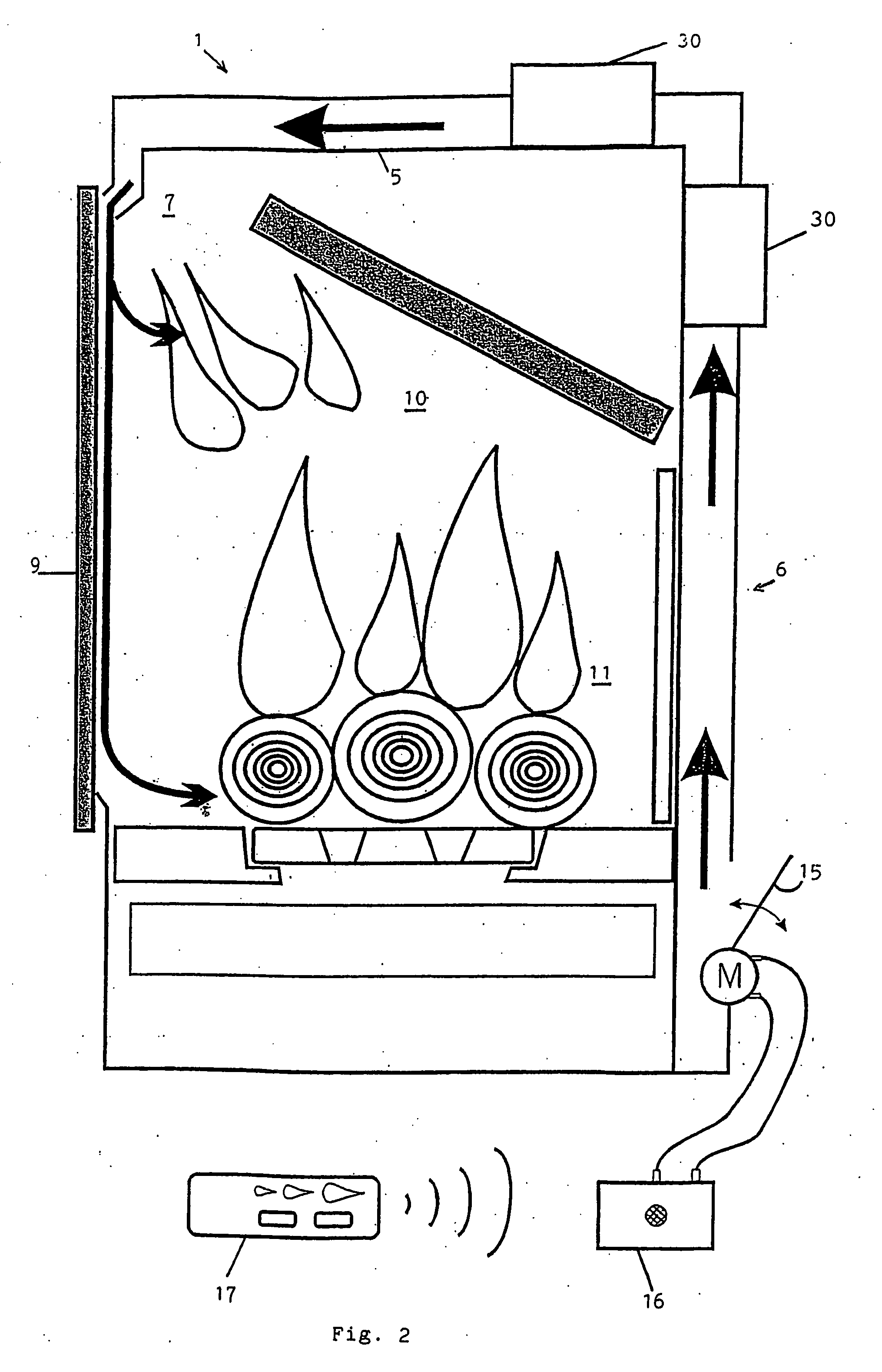

High output heating device

InactiveUS20050279344A1Increase productionReduce consumptionDoors for stoves/rangesCombustion-air/flue-gas circulation for stovesCombustion chamberEngineering

The invention concerns a multiple-fuel heating apparatus wherein: the combustion chamber (1) forms the main support structure of the heating apparatus and is made of sheet metal bent and welded (2) so as to be completely sealed, optionally except at the joint with said door; the elements (20) forming the outer cover are fixed to the combustion chamber, the fixing elements not passing through the chamber and said elements not being necessarily fixed together.

Owner:THERMIC INVESTMENTS

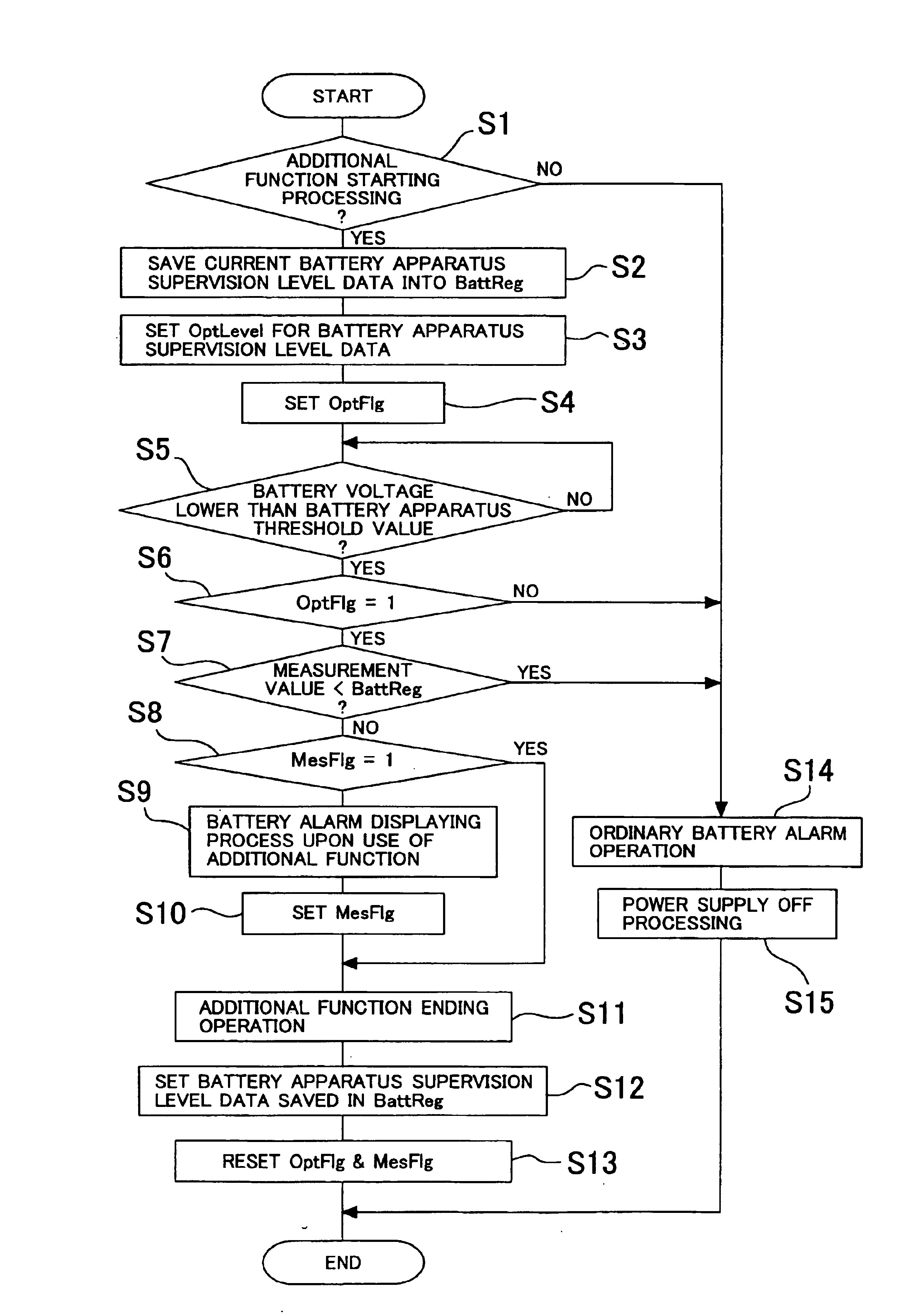

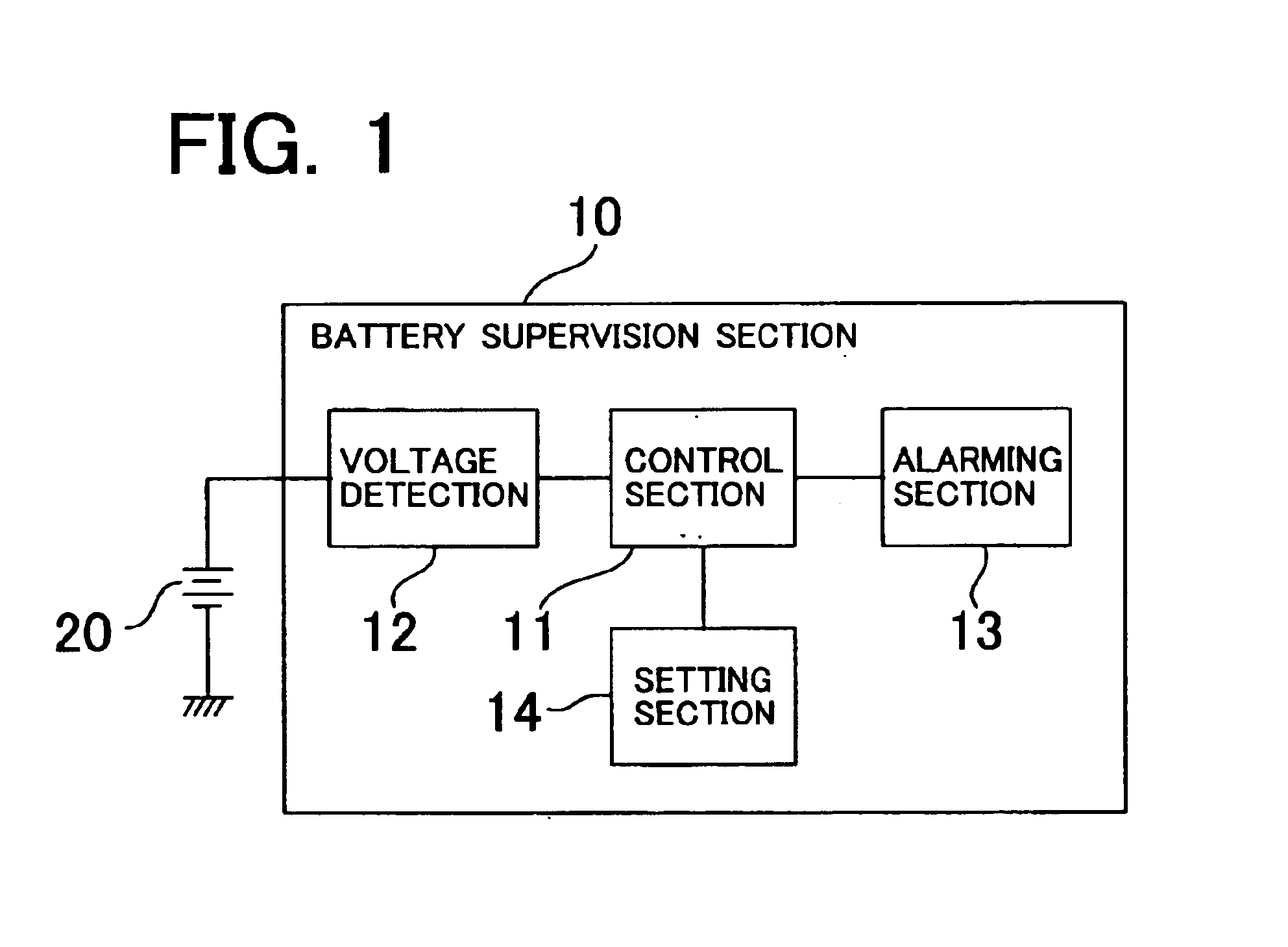

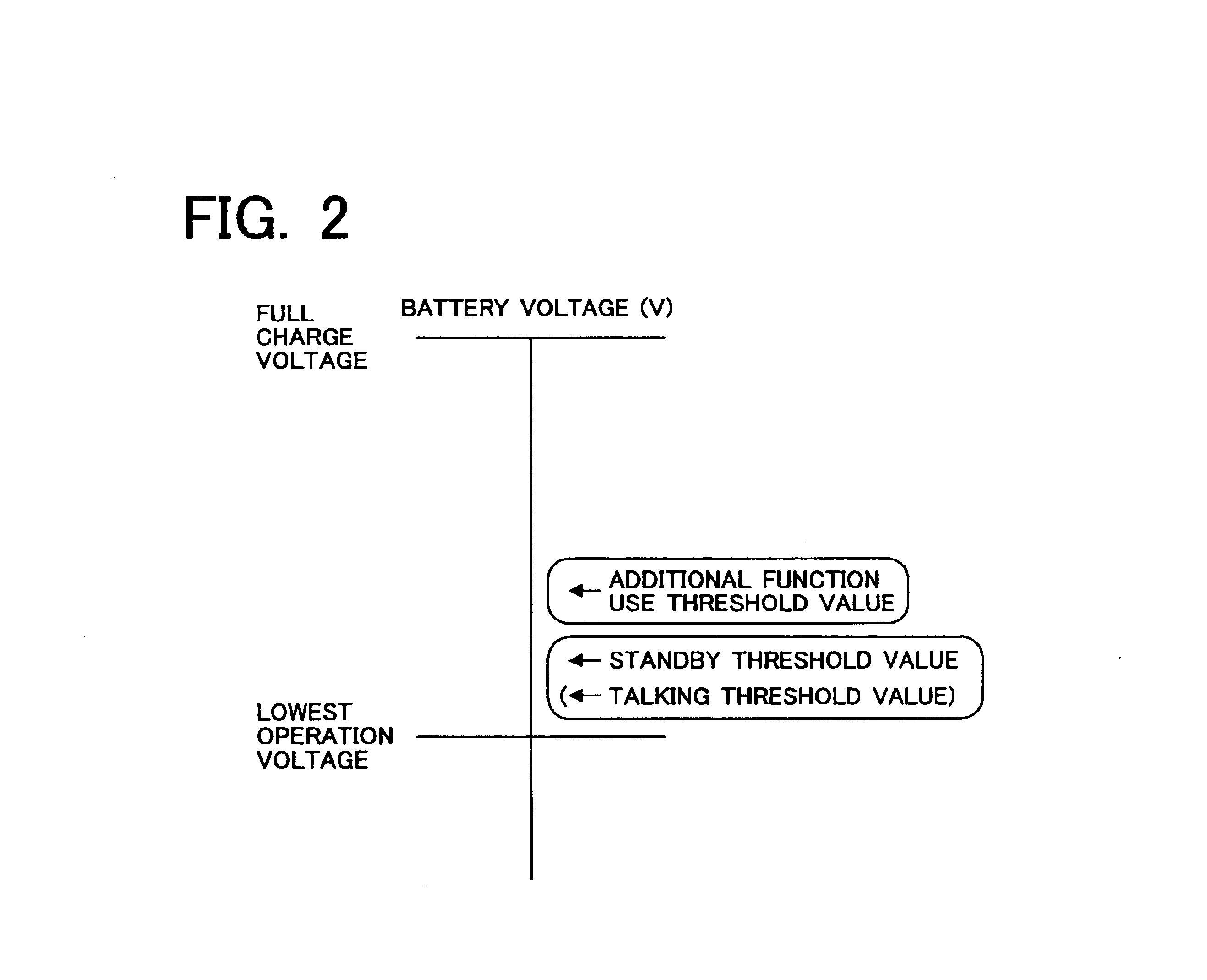

Portable telephone with a battery alarm function indicating lowest level for communication

InactiveUS6898446B2Low working voltageMultiple functionsCordless telephonesPower managementRechargeable cellVoltage drop

A portable telephone apparatus including a battery alarm function wherein consumption of a battery apparatus through use of an additional function other than a talking function can be prevented to assure a lowest operation voltage for the talking function. The portable telephone apparatus includes a rechargeable battery, and a battery supervision section. The battery supervision section includes a voltage detection section for supervising and detecting a voltage of the battery controlled by a control section, and an alarming section for issuing a lowest operation voltage level alarm under the control of the control section when the detected voltage drops to a lowest operation voltage level that a talking function of the portable telephone apparatus can operate. The alarming section issues a supervision voltage level alarm when the detected voltage of the battery drops to a supervision voltage level different from the lowest operation voltage level.

Owner:LENOVO INNOVATIONS LTD HONG KONG

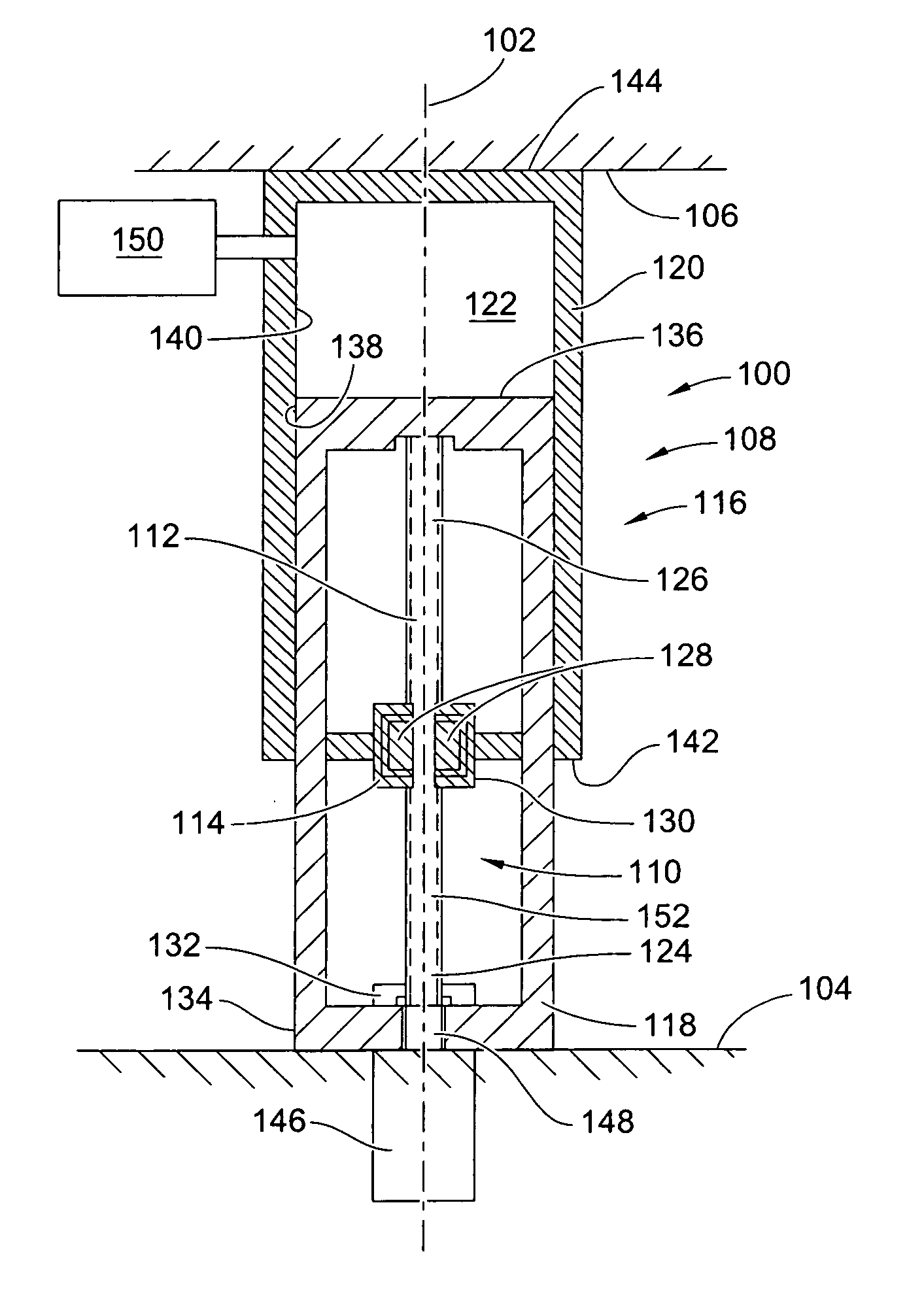

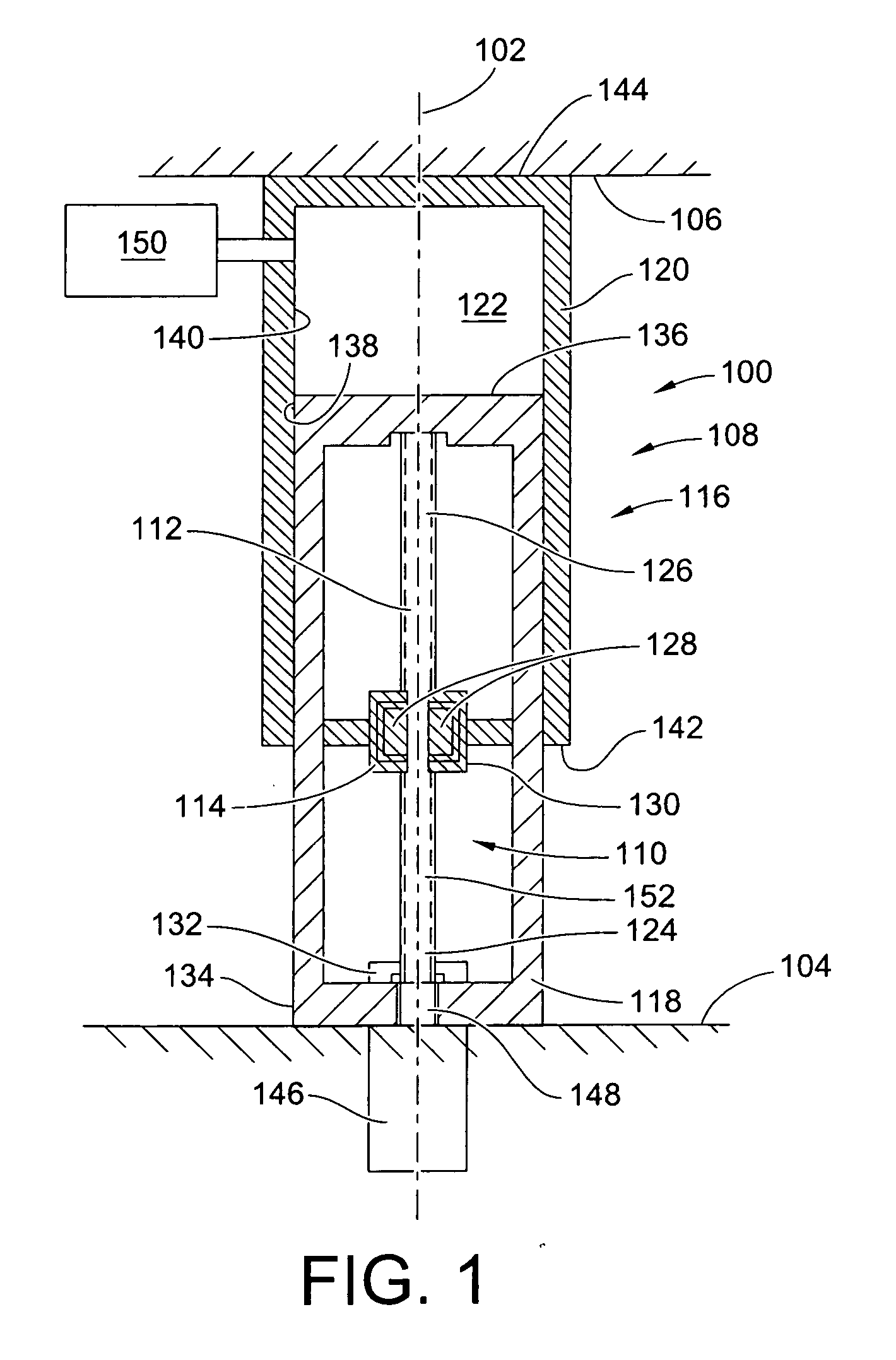

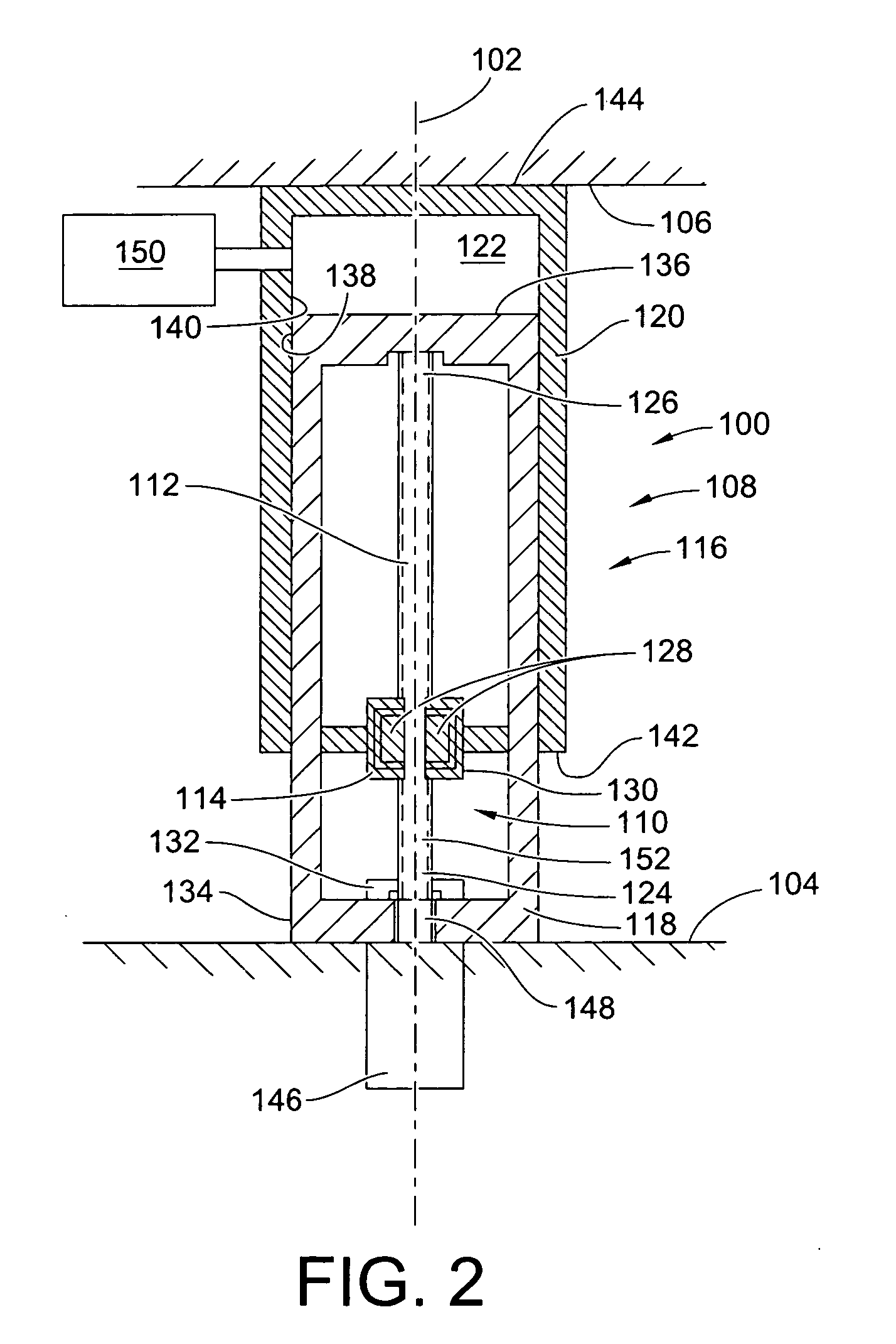

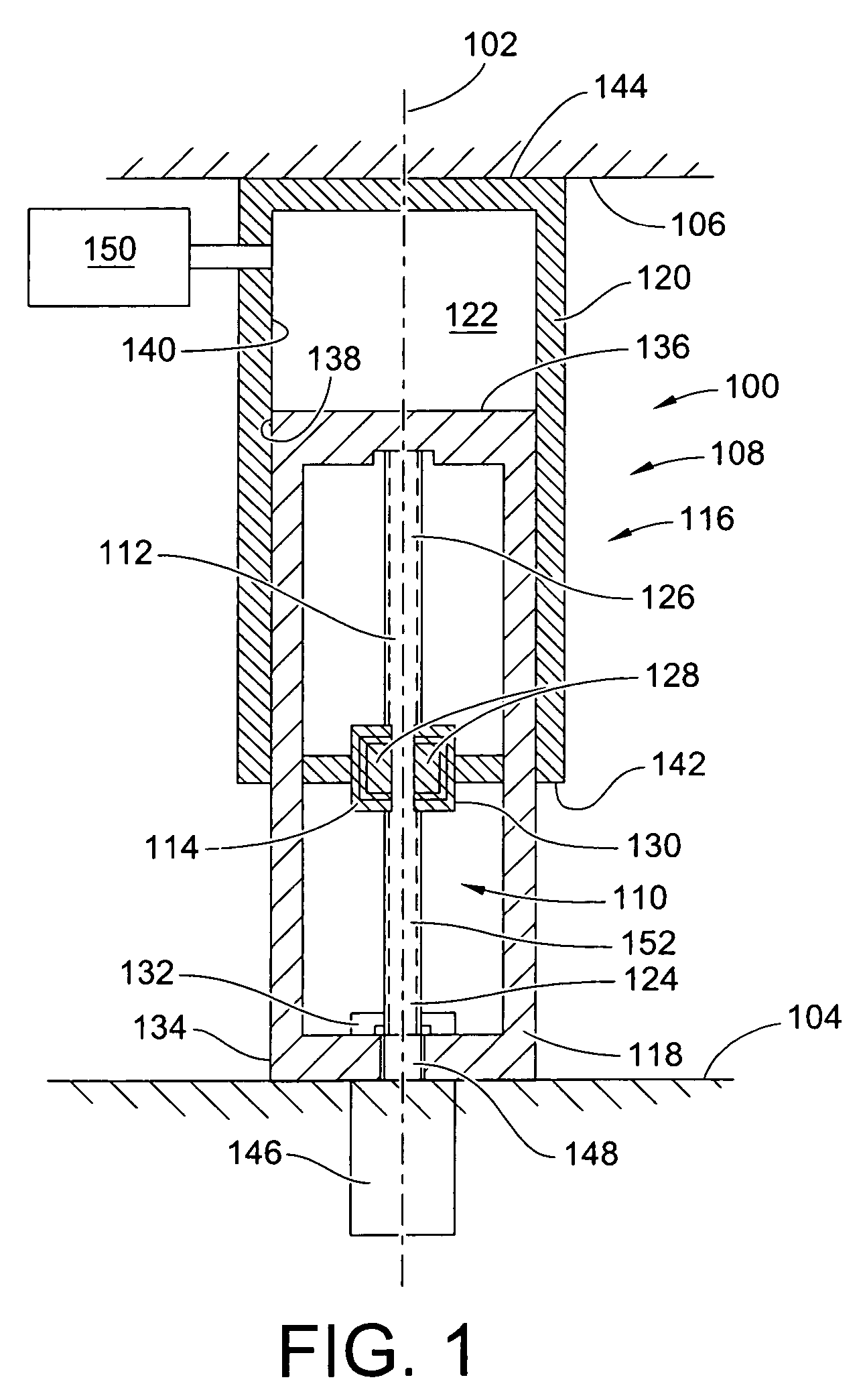

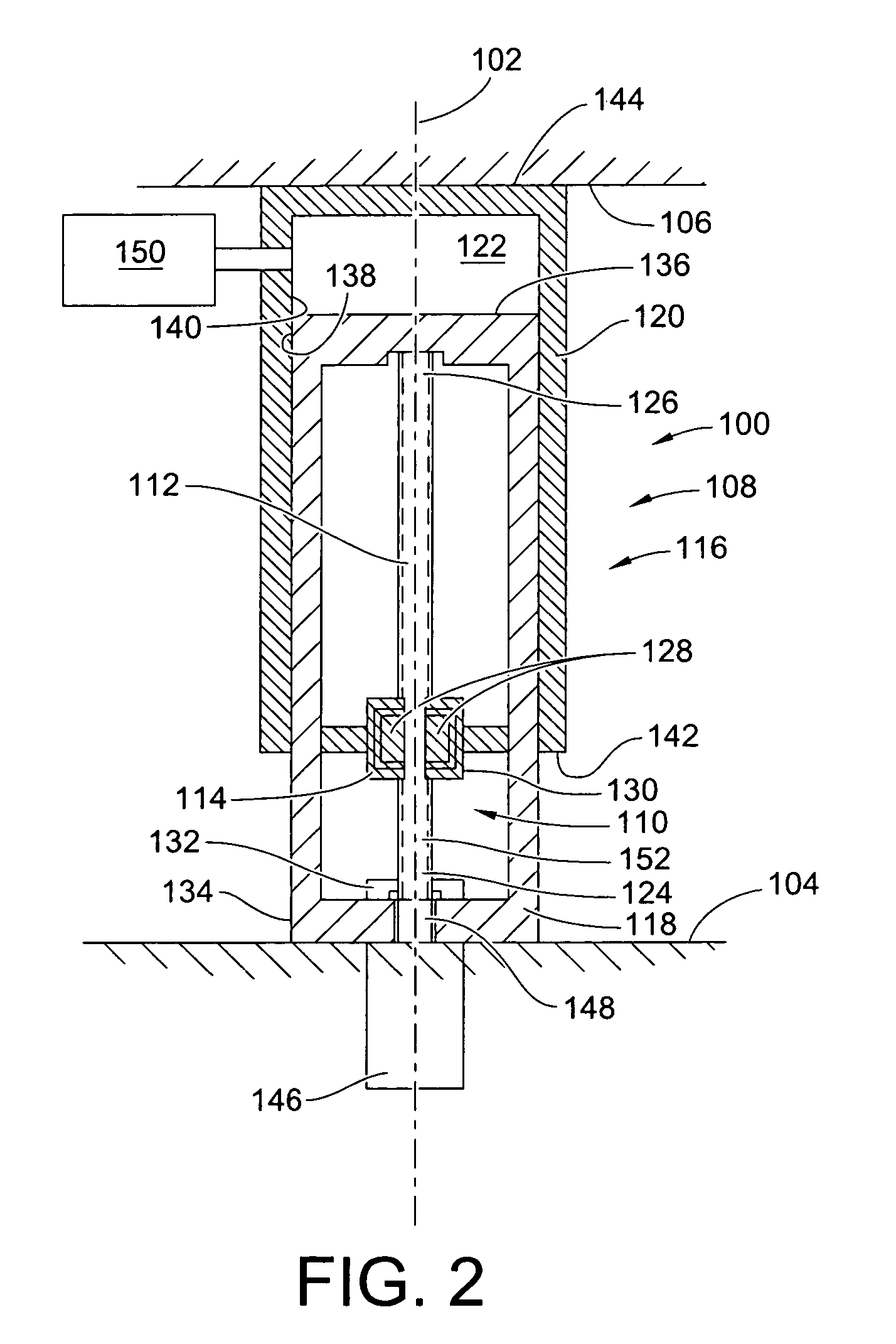

Pneumatic biasing of a linear actuator and implementations thereof

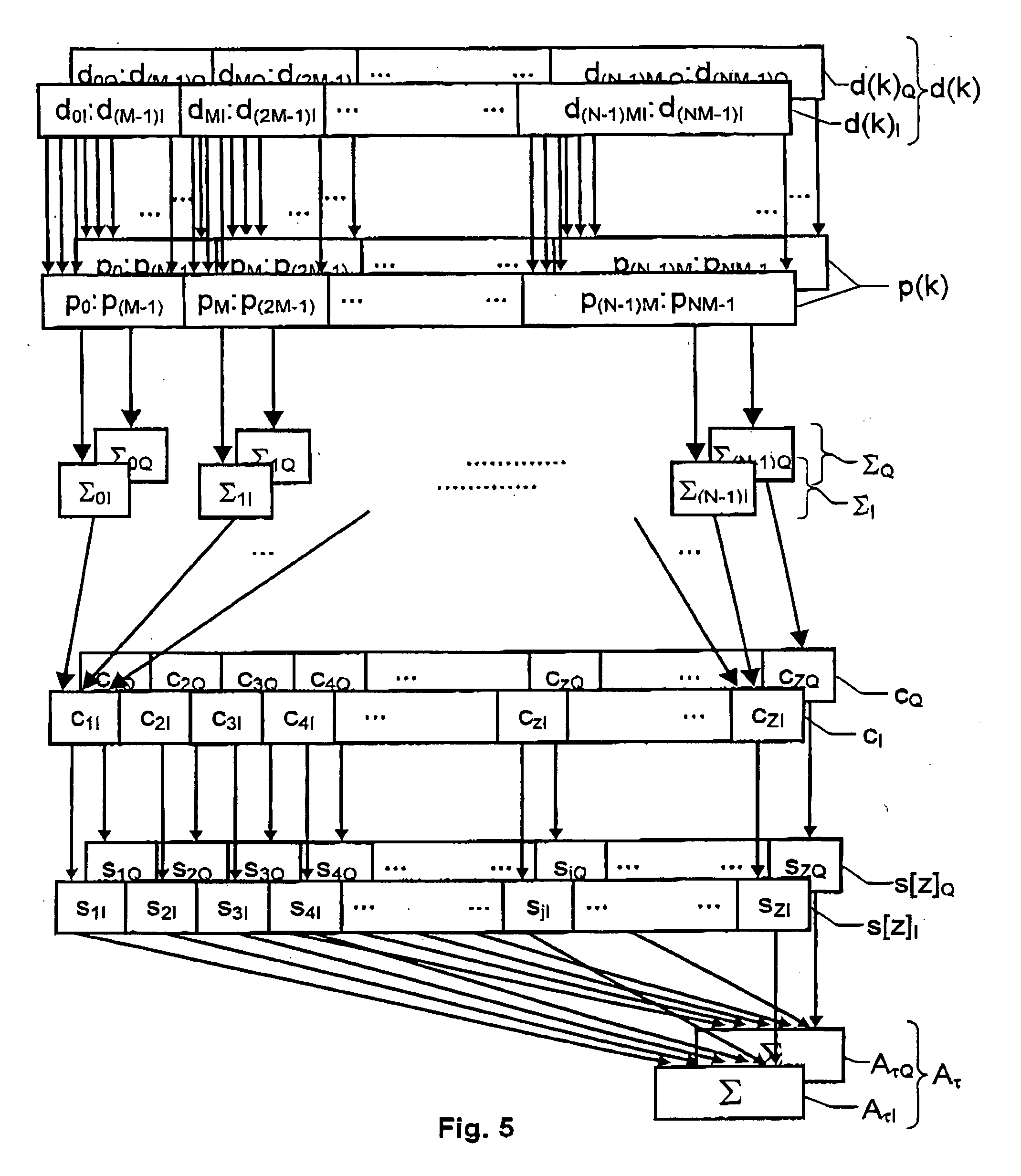

InactiveUS20070068399A1Improve operationImprove reliabilityServomotor componentsShaping safety devicesImproved methodLinear actuator

An improved method and apparatus are provided for constructing and operating a linear actuator, and equipment incorporating a linear actuator, by operatively connecting a pressure biasing pneumatic arrangement between the driving member and the driven member of a mechanical linear actuator for applying a unidirectional biasing force between the driving and driven members, along an axis of motion, regardless of the location or movement of the driving and driven elements with respect to one another along the axis of motion. The pneumatic biasing arrangement is also configured, connected and operated to reduce the force which must be exerted by the driving and driven members in extending and retracting the linear actuator. The pneumatic biasing arrangement may further be configured for preferentially aiding extension or retraction of the actuator.

Owner:UNICO LLC

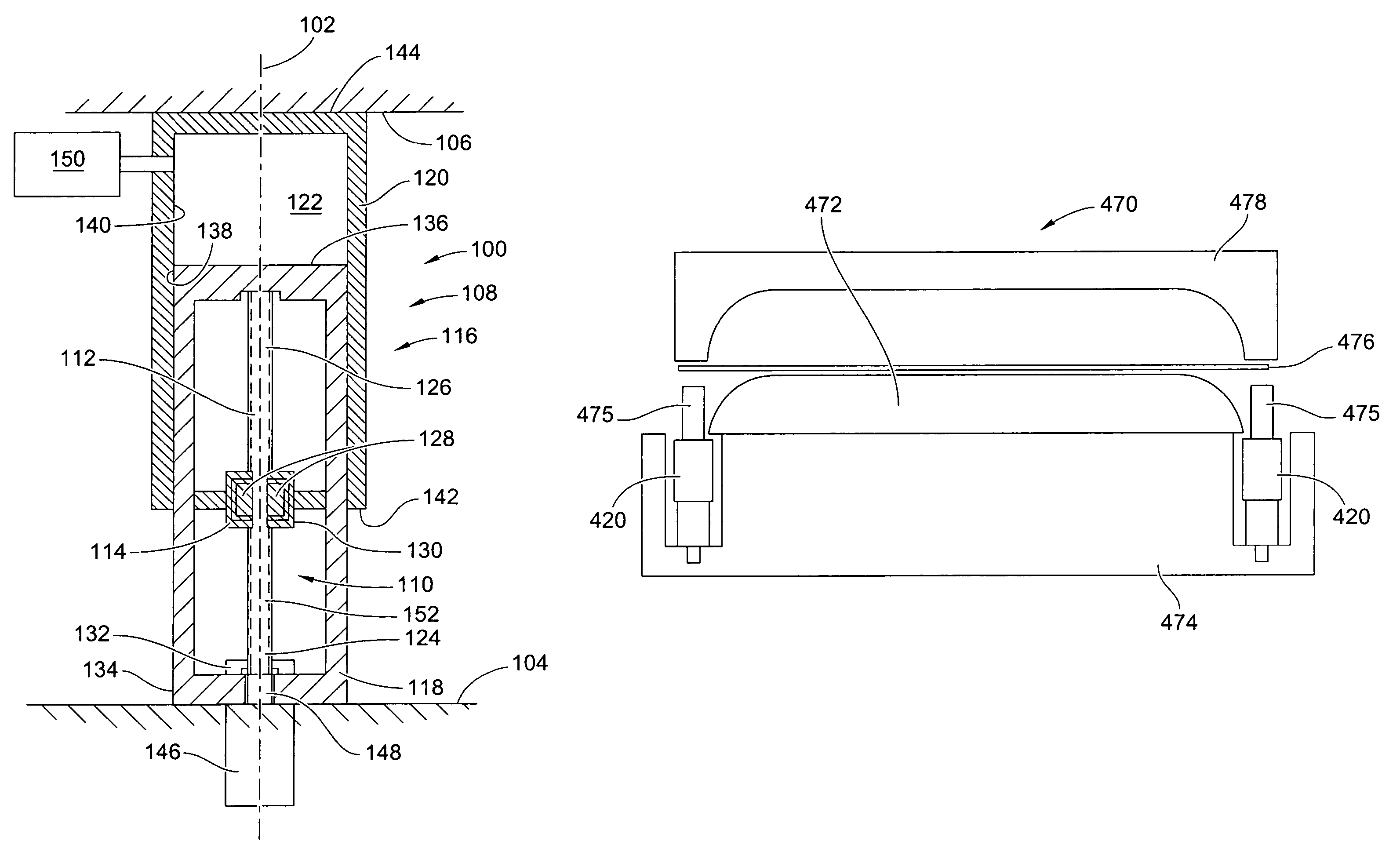

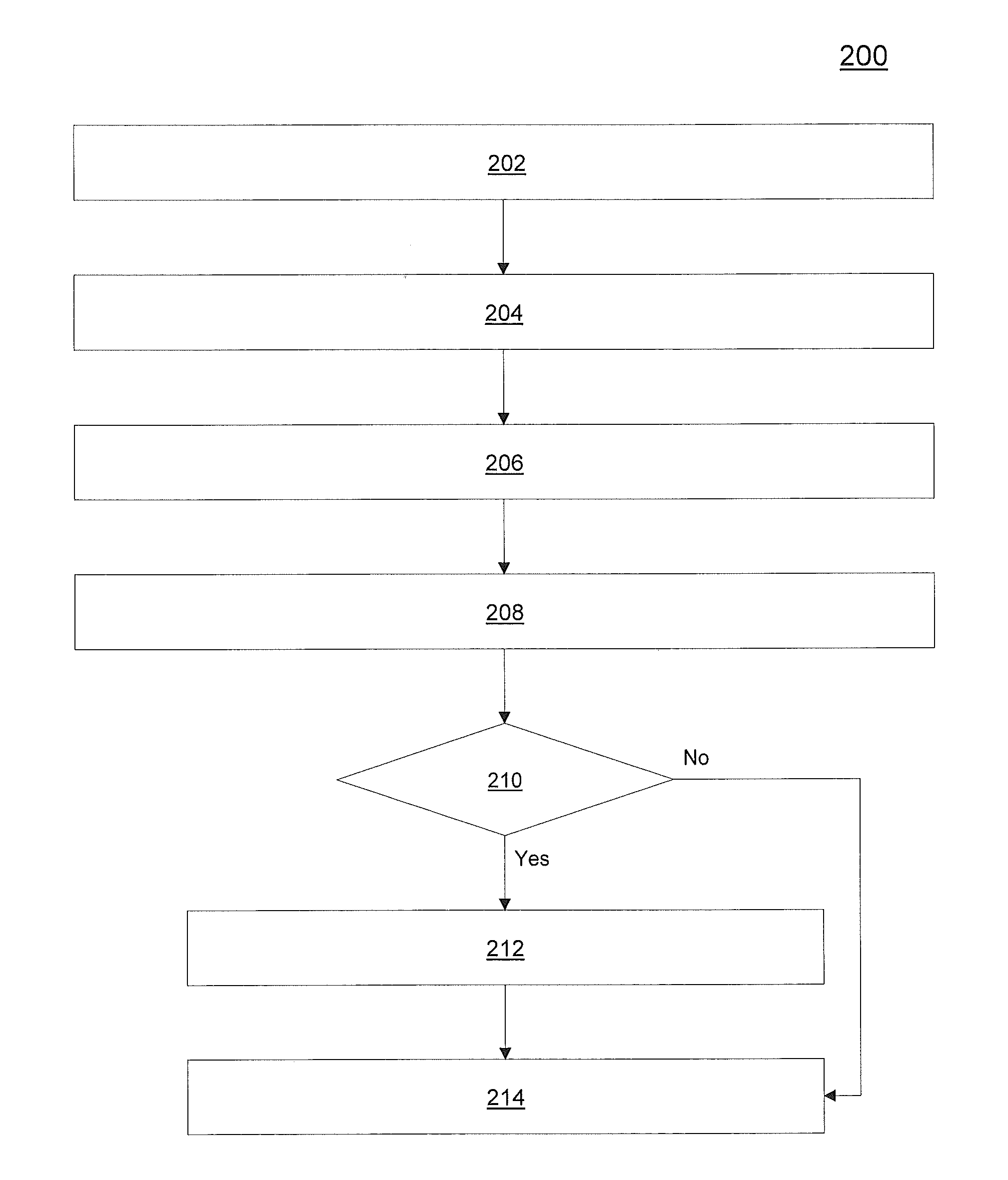

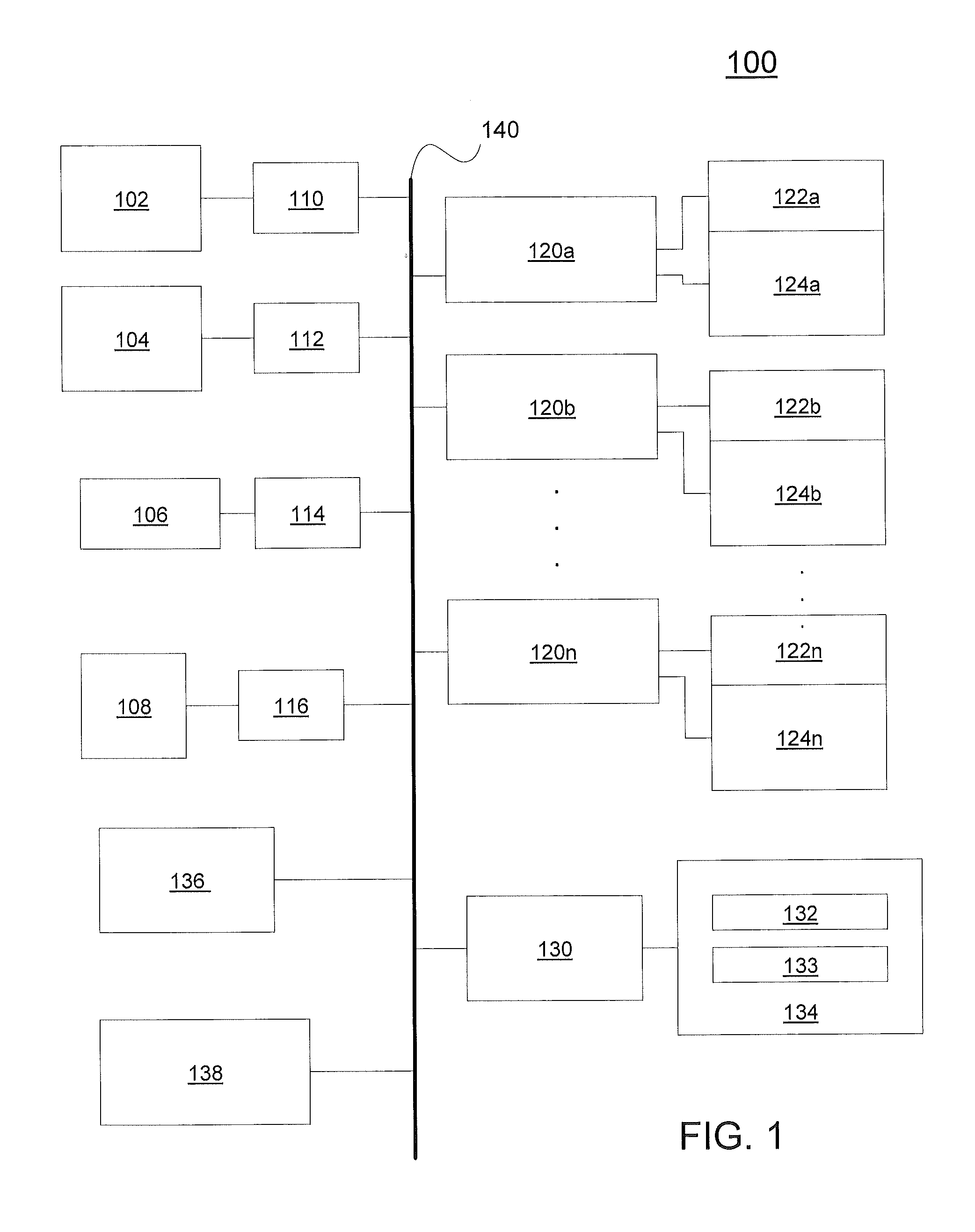

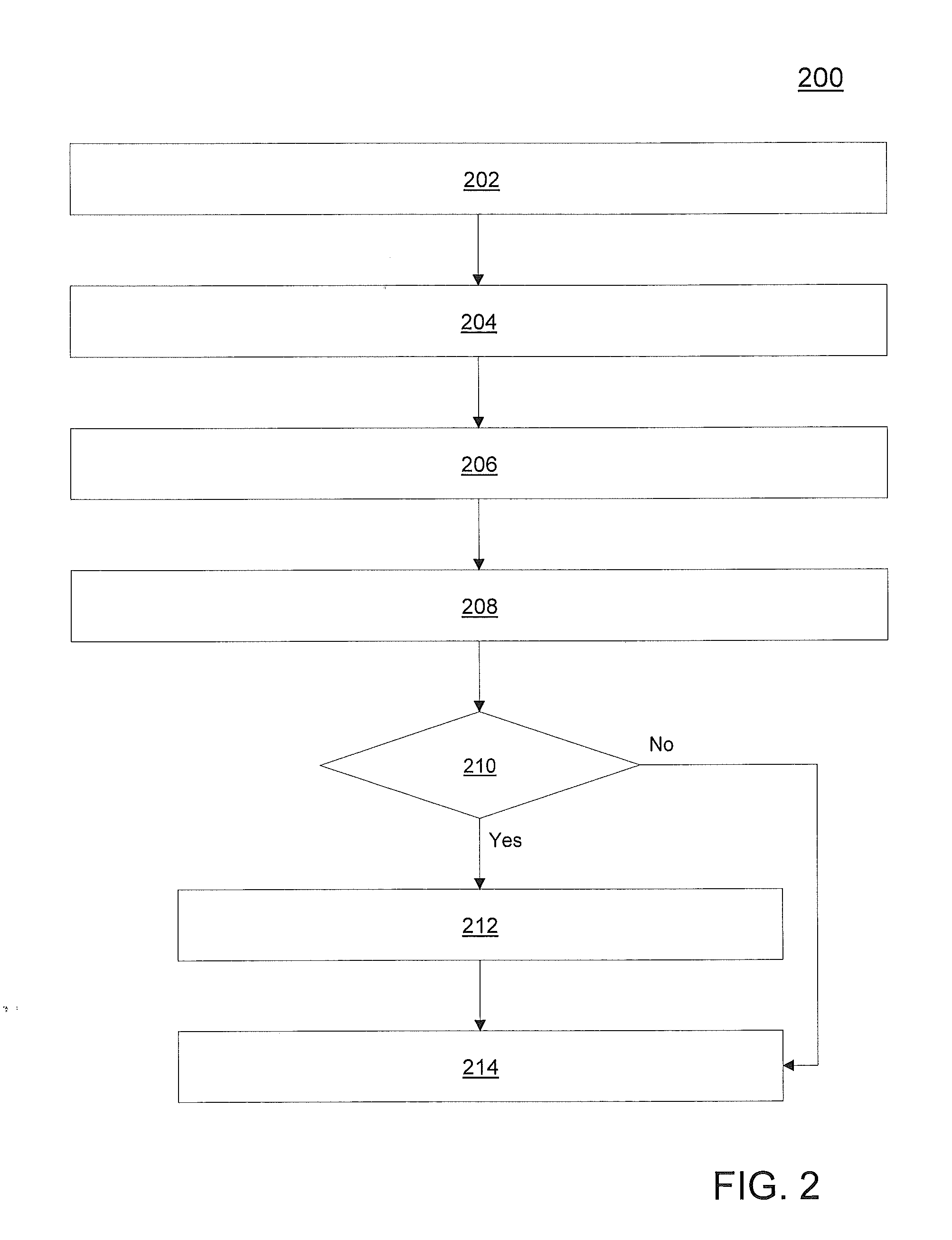

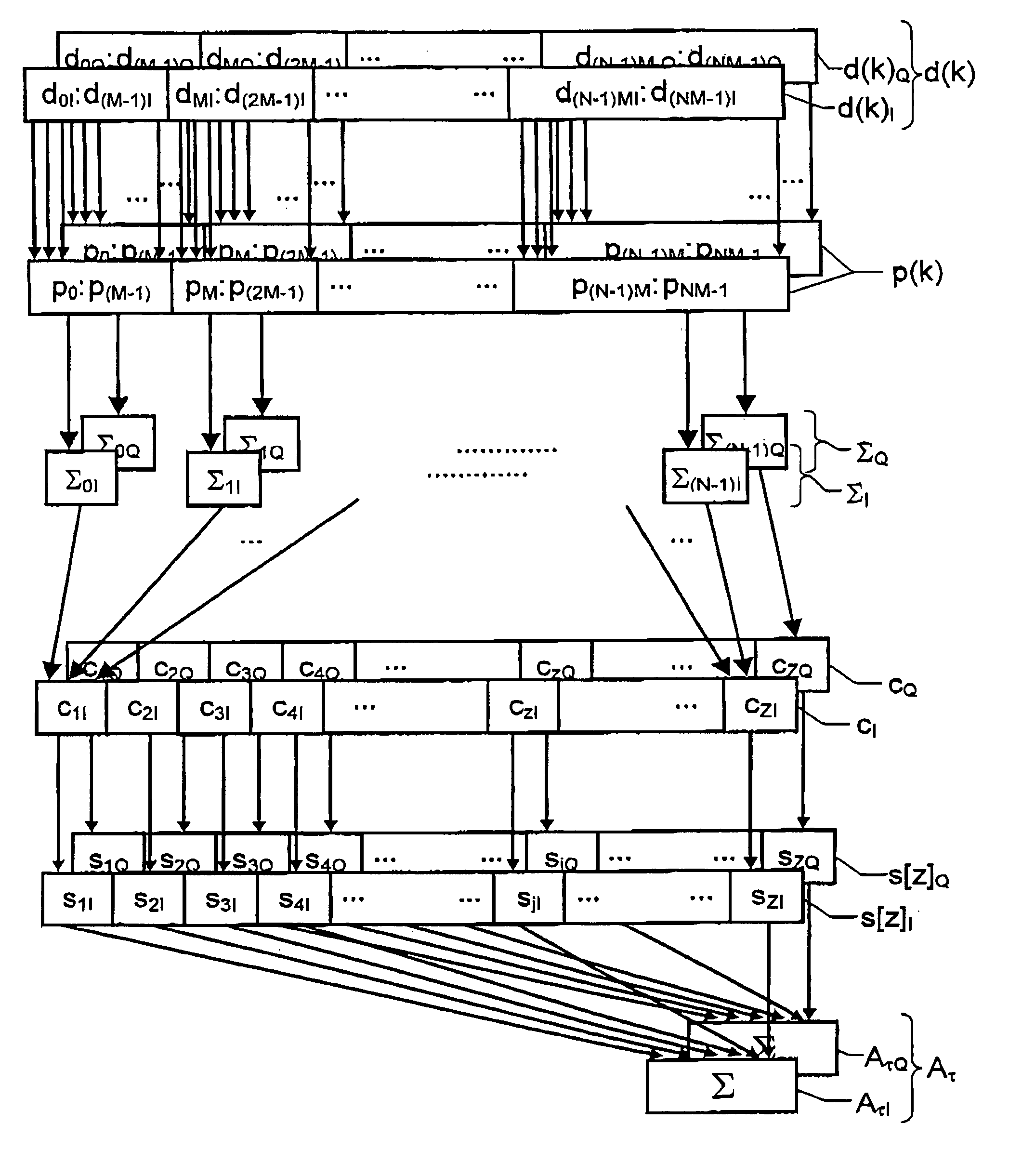

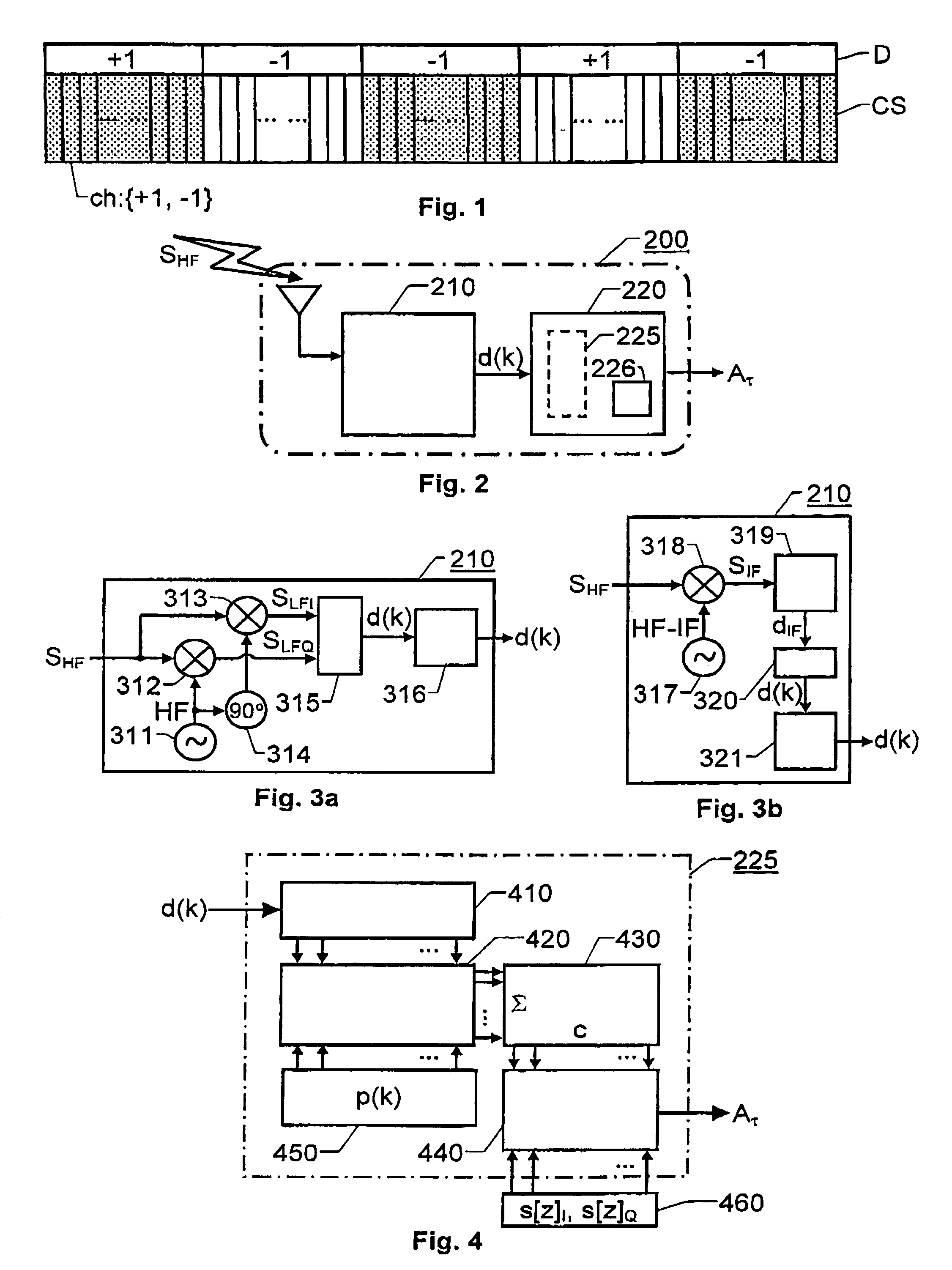

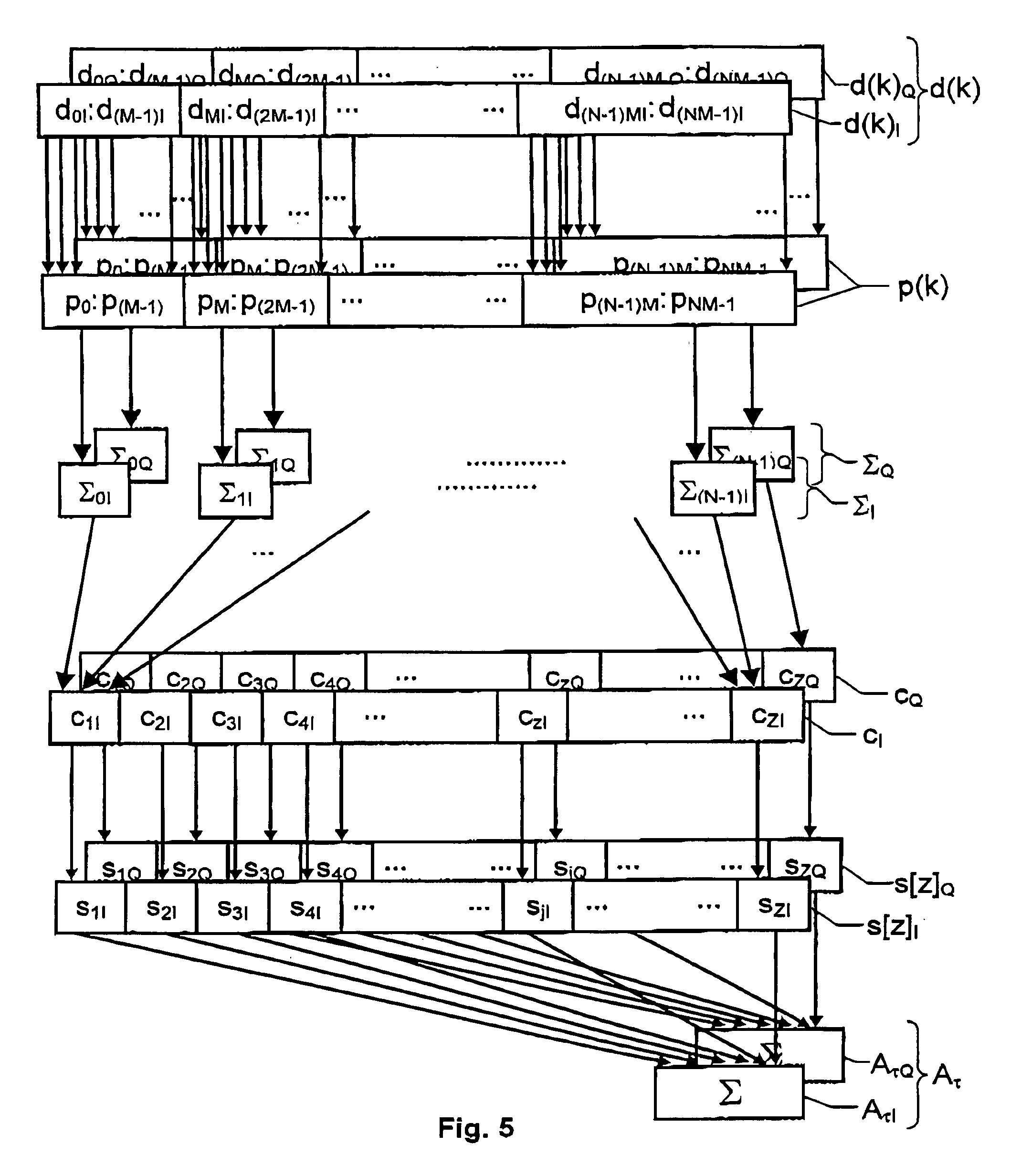

Software based spread spectrum signal processing

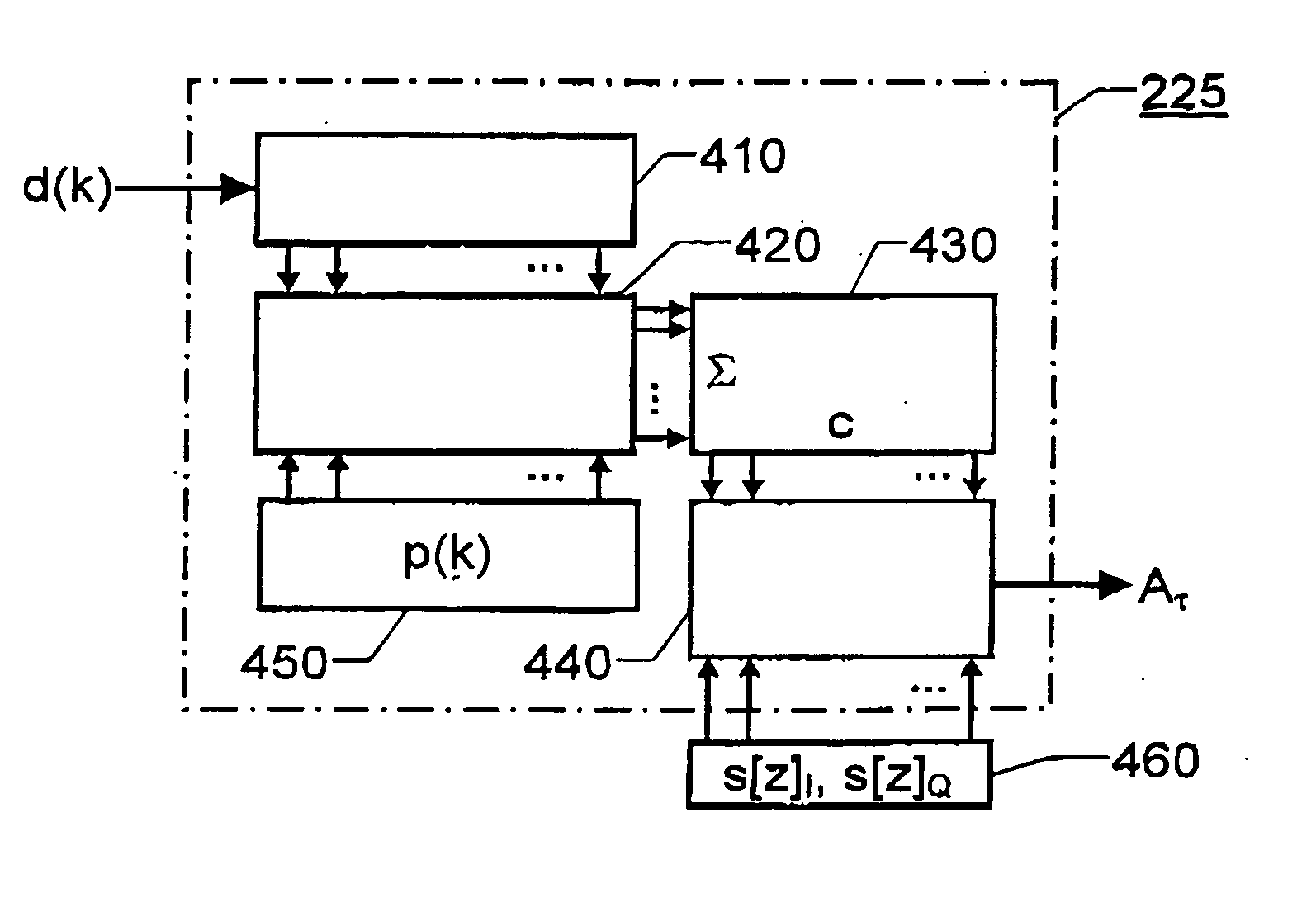

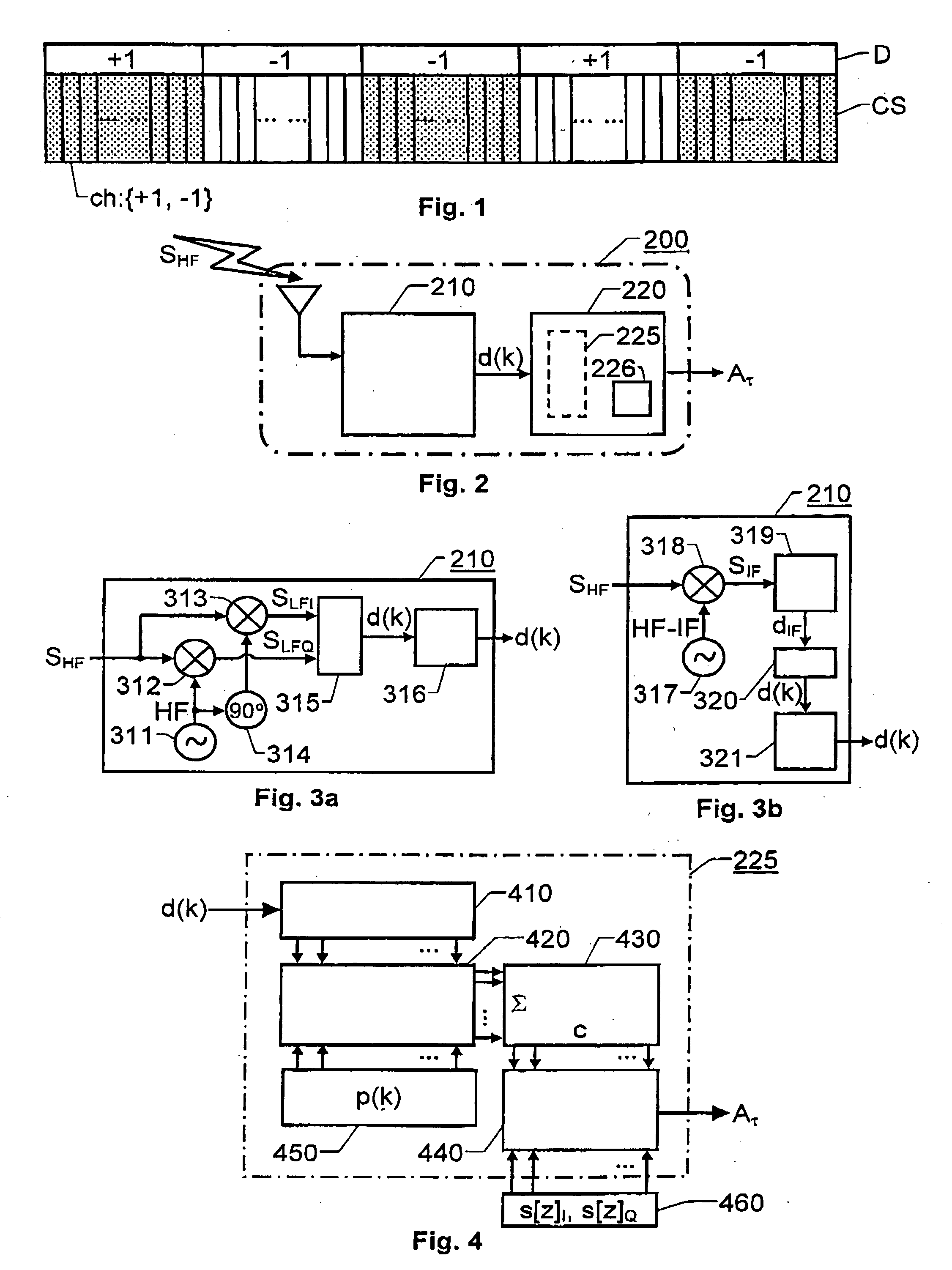

ActiveUS20060274822A1Reduce in quantityReduce memory requirementsFrequency-division multiplexOrthogonal multiplexData streamComputer science

The present invention relates to production of a decoded signal (Aτ) based on in an incoming stream of data samples (d(k)) representing at least one downconverted digitized spread spectrum source signal. A number (NM) of the received data samples (d(k)) are divided into a first number (N) of data blocks, where each data block contains a second number (M) of samples. The second number (M) is an integer larger than or equal to two. Each of the data blocks is then correlated with a respective local code replica segment (p(k)) to produce a first number (N) of intermediate accumulation results (ΣI; ΣQ). To enable production of a decoded signal (Aτ) being compensated for a Doppler shift relative to a downconverting frequency for the least one spread spectrum source signal, the intermediate accumulation results (ΣI; ΣQ) are correlated with a carrier vector (s[z]I; s[zQ) expressing such a Doppler shift. However, according to the invention, the carrier vector (s[z]I; s[z]Q) only contains a target number (Z) of carrier values (s1I:sZI; s1Q:sZQ) (i.e. different carrier amplitude levels), where the target number (Z) is smaller than or equal to the first number (N). Normally, the target number (Z) is substantially smaller than the first number (N). Thus, depending on the first number (N) and the target number (Z) for the relevant carrier vector (s[Z]I; s[Z]Q), a number of consecutive results of the intermediate accumulation results (ΣI; ΣQ) are combined into a number of aggregated accumulation results (c1I:cZI; c1Q:cZQ), which is equal to the target number (Z). Thereafter, the aggregated accumulation results (c1I:cZI; c1Q:cZQ) are correlated with the carrier vector (s[Z]I; s[z]Q) to produce the decoded signal (Aτ). The invention is well adapted for implementation of software GNSS receivers.

Owner:QUALCOMM TECH INT

Pneumatic biasing of a linear actuator and implementations thereof

InactiveUS7748308B2Improving reliability and operationBacklash within the mechanical actuator can be substantially eliminatedServomotor componentsShaping safety devicesEngineeringImproved method

An improved method and apparatus are provided for constructing and operating a linear actuator, and equipment incorporating a linear actuator, by operatively connecting a pressure biasing pneumatic arrangement between the driving member and the driven member of a mechanical linear actuator for applying a unidirectional biasing force between the driving and driven members, along an axis of motion, regardless of the location or movement of the driving and driven elements with respect to one another along the axis of motion. The pneumatic biasing arrangement is also configured, connected and operated to reduce the force which must be exerted by the driving and driven members in extending and retracting the linear actuator. The pneumatic biasing arrangement may further be configured for preferentially aiding extension or retraction of the actuator.

Owner:UNICO LLC

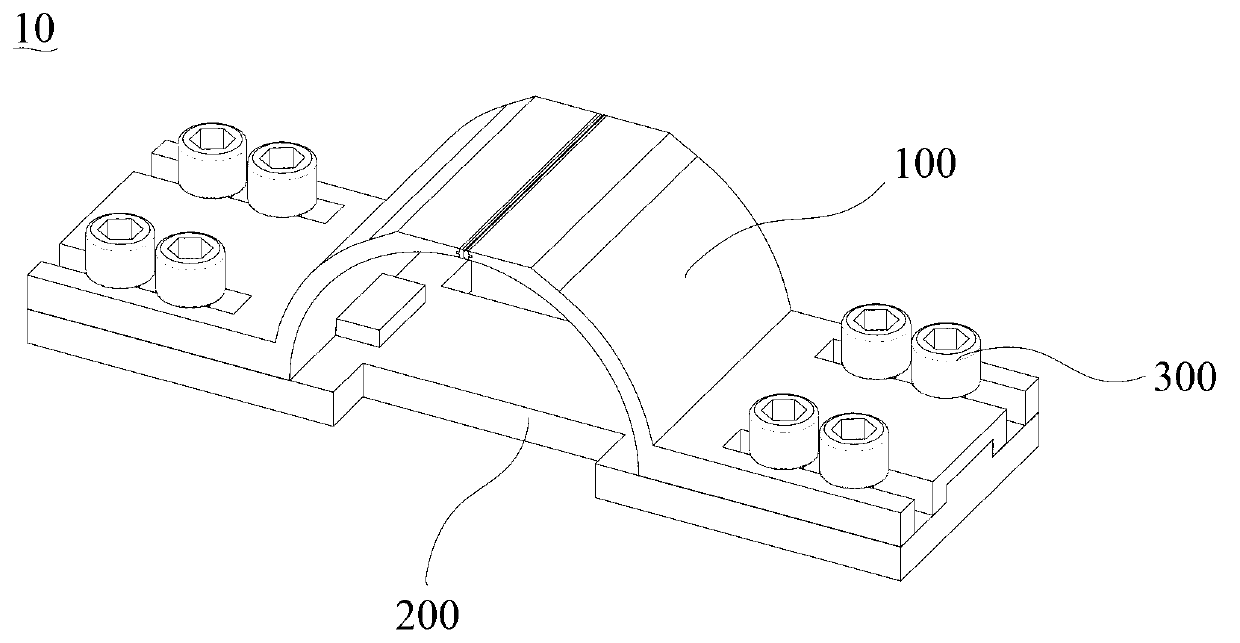

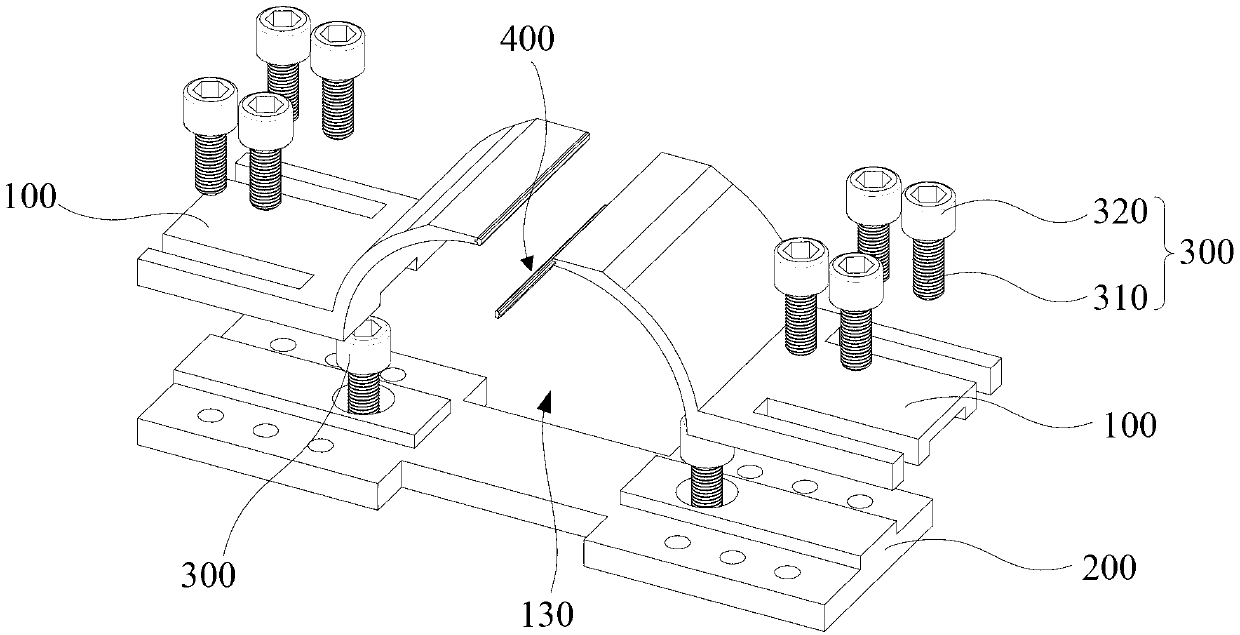

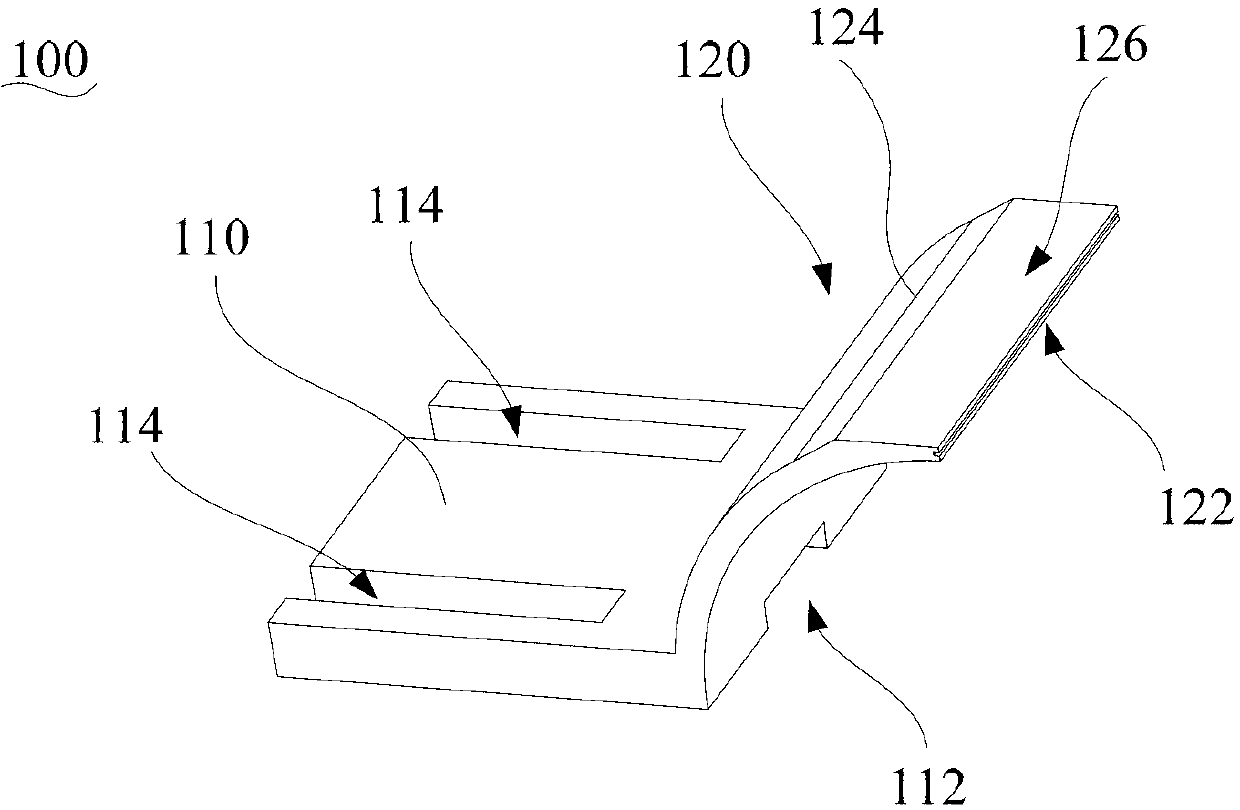

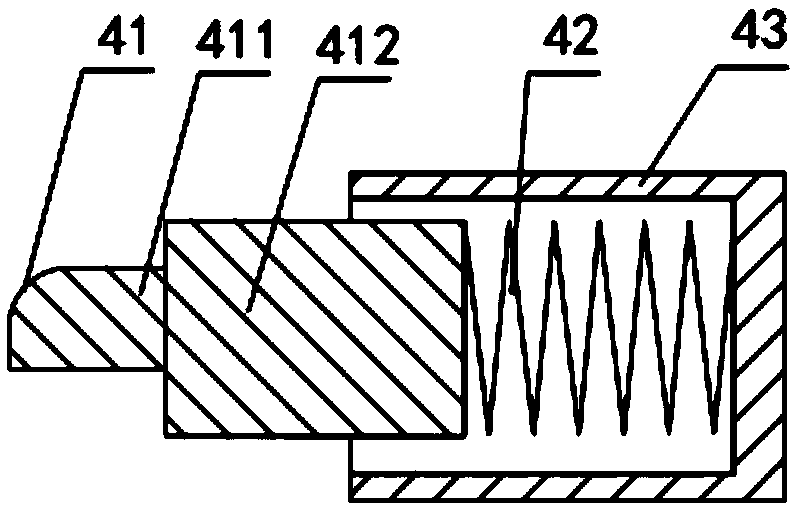

Integrally-formed shoulder tab mould

InactiveCN104005183ASolving technical problems with high operational requirementsWay to overcomeWork-feeding meansEngineering

An integrally-formed shoulder tab mould is formed by a base plate, a cover plate, a clamping plate and a fixing piece; one side of the base plate is hinged to the cover plate which comprises the same structure with the base plate and the cover plate and the base plate are in mirror symmetry; the base plate is formed by a base plate positioning plate, a base plate backing plate, a base plate cover plate, a left base plate clamping plate and a right base plate clamping plate; the base plate backing plate is composited between the base plate positioning plate and the base plate cover plate; a base plate seam through groove which is adaptive to a shoulder tab in shape is formed in the middle of the base plate positioning plate; a base plate cover plate through groove is formed at a base plate cover plate position which is corresponding to the base plate seam through groove; the left base plate clamping plate and the right base plate clamping plate are arranged in a base plate clamping plate through groove in an embedded mode, wherein the base plate clamping plate through groove is formed between the base plate positioning plate and the base plate cover plate. According to the integrally-formed shoulder tab mould, the base plate, the cover plate, the clamping plate and the fixing piece are matched with each other and accordingly the integral forming is achieved and the technical problems that the machining mode is complicated, the positioning is inconvenient, and the requirements for the operation level of workers are high in the process of shoulder tab manufacture are fundamentally solved.

Owner:TIANJIN SANDA CLOTHING

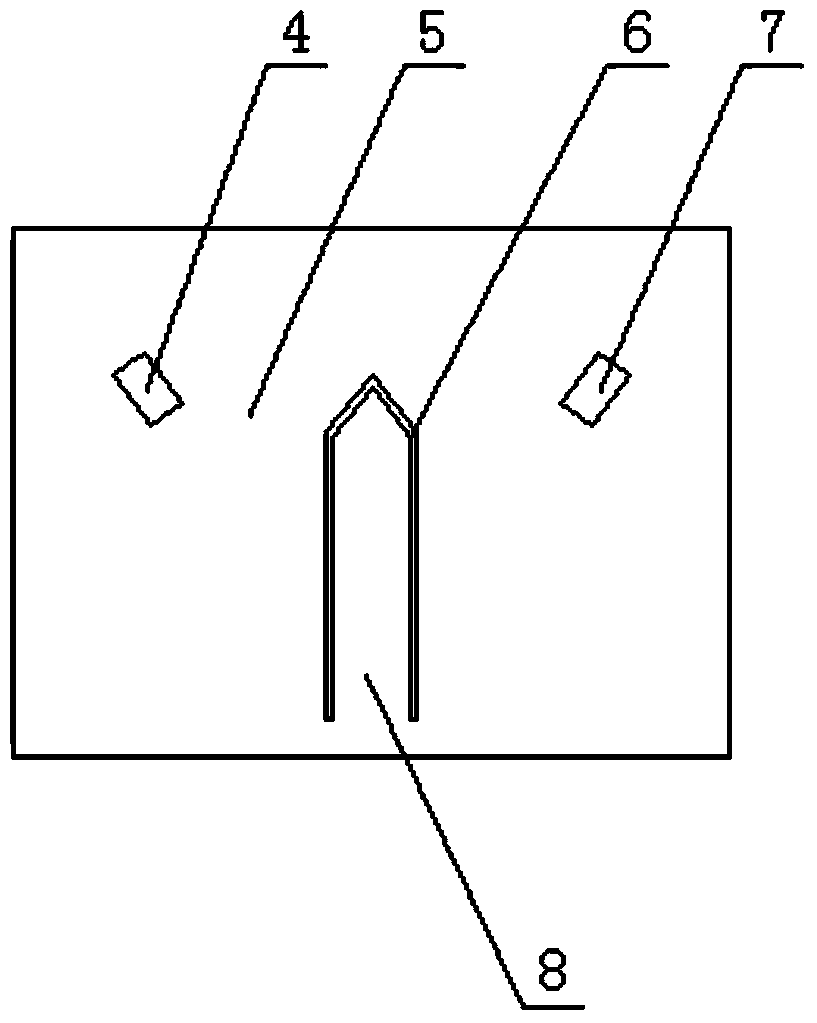

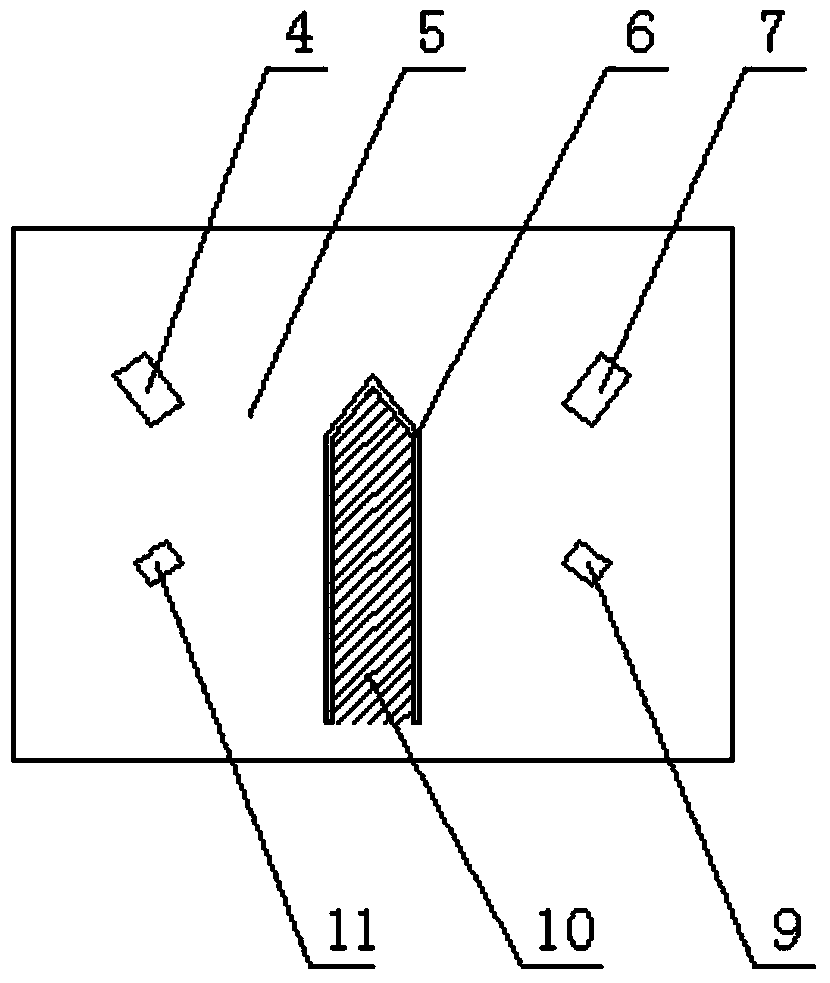

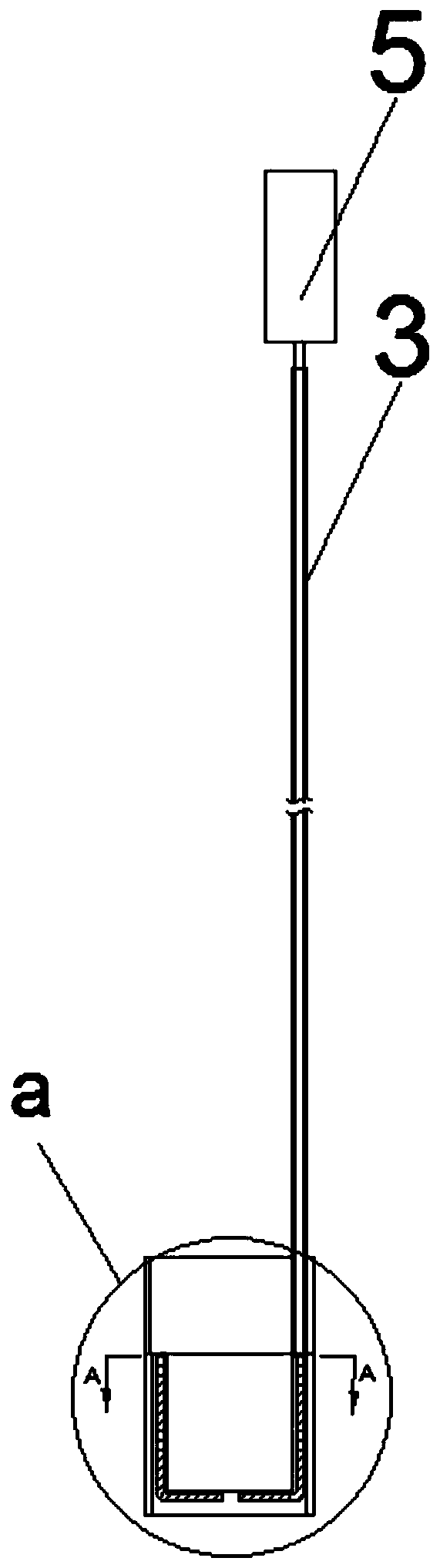

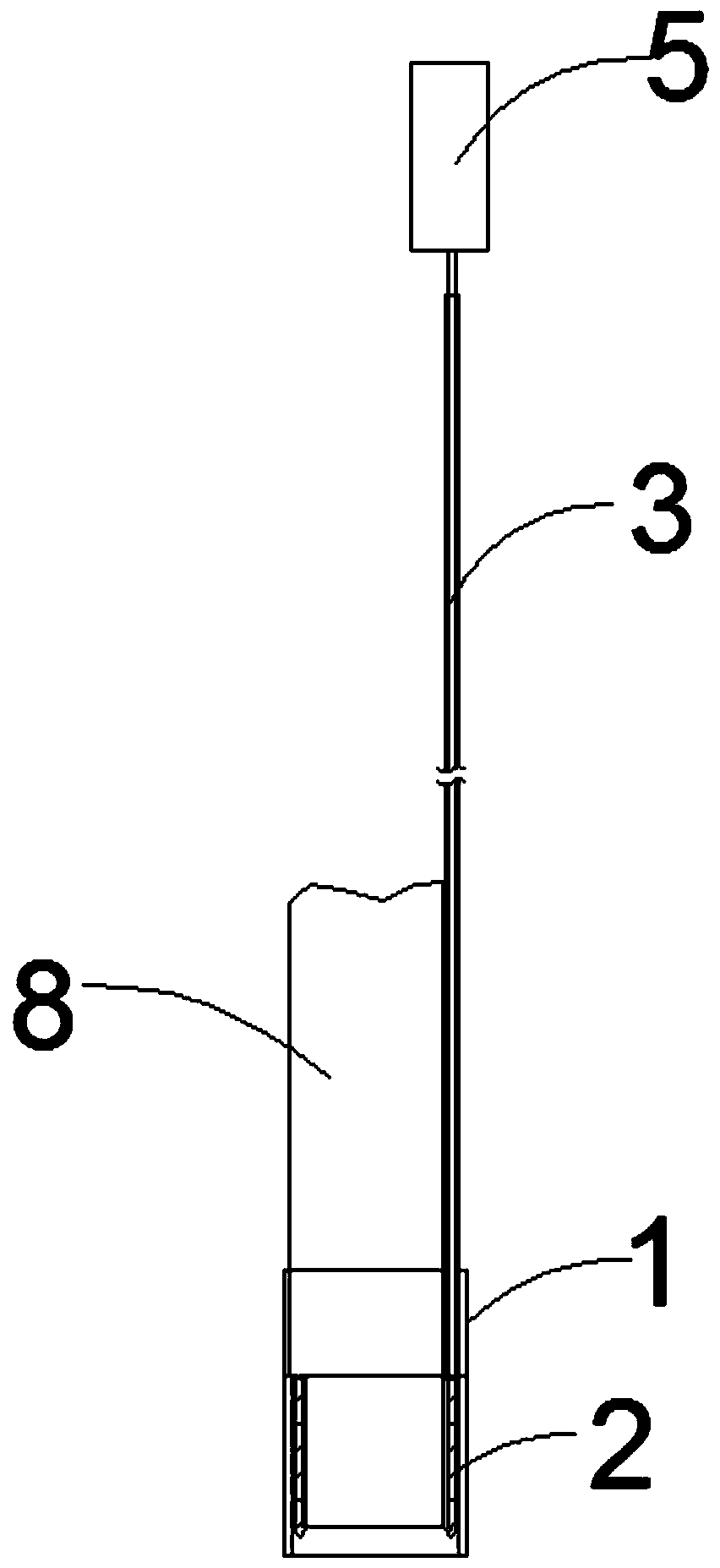

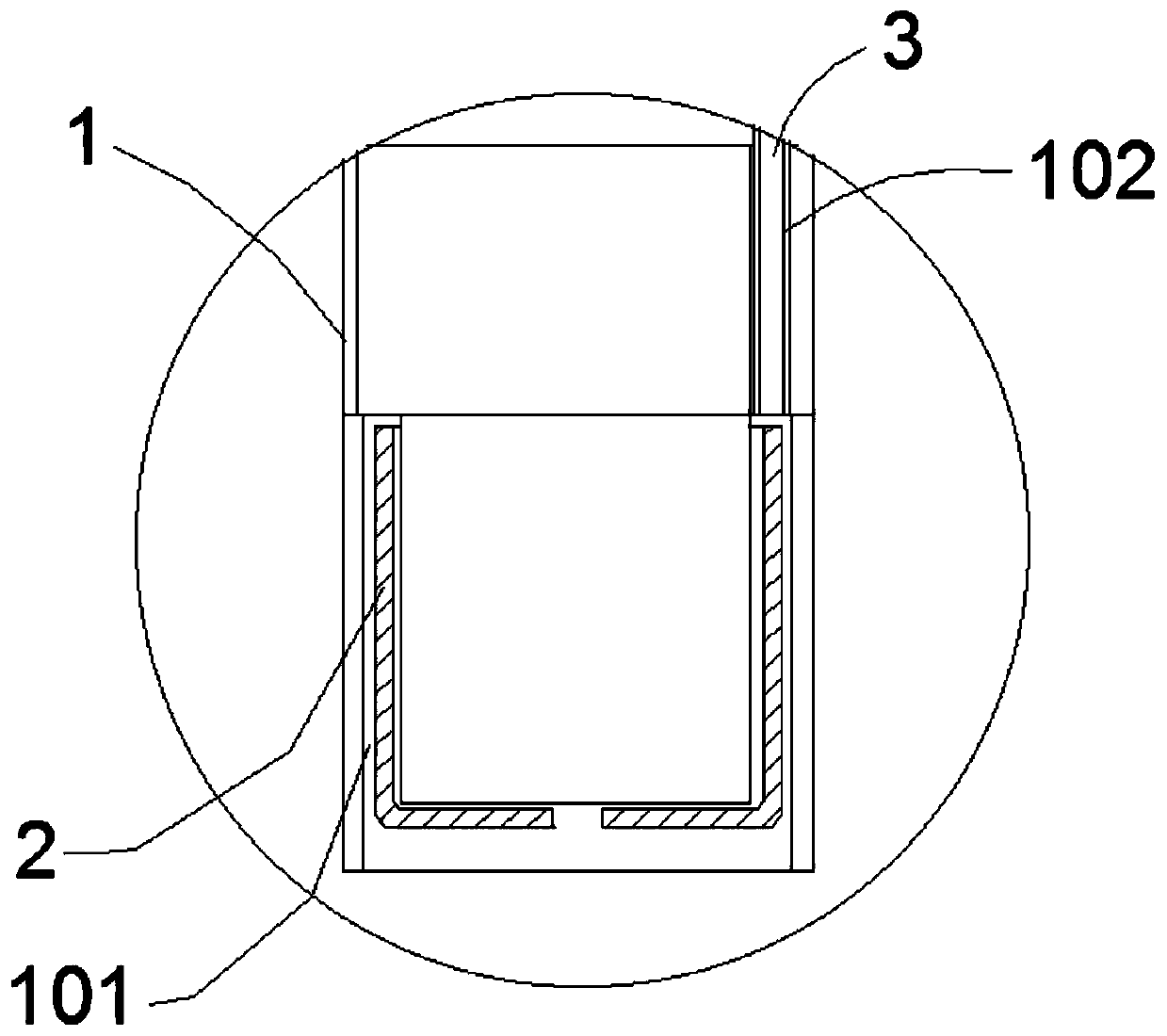

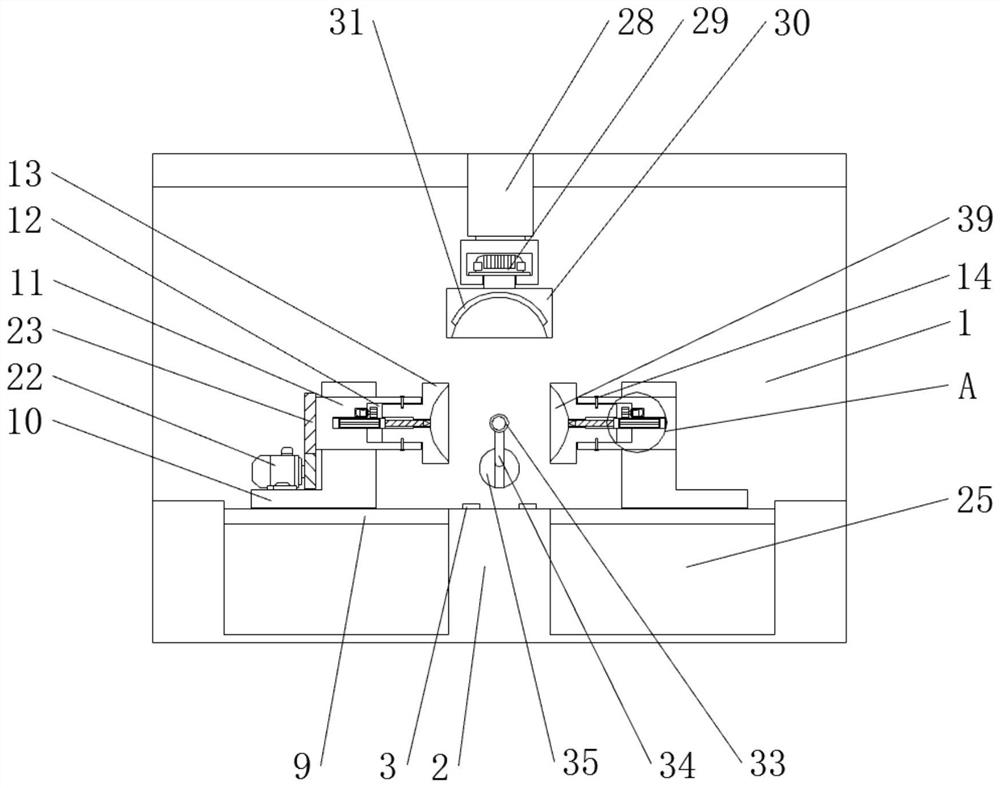

Fixing device used for fixing back skin of experimental animal

The invention relates to a fixing device used for fixing the back skin of an experimental animal. The fixing device used for fixing the back skin of the experimental animal comprises a base and fixing tables, wherein each fixing table comprises a connecting part and a fixing and clamping part connected with the connecting part, the fixing tables are connected with the base in a detachable mode through the connecting parts, the fixing and clamping parts of the two fixing tables are matched to form a fixing through hole allowing the experimental animal to pass through, and the end faces, away from the connecting parts, of the two fixing and clamping parts are matched to clamp the back skin of the experimental animal so that the back skin which is pulled up of the experimental animal can be spread on the outer walls of the fixing and clamping parts. The fixing device used for fixing the back skin of the experimental animal has the advantages that the back skin of the experimental animal can be fixed, negative influence of respiratory movement of the experimental animal on imaging is effectively avoided, damage to the experimental animal is small due to the fact the non-invasive fixing method is adopted, and long-time and stable observation and study of a subcutaneous transplantation tumor model on the back of the experimental animal by means of a photoacoustic imaging system is available.

Owner:SHENZHEN INST OF ADVANCED TECH

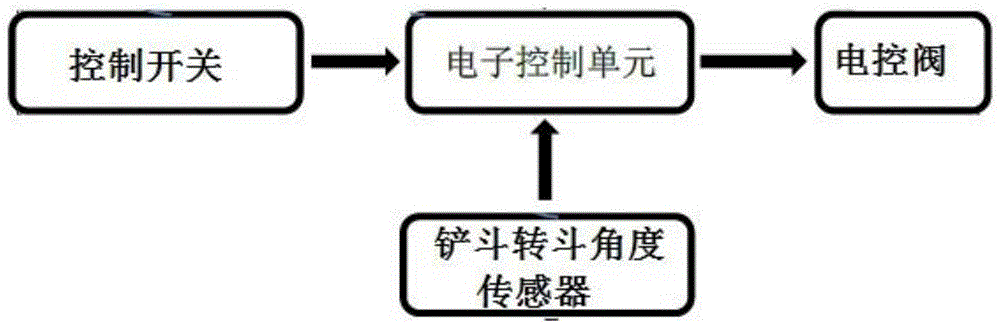

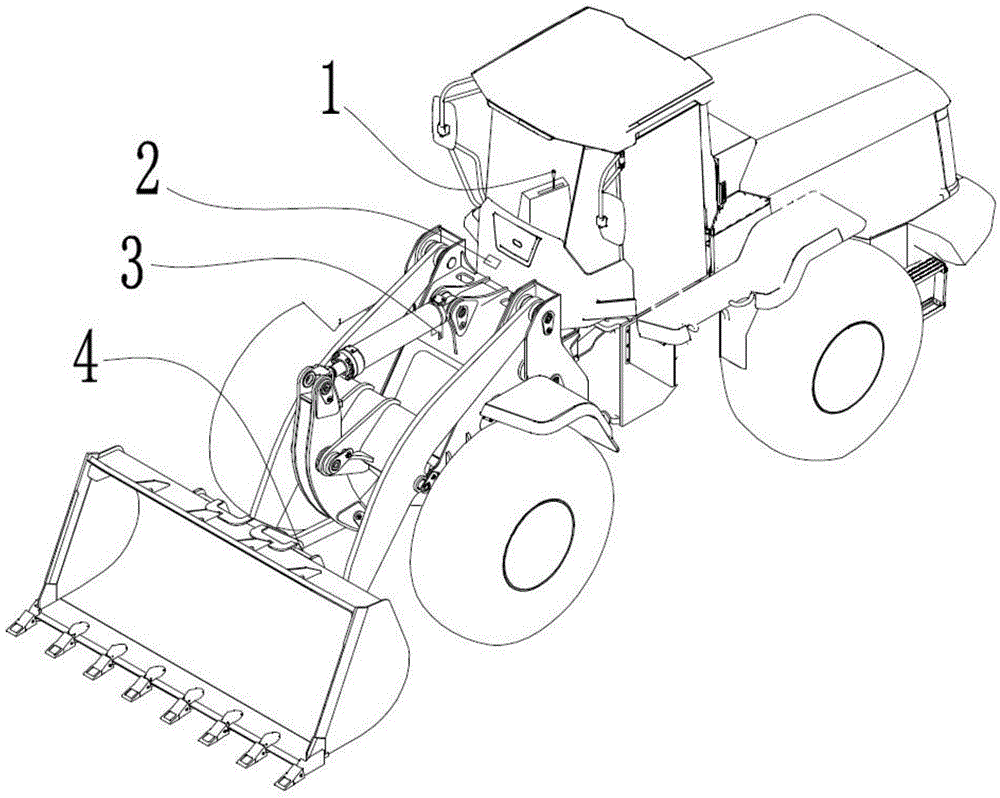

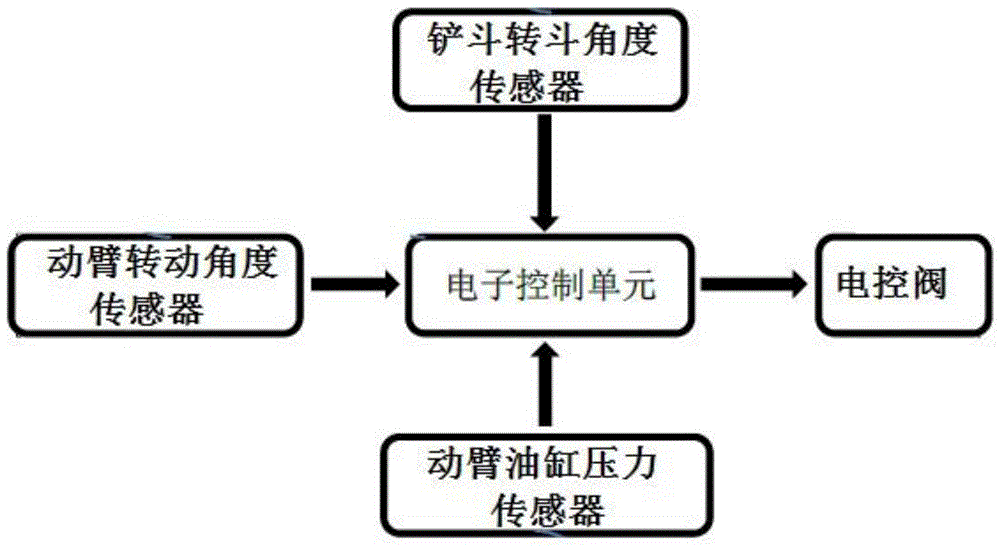

Shovel loading control system and shovel loading control method for loader

ActiveCN104405005ALow level of operation requiredSoil-shifting machines/dredgersControl systemControl valves

The invention relates to a shovel loading control system and a shovel loading control method for a loader. The shovel loading control system and shovel loading control method solve the disadvantage that the prior art manually controls a bucket to shake forwardly and backwardly to enable materials to turn over towards the back to fall into the bucket. The shovel loading control system of the loader comprises the bucket, a lifting device, a rotating bucket oil cylinder and an electronically controlled valve for controlling the action of the rotating bucket oil cylinder, an electronic control unit is connected with the electronically controlled valve, after finishing shovel loading and bucket retracting, the electronic control unit sends signals to the electronically controlled valve to control the electronically controlled valve to act to enable the rotating bucket oil cylinder to drive the bucket to shake forwardly and backwardly for several times around the hinge point thereof. According to the shovel loading control system of the loader, after finishing shovel loading and bucket retracting, the electronic control unit controls the electronically controlled valve to automatically finish the forward and backward shaking of the bucket to shake off the materials which are not completely shoveled into the bucket and the materials higher than a front knife board of the bucket and likely to scatter in the transportation process. The shaking of the bucket is automatically finished by the control system, the shaking of the bucket operated by an operator through an operation handle is avoided, and accordingly the operation difficulty is lowered.

Owner:GUANGXI LIUGONG MASCH CO LTD

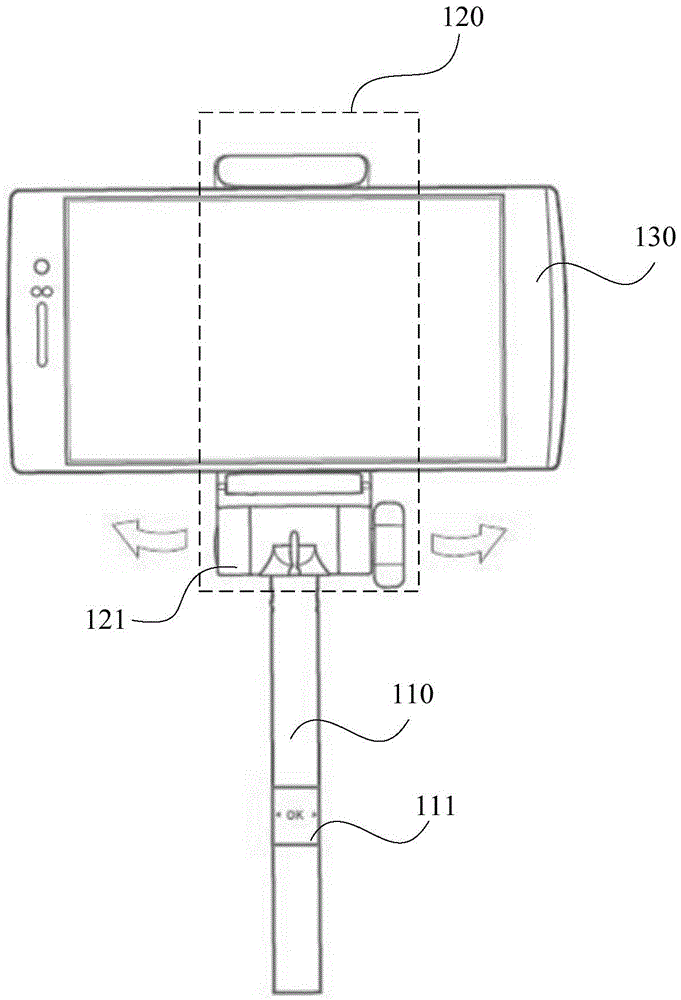

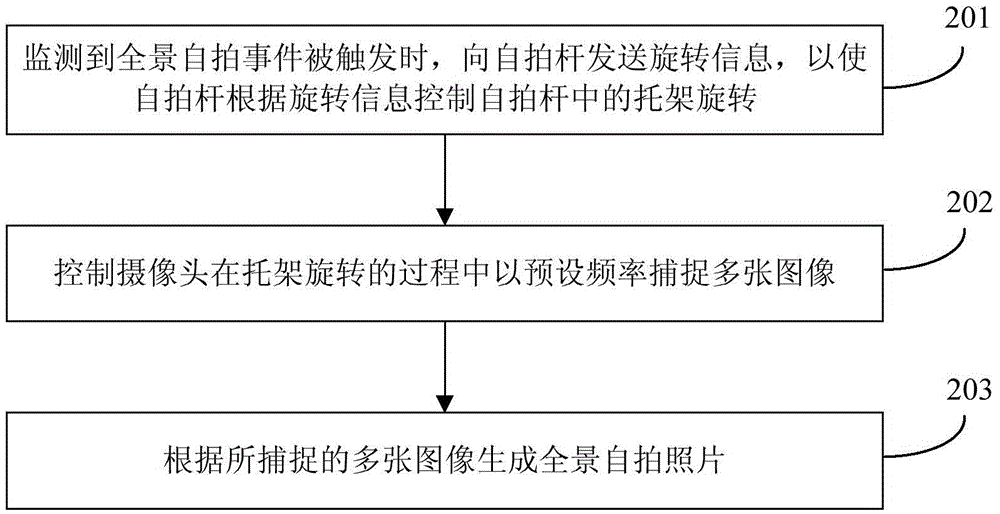

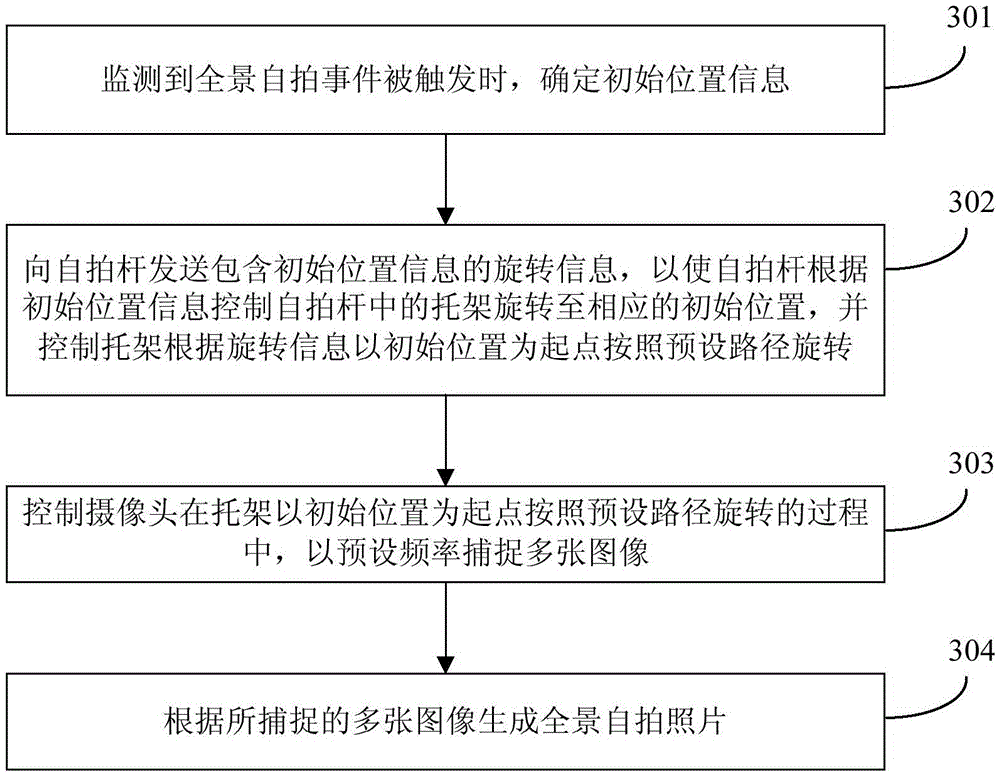

Method, device and system for taking panoramic photo, mobile terminal and selfie stick

ActiveCN105657257AGood effectLow level of operation requiredTelevision system detailsColor television detailsComputer terminalComputer science

The embodiment of the invention discloses a method, a device and a system for taking a panoramic photo, a mobile terminal and a selfie stick. The method comprises the steps of when monitoring that a panoramic selfie event is triggered, sending rotation information to the selfie stick, thus the selfie stick controls the support in the selfie stick to rotate according to the rotation information; controlling a camera to capture a plurality of images at preset frequency; and generating a panoramic selfie according to the captured plurality of images. According to the method provided by the embodiment of the invention, the user does not need to take the panoramic selfie through moving the mobile terminal or the selfie stick in the hand, the mobile terminal can rotate automatically and take the panoramic selfie only through holding the selfie stick by the hand and remaining still, the requirement on the operation level of the user is reduced, the obtained panoramic selfie is good in effect, the distortion of the facial image is avoided, and the photographing experience of the user is effectively enhanced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

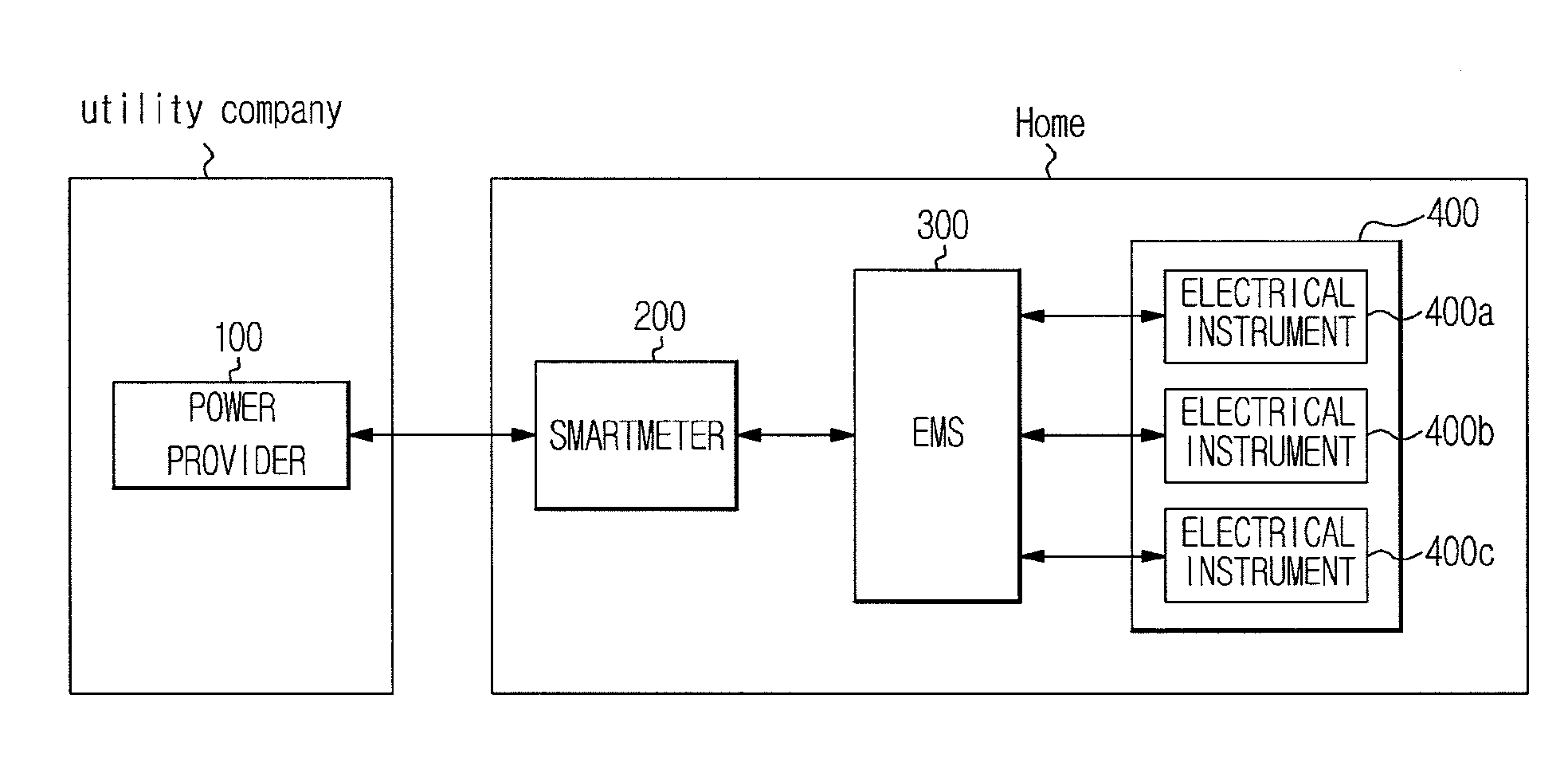

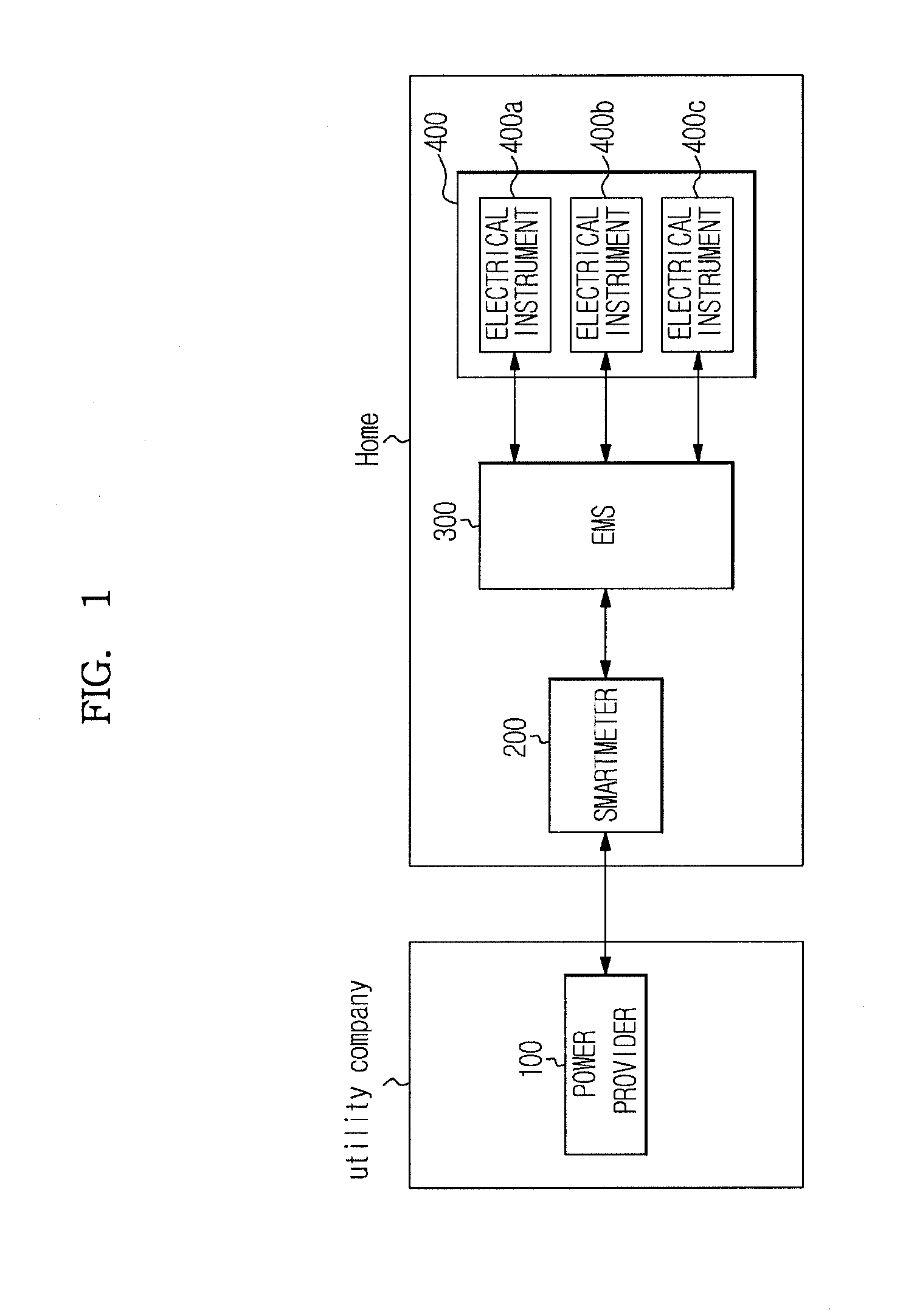

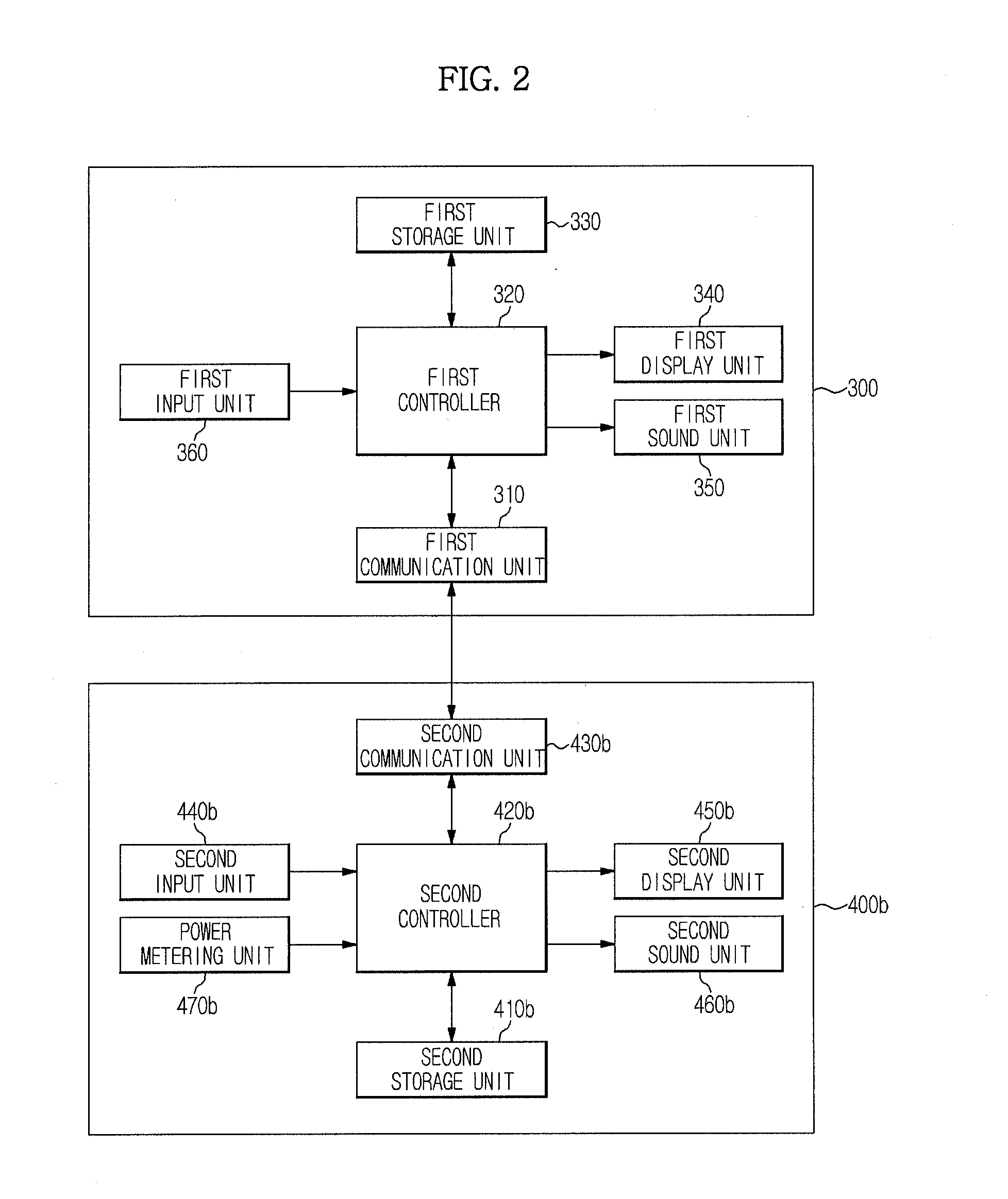

Electrical instrument, power management apparatus, power management system having the same, and method for controlling the same

ActiveUS20120197451A1Eliminate inconvenienceLow level of operation requiredMechanical power/torque controlLevel controlElectricity priceElectrical devices

A power management system includes a plurality of electrical instruments and a power management apparatus. Each of the plurality of electrical instruments has at least one characteristic function and an arbitration function which is discriminated from the characteristic function and requires power arbitration. Each electrical instrument includes a plurality of operation algorithms having at least one characteristic function, operation levels respectively corresponding to the plurality of operation algorithms, power information for the respective operation levels, and power information of the arbitration function. The power management apparatus receives power rate information from a power provider, determines the operation levels of the plurality of electrical instruments and controls the electrical instruments to be driven at the determined operation levels. When an arbitration function selection signal is received from at least one of the electrical instruments while the electrical instruments are driven, the power management apparatus adjusts operation levels of other electrical instruments.

Owner:SAMSUNG ELECTRONICS CO LTD

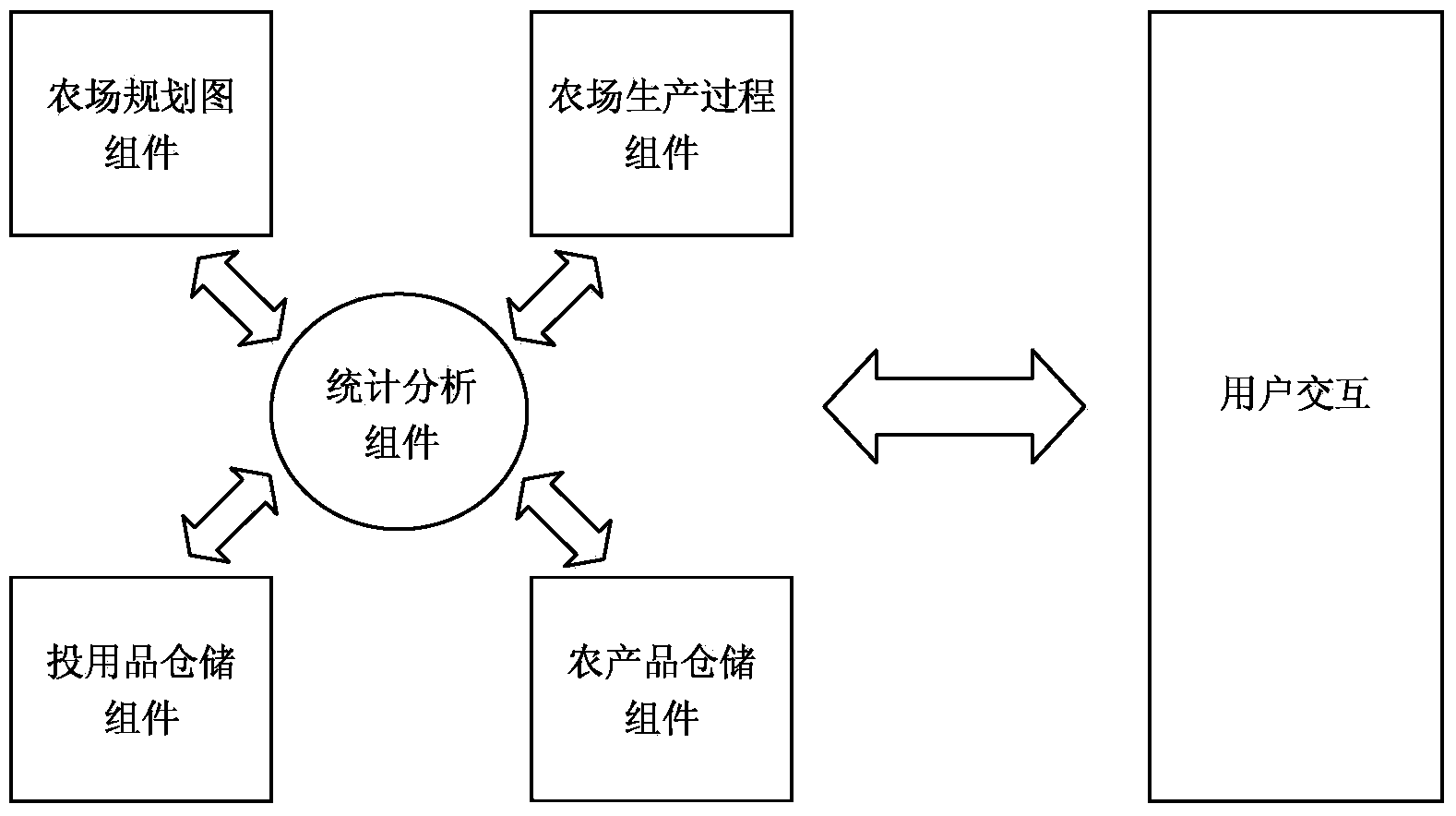

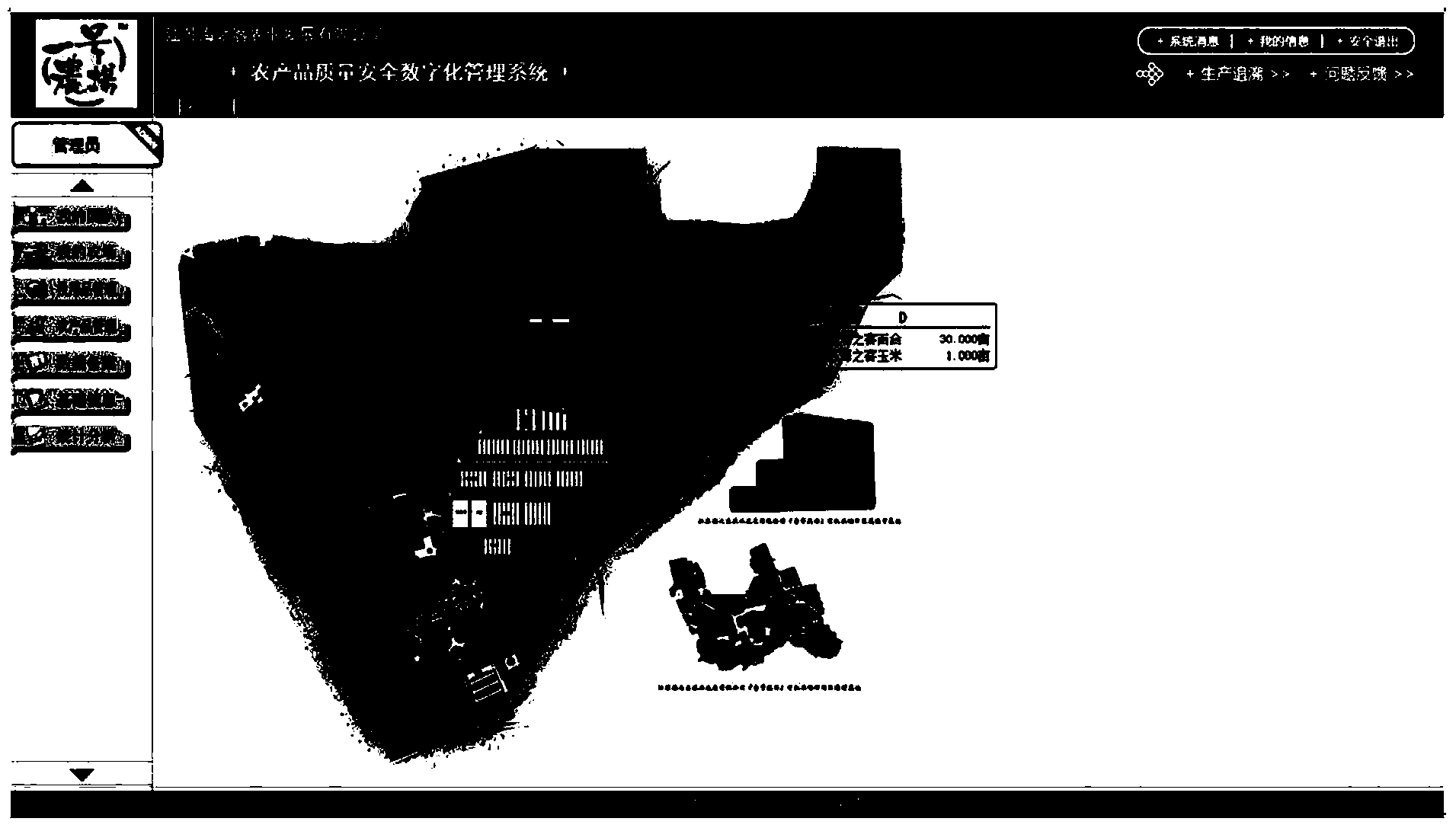

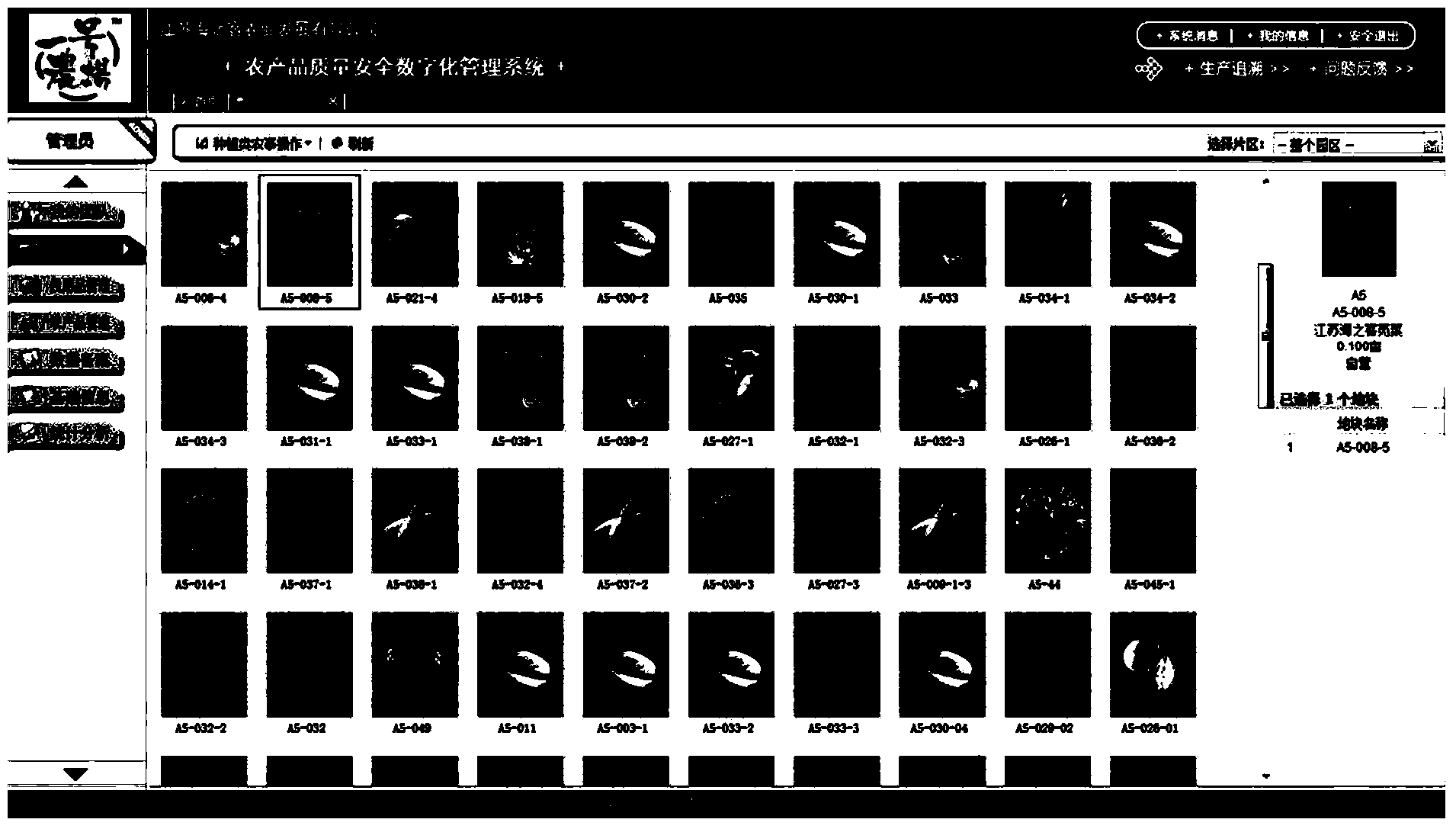

Agricultural product digital production management system and method based on visualization graphics technology

InactiveCN104376421AIncrease interactionShow visual production managementResourcesGraphicsStatistical analysis

The invention discloses an agricultural product digital production management system and method based on the visualization graphics technology. The system comprises a farm planning map visualization assembly, a farm production process visualization assembly, a warehouse management visualization assembly and a statistic analysis visualization assembly. The farm planning map visualization assembly is used for providing necessary farm distribution information for an enterprise operator; the farm production process visualization assembly is used for helping a user to recognize the production process of land parcels; the statistic analysis visualization assembly is used for tightly connecting the farm planning map visualization assembly, the farm production process visualization assembly and the warehouse management visualization assembly. By means of the agricultural product digital production management system and method, the agricultural production machine account is promoted to be managed in a computer information mode instead of a traditional paper mode, and the agricultural product digital production management system and method have important significance in standardizing enterprise operation and management of government supervision departments, controlling and improving the quality of the agricultural products and promoting the sound development of the agricultural industry.

Owner:常州市农畜水产品质量监督检验测试中心 +2

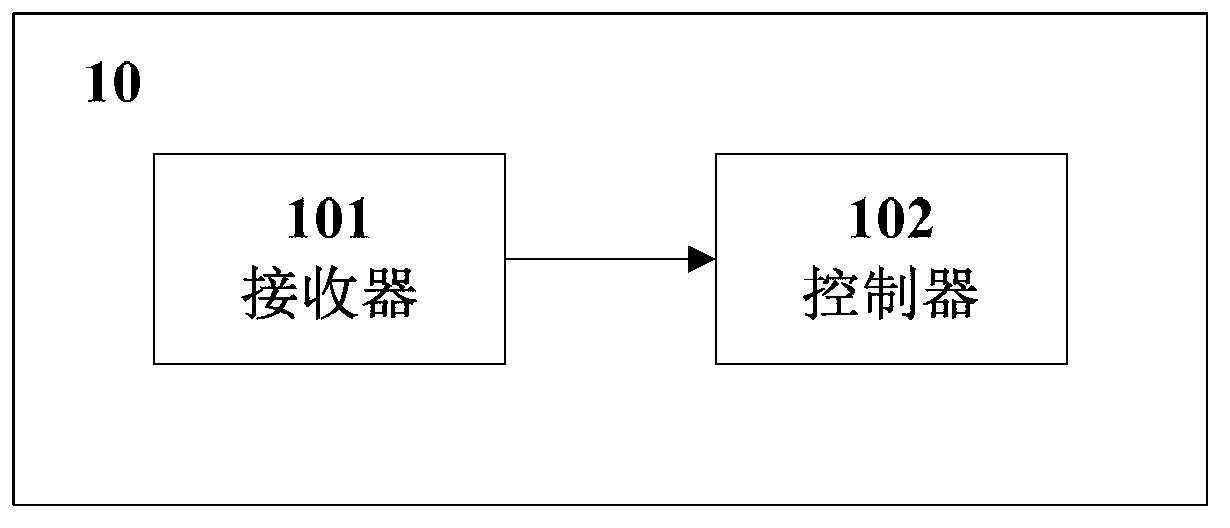

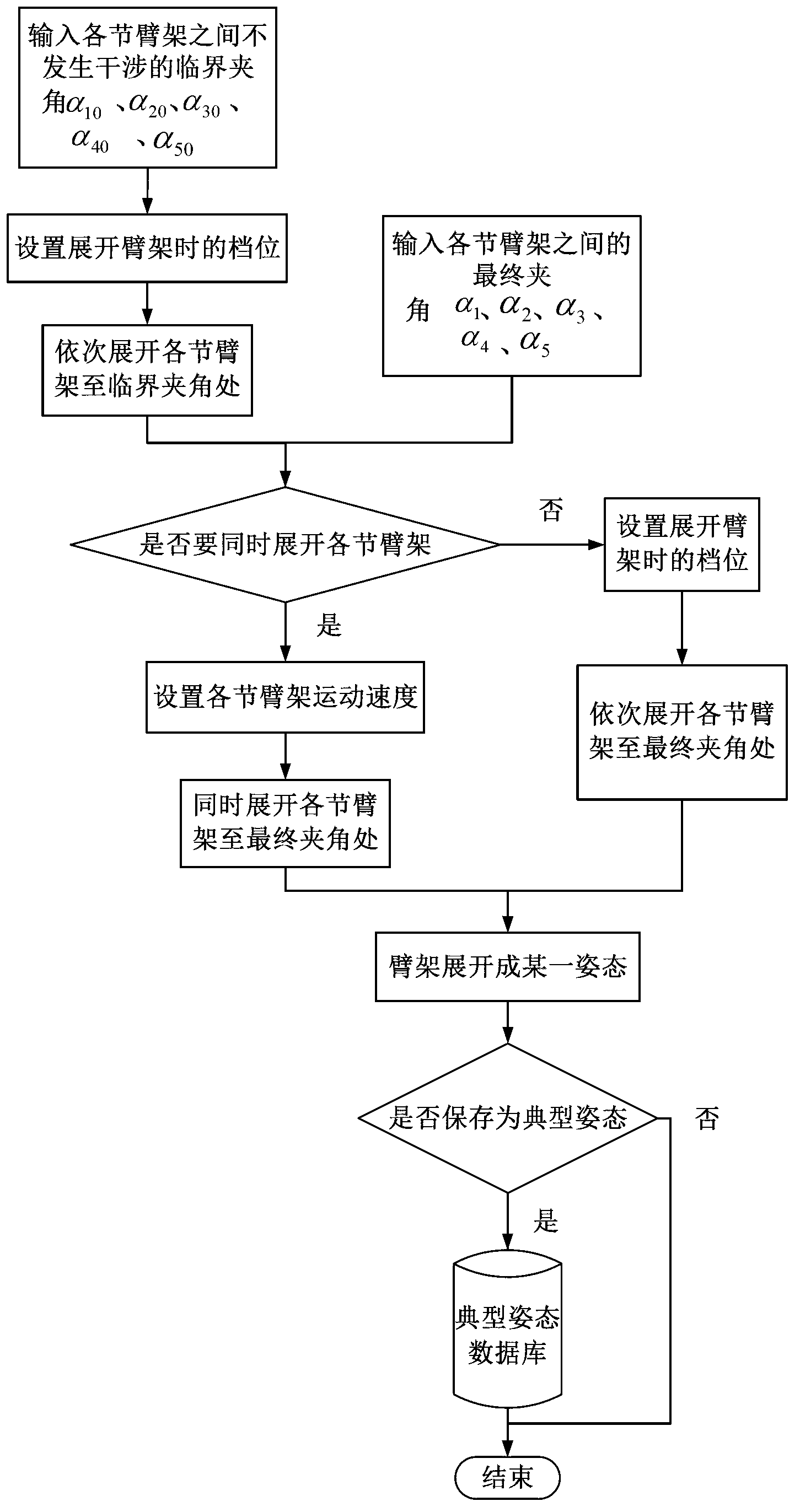

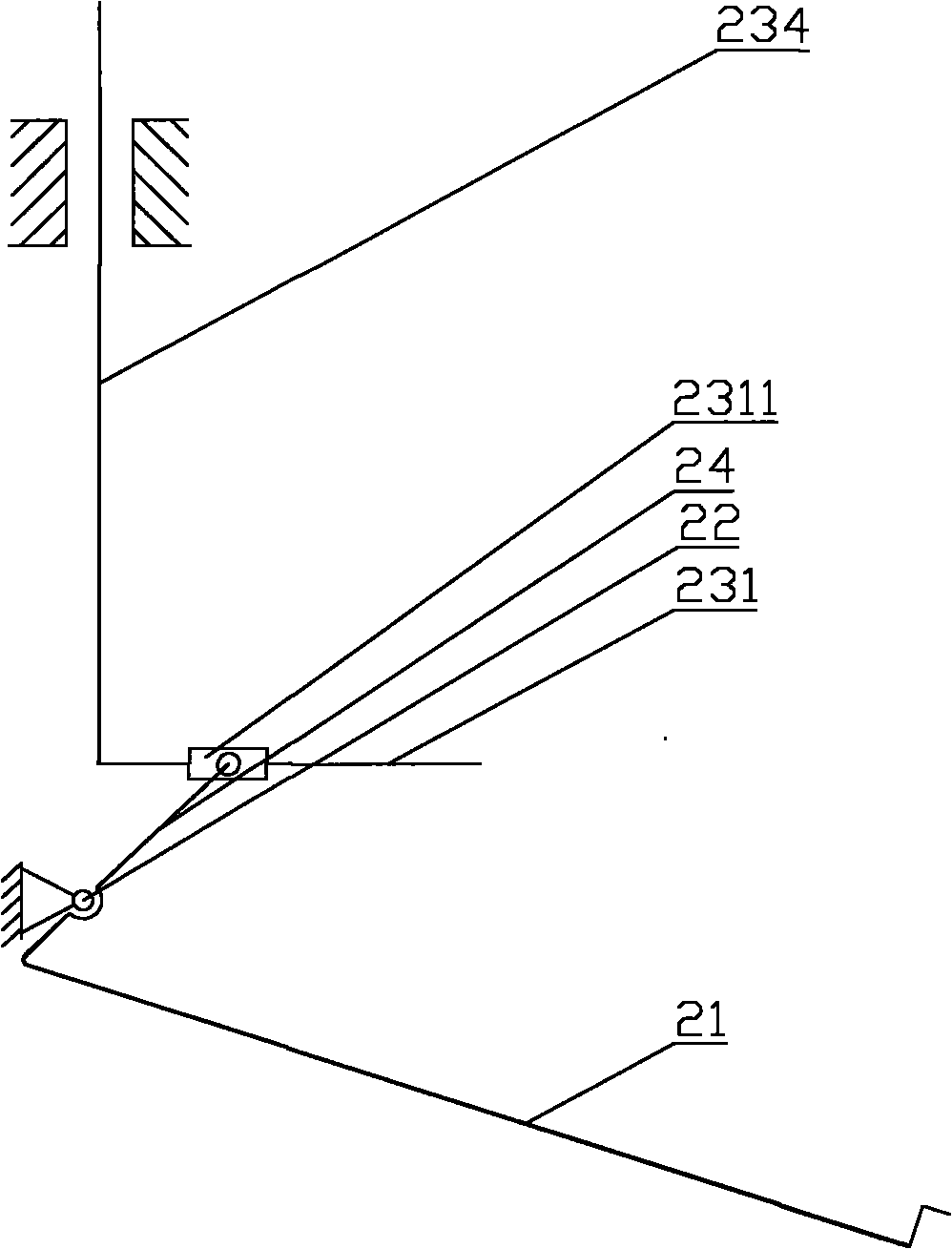

Intelligent arm support control device, intelligent arm support control system, intelligent arm support control method and engineering machine

ActiveCN103321428AReduce workloadLow level of operation requiredBuilding material handlingControl systemEngineering

The invention discloses an intelligent arm support control device, an intelligent arm support control system, an intelligent arm support control method and an engineeringmachine. An arm support comprises a plurality of arm sections which are connected mutually. The intelligent arm support control device comprises a receiver and a controller, the receiver is used for receiving signals of typical postures of the arm support, and the controller is connected with the receiver and used for determining an inclining angle of each arm section corresponding to the typical postures and controlling each arm section to unfold to a corresponding inclined angle according to the typical postures. By the technical scheme, by means of only selecting one typical posture of the arm support by a machinist, the arm support can unfold to the typical posture automatically, no manual intervention is required, workload of the machinist is greatly lowered, requirements on operation level and experience of the machinist are lowered, and working efficiency is improved.

Owner:ZOOMLION HEAVY IND CO LTD

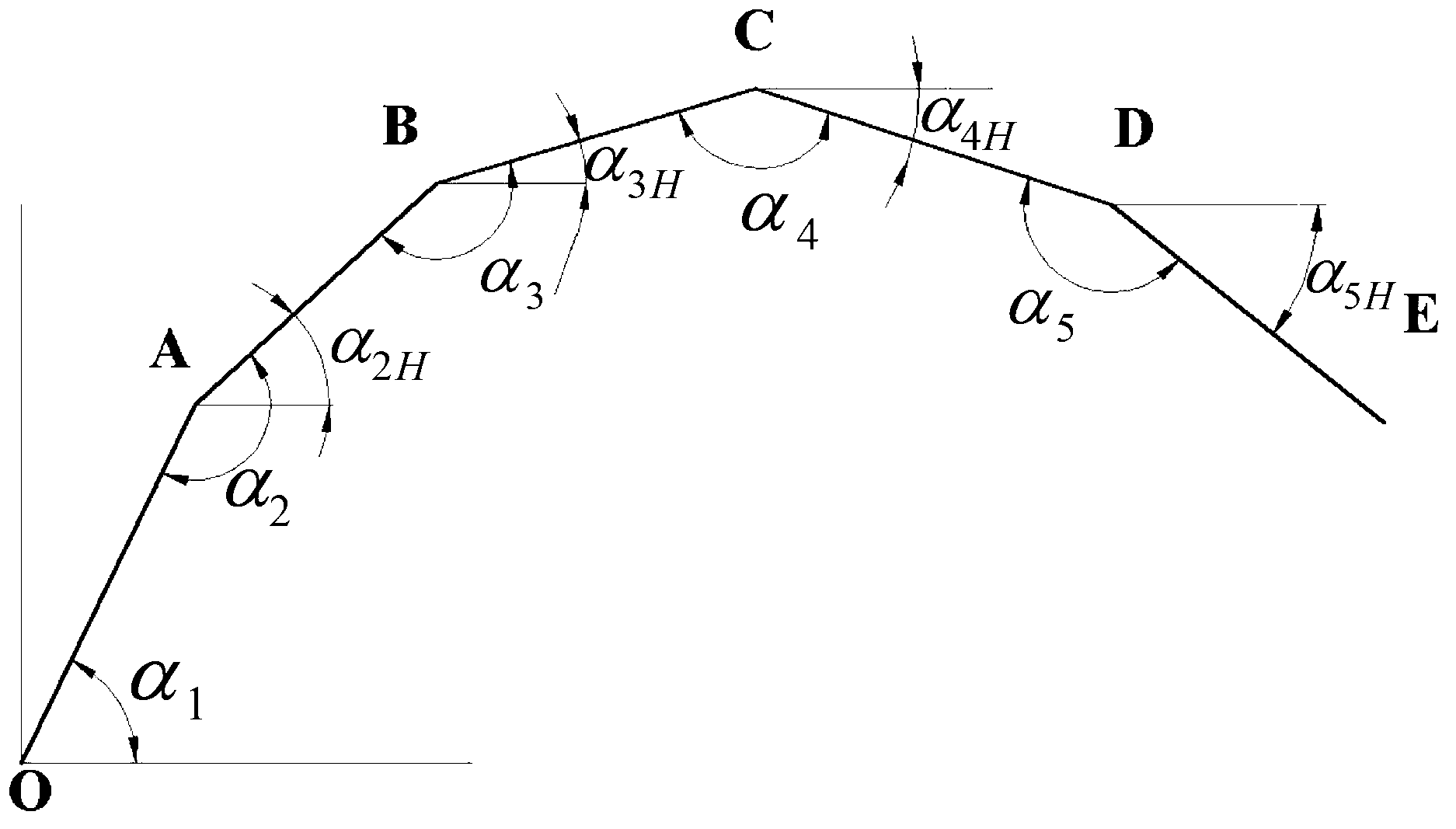

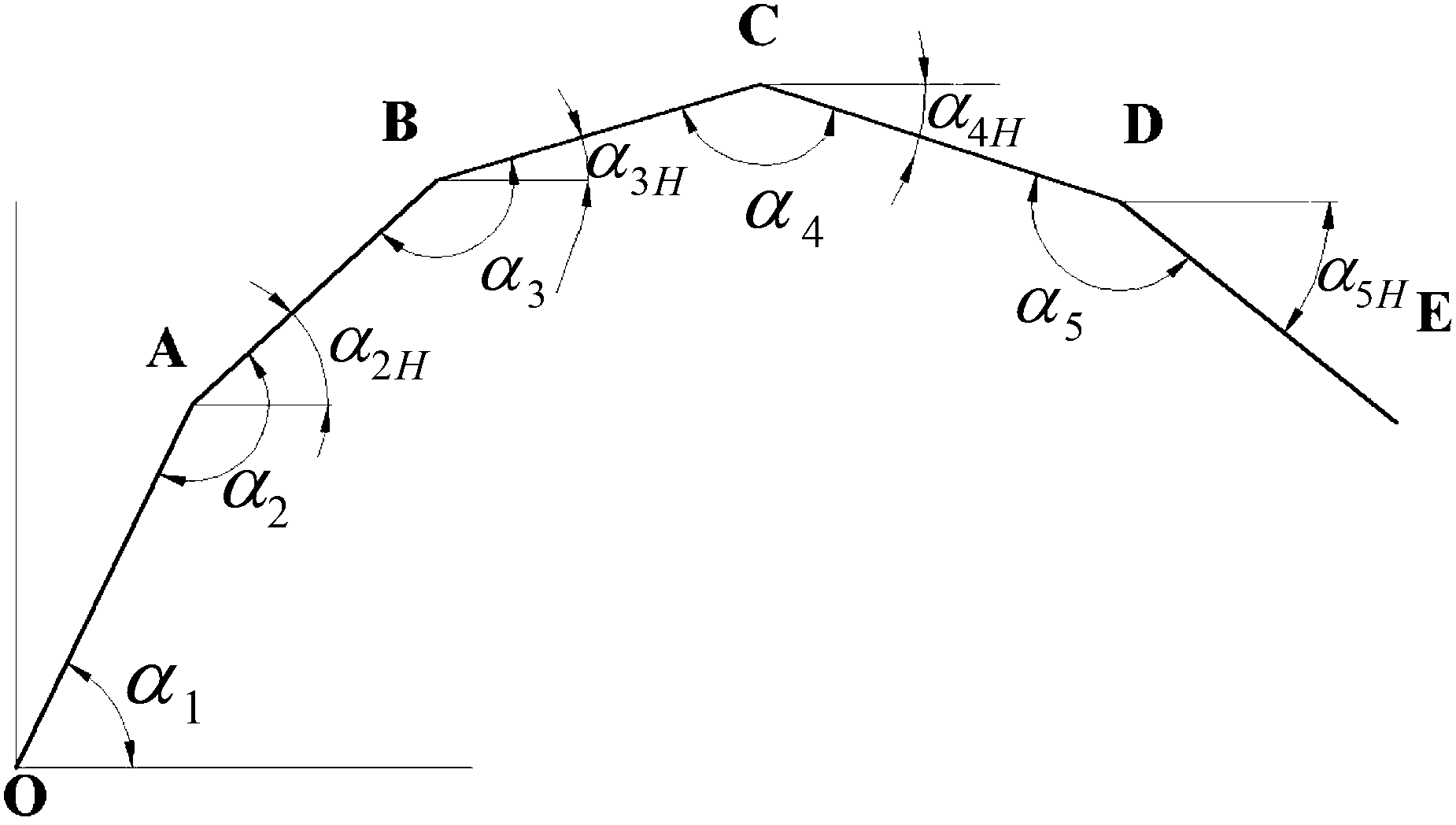

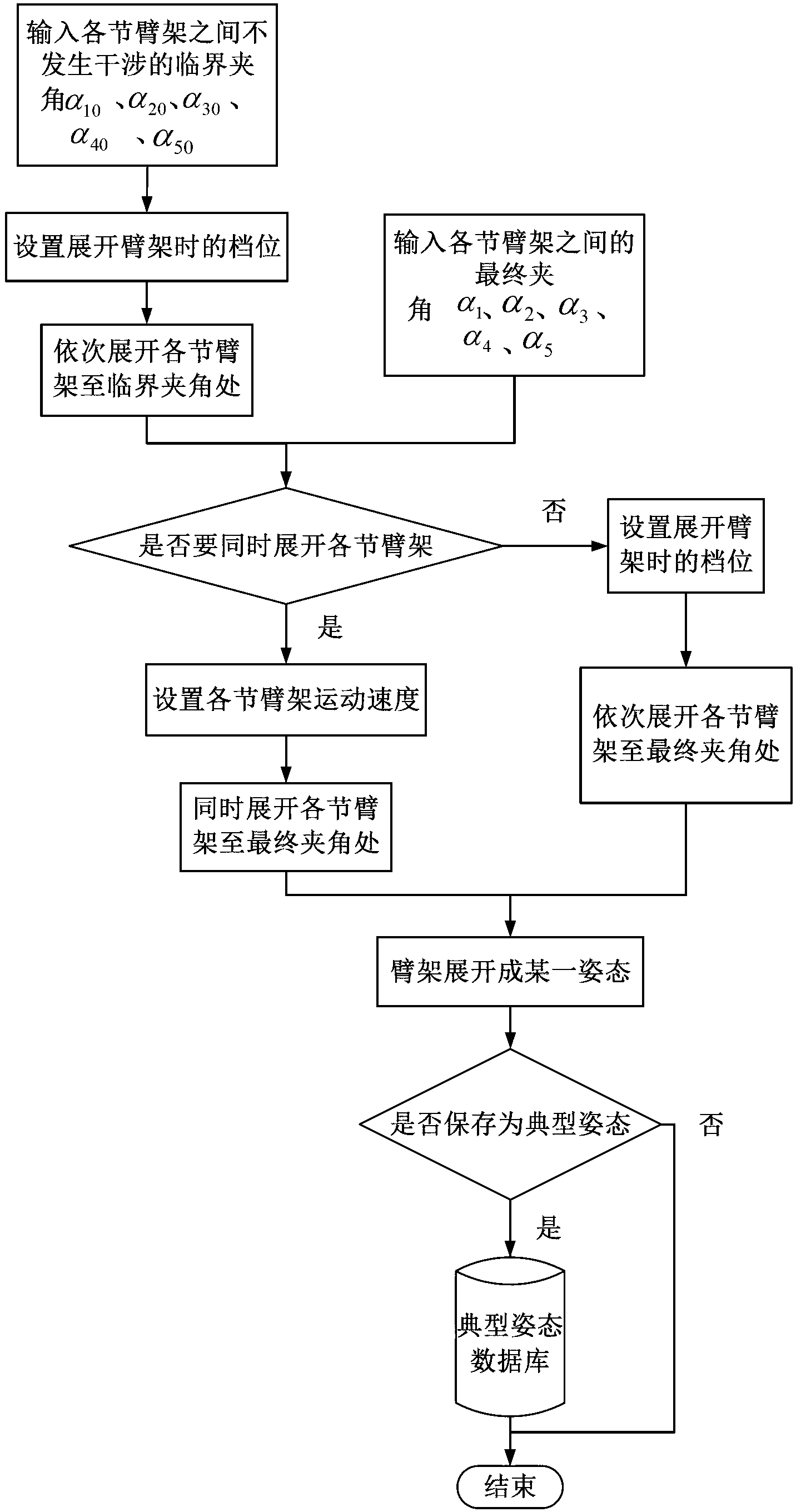

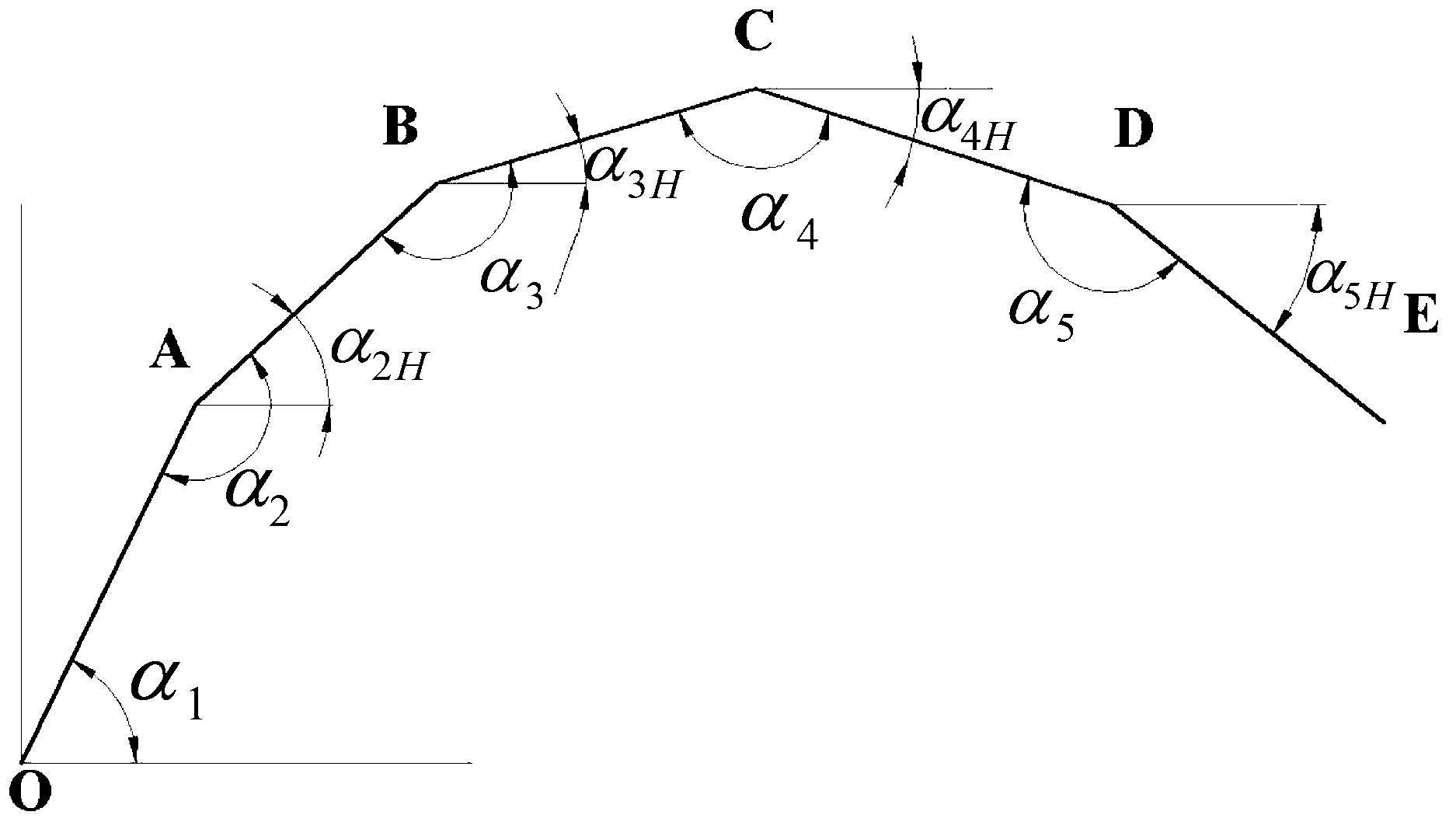

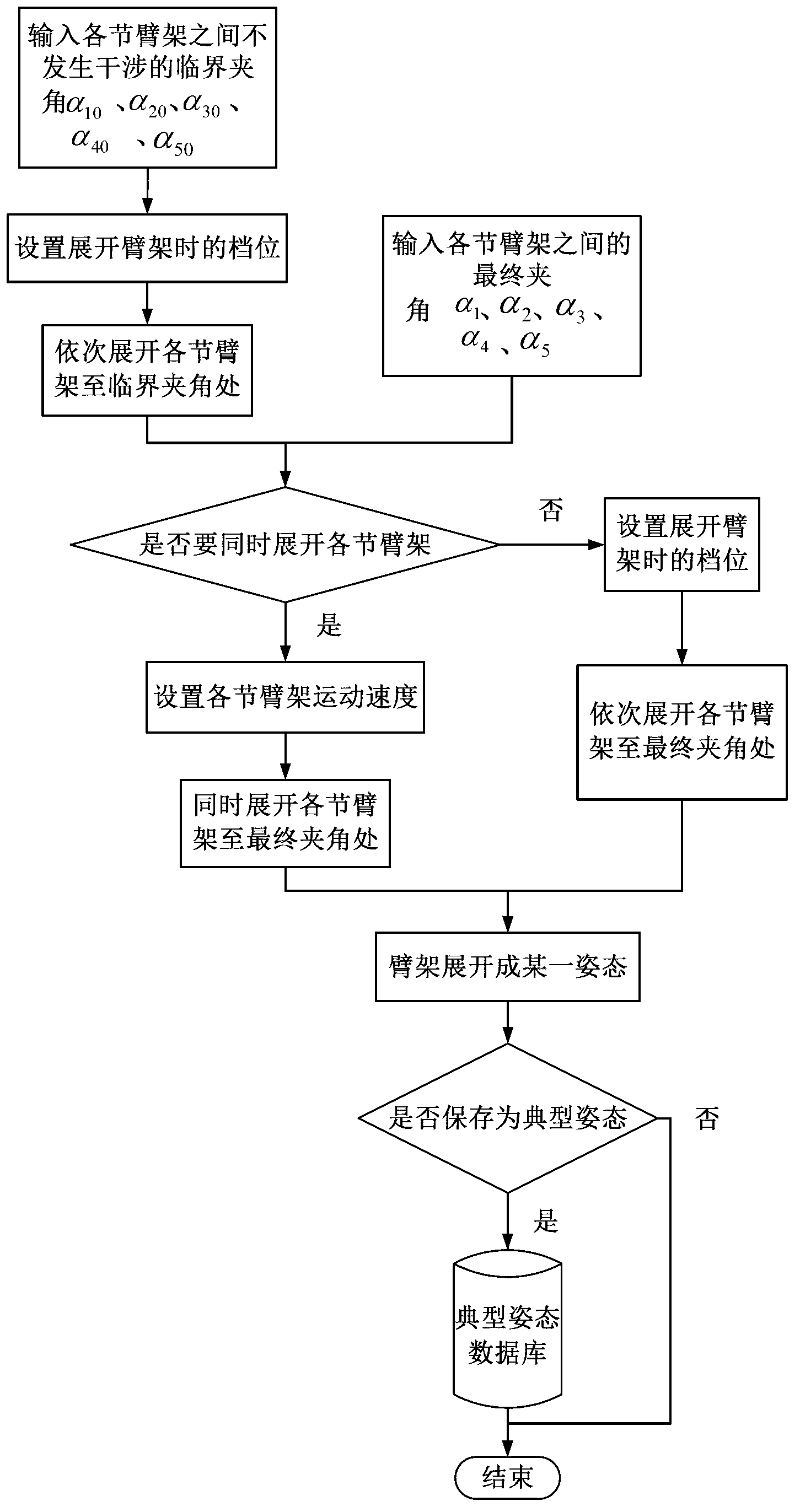

Device and method for expanding and retracting of cantilever crane, intelligent control system and engineering machinery

The invention discloses a device and a method for expanding and retracting of a cantilever crane, an intelligent cantilever crane control system and engineering machinery. The cantilever crane comprises multiple sections connected mutually. The device comprises a receiver and a controller; the receiver is used for receiving an expanding instruction of the cantilever crane, current included angle and target included angle of adjacent sections and critical included angle of the adjacent sections without interferences; the controller is connected with the receiver and used for receiving the expanding instruction, regulating the sections so as to keep the included angle between the adjacent sections larger than or equal to the critical included angle when the current included angle is smaller than the critical included angle, and then regulating the sections further according to the target included angle. According to the technical scheme, the cantilever crane can be expanded and retracted automatically, interference during expanding and retracting of each section can be omitted, and damages to the cantilever crane, oil cylinders or upper assemblies of pump trucks are avoided.

Owner:ZOOMLION HEAVY IND CO LTD

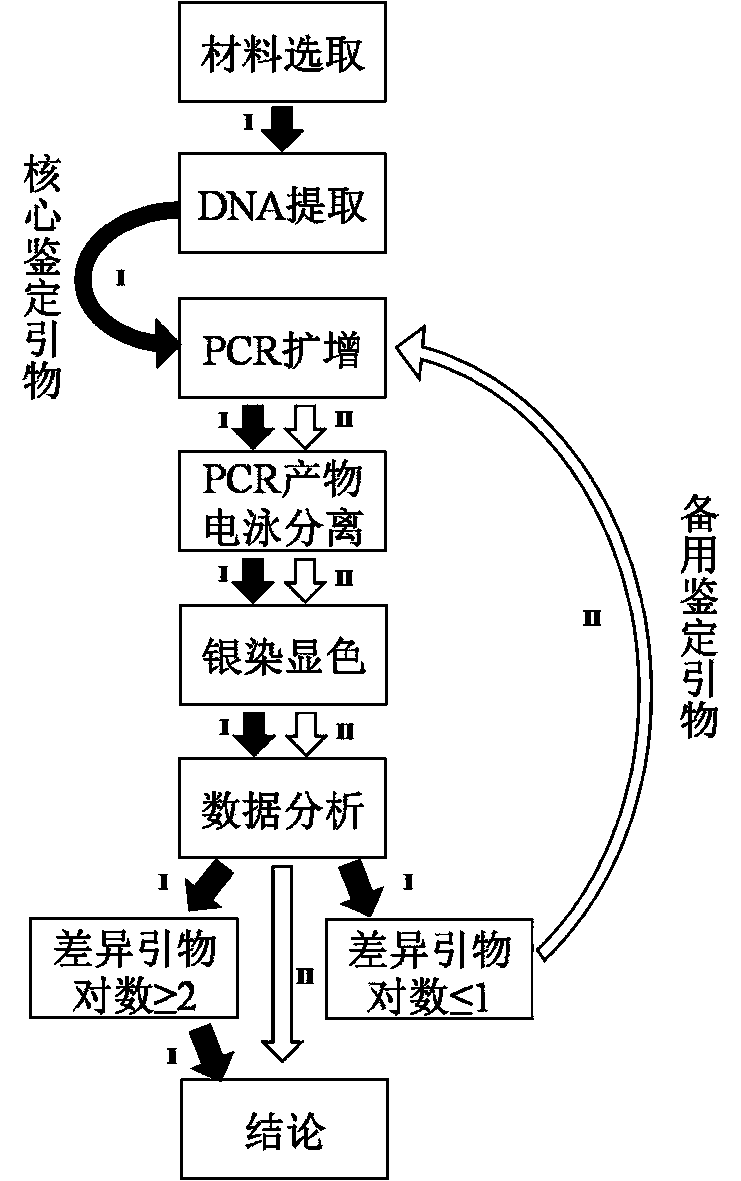

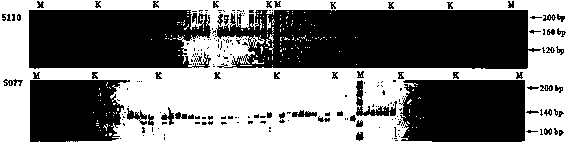

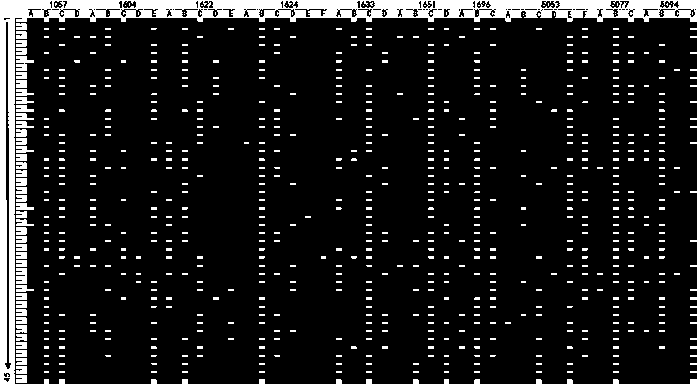

SSR (Simple Sequence Repeat) core primer group and method thereof for identifying tea variety

InactiveCN104004756AImprove identification efficiencyAvoid identification errorsMicrobiological testing/measurementDNA/RNA fragmentationElectrophoresisDNA extraction

The invention relates to an SSR (Simple Sequence Repeat) core primer group and a method thereof for identifying a tea variety, and belongs to the technical field of biology. The method is characterized by comprising the following steps: (1) material selection; (2) genome DNA extraction; (3) PCR (Polymerase Chain Reaction) amplification of a target product; (4) electrophoretic separation of a PCR product; (5) silver staining development; (6) data analysis; and (7) result judgment. The SSR core primer group and the method thereof for identifying the tea variety, which are disclosed by the invention, have the characteristics of easiness and convenience for operation, accuracy in result, high repeatability, high identification capacity, low cost and the like and are suitable for identifying the tea variety.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Method for detecting pathogen of sugarcane ratoon stunting disease

InactiveCN101984074ALow level of operation requiredStrong specificityMicrobiological testing/measurementDiseaseFluorescence

The invention relates to a rapid detection method of the pathogen of the sugarcane ratoon stunting disease. The method is characterized in that a sugarcane sample is frozen quickly with liquid nitrogen to perform grinding treatment, four specific primers are designed according to the ITS sequence of the pathogen of the sugarcane ratoon stunting disease, the loop-mediated isothermal amplification of the target fragment of the pathogen is performed; and the reaction product of the loop-mediated isothermal amplification is detected and identified, fluorescent dye GlodView is added in the reaction tube, and the judgement is made through visual inspection under the ultraviolet light of a money genuineness testing pencil. The detection method of the invention has reliability, high sensitivity, short detection time and low cost, and can diagnose the sugarcane ratoon stunting disease accurately and rapidly. The method does not require other special instruments, is convenient to operate and is particularly suitable for the field rapid and accurate detection of the sugarcane ratoon stunting disease.

Owner:FUJIAN NORMAL UNIV

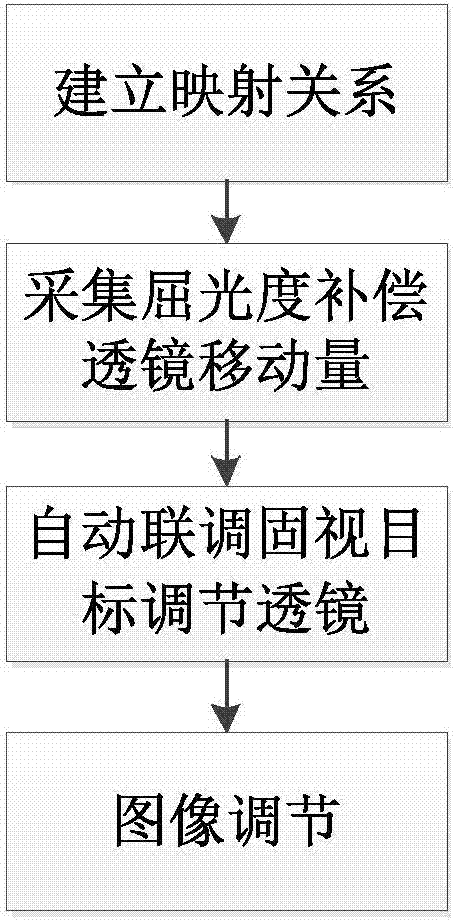

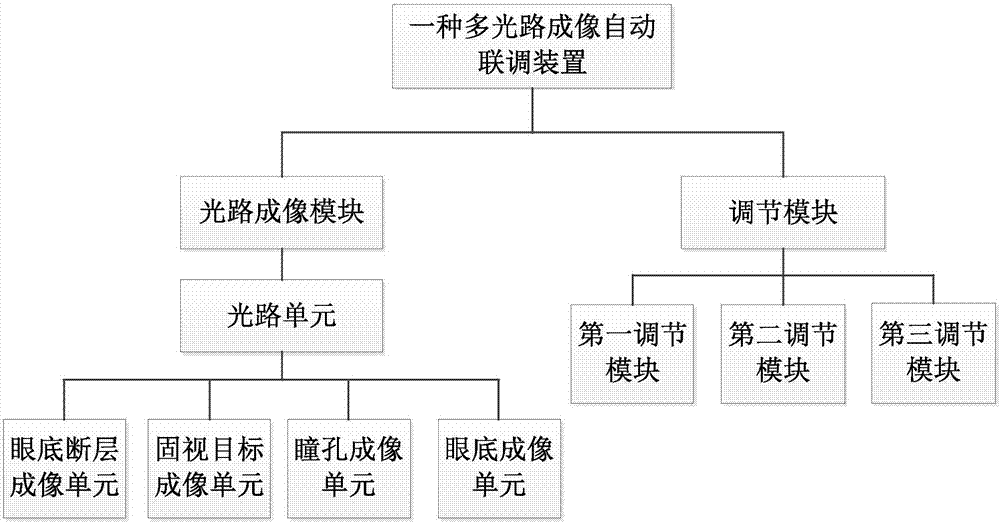

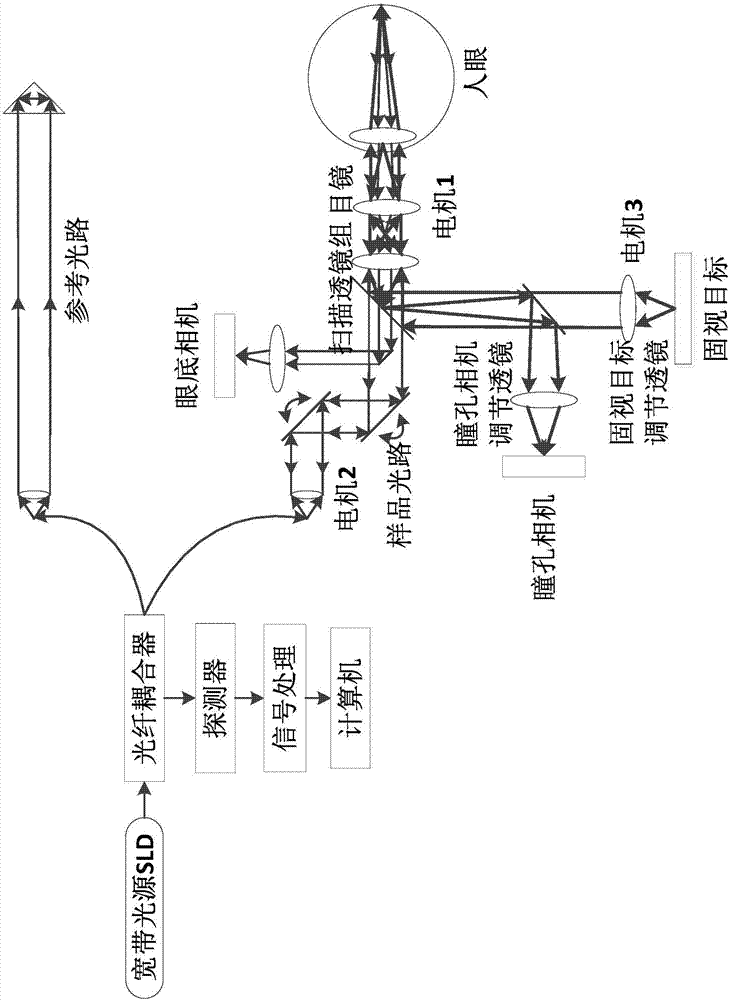

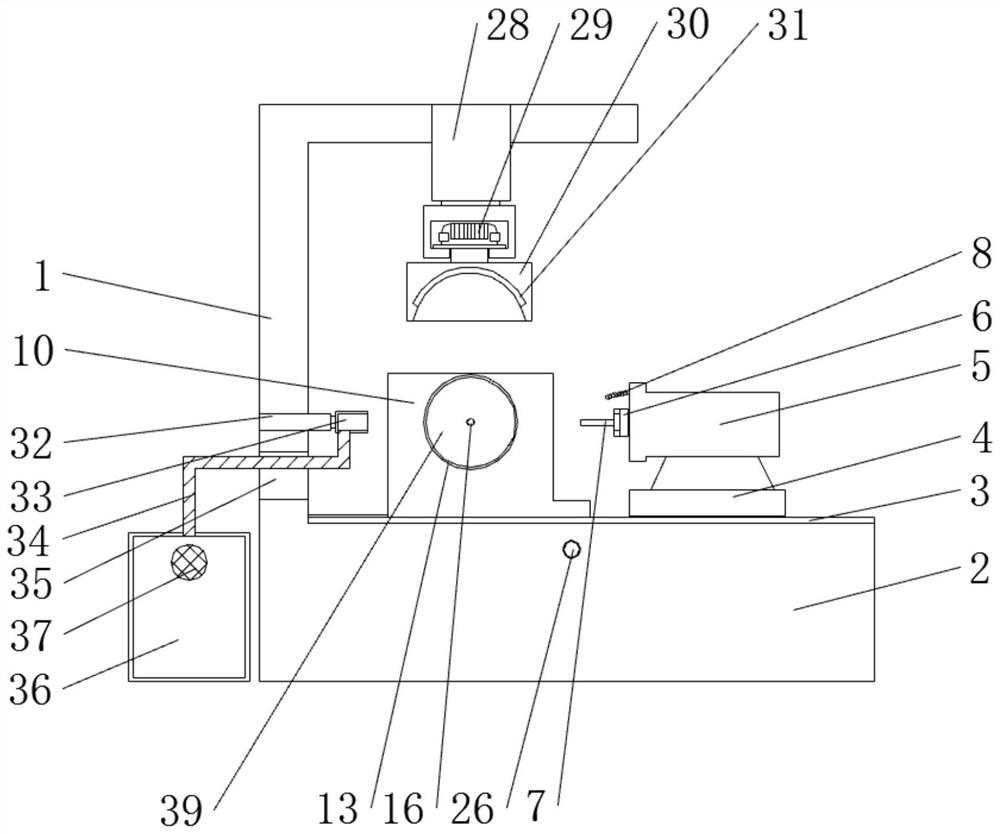

Automatic joint debugging method for multi-light path imaging and device thereof

PendingCN107224268AReduced commissioning timeImprove debug repeatabilityOthalmoscopesComputer visionTomography

The invention provides an automatic joint debugging method for multi-light path imaging and a device thereof. The method includes the steps of building a mapping relation, collecting movement amount of dioptric offset lens, automatically conducting joint debugging on an adjustment lens of a vision fixing target, and adjusting an image. The invention also relates to the automatic joint debugging device for multi-light path imaging. The device includes a light-path imaging module and an adjustment module, wherein the light-path imaging module is provided with a light path unit, and the adjustment module is used for automatically adjusting the light path unit which is composed of an eye-ground coherence tomography unit, a vision fixing target imaging unit, a pupil imaging unit and an eye ground imaging unit; the vision fixing target imaging unit is provided with a third adjusting module, the eye-ground coherence tomography unit is provided with a second adjusting module, and the eye ground imaging module is provided with a third adjusting module. By installing the adjusting modules of different precision on a position in a need of adjustment according to the demands for precision adjustment, the automatic joint debugging method for multi-light path imaging is utilized to achieve automatic joint debugging of multi-light path imaging, so that the debug time is reduced, the debug repeatability is improved, and the demands of staff's operational levels are decreased.

Owner:ZD MEDICAL HANGZHOU CO LTD

Noise control of thermal components in a hybrid electric vehicle

ActiveUS20140198919A1Low level of operation requiredHybrid vehiclesElectrical apparatusNoise controlEngineering

Noise control for a vehicle is implemented by identifying sources of noise that are indicative of vehicle noise producing components. The sources of noise include a thermal management device of a hybrid-electric component of the vehicle and non-hybrid-electric components of the vehicle. The noise control is further implemented by determining a decibel value of the noise produced by each of the vehicle noise producing components, selecting the decibel value of one of the vehicle noise producing components having a highest decibel value as a mask limit, and determining an operational limit for the thermal management device. The operational limit includes a lowest threshold operating value which, when implemented, maintains a threshold level operating efficiency of the hybrid-electric component. If a decibel value of the noise produced by the thermal management device exceeds the mask limit, the noise control includes reducing a level of operation of the thermal management device to coincide with the decibel value of the operational limit.

Owner:GM GLOBAL TECH OPERATIONS LLC

Software based spread spectrum signal processing

ActiveUS7848217B2Reduced implementation lossHigh sensitivityFrequency-division multiplexOrthogonal multiplexCarrier signalComputer science

A software correlator comprising: a partitioning module adapted to divide a number of the received data samples into a first number of data blocks; a first correlation module adapted to correlate each of the data blocks with a respective local code replica segment to produce a first number of intermediate accumulation results; an aggregation module adapted to combine a number of consecutive results of the intermediate accumulation results into a target number of aggregated accumulation results, the target number expresses a number of discrete carrier values in a carrier vector that represents a Doppler shift of the at least one spread spectrum source signal relative to a downconverting frequency for this signal; and a second correlation module adapted to correlate the aggregated accumulation results with the carrier vector to produce the decoded signal, which is compensated for the Doppler shift relative to the downconverting frequency.

Owner:QUALCOMM TECH INT

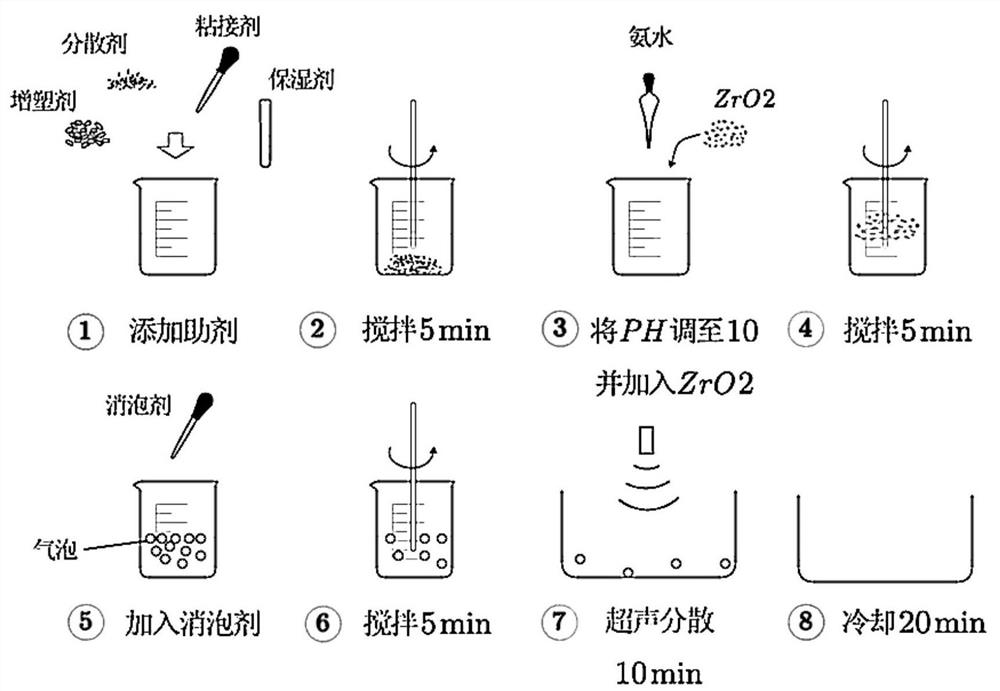

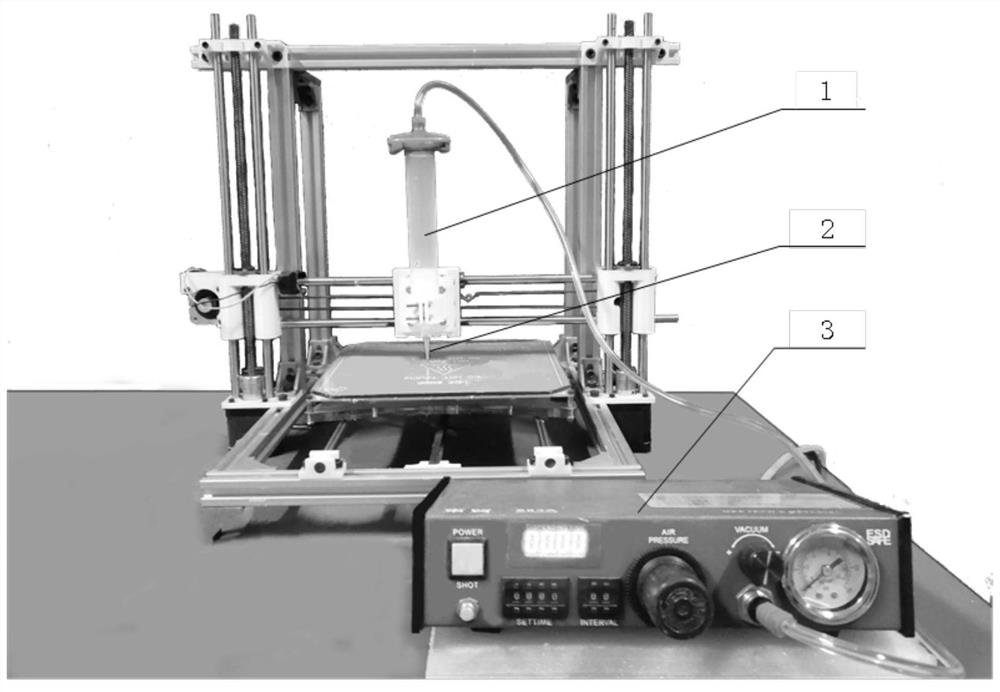

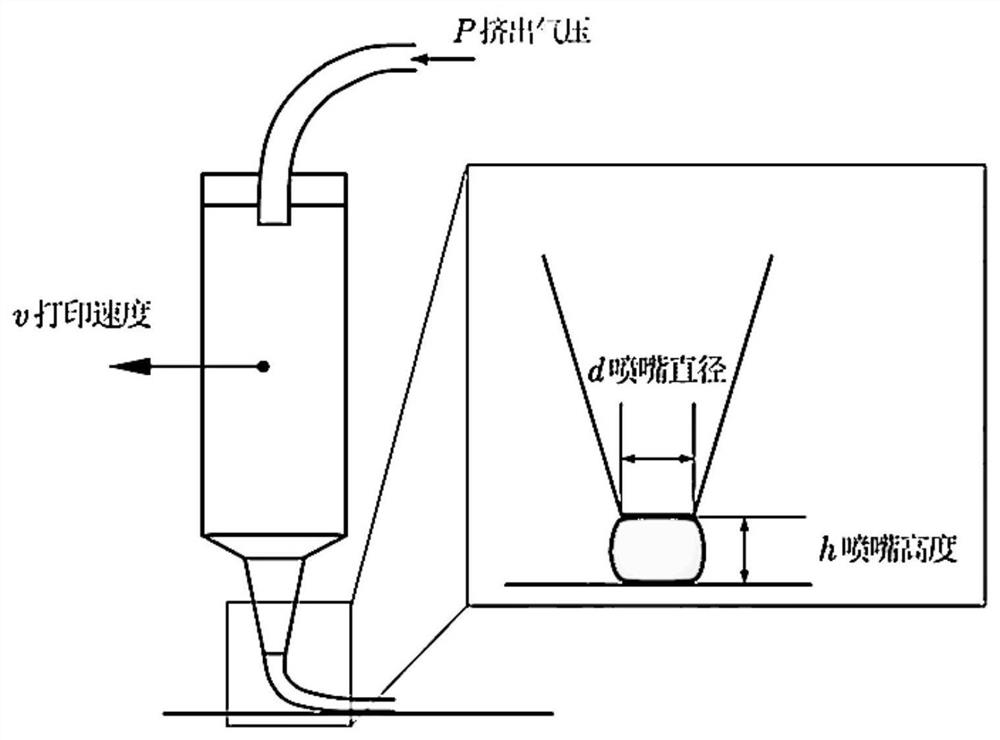

Preparation method of zirconia ceramic material extrusion type 3D printing material

PendingCN113372114ALow costLow level of operation requiredAdditive manufacturing apparatusBiocompatibilityDental crowns

The invention provides a preparation and printing method of a zirconia ceramic material extrusion type 3D printing material. The zirconium oxide ceramic material capable of being applied to extrusion type 3D printing is prepared by mixing a plurality of auxiliaries with zirconium oxide powder and carrying out defoaming and dispersing treatment. By accurately controlling the material ratio, printing parameters and a high-temperature glue discharging process, the material can be used for manufacturing zirconia ceramic products with excellent mechanical properties and biocompatibility, and can be applied to the medical fields of implants, dental crowns, skeleton manufacturing and the like; the manufacturing cost of the die can be saved, the requirement on the operation level of technicians is reduced, the production time of a single part is greatly shortened, the manufacturing period of small-batch products is shortened, and the economic benefit is further improved.

Owner:HEFEI UNIV OF TECH

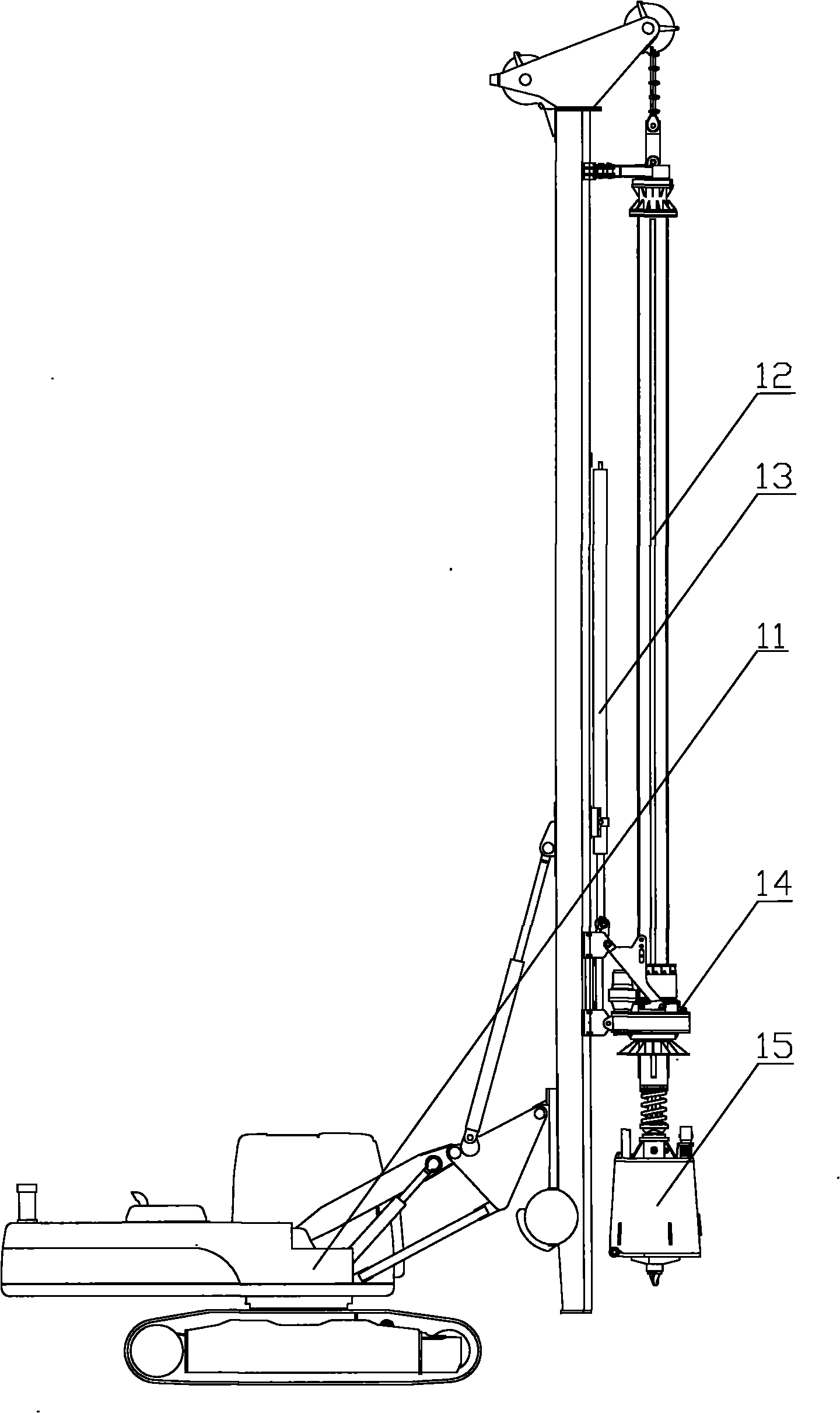

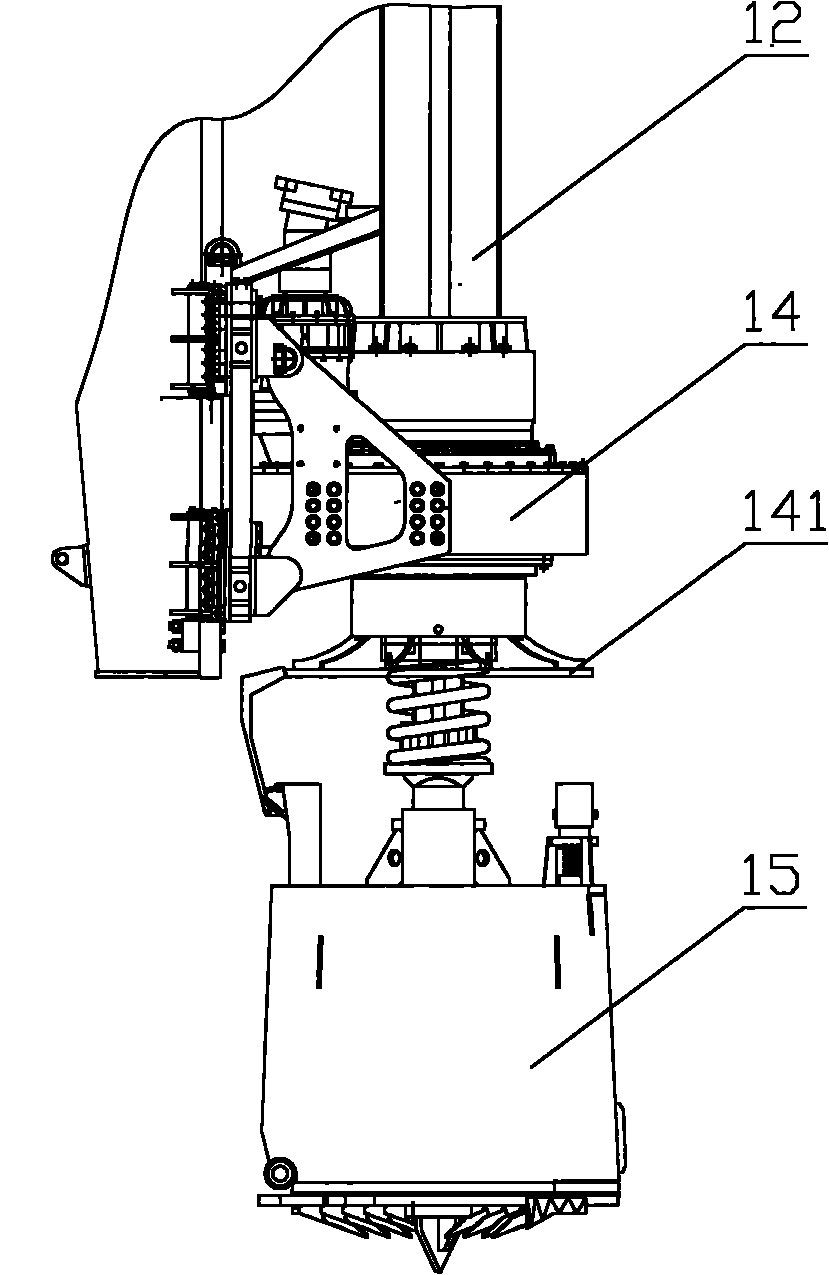

Piling machinery and sluice gate device thereof

InactiveCN101832100AImprove work efficiencyImprove reliabilityRotary drillingRotary-drilling machinesElectrical and Electronics engineeringSluice gate

The invention discloses a sluice gate device of a piling machinery. The sluice gate device comprises a sluice gate which is hinged to a bucket body through a first articulated shaft (22). The sluice gate device further comprises a power mechanism for driving the sluice gate to rotate around the first articulated shaft (22) so as to drive the sluice gate to close. Therefore, acting force for closing the sluice gate is provided by the power mechanism, and the acting force of the power mechanism can be predefined according to requirements during closing the sluice gate, thus the acting force formoving the sluice gate and the moving speed are stable, and the reliability of sluice gate closing is improved. Besides, the power mechanism is adopted to drive the sluice gate to close, which avoidsrepeating collisions, as a result, requirements on operation skills and experiences of operators are lowered, and the efficiency for closing the sluice gate is improved. The invention also discloses the piling machinery with the sluice gate device.

Owner:BEIJING SANY HEAVY MASCH CO LTD

Anastomosis clamp and anastomosis set containing anastomosis clamp

PendingCN111281467AIncrease success rateSimple connection structureWound clampsHuman bodyPeristalsis

The invention discloses an anastomosis clamp and an anastomosis set containing the anastomosis clamp. The anastomosis clamp comprises a carrier transparent cap, a pushing rod and a fixing clamp, wherein the carrier transparent cap is arranged at the front end of an endoscope; the front end of the carrier transparent cap is provided with a fixing clamp containing cavity, and the rear end of the carrier transparent cap is provided with a pushing cavity; the pushing cavity is communicated with the fixing clamp containing cavity; the fixing clamp is arranged in the fixing clamp containing cavity;one end of the pushing rod extends into the pushing cavity; the pushing cavity is located outside the endoscope; when the pushing rod is pushed forwards, the fixing clamp stretches out of the fixing clamp containing cavity, and the front end of the fixing clamp is tightened in the direction of the center axis. The anastomosis set comprises a traction clamp and the above anastomosis clamp, and thetraction clamp pulls the lesion tissues, so that the lesion tissues get close to the carrier transparent cap or enter the carrier transparent cap. The device is simple in structure, is not affected byhuman tissue peristalsis after entering a human body, cannot generate structural deformation and winding phenomena, and improves the success rate of an operation.

Owner:JIANGSU VEDKANG MEDICAL SCI & TECH

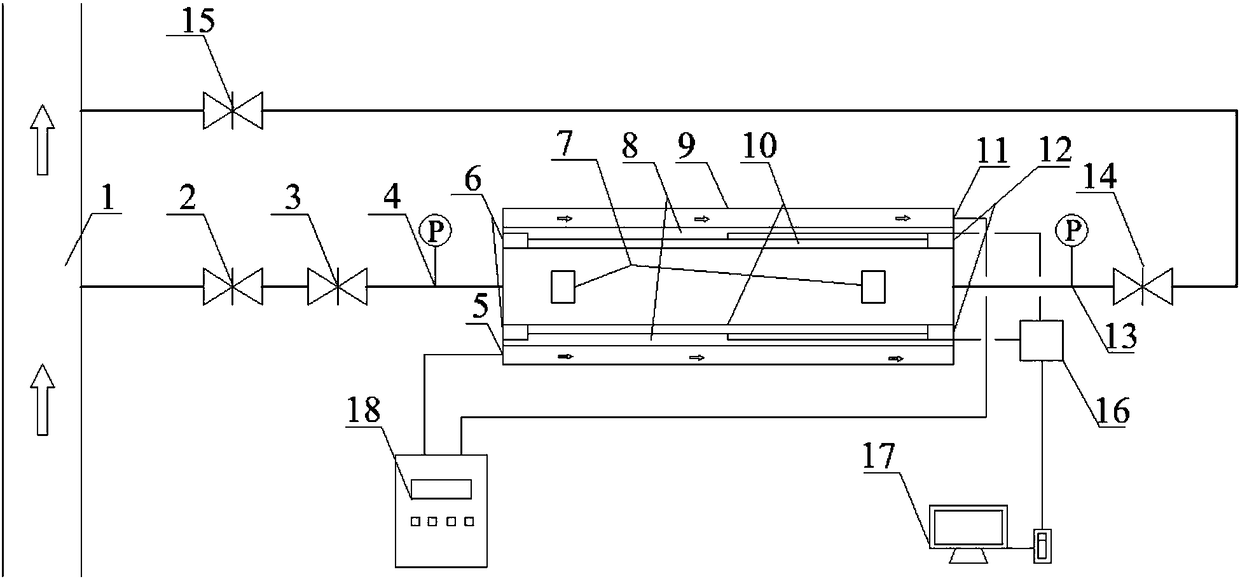

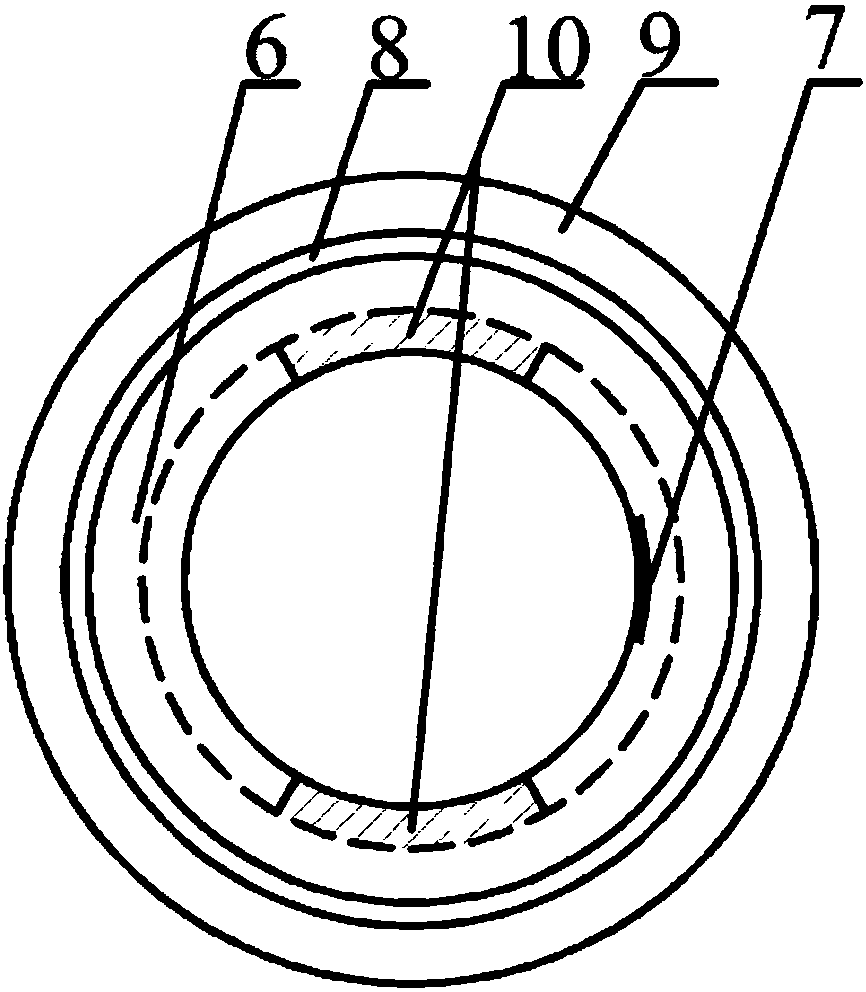

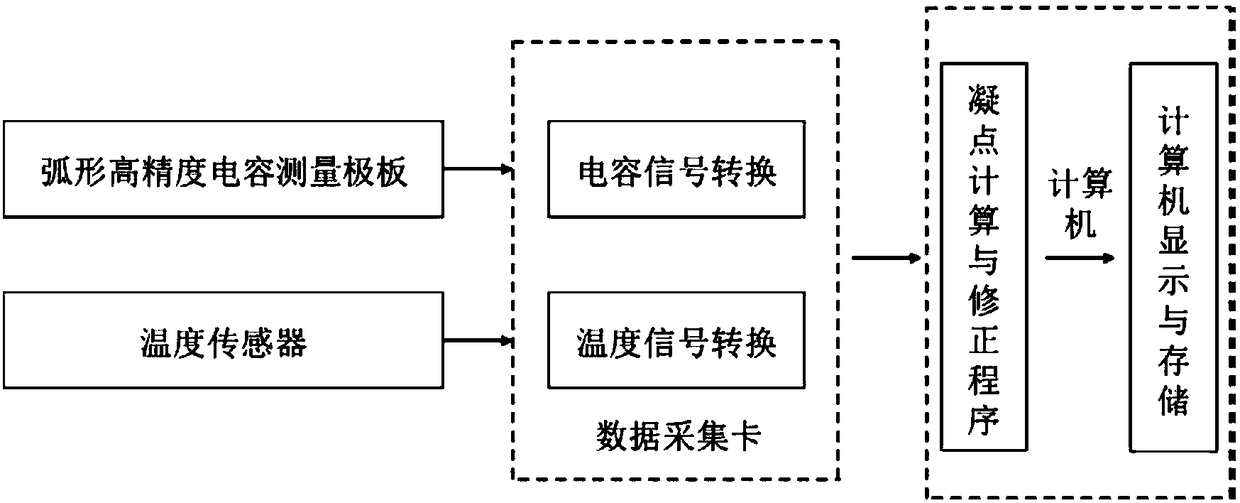

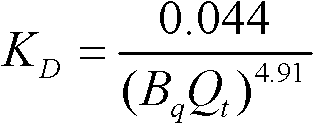

Online freezing point measuring device for crude oil conveying pipeline and method

ActiveCN108508058ALow level of operation requiredSimple structureMaterial capacitanceInvestigating phase/state changeWater bathsShielded cable

The invention discloses an online freezing point measuring device for a crude oil conveying pipeline and a method thereof. The device comprises an inlet valve, an inlet safety valve, an inlet pressuregauge, a sample measuring unit, a data acquisition card, an outlet pressure gauge, an outlet safety valve and an outlet valve, which are connected in sequence; the sample measuring unit comprises aninlet shielding ring, a temperature sensor, a shielding cover, a double-pipe heat exchanger, an arc-shaped high-precision capacitance measuring polar plate and an outlet shielding ring; the temperature sensor, the arc-shaped high-precision capacitance measuring polar plate, the data acquisition card, and a computer are connected by a double-shielded cable; and a digital display automatic temperature control water bath is connected with the double-pipe heat exchanger. The invention further discloses a method for measuring crude oil freezing points online by adopting the device. The device is simple in structure and high in degree of automation in a testing process, reduces the influence of subjective factors on the measurement of the freezing points, and improves the precision of the freezing point measurement.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

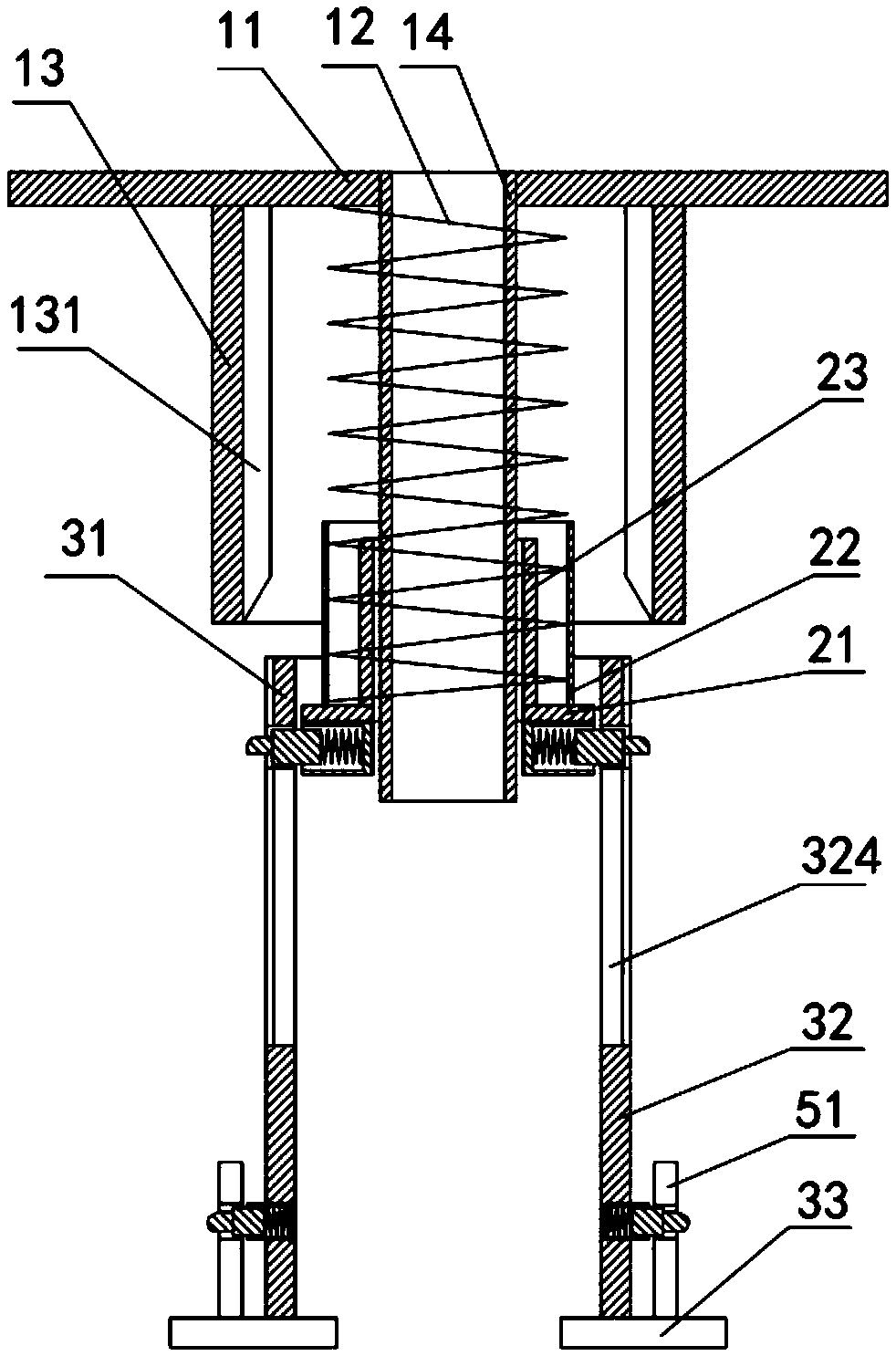

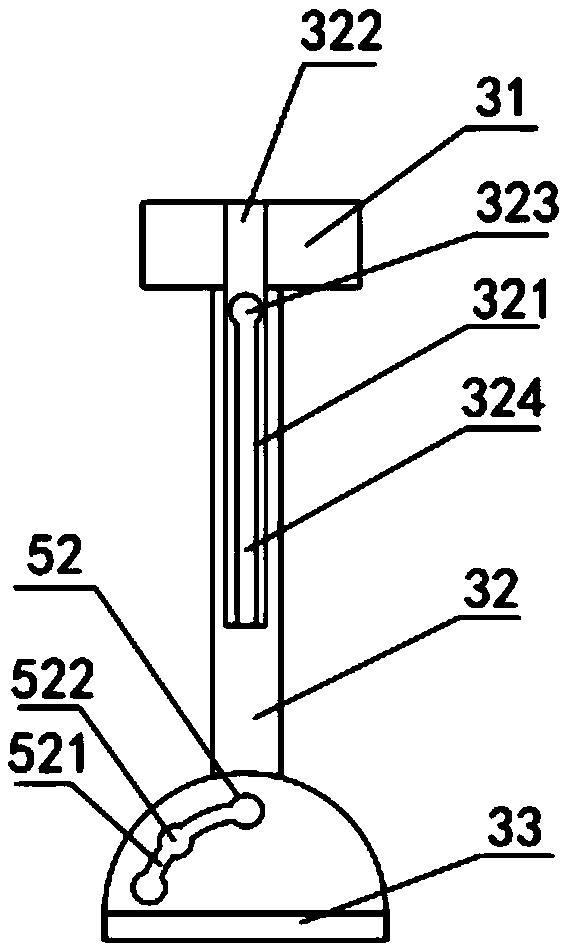

Acupuncture needle inserting assist device

The invention belongs to the technical field of medical apparatus and instruments, and particularly relates to an acupuncture needle inserting assist device. The acupuncture needle inserting assist device comprises an upper end assembly, a middle end assembly and a lower end assembly, wherein the upper end assembly comprises a supporting plate, a spring, an elliptic cylinder and a cylinder A, thecylinder A is arranged in the middle of the elliptic cylinder, the inner side wall of the elliptic cylinder is provided with protruding edges, the middle end assembly comprises an elliptic plate, a cylinder B and a cylinder C, the lower end of the cylinder A penetrates through the cylinder C, the spring is arranged on the periphery of the cylinder A, the top of the spring is fixed to the bottom ofthe supporting plate, the bottom of the spring is fixed to the top of the elliptic plate, both ends of a long shaft of the elliptic plate are provided with self-locking mechanisms A, the lower end assembly comprises elliptic rings, vertical columns and bases, the side walls of the upper ends of the vertical columns are provided with clamping grooves A cooperating with the self-locking mechanismsA, the outer side walls of the vertical columns are provided with grooves cooperating with the protruding edges, and the bottoms of the vertical columns are hinged to the tops of the bases. The acupuncture needle inserting assist device has the advantages that the stability of the operation process of an operator can be increased, the improvement of the stability and no limitation of the needle inserting depth are effectively combined, and the requirements for the finger force level of the operator are reduced.

Owner:李京俊

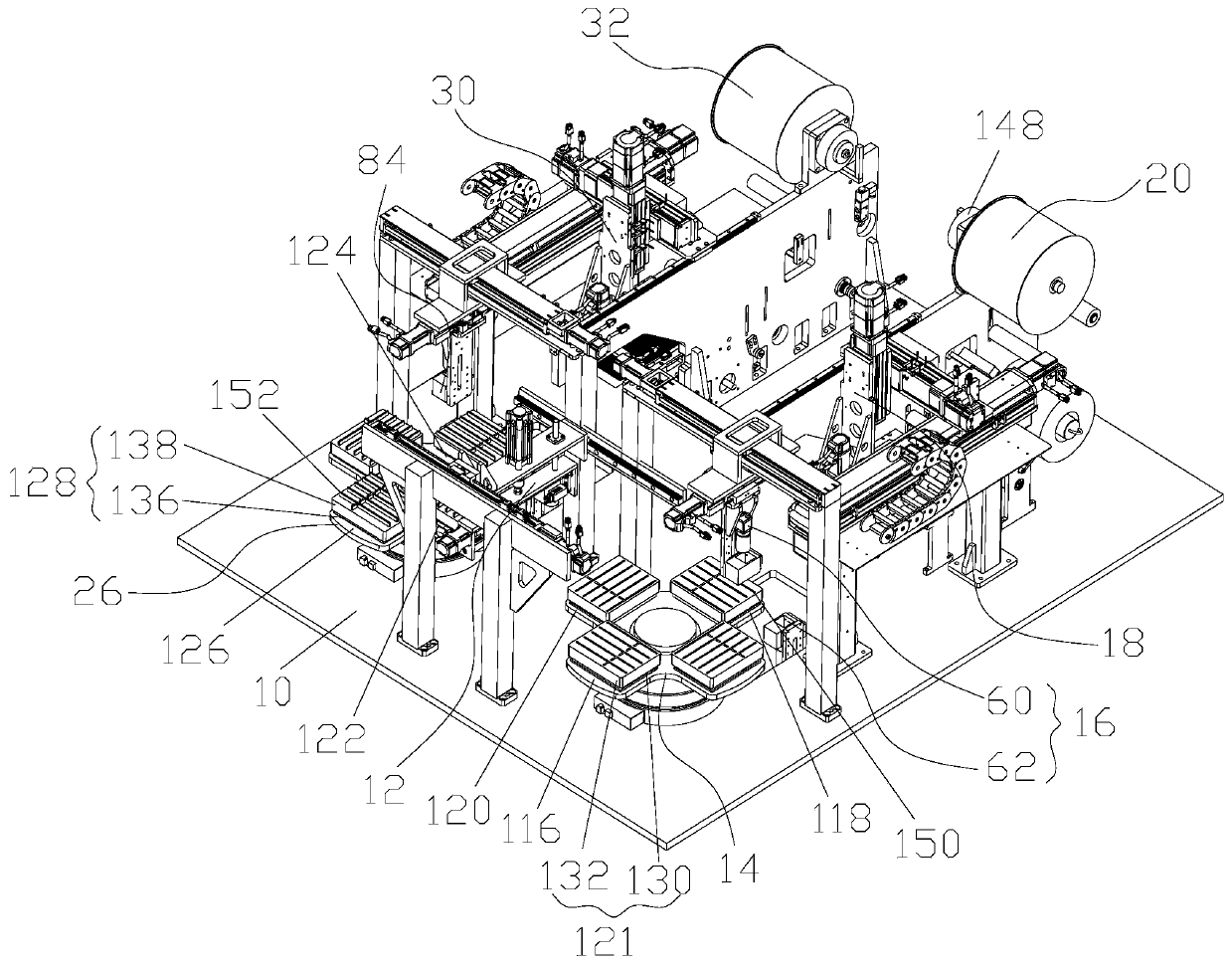

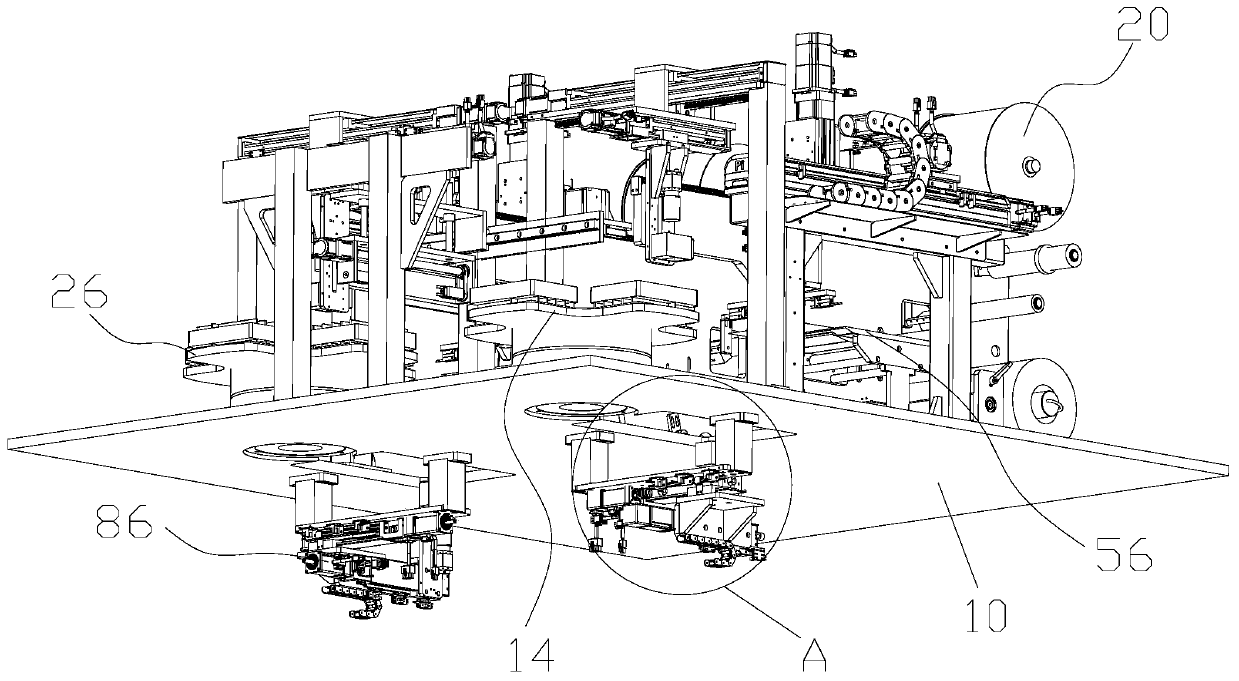

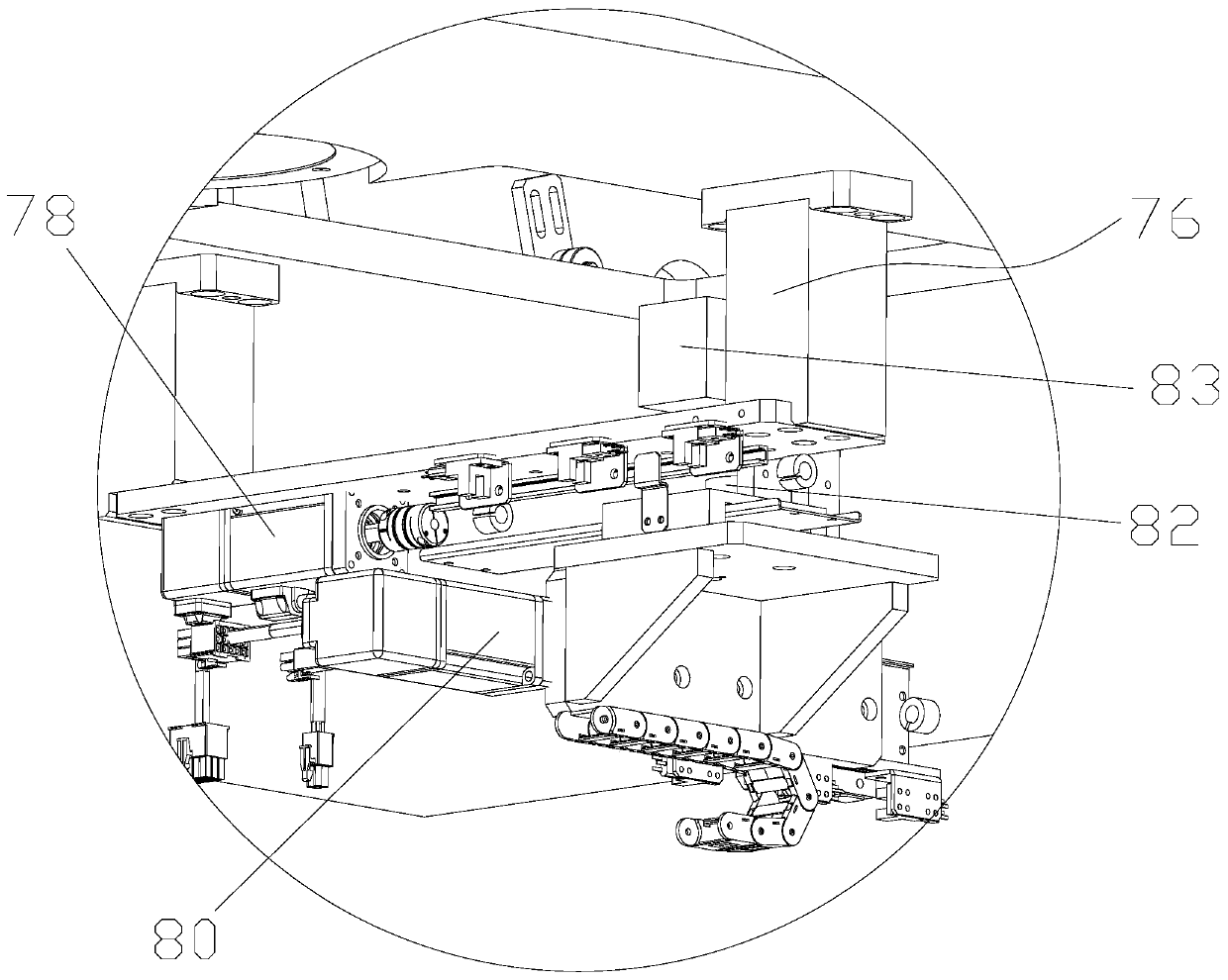

Automatic adhesive tape sticking machine

PendingCN110626855AImprove fitting accuracySatisfy the needs of laminating productionLaminating printed circuit boardsConveyor partsEngineeringRotating disc

The invention relates to an automatic adhesive tape sticking machine. The automatic adhesive tape sticking machine comprises a table plate, a first adhesive tape laminating mechanism, a second adhesive tape laminating mechanism and a transfer turnover mechanism, wherein the first adhesive tape laminating mechanism, the second adhesive tape laminating mechanism and the transfer turnover mechanism are arranged on the table plate. The first adhesive tape laminating mechanism and the second adhesive tape laminating mechanism are arranged side by side in the X-axis direction, the first adhesive tape laminating mechanism comprises a first rotating disc, a first photographing mechanism, a first adhesive tape sticking mechanism and a first material roll discharging mechanism, the first adhesive tape sticking mechanism comprises a first film stripping mechanism and a first adhesive tape compensating mechanism located above the first film stripping mechanism, the second adhesive tape laminatingmechanism comprises a second rotating disc, a second photographing mechanism, a second adhesive tape sticking mechanism and a second material roll discharging mechanism, and the second adhesive tape sticking mechanism comprises a second film stripping mechanism and a second adhesive tape compensating mechanism located above the second film stripping mechanism. Through fine adjustment of a servo motor, the error between laminating target precision can be compensated, the laminating precision of adhesive tapes can be greatly improved, and the laminating production needs for higher and higher precision now can be met.

Owner:JIANGSU BVM INTELLIGENT TECH

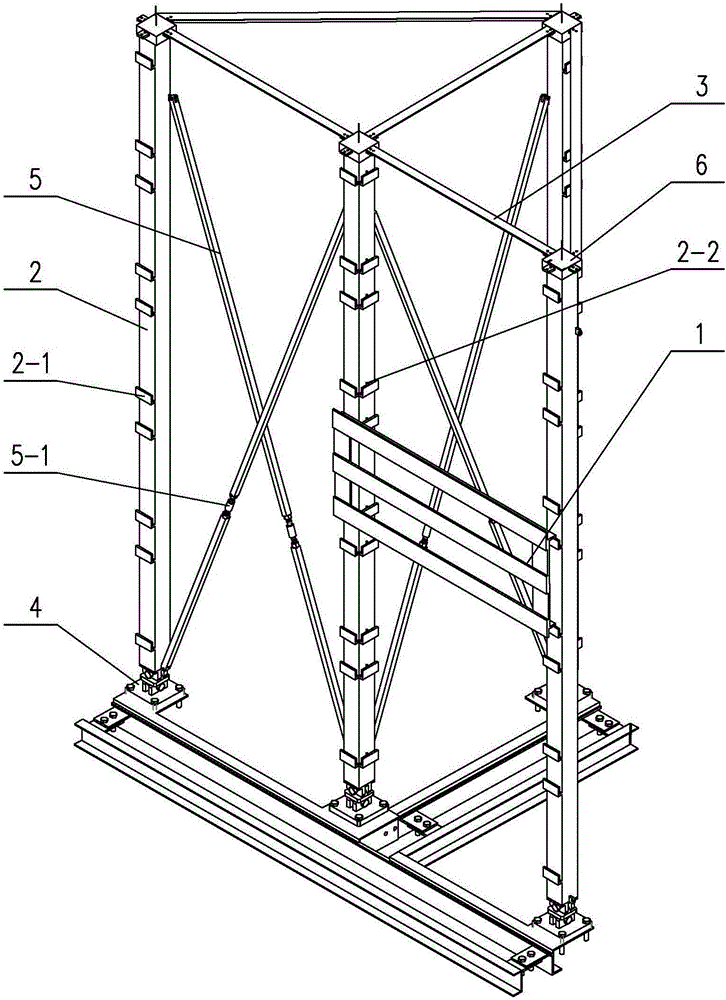

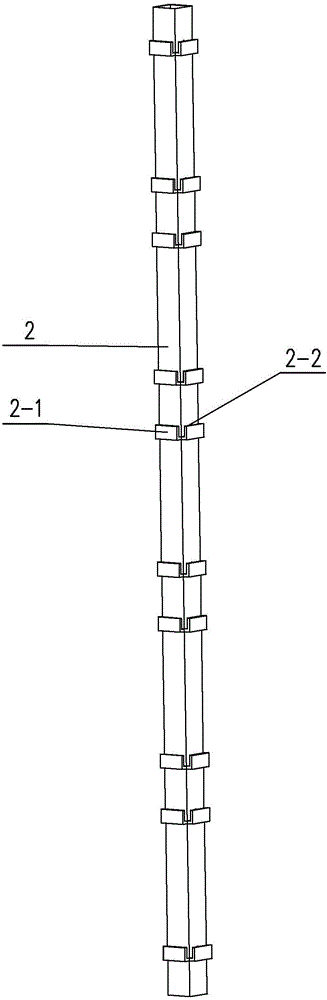

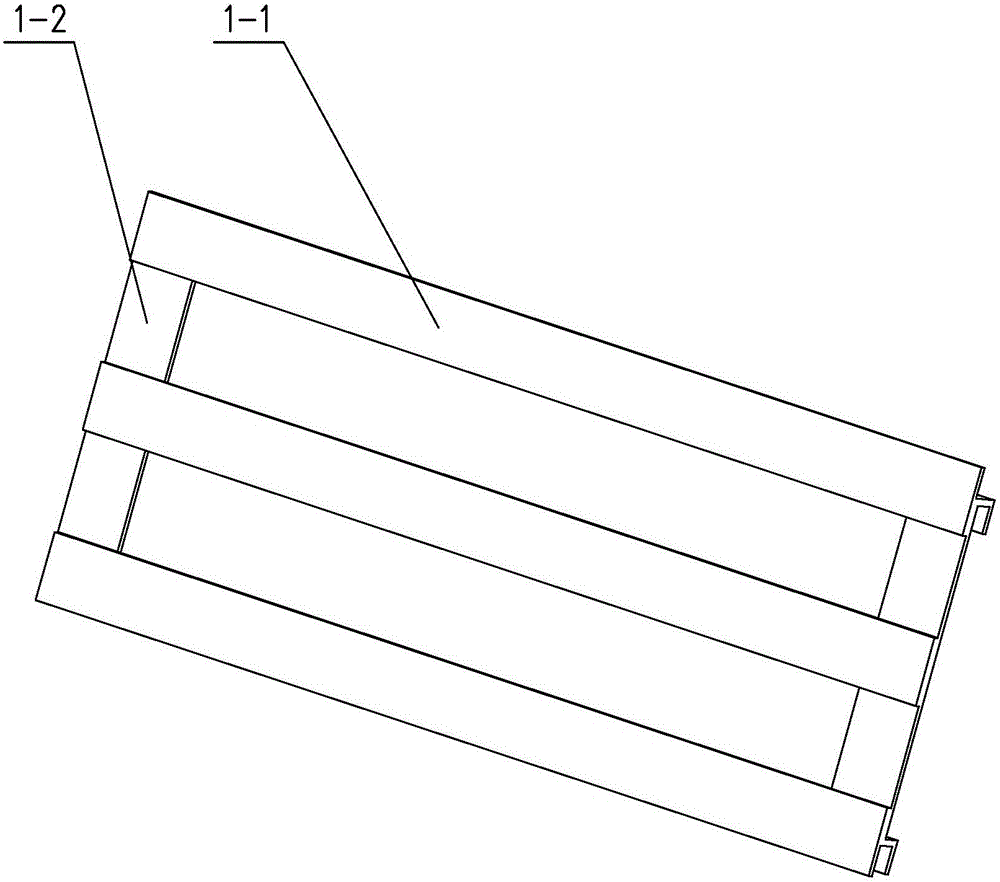

Scale device for masonry wall building

ActiveCN105064703ASimple and efficient operationHigh precisionBuilding material handlingStructural engineeringBuilding process

The invention provides a scale device for masonry wall building, and relates to the scale device, in particular to the scale device for masonry wall building. The scale device aims to solve the problems that in an existing reinforcement masonry wall building process, vertical detection needs to be conducted repeatedly, the requirement for the technical level of workers is high, working efficiency is low, and labor intensity is high. The scale device for masonry wall building comprises guiding rules and a plurality of stand columns. The stand columns are vertically arranged to form a prismoid shape. The top ends of every two adjacent stand columns are connected through horizontal supports. The outer side wall of each stand column is evenly provided with a plurality of sets of hooks in the vertical direction. Each guiding rule comprises three scales. The guiding rules are hung on the hooks on the outer sides of the every two adjacent stand columns through hanging plates. The bottom end of each stand column is provided with a universal hinge support. The scale device is used for auxiliary positioning in the wall building process.

Owner:HARBIN DACHENG GREEN BUILDING TECH DEV

Tapping machine convenient for fixing raw materials for bolt ball processing

ActiveCN112692384AEasy to processEasy to adjustThread cutting machinesPositioning apparatusGear wheelElectric machinery

The invention discloses a tapping machine convenient for fixing raw materials for bolt ball processing. The tapping machine comprises a rack, a second slide rail, a clamping plate, a bolt, a partition plate, a first hydraulic drive device and a second hydraulic drive device, wherein a workbench is fixed to the middle of the rack, the first slide rail is fixed to the top of the workbench, and a sliding table is connected to the top of the first slide rail in a sliding mode; and a spindle box is fixedly mounted at the top of the sliding table, a tool rest is fixedly mounted on the front side of the spindle box, and a screw tap is fixed to the front side of the tool rest. According to the tapping machine convenient for fixing raw materials for bolt ball processing, a screw, a gear shaft and a connecting gear are arranged, a step motor drives the gear shaft to rotate through the connecting gear, and the gear shaft drives the screw to rotate, so that the screw spirally moves along a screw hole until one end of the screw enters a to-be-bolted ball, accurate positioning of the bolt ball is conveniently completed, and errors after the angle of the bolt ball is adjusted are reduced; the clamping speed is increased in the mode that the two clamping plates clamp the bolt ball, and therefore, the tapping machine is high in production efficiency.

Owner:徐州通域空间结构有限公司

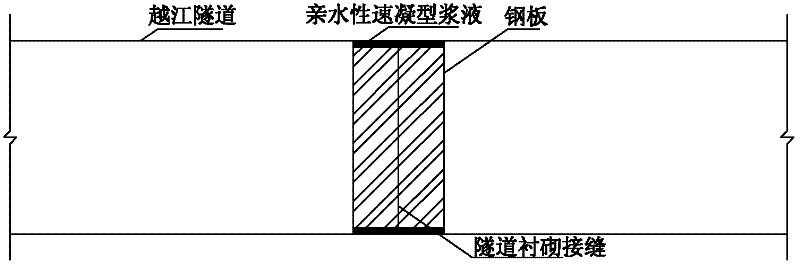

Tunnel seepage protection method for soft soil stratum by existing shield method

ActiveCN102536270ALow level of operation requiredImprove leakageMining devicesUnderground chambersGeomorphologyPermeability coefficient

The invention discloses a tunnel seepage protection method for a soft soil stratum by an existing shield method, which includes: acquiring stratum division information of shallow soil containing a tunnel; determining permeability coefficient of the stratum; obtaining theoretical maximum seepage through the stratum permeability coefficient and lining permeability coefficient; distributing detection points at the theoretical maximum seepage position of the tunnel, a structural longitudinal inflection point of the tunnel and a seam between the tunnel and the lining; and timely taking plugging measures when seepage occurs at the detection points. Waterproofing and seepage protection effects are evident for the tunnel, and the method is simple and low in operation cost.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com