Integrally-formed shoulder tab mould

A shoulder loop and one-piece technology, which is applied in the field of integrated shoulder loop molds, can solve problems such as low processing efficiency, uneven processing allowance, and complicated operation, meet the requirements of lowering the operation level, and solve the problem of cumbersome processing methods and seams. The effect of making the process simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

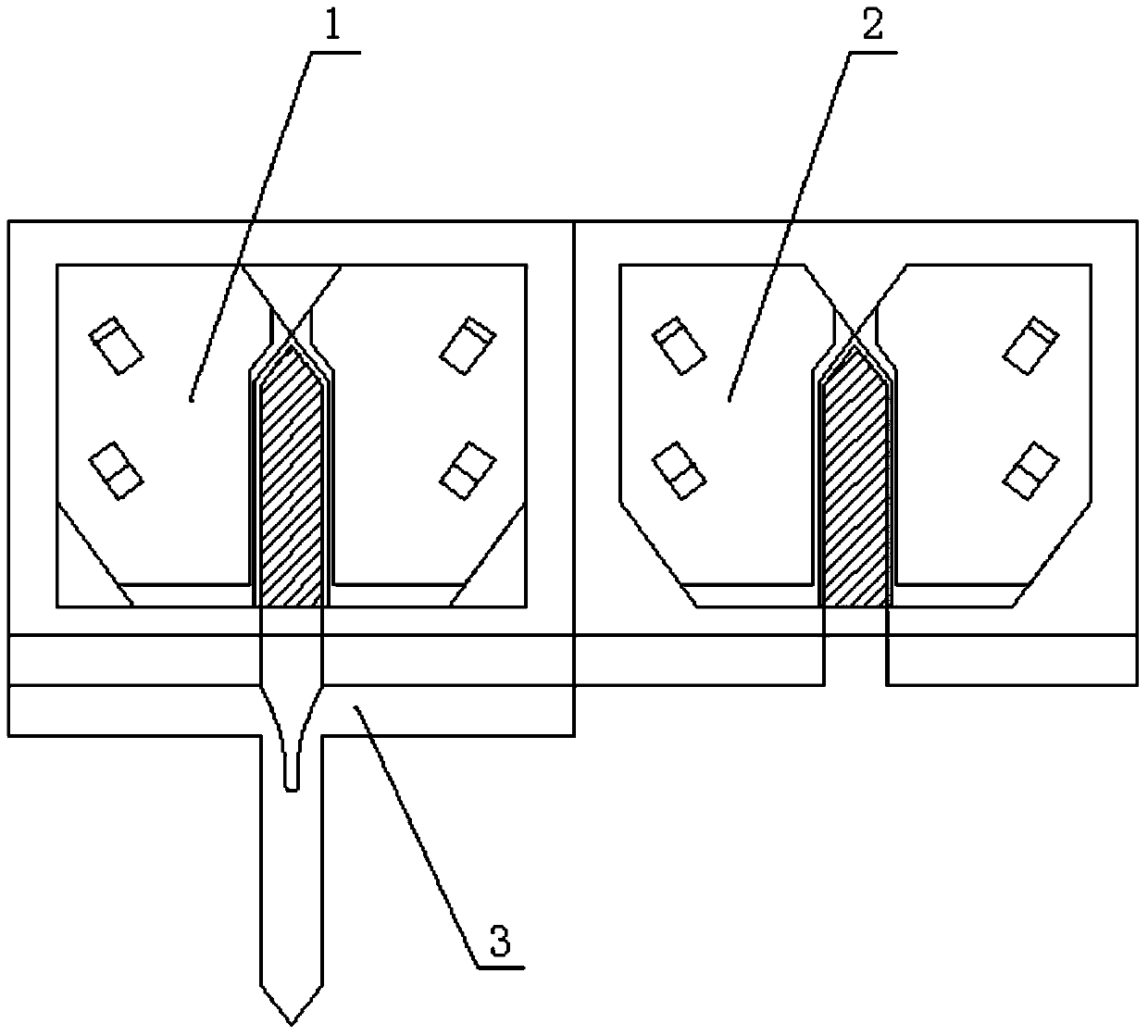

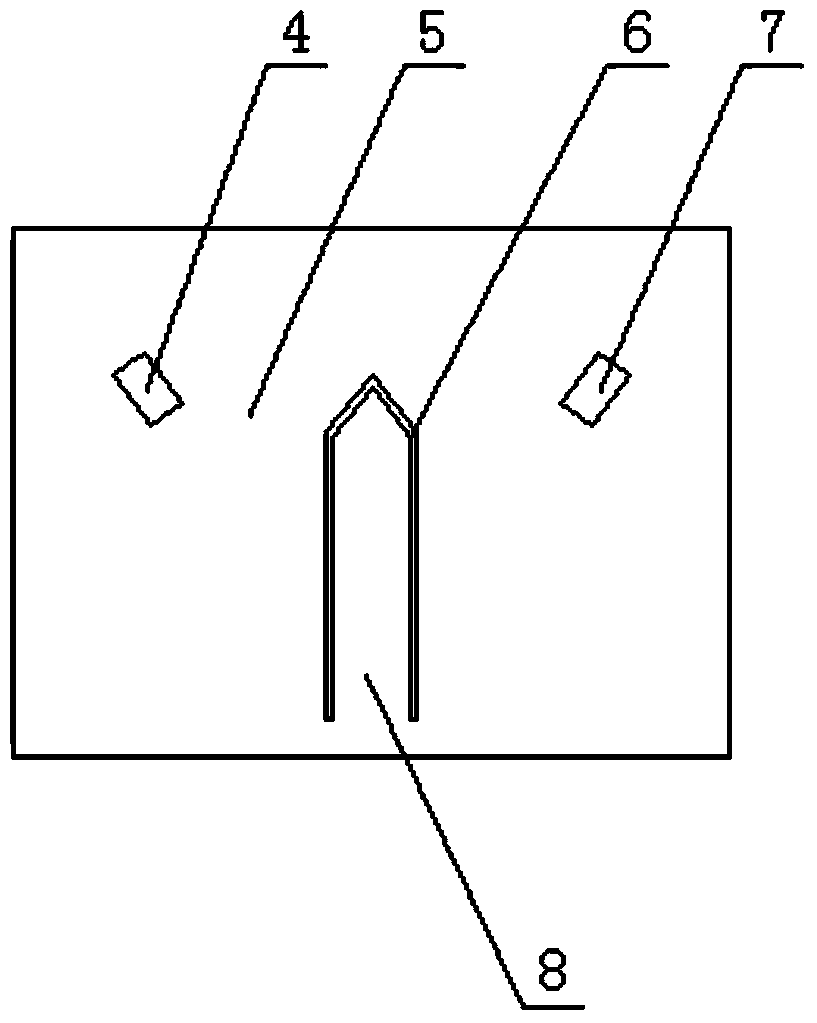

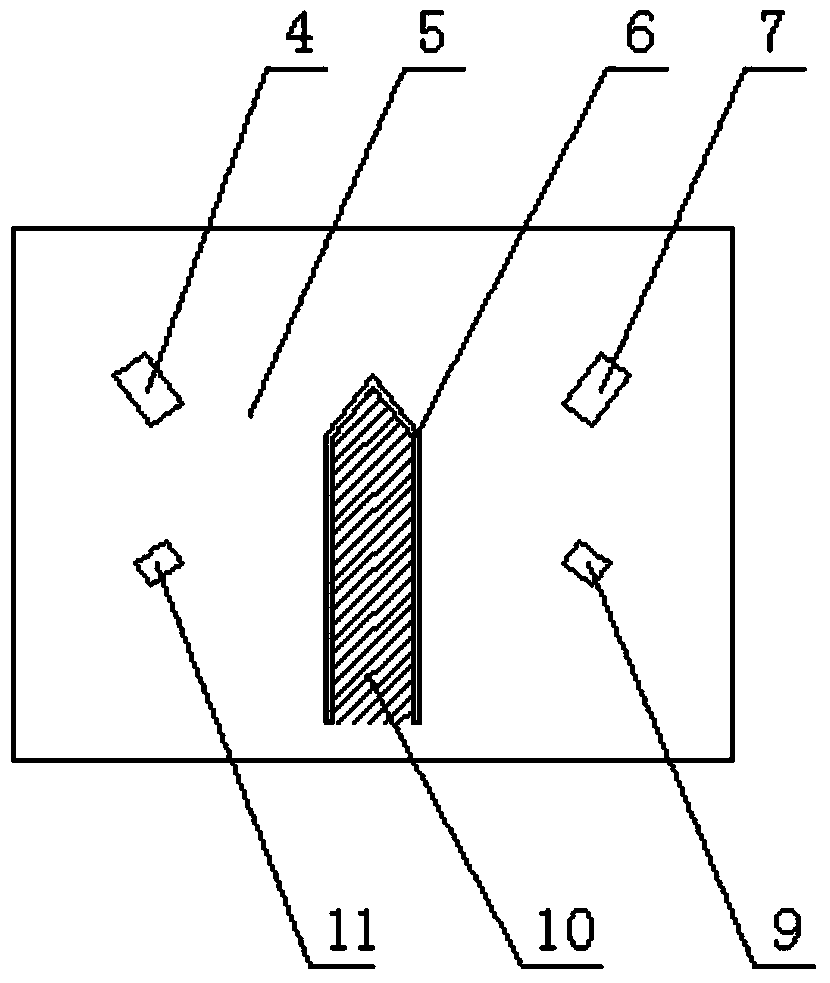

[0027] An integrally formed shoulder loop mold is composed of a base plate (1), a cover plate (2), a splint (3), and a fixing piece (29). One side of the base plate is hingedly connected with a cover plate that is mirror-image symmetrical and has the same structure as the base plate. The base plate is composed of a base plate positioning plate (5), a base plate backing plate (12), a base plate cover plate (26), a left base plate splint (20), and a right base plate splint (21), and the base plate positioning plate and the base plate cover plate are combined There is a base plate backing plate, the middle part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com