High output heating device

a heating device and high output technology, applied in the field of high output, multifuel, domestic heating devices, can solve the problems of adversely affecting the output of the device, complex and inefficient techniques for fixing parts, and drawbacks in assembly methods, so as to achieve high output and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

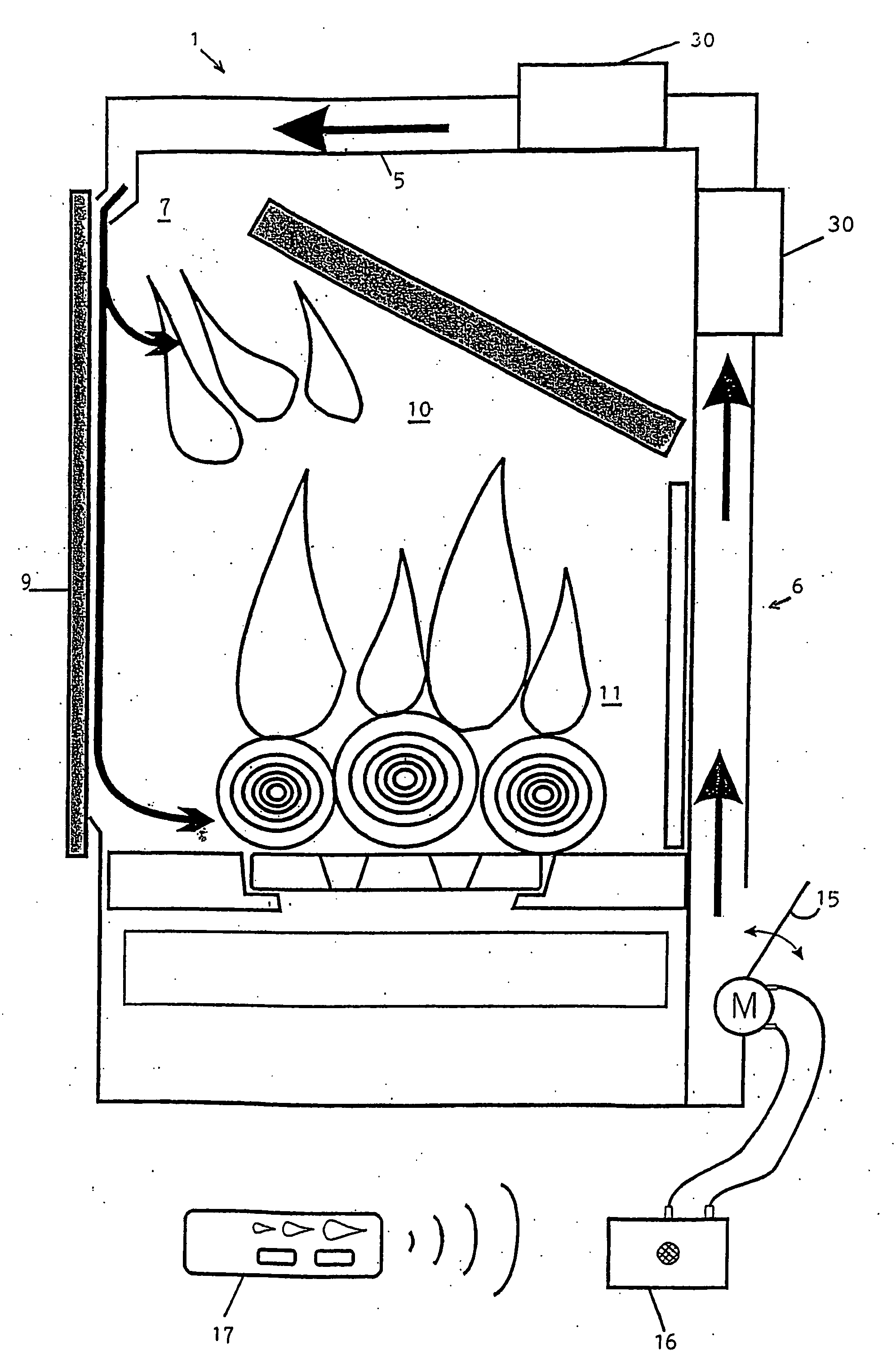

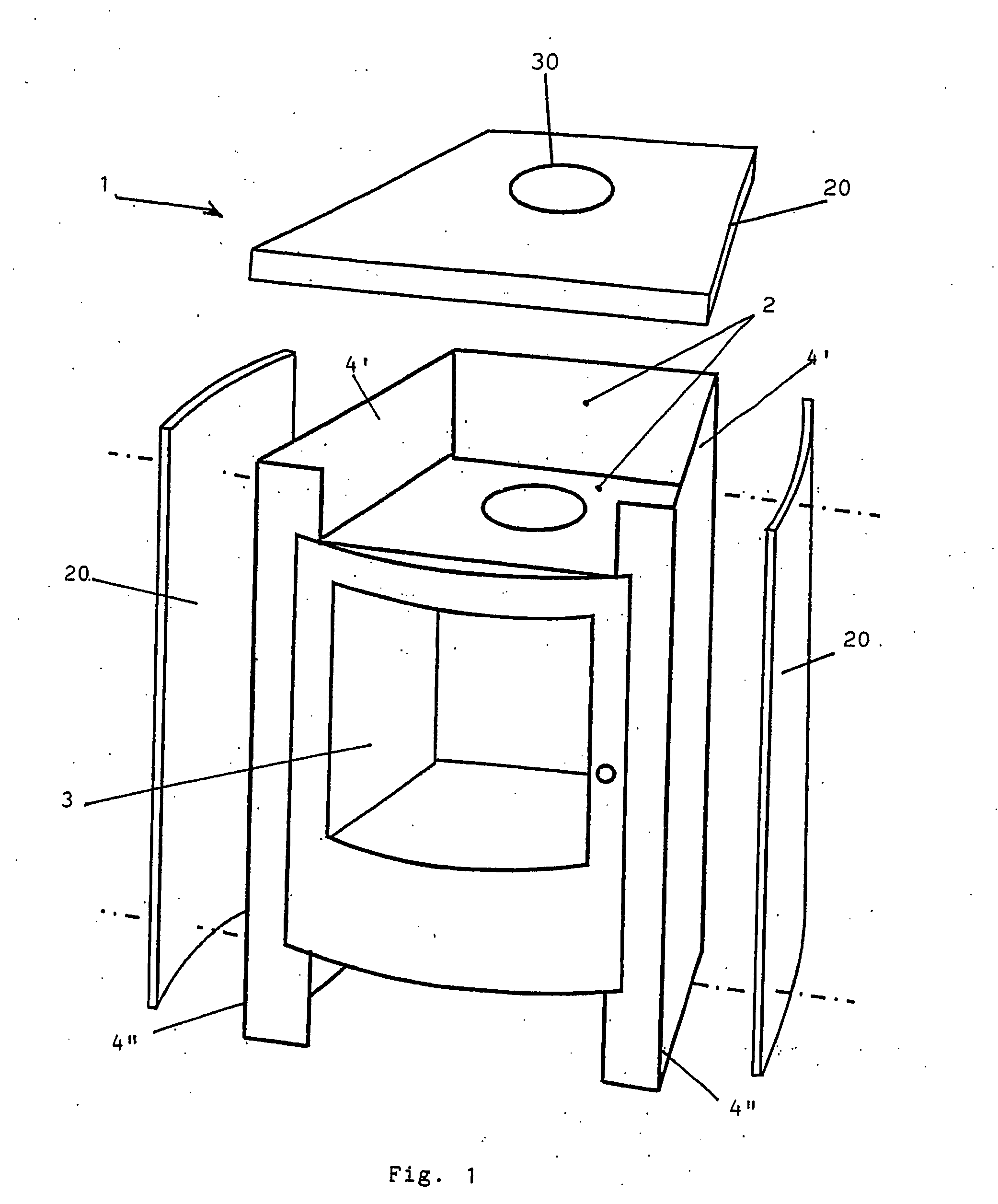

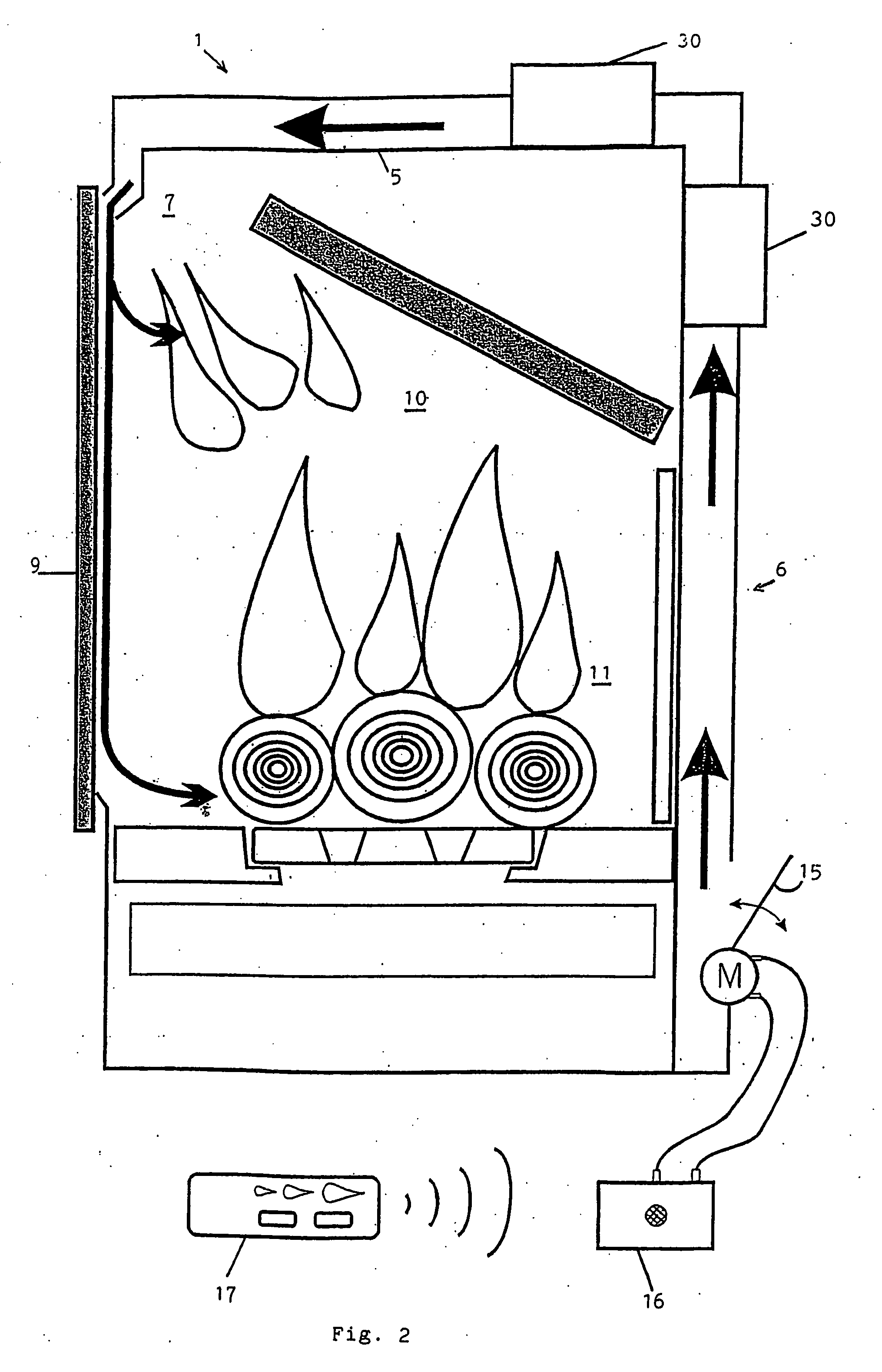

[0039] As described in FIG. 1, the present invention proposes a combustion chamber 1 made of folded and welded sheet steel 2. Alternatively, a different weldable metal could be used. In this way, a combustion chamber is made in a prismatic shape, constructed in accordance with the principle of the “thermos”. The only aperture provided toward the area to be heated is that allowing the placement of a door 3, for instance also in steel or in decorative cast iron, on the front face.

[0040] The principle of a closed combustion chamber according to the invention is a great advantage in as much that the latter may be made in an almost perfectly sealed manner. Slight losses of seal may in fact inevitably occur at the door joint. Therefore, an exceptionally high output is obtained (of the order of 80%). Moreover, the stove or the heating device may comprise only said combustion chamber and have compact dimensions, solely depending on the nominal power desired.

[0041] Advantageously, the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com