Scale device for masonry wall building

A masonry wall and ruler technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of low work efficiency and high labor intensity, and achieve the effects of easy operation, reduced labor intensity, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

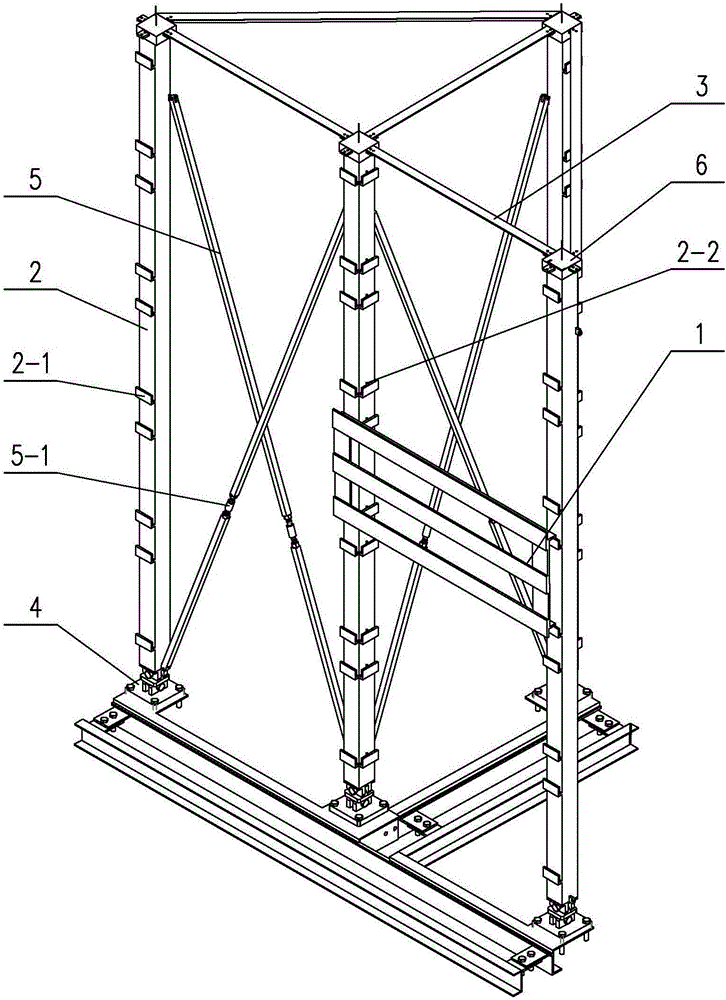

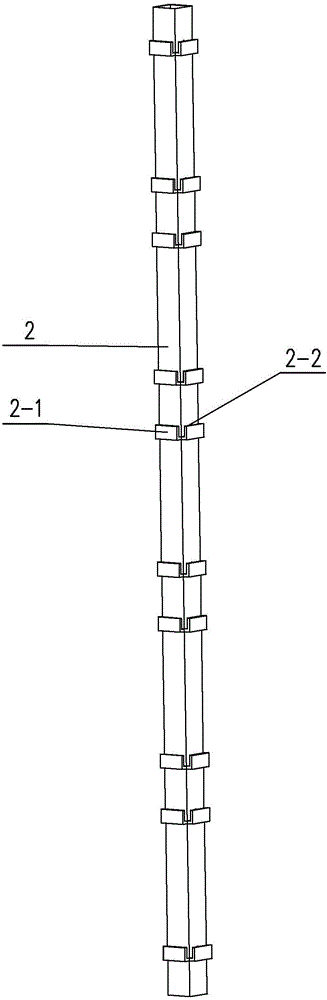

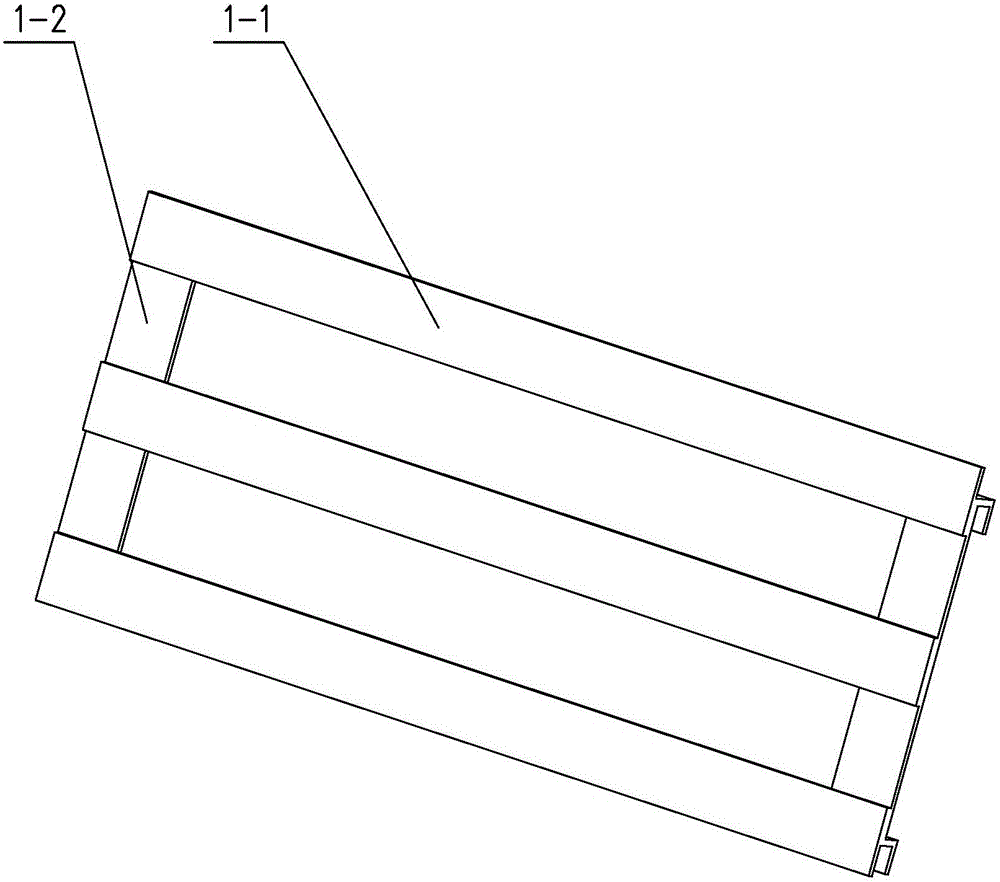

[0016] Specific implementation mode one: combine Figure 1 to Figure 9 Explain that a scale device for building block masonry walls described in this embodiment includes a ruler 1 and a plurality of columns 2, and the plurality of columns 2 are respectively vertically arranged, and the shape formed by the plurality of columns 2 is a prism Body shape, the tops of two adjacent columns 2 are respectively connected by horizontal supports 3, and the outer wall of each column 2 is evenly arranged with multiple sets of hooks 2-1 along the vertical direction, and the ruler 1 includes three scales 1-1, The three scales 1-1 are arranged evenly from top to bottom along the vertical direction, each scale 1-1 is set horizontally, and the left and right ends of the scale 1-1 are respectively provided with connecting plates 1-2, adjacent to each other The scales 1-1 are respectively connected by connecting plates 1-2, and the upper edge of each scale 1-1 is provided with a scale respectively...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 , image 3 and Figure 4 Description, the upper end surfaces of the two hanging plates 1-3 of the scale 1-1 at the top of the ruler 1 described in this embodiment are all provided with first threaded through holes 1-4, and each first threaded through hole 1-4 Adjusting bolts are respectively screwed inside. Other compositions and connection methods are the same as those in Embodiment 1.

[0021] In such a design, the end of the adjusting bolt is pressed against the hook 2-1 of the column 2, and the distance between the lower end surface of the hanging plate 1-3 and the upper end surface of the hook 2-1 is adjusted by rotating the adjusting bolt, which is used to adjust the ruler 1 level.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination figure 1 and figure 2 Note that in this embodiment, the outer wall of each column 2 is respectively provided with a plurality of second threaded through holes 2-2 along the vertical direction, and each second threaded through hole 2-2 is respectively arranged on a hook 2-2. 1, each second threaded through hole 2-2 is respectively screwed with a set bolt. Other compositions and connection modes are the same as those in Embodiment 1 or 2.

[0023] After hanging the ruler 1 in this way, tighten the fixing bolts so that the hanging plate 1-3 of the ruler 1 is close to the inner wall of the hook 2-1 of the column 2 to prevent the gap between the ruler 1 and the column 2 , to ensure that the verticality standard is reached by ruler 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com