Billet continuous casting machine crystallizer liquid level cesium source calibration device and method

A billet continuous casting and calibration device technology, applied in the field of billet continuous casting machine crystallizer liquid level control equipment, cesium source calibration device, can solve the problem that the measurement position cannot be completely fixed, the labor intensity of the operator is large, and the measurement error is large and other problems, to achieve the effect of improving accuracy and calibration efficiency, reducing labor intensity, and reducing calibration errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

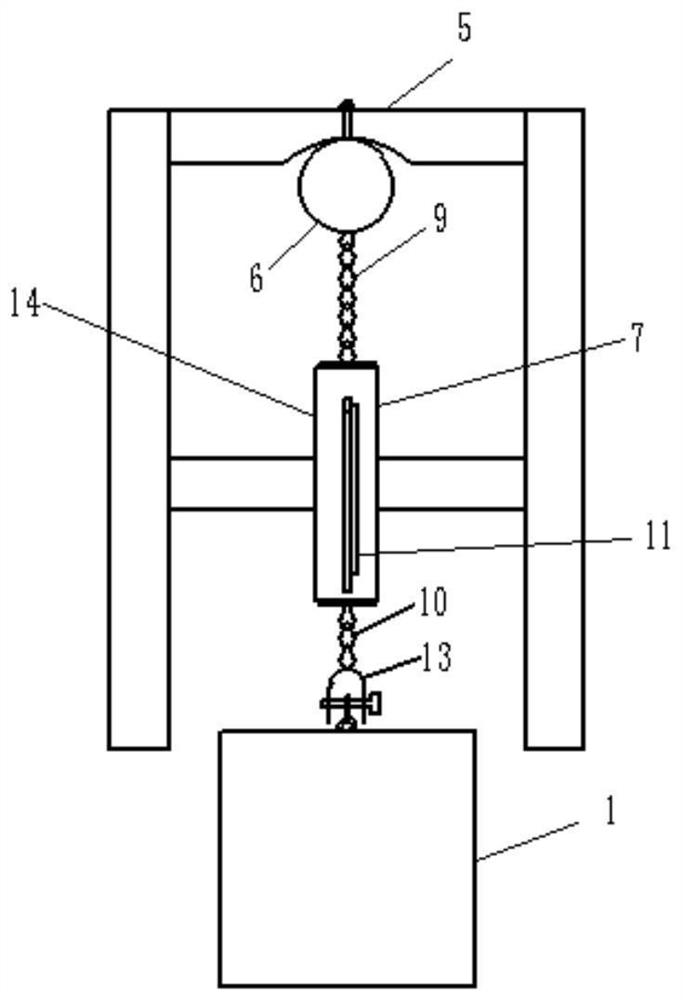

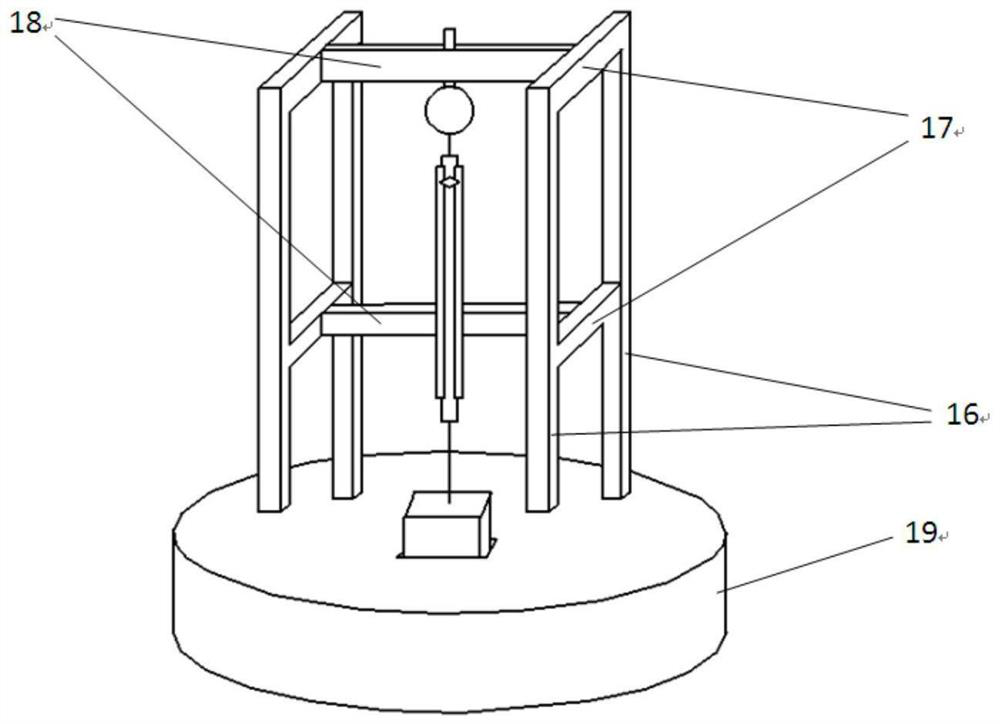

[0032] The casium source calibrating device for liquid level of the billet continuous casting machine crystallizer of the present invention is composed of three parts: a calibration test block part, a calibration elevator part and a calibration value indicator.

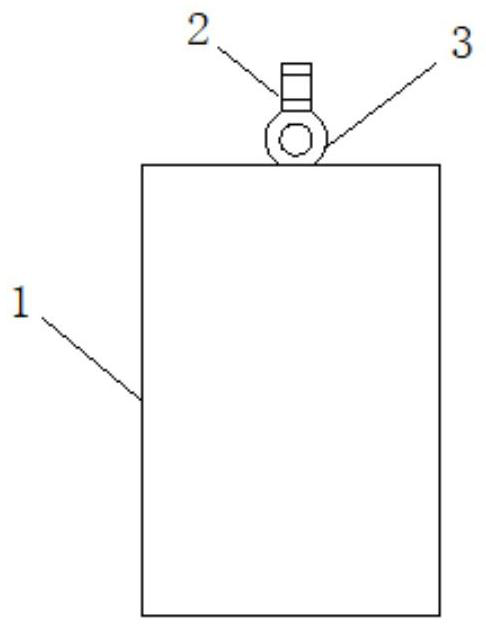

[0033] The calibration test block part is composed of a calibration test block 1 matching the caliber of the crystallizer, a calibration test block suspension ring 2, a calibration test block preset ring 3, and a calibration test block stand rod 4.

[0034] The calibration lift part is composed of a calibration bracket 5, a hand hoist 6, an upper chain 9, a lower chain 10, and a shackle 13.

[0035] The calibration value indicator part is made of scale box 7, pointer seat 8, pointer 12, scale 11, scale fine-tuning bolt 15, and scale window 14 is arranged on the mark box 7.

[0036] figure 1 It shows that the overall structure of the cesium source calibration device for the crystallizer liquid level of the billet cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com