Calibration device and method for g-clip

A technology of correction device and correction rod, which is applied in clamps, manufacturing tools, etc., can solve the problems of high labor intensity for workers, short length of correction axis, troublesome operation, etc., and achieve the effect of short length, fast correction and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

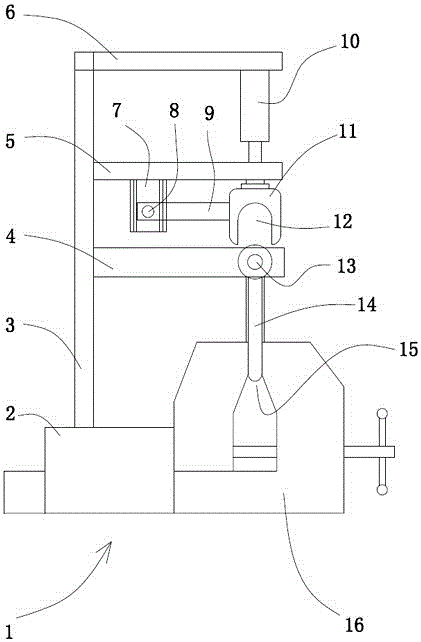

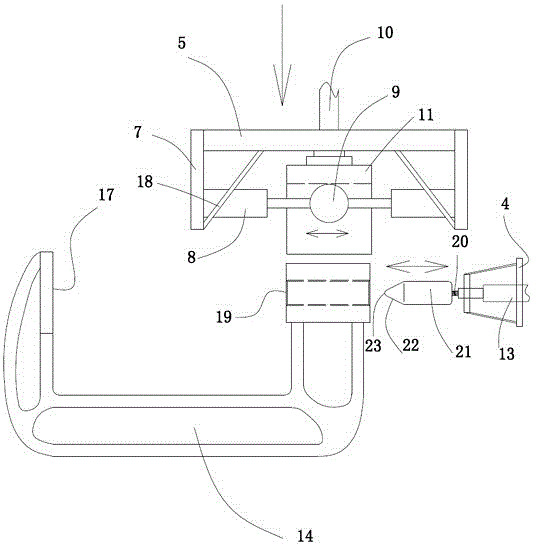

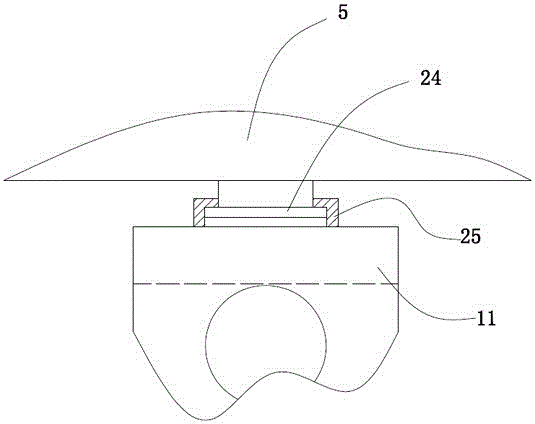

[0030] Embodiment: a kind of correction device of G type clip (see attached figure 1 ), including a clamping table 1 for clamping G-shaped clamps. The clamping table is divided into a fixed part 2 and a movable part 16. The movable part is movable relative to the fixed part. A rotating screw is arranged on the movable part. The connection between the movable part and the fixed part The clamping seam 15 of the G-shaped clip is formed between them, and the limiting device of the G-shaped clip is arranged at the clamping seam, and the position of the G-shaped clip is limited by the limiting device at the clamping seam.

[0031] A bracket is fixed on the fixed part, and the bracket includes a vertical bar 3, a fixed horizontal bar 6 fixed on the top of the vertical bar, a proofreading shaft supporting the horizontal bar 4 fixed on the lower part of the vertical bar, and a lifter that can move up and down along the vertical bar on the vertical bar. Crossbar 5. A lifting device 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com