Nano wave adsorption compound coating composition and its preparation and spraying method thereof

A technology of composite coatings and compositions, applied in the field of coatings, can solve the problems of limited promotion prospects, secondary electromagnetic pollution, etc., and achieve the effects of no secondary pollution, wide absorption frequency band, and high electromagnetic wave absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

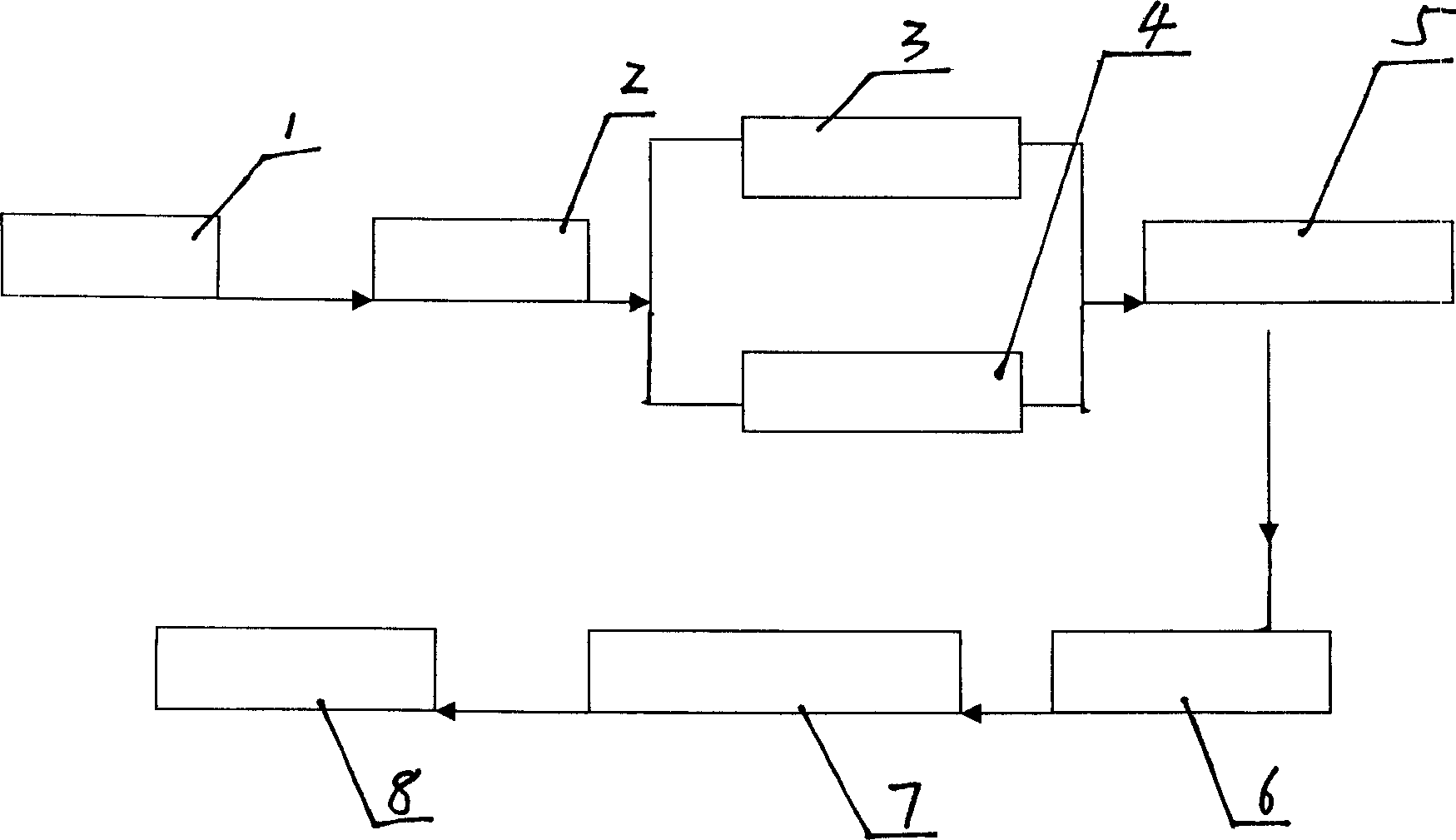

[0101] Process flow of the present invention, its steps are:

[0102] The first step, at first carry out the preparation of solvent composition 1, solvent composition is made up of methyl isobutyl ketone: ethylene glycol butyl ether: n-butanol=3.7: 2.3: 0.9 by mass ratio;

[0103] The second step, the preparation of resin solution 2:

[0104] The solvent composition and the resin form the resin solution, the mass ratio of which is solvent composition:resin=55%:45%. Add the resin to the solvent at a constant speed and slowly, heat and stir with a strong stirrer, and condense and reflux at 60°C for 30min , the resin solution should be uniform and transparent;

[0105] The 3rd step, the preparation of bottom carbon black spray composition 4: form bottom carbon black spray composition by resin solution, carbon black, its mass ratio is that the composition of 75%: 25% stirs and is mixed with bottom carbon black spray coating Solution, sealed for use;

[0106] The fourth step, th...

Embodiment 2

[0118] The first step, at first carry out the preparation of solvent composition 1:

[0119] The solvent composition is composed of methyl isobutyl ketone: ethylene glycol butyl ether: n-butanol=3.9: 2.1: 1.0 by mass ratio;

[0120] The second step, the preparation of resin solution 2:

[0121] The solvent composition and the resin form the resin solution, the mass ratio of which is solvent composition:resin=57%:43%. Add the resin to the solvent at a constant speed and slowly, heat and stir with a strong stirrer, and reflux at 65°C for 35min , the resin solution should be uniform and transparent;

[0122] The preparation of the 3rd step, bottom carbon black spray composition 4:

[0123] The bottom carbon black spray coating composition is composed of resin solution and carbon black, the mass ratio of which is 78%:22%, which is evenly stirred to prepare the bottom carbon black spray coating solution, which is sealed for use;

[0124] The fourth step, the preparation of surfa...

Embodiment 3

[0136] ① Preparation of solvent composition:

[0137] Weigh methyl isobutyl ketone according to the following mass ratio: ethylene glycol butyl ether: n-butanol=4.0: 2.2: 1.1 composition and stir to prepare solvent composition;

[0138] ② Preparation of resin solution:

[0139] The solvent composition and the resin form the resin solution, the mass ratio of which is solvent composition:resin=58%:42%. Add the resin to the solvent at a constant speed and slowly, heat and stir with a strong stirrer, and condense and reflux at 70°C for 45min , the resin solution should be uniform and transparent;

[0140] ③. Preparation of bottom carbon black spray composition:

[0141] Take by weighing resin solution by following mass ratio: carbon black=80%: the composition of 20% is stirred evenly and is mixed with bottom carbon black spray coating solution, seals up for use;

[0142] ④. Preparation of surface absorbing composite coating composition:

[0143] Take the resin solution by weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com