Ultralow-temperature rolling imprinting strengthening method and device for surface of austenitic stainless steel plate

A technology of austenitic stainless steel and stainless steel plate, applied in the field of ultra-low temperature rolling imprinting strengthening on the surface of austenitic stainless steel plate, can solve the problems of complex rolling imprinting process, low service life, poor hardness and wear resistance, etc., and achieve surface improvement. Good performance, low strength and hardness, and small equipment tonnage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

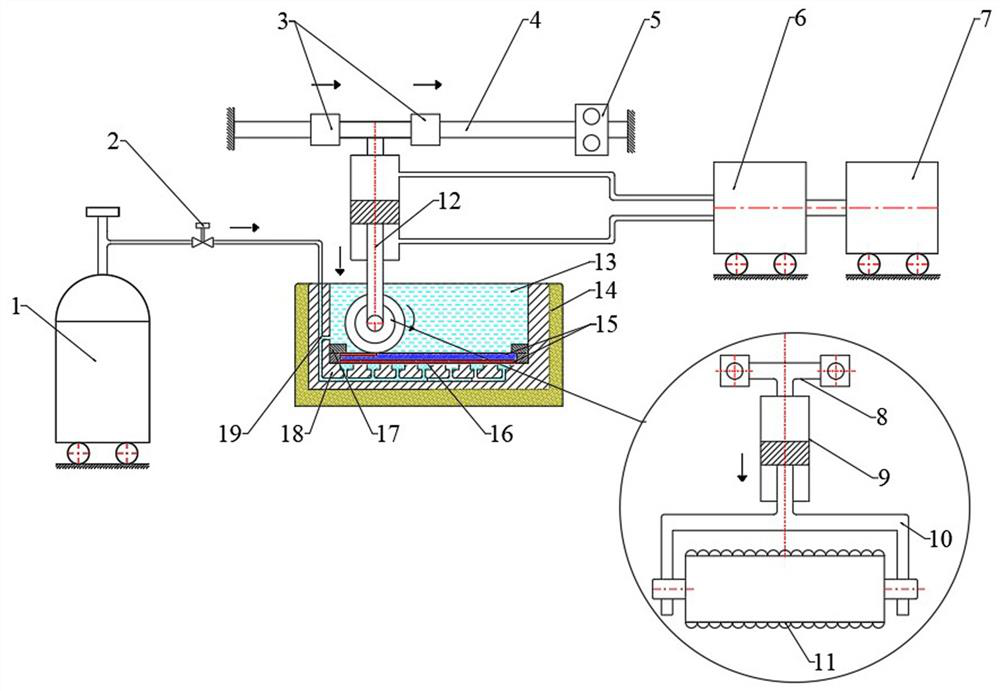

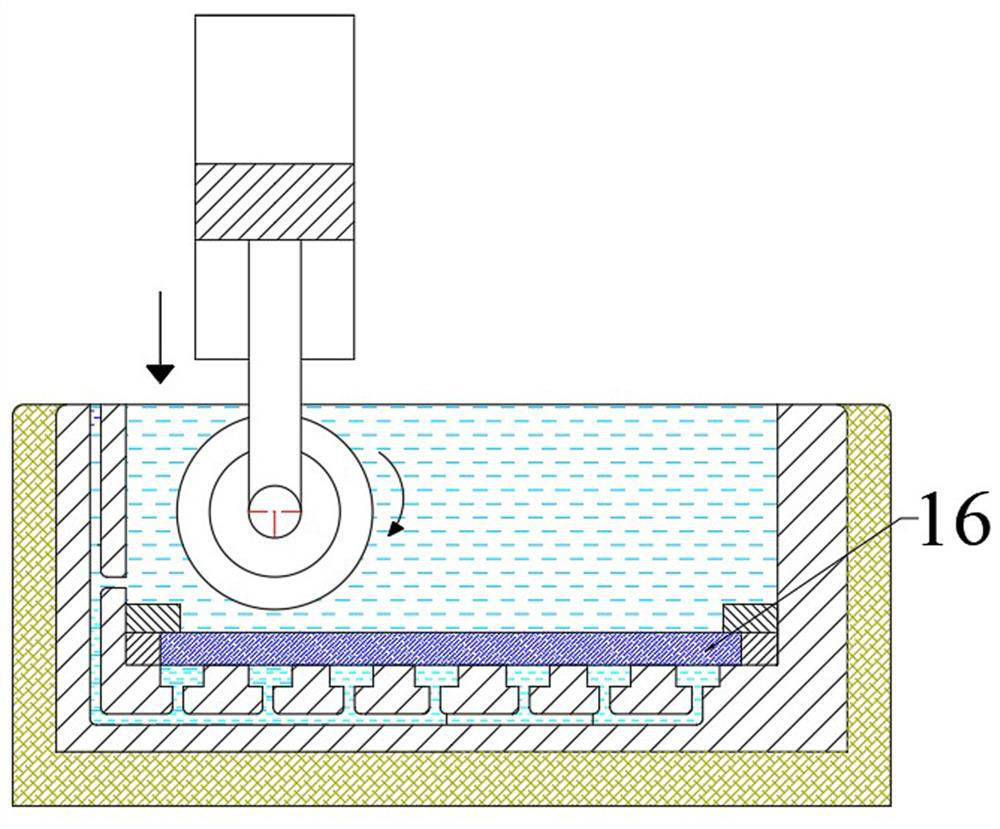

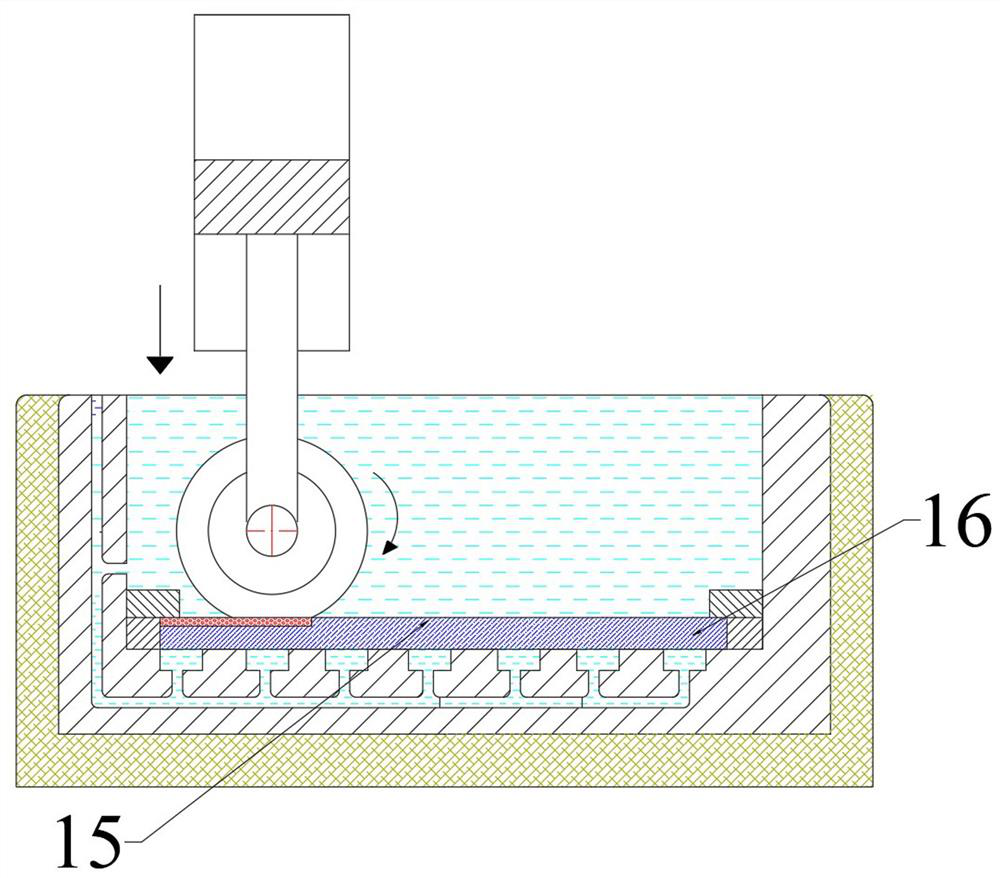

[0037] The ultra-low temperature rolling embossing strengthening process on the surface of stainless steel plate see figure 2 , image 3 and Figure 4 .

[0038] Take 304 austenitic stainless steel plate ultra-low temperature rolling stamping upper and lower surface strengthening modification process as an example, such as figure 2 , image 3 and Figure 4 shown.

[0039]The whole ultra-low temperature rolling embossing forming process of 304 stainless steel plate can be divided into 3 main stages: (1) ultra-low temperature cryogenic treatment stage of 304 stainless steel plate and corrugated roll; (2) ultra-low temperature rolling embossing stage on the surface of stainless steel plate; (3) under the stainless steel plate Surface ultra-low temperature rolling embossing stage. With the advantage of 304 austenitic stainless steel inducing martensitic transformation effect in ultra-low temperature medium to improve its strength, hardness and wear resistance, the 10mm thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com