Epoxy resin-based well cementing fluid and preparation method thereof

A technology of epoxy resin and cementing fluid, which is applied in the field of oil and gas well cementing, can solve the problems that the curing time of resin materials cannot be effectively controlled, the curing time of sealing agent is long, and the impact on well completion operations can be solved, so as to improve the mechanical properties and structural stability, high strength, and improved rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

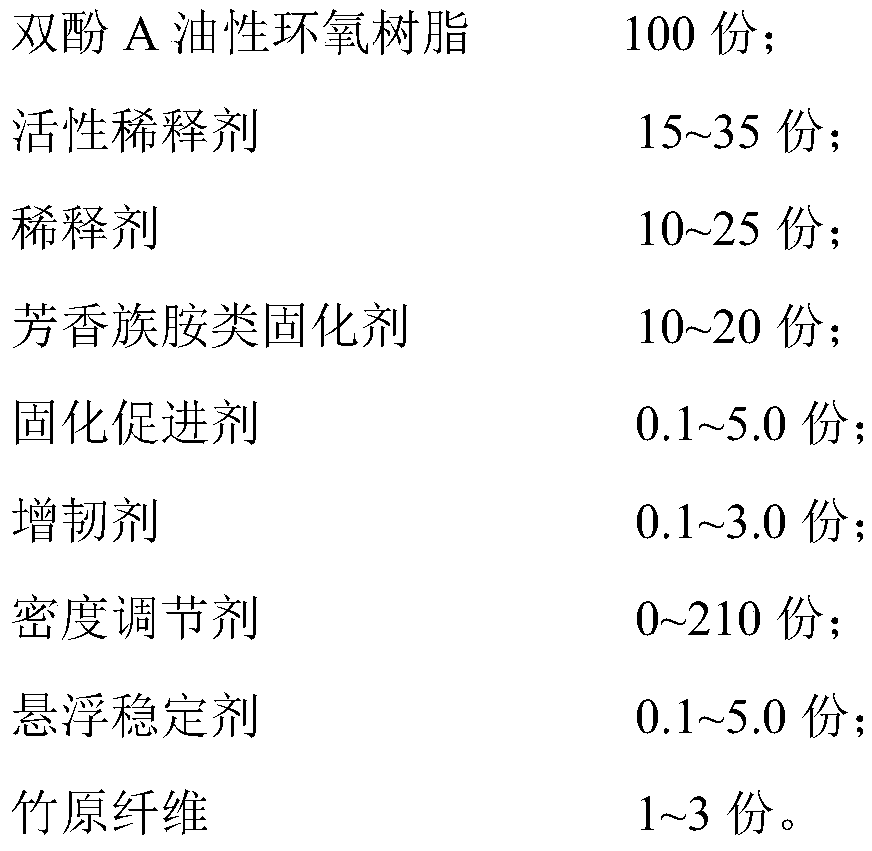

Method used

Image

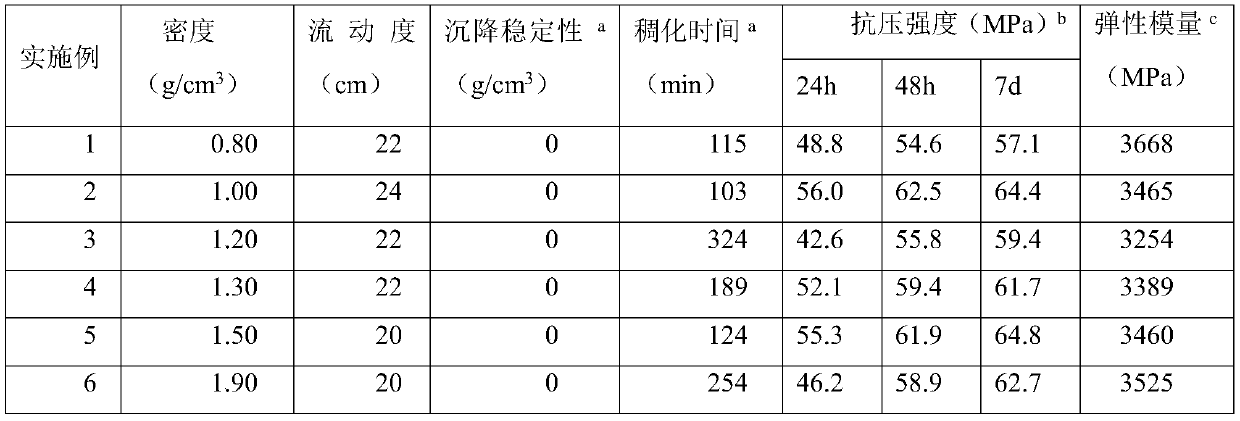

Examples

Embodiment 1

[0036] First prepare modified nano-graphene oxide, the process is as follows: screen nano-graphene oxide powder to obtain graphene oxide with a diameter of about 2 μm and a thickness of about 1 nm; get 0.3g nano-graphene oxide and dissolve it in 61.5wt% ethanol aqueous solution, use After ultrasonic treatment for 3 hours, a uniform dispersion was formed, which was placed in a four-necked flask and stirred at a speed of about 1000r / min; the pH value of the system was adjusted to 4 with acetic acid; then 45mL of γ-aminopropyl triethoxy Slowly drop the mixture of absolute ethanol and base silane into a four-necked flask, and place it in a microwave reactor at 80°C for 8 hours to obtain a paste product, which is washed and centrifuged with absolute ethanol, and then placed in a vacuum freezer. Dried in a desiccator and ground to obtain surface-modified nano graphene oxide powder.

[0037] Preparation of epoxy resin-based cementing fluid:

[0038] (1) Weigh bisphenol A oily epoxy ...

Embodiment 2

[0042] (1) Weigh bisphenol A oily epoxy resin, epoxy fatty acid methyl ester, modified nano graphene oxide (prepared by Example 1), gas phase dioxide Add silicon and hollow glass microspheres into the mixing container in sequence, and stir evenly at 25°C±2°C without solid phase precipitation to obtain component A of the synthetic cementing fluid;

[0043] (2) Weigh m-aminobenzylamine, 2,4,6-tris(dimethylaminomethyl)phenol, butyl acetate and bamboo fiber in a weight ratio of 15:3:20:1.5 and add them to another mixing container in sequence , mixed uniformly at 25°C±2°C to obtain component B of the synthetic cementing fluid;

[0044] (3) Add component A and component B into a mixing container at a weight ratio of 3.08:1, and mix well to obtain a modified nano-fiber epoxy resin cementing fluid for well cementing.

Embodiment 3

[0046] (1) Weigh bisphenol A oily epoxy resin, alkylene glycidyl ether, modified nano-graphene oxide (prepared by Example 1), microsilicon Add the barite and barite into the mixing container respectively in this order, and stir evenly at 25°C±2°C without solid phase precipitation to obtain component A of the synthetic cementing fluid;

[0047] (2) Weigh m-aminobenzylamine, N,N-diethylaminopropylene oxide, butyl acetate and bamboo fiber in a weight ratio of 10:0.5:15:2.0, and mix them at 25°C±2°C Uniform, to obtain synthetic cementing fluid B component;

[0048] (3) After component A and component B are placed in a mixing container with a weight ratio of 5.7:1 and fully mixed, the modified nano-fiber epoxy resin cementing fluid for well cementing is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com