Insulating coating for electrical equipment and preparation method of insulating coating

A technology for insulating coatings and electrical equipment, used in conductive coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve the problems of inability to meet insulation requirements, insulation performance can only meet general requirements, simple components, etc., to achieve good antistatic ability, good Good gloss and dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

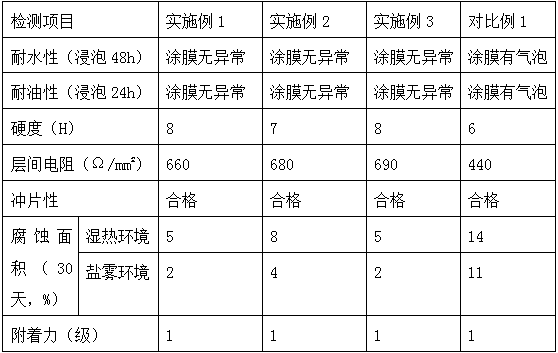

Examples

Embodiment 1

[0028] An insulating coating for electrical equipment, comprising the following raw materials in parts by weight: 25 parts of organic resin, 18 parts of acrylate emulsion, 11 parts of calcium carbonate, 7 parts of silicon nitride, 6 parts of titanium dioxide, 12 parts of hollow glass microspheres, 12 parts of sepiolite, 5 parts of acetone, 8 parts of ethylene glycol, 7 parts of phosphate-modified acrylic leveling agent, 8 parts of dispersant, 3 parts of curing agent, 8 parts of titanate coupling agent and 9 parts of water.

[0029] A preparation method for an insulating coating for electrical equipment, comprising the following preparation steps:

[0030] a. Import the organic resin into the reaction kettle, heat to 120°C, react for 24 minutes, then cool down to 72°C, add phosphate-modified acrylic leveling agent, acetone and water, stir and react for 0.6h, after the reaction, cool to room temperature , get material one;

Embodiment 2

[0040] An insulating coating for electrical equipment, comprising the following raw materials in parts by weight: 33 parts of organic resin, 24 parts of acrylate emulsion, 13 parts of calcium carbonate, 11 parts of silicon nitride, 10 parts of titanium dioxide, 9 parts of hollow glass microspheres, 12 parts of sepiolite, 7 parts of acetone, 4 parts of ethylene glycol, 5 parts of phosphate-modified acrylic leveling agent, 4 parts of dispersant, 4 parts of curing agent, 8 parts of titanate coupling agent and 12 parts of water.

[0041] A preparation method for an insulating coating for electrical equipment, comprising the following preparation steps:

[0042] a. Import the organic resin into the reaction kettle, heat to 120°C, react for 24 minutes, then cool down to 72°C, add phosphate-modified acrylic leveling agent, acetone and water, stir and react for 0.6h, after the reaction, cool to room temperature , get material one;

[0043] b, calcium carbonate, silicon nitride, titan...

Embodiment 3

[0052] An insulating coating for electrical equipment, comprising the following raw materials in parts by weight: 31 parts of organic resin, 22 parts of acrylate emulsion, 14 parts of calcium carbonate, 9 parts of silicon nitride, 8 parts of titanium dioxide, 11 parts of hollow glass microspheres, 10 parts of sepiolite, 6 parts of acetone, 5 parts of ethylene glycol, 6 parts of phosphate-modified acrylic leveling agent, 4 parts of dispersant, 4 parts of curing agent, 7 parts of titanate coupling agent and 12 parts of water.

[0053] A preparation method for an insulating coating for electrical equipment, comprising the following preparation steps:

[0054] a. Import the organic resin into the reaction kettle, heat to 120°C, react for 24 minutes, then cool down to 72°C, add phosphate-modified acrylic leveling agent, acetone and water, stir and react for 0.6h, after the reaction, cool to room temperature , get material one;

[0055] b, calcium carbonate, silicon nitride, titani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com