Method for preparing titanium dioxide pigment with high-temperature resistance

A technology of titanium dioxide and high temperature resistance, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve problems affecting performance, rough and porous, unsuitable for operation, etc., to achieve increased suspension performance, uniform system, and good whitening The effect of degree and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

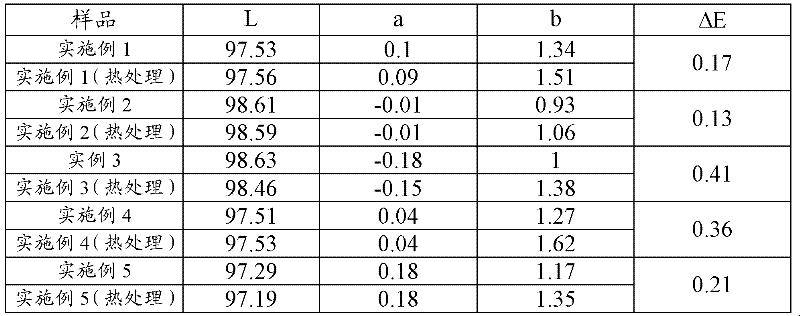

Embodiment 1

[0035] With deionized water, 1000g of titanium dioxide primary product (rutile titanium dioxide produced by the chlorination method, Pangang Group Jinzhou Titanium Industry Co., Ltd.) is formulated into a slurry with a mass concentration of 320g / L, and the mass percentage of adding sodium hydroxide is 10% sodium hydroxide aqueous solution to adjust the pH to 10.5, add 0.3L of sodium hexametaphosphate aqueous solution containing sodium hexametaphosphate with a mass concentration of 70g / L, then pass the slurry into the sand mill for sand grinding, after sand grinding The slurry was filtered through a sieve to remove coarse particles, and then added to the coating tank while stirring and heating up to 65°C, and the temperature was kept constant until the coating was completed. Start to pack dense silicon dioxide, drop the relative titania initial product amount (in terms of TiO 2 by mass) 1.5% aqueous solution of sodium silicate (as SiO 2 mass meter), the sodium silicate aqueous...

Embodiment 2

[0037] With deionized water, 1000g of titanium dioxide primary product (rutile titanium dioxide produced by sulfuric acid method, Ningbo Xinfu Titanium Dioxide Co., Ltd.) is prepared into a slurry with a concentration of 320g / L, and adding a mass percentage of 20% sodium hydroxide aqueous solution, Adjust the pH to 10, add 0.4L of sodium hexametaphosphate aqueous solution with a mass concentration of 70g / L, then pass the slurry into the sand mill for sanding, and filter the sanded slurry through a sieve to remove coarse particles, then add Into the coating tank, while stirring and raising the temperature to 70°C, and keep the temperature constant until the coating is completed. Start to pack dense silicon dioxide, drop the relative titania initial product amount (in terms of TiO 2 by mass) 2.7% aqueous solution of sodium silicate (as SiO 2 mass), the dropping time was 3 hours, the mass concentration of the sodium silicate aqueous solution was 30 g / L, and simultaneously, a 2% ...

Embodiment 3

[0039] With deionized water, 1000g of titanium dioxide primary product (anatase titanium dioxide produced by sulfuric acid method, Ningbo Xinfu Titanium Dioxide Co., Ltd.) is prepared into a slurry with a concentration of 320g / L, and adding a 20% aqueous sodium hydroxide solution Adjust the pH to 8, add 0.5L of sodium hexametaphosphate aqueous solution with a mass concentration of 70g / L, then pass the slurry into the sand mill for sand grinding, and filter the coarse particles through the screen after sand grinding, then add Into the coating tank while stirring and raising the temperature to 55°C and holding the temperature until the coating is complete. Start to pack dense silicon dioxide, drop the relative titania initial product amount (in terms of TiO 2 by mass) 1.0% sodium silicate aqueous solution (as SiO 2 mass), the dropping time is 3h, the mass concentration of the sodium silicate aqueous solution is 65g / L, and simultaneously, a sulfuric acid solution with a mass per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com