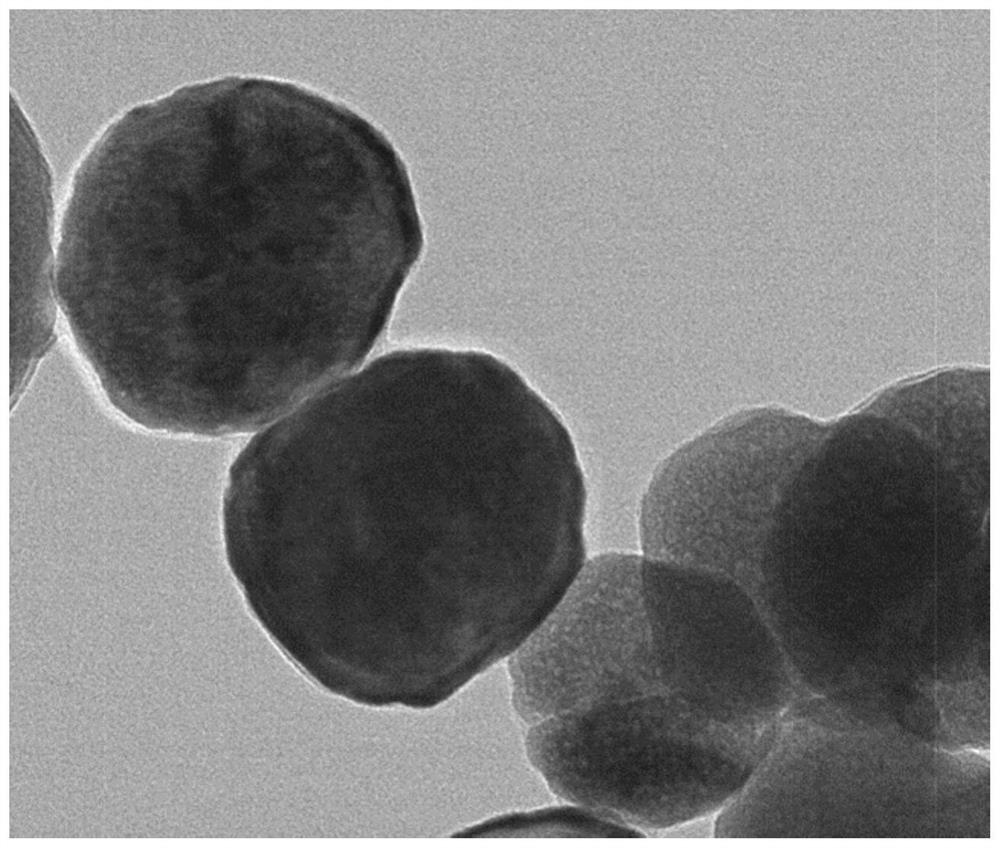

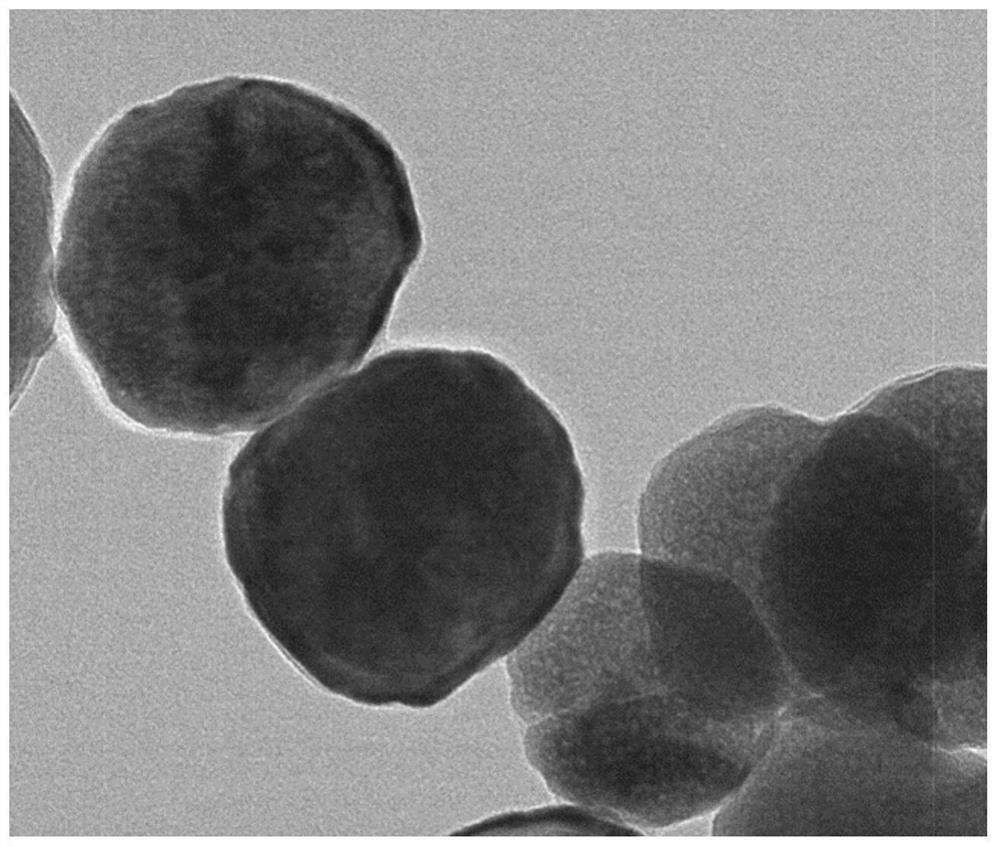

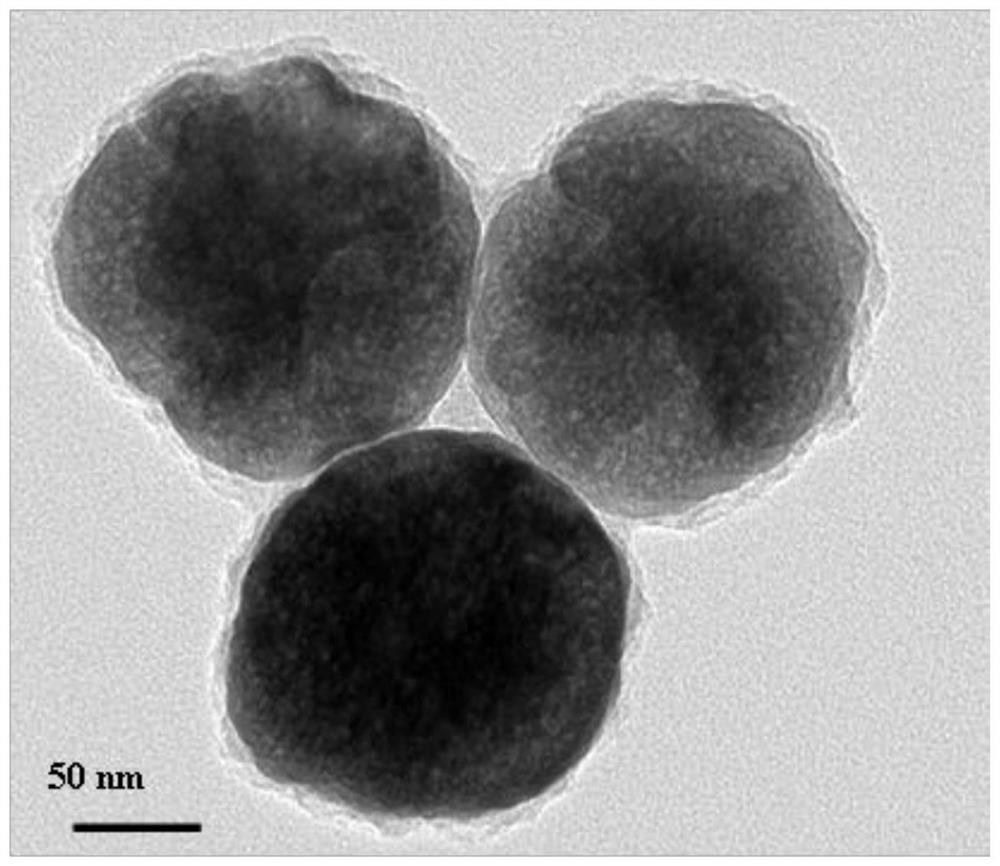

Magnetic core-shell nano-microsphere for adsorbing phenolic pollutants as well as preparation method and application

A technology of nano-microspheres and pollutants, applied in water pollutants, adsorption water/sewage treatment, chemical instruments and methods, etc., can solve the problem of destroying the compatibility of magnetic nanoparticles and polymers, affecting the adsorption operation of magnetic adsorbents, etc. problem, to achieve the effect of improving compatibility, improving recovery efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The preparation method of magnetic core-shell nano-microspheres for adsorbing phenolic pollutants provided in this example specifically includes the following steps:

[0069] S1 Preparation of nano-iron powder

[0070] S1-1 takes the green tea leaves to dry and pulverize, then adds deionized water for heating reaction, and obtains the green tea extract after filtering. Specifically, in this embodiment, the tea leaves are pulverized to 200 mesh, and the weight ratio of green tea leaves to deionized water is 2: 30, the heating temperature is 60°C, the heating reaction time is 0.5h, and then the reaction solution is filtered to obtain the green tea extract;

[0071] S1-2 Add reaction additives to the green tea extract, that is, add C, Si, Mo, S and P in powder state, then mix with the aqueous solution of ferrous nitrate, stir and react at 20°C to obtain the reaction product;

[0072] Wherein, calculated in parts by weight, the weight of C, Si, Mo, S and P satisfies the fo...

Embodiment 2

[0085] The preparation method of magnetic core-shell nano-microspheres for adsorbing phenolic pollutants provided in this example specifically includes the following steps:

[0086] S1 Preparation of nano-iron powder

[0087] S1-1 takes the green tea leaves to dry and pulverize, then adds deionized water for heating reaction, and obtains the green tea extract after filtration. Specifically, in this embodiment, the tea leaves are pulverized to 300 mesh, and the weight ratio of green tea leaves to deionized water is 1: 10. The heating temperature is 70°C, the heating reaction time is 1h, and then the reaction solution is filtered to obtain the green tea extract;

[0088] S1-2 Add reaction additives to the green tea extract, that is, add C, Si, Mo, S and P in powder state, then mix with the aqueous solution of ferrous nitrate, stir and react at 20°C to obtain the reaction product;

[0089] Wherein, calculated in parts by weight, the weight of C, Si, Mo, S and P satisfies the fol...

Embodiment 3

[0102] The preparation method of magnetic core-shell nano-microspheres for adsorbing phenolic pollutants provided in this example specifically includes the following steps:

[0103] S1 Preparation of nano-iron powder

[0104]S1-1 takes the green tea leaves to dry and pulverize, then adds deionized water for heating reaction, and obtains the green tea extract after filtration. Specifically, in this embodiment, the tea leaves are pulverized to 500 mesh, and the weight ratio of green tea leaves to deionized water is 3: 20. The heating temperature is 65°C, the heating reaction time is 1.5h, and then the reaction solution is filtered to obtain the green tea extract;

[0105] S1-2 Add reaction additives to the green tea extract, that is, add C, Si, Mo, S and P in powder state, then mix with the aqueous solution of ferrous nitrate, stir and react at 20°C to obtain the reaction product;

[0106] Wherein, calculated in parts by weight, the weight of C, Si, Mo, S and P satisfies the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com