High performance urchin-like nickel oxide/nickel cobaltate microsphere lithium oxygen battery positive pole catalytic material and preparation method thereof

A lithium-oxygen battery and catalytic material technology, applied in battery electrodes, fuel cell-type half-cells and secondary battery-type half-cells, circuits, etc., to achieve good practical application value, good repeatability, and transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In a specific embodiment of the present invention, a kind of preparation method of nickel oxide / nickel cobaltate microsphere material is provided, comprising steps as follows:

[0036] S1. Prepare the reaction solution: dissolve cobalt chloride, nickel chloride and urea in water to obtain the reaction solution;

[0037] S2. Prepare the solid-phase precursor: react the reaction solution prepared in S1. at 120-180°C for 12-36 hours, and purify the solid-phase precursor after the reaction;

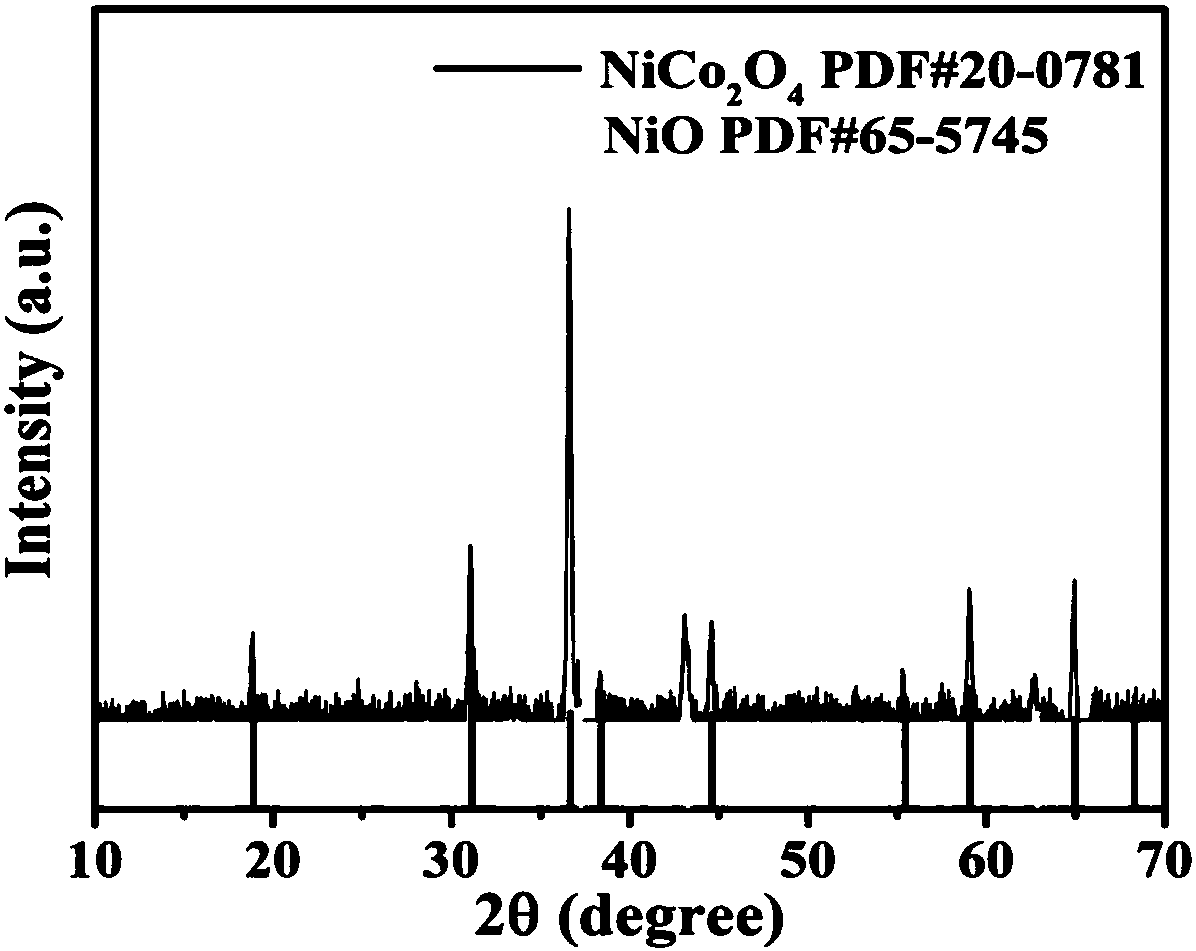

[0038] S3. Preparation of nickel oxide / nickel cobaltate microsphere material: put the solid-phase precursor prepared in S2. at 300-500°C for 4-6 hours for calcination, and obtain the nickel oxide / nickel cobaltate microsphere material after the reaction;

[0039] In yet another specific embodiment of the present invention, in the step S1., the molar ratio of cobalt chloride, nickel chloride and urea is 1:2:4-6; further, the cobalt chloride, nickel chloride The molar ratio of cobalt chlor...

Embodiment 1

[0051] Sea urchin-shaped nickel oxide / nickel cobaltate microspheres are prepared through the following steps:

[0052] (1) Preparation of reaction solution

[0053] Dissolve 2mmol nickel chloride, 4mmol cobalt chloride and 10mmol urea in 75mL deionized water, stir and sonicate for 1 hour to form a rose-red mixed solution;

[0054] (2) Preparation of solid phase precursor

[0055] Transfer the solution prepared in step (1) to a 100mL polytetrafluoroethylene liner for high temperature and high pressure hydrothermal reaction. The reaction temperature is controlled at 150°C and the reaction time is controlled at 24h. After fully reacting, cool to room temperature and use The reaction product was centrifuged and washed with ionized water and ethanol, and the solid-phase precursor was obtained after vacuum drying at 120°C for 24 hours;

[0056] (3) Subsequent heat treatment

[0057] Place the precursor collected in step (2) in a muffle furnace, in an air atmosphere, at 5°C min -...

Embodiment 2

[0062] Sea urchin-shaped nickel oxide / nickel cobaltate microspheres are prepared through the following steps:

[0063] (1) Preparation of reaction solution

[0064] Dissolve 2mmol nickel chloride, 4mmol cobalt chloride and 10mmol urea in 75mL deionized water, stir and sonicate for 1 hour to form a rose-red mixed solution;

[0065] (2) Preparation of solid phase precursor

[0066] Transfer the solution prepared in step (1) to a 100mL polytetrafluoroethylene liner for high temperature and high pressure hydrothermal reaction. The reaction temperature is controlled at 120°C and the reaction time is controlled at 24h. After fully reacting, cool to room temperature and use The reaction product was centrifuged and washed with ionized water and ethanol, and the solid-phase precursor was obtained after vacuum drying at 120°C for 24 hours;

[0067] (3) Subsequent heat treatment

[0068] Place the precursor collected in step (2) in a muffle furnace, in an air atmosphere, at 5°C min -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com