Bean flour refill bag, soybean milk manufacturing method and equipment for preparing soybean milk

A production method and technology of material packaging, applied in packaging, dairy products, liquid materials and other directions, can solve the problems of uneven concentration of soy milk, affect the taste of soy milk, uneven preparation, etc. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

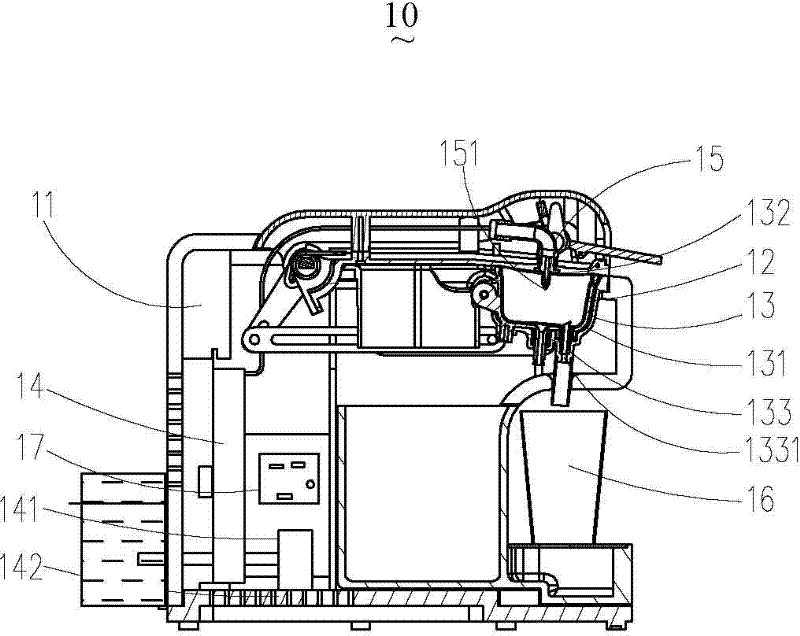

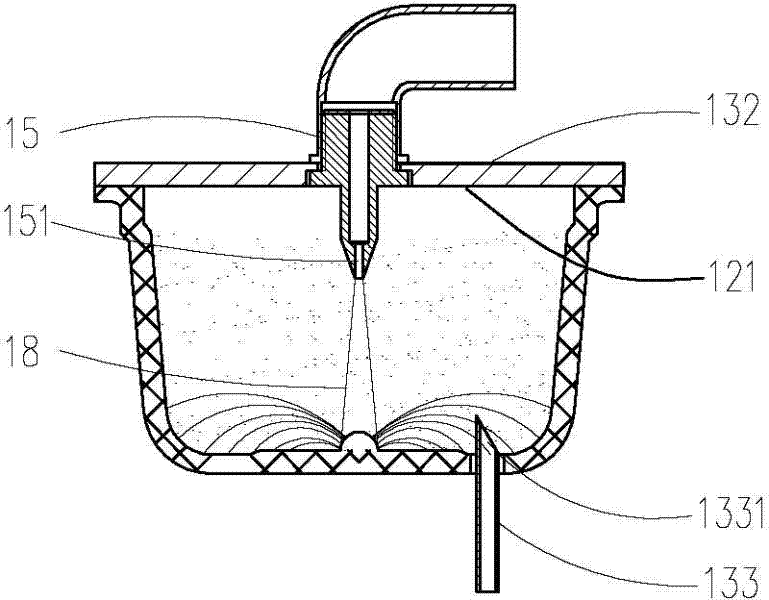

[0040] Please also refer to figure 1 The schematic diagram of the equipment for preparing soybean milk according to the first preferred embodiment, the equipment for preparing soybean milk 10 includes a machine base 11, a holder 13 for carrying a bag 12, a liquid supply mechanism 14, an injection head 15, and a milk cup 16 And comprise the control device 17 of pulping program. The holder 13 , the liquid supply mechanism 14 and the injection head 15 are arranged on the base 11 . One end of the injection head 15 communicates with the liquid supply mechanism 14 , and the other end is aligned with the material bag 12 . The pulping procedure comprises a method of preparing soymilk.

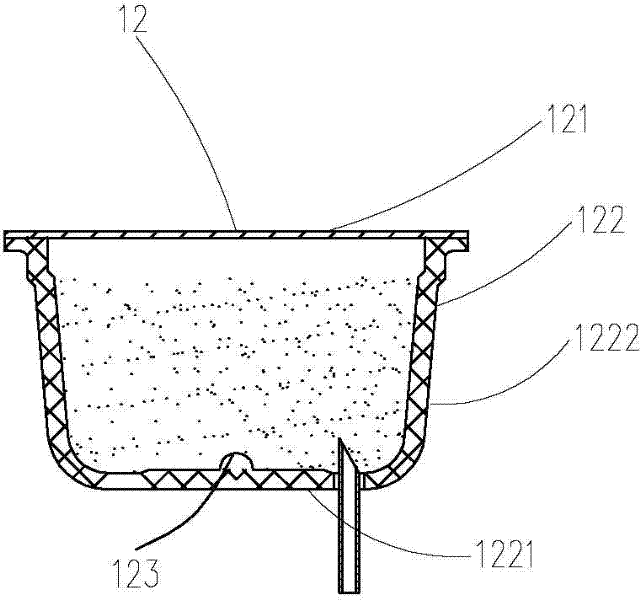

[0041] see figure 2 , the material bag 12 includes a diaphragm 121 and a container 122 , the container 122 includes a bottom wall 1221 and a side wall 1222 extending upward from the bottom wall 1221 , the diaphragm 121 covers the opening of the container 122 . The material bag 12 has a diameter of...

Embodiment approach 2

[0054] see Figure 5 The schematic diagram of the equipment for preparing soybean milk in the second preferred embodiment, the difference between the equipment for preparing soybean milk 20 and the equipment for preparing soybean milk 10 is that the equipment for preparing soybean milk 20 also includes an air pump 21 installed on the machine base 11, the air pump One end of 21 communicates with the outside world, and the other end is connected with the injection head 15 .

[0055] The soymilk preparation method also includes an aeration and discharge stage: the air pump 21 is used to inflate the material bag 12, and the soymilk in the material bag 12 is squeezed out through the outlet hole 1331 by air pressure. In this way, the soymilk in the material bag 12 can be discharged quickly, reducing the time for discharging milk, and improving the overall efficiency of making soymilk. In addition, the soymilk in the material bag 12 can be discharged more thoroughly by using the air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com