Diamond composite material and preparation method thereof

A composite material and diamond technology, applied in the field of diamond composite materials and their preparation, can solve the problems of insufficient bonding and insufficient performance of composite materials, achieve high hardness values, reduce equipment maintenance and parts replacement costs, and improve the impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] see Figure 1-7 As shown, the present embodiment is a diamond composite material prepared from the following components in parts by weight:

[0046] 90 parts of diamond particles, 12 parts of nickel-chromium alloy powder, 4 parts of binder, 60 parts of high manganese steel powder;

[0047] The diamond composite material is prepared by the following steps:

[0048] Step 1: Ultrasonic treatment of diamond particles in acetone solution, cleaning and rinsing with distilled water;

[0049] Step 2: add the binder to the cleaned diamond particles and mix well, then add nickel-chromium alloy powder for stirring, apply the nickel-chromium alloy powder evenly on the surface of the diamond particles, and then place it in a 200-250°C Pretreated diamond particles are obtained by keeping the temperature for 1 to 2 hours;

[0050] Step 3: Mix the pretreated diamond particles and high manganese steel powder evenly, and then use ultra-fine grinding equipment to grind to obtain mixed ...

Embodiment 2

[0065] see Figure 1-7 As shown, the present embodiment is a diamond composite material prepared from the following components in parts by weight:

[0066] 110 parts of diamond particles, 20 parts of nickel-chromium alloy powder, 6 parts of binder, 100 parts of high manganese steel powder;

[0067] The diamond composite material is prepared by the following steps:

[0068] Step 1: Ultrasonic treatment of diamond particles in acetone solution, cleaning and rinsing with distilled water;

[0069] Step 2: add the binder to the cleaned diamond particles and mix well, then add nickel-chromium alloy powder for stirring, apply the nickel-chromium alloy powder evenly on the surface of the diamond particles, and then place it in a 200-250°C Pretreated diamond particles are obtained by keeping the temperature for 1 to 2 hours;

[0070] Step 3: Mix the pretreated diamond particles and high manganese steel powder evenly, and then use ultra-fine grinding equipment to grind to obtain mixe...

Embodiment 3

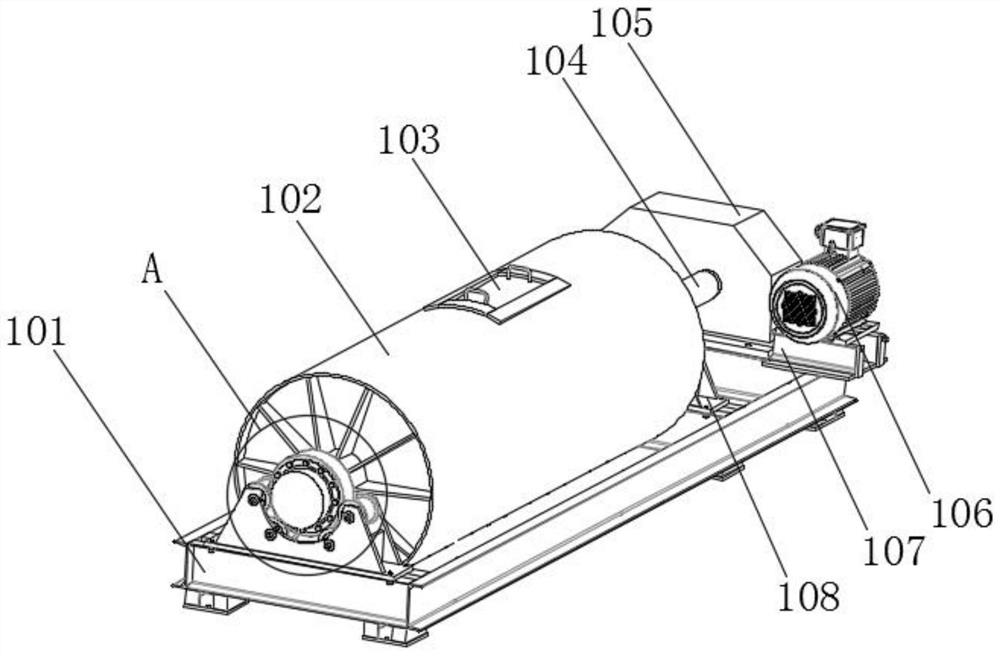

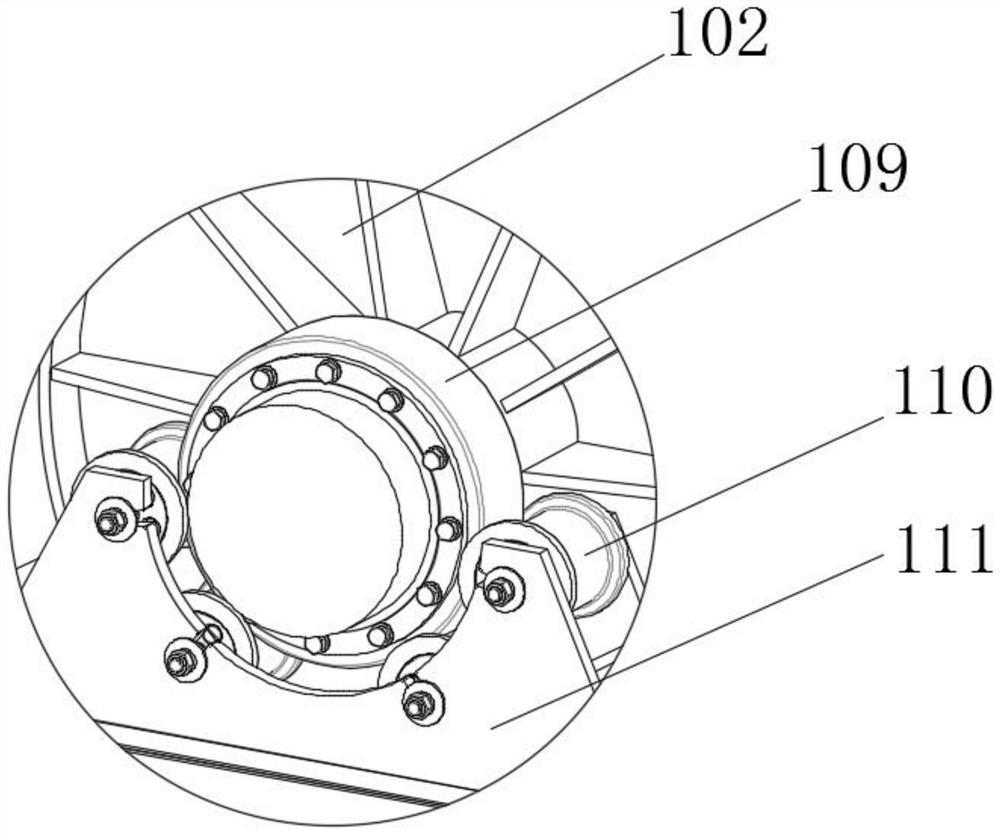

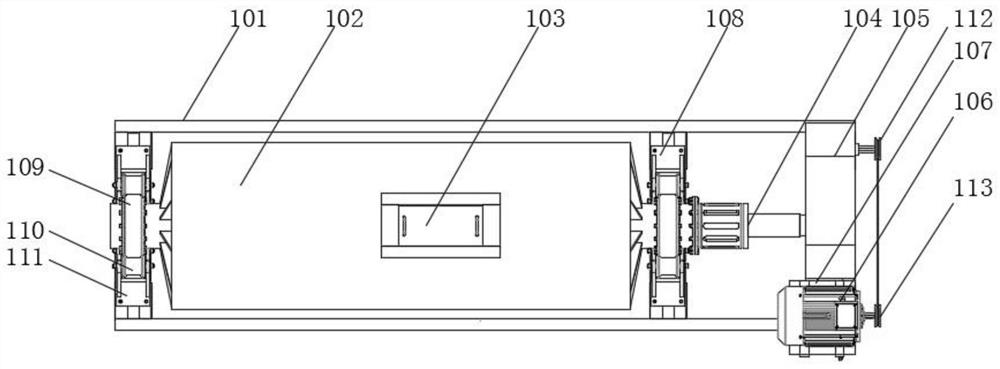

[0085] see Figure 1-7 As shown, the ultrafine grinding equipment in this embodiment includes a load-bearing base 101, a rotating abrasive bin 102, a reduction box 105, a drive motor 106, and a grinding wheel 110. A rotating abrasive bin 102 is arranged above the load-bearing base 101. Both ends of the rotating abrasive bin 102 are sleeved with load-bearing plates 109 through rotating shafts, and the load-bearing plates 109 at both ends are mounted on the first support base 108 and the second support base 111 respectively. The first support base 108 and the second support base 109 The support bases 111 are all mounted on the top of the load-bearing base 101, and several wear-reducing wheels 110 are installed in the inner cavities of the first support base 108 and the second support base 111. The load-bearing discs 109 are all installed in the draw-in grooves of several wear-reducing wheels 110;

[0086] One end of the rotating abrasive bin 102 is connected to one end of the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com