Method for treating waste water

A waste water treatment and waste water technology, which is applied in the direction of energy waste water treatment, biological water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of cost of money, land, and sewage treatment and discharge can not be stably met, and achieve energy saving and water resources, and the effect on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

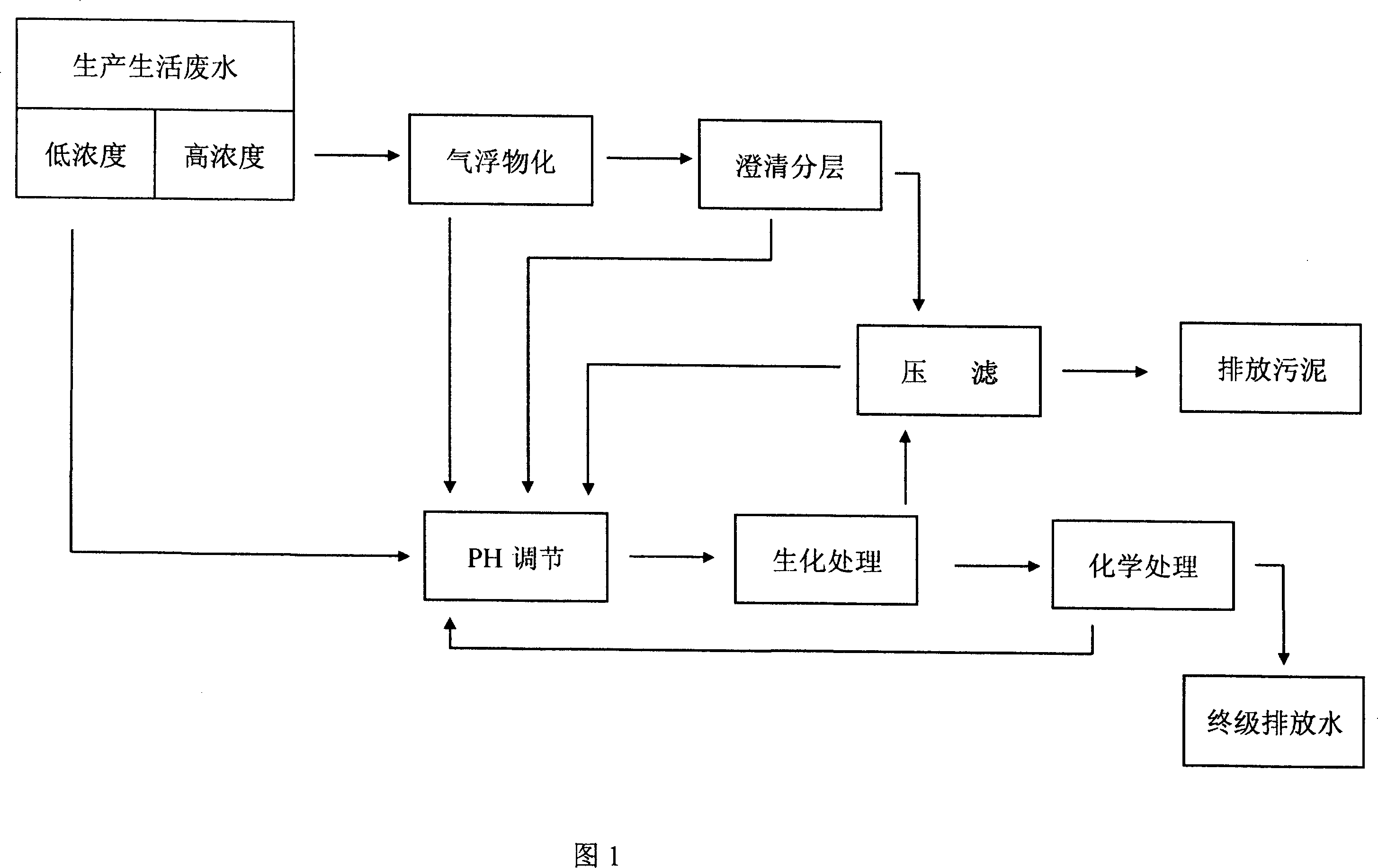

[0025] Wastewater treatment method

[0026] 1. Air flotation physical treatment;

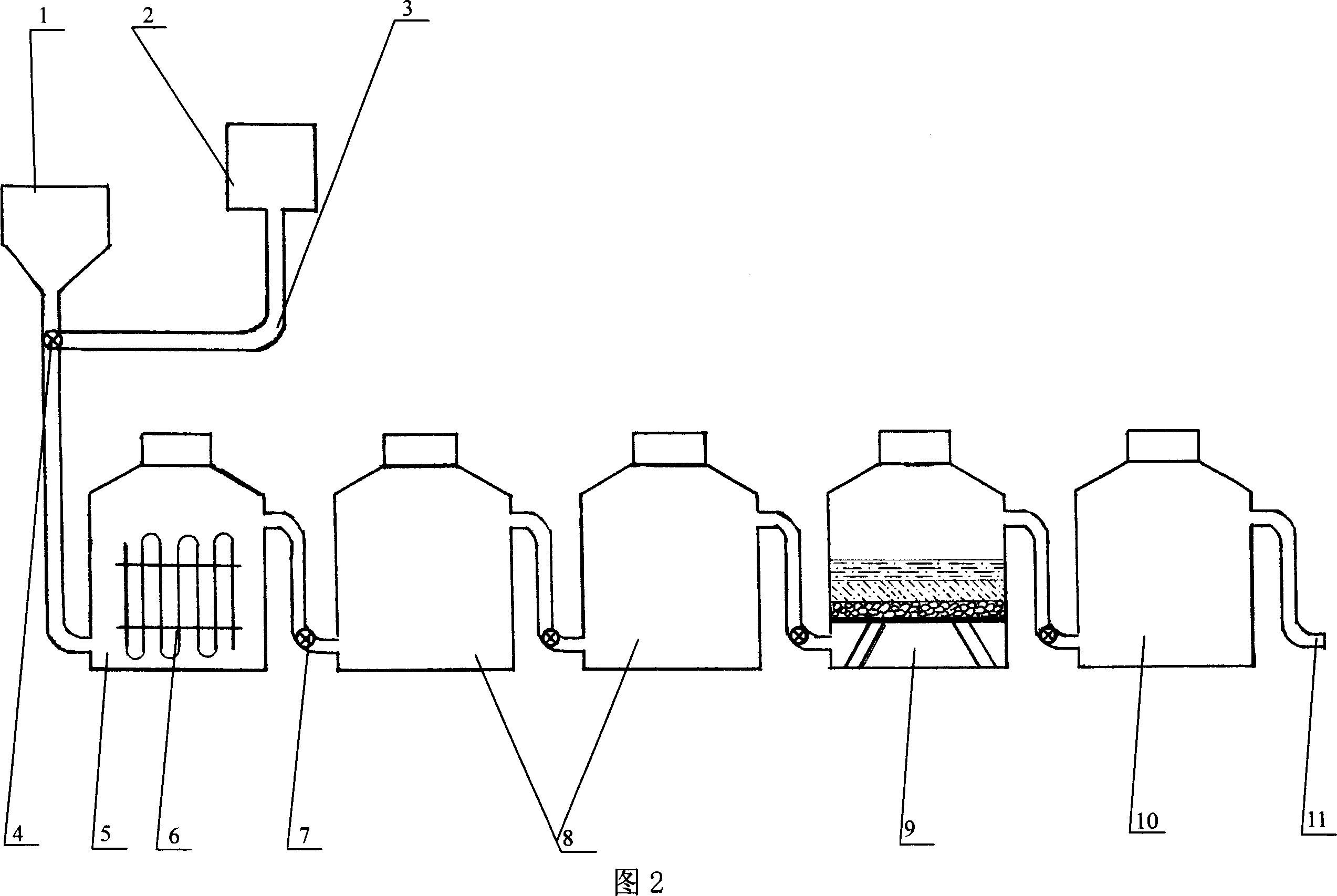

[0027] The waste water containing high-concentration raffinate and high-COD produced by various dyeing and finishing is classified through pipelines, collected and stored in special containers, and then treated by air flotation physical-chemical device (JM-V air flotation water purifier). Low concentration wastewater and thick suspensions are formed. The low-concentration wastewater formed after the air flotation treatment has a color removal rate of more than 50%, a COD removal of 55-80%, and a BOD removal of about 50%.

[0028] According to the original design scheme of the JM-V type air flotation water purifier, tap water is used as the vaporized water. We use low-concentration waste water that has been treated by air flotation and physicochemical treatment instead of tap water as gasification water, which not only saves tap water, but also reduces the total amount of waste water discharge....

Embodiment 2

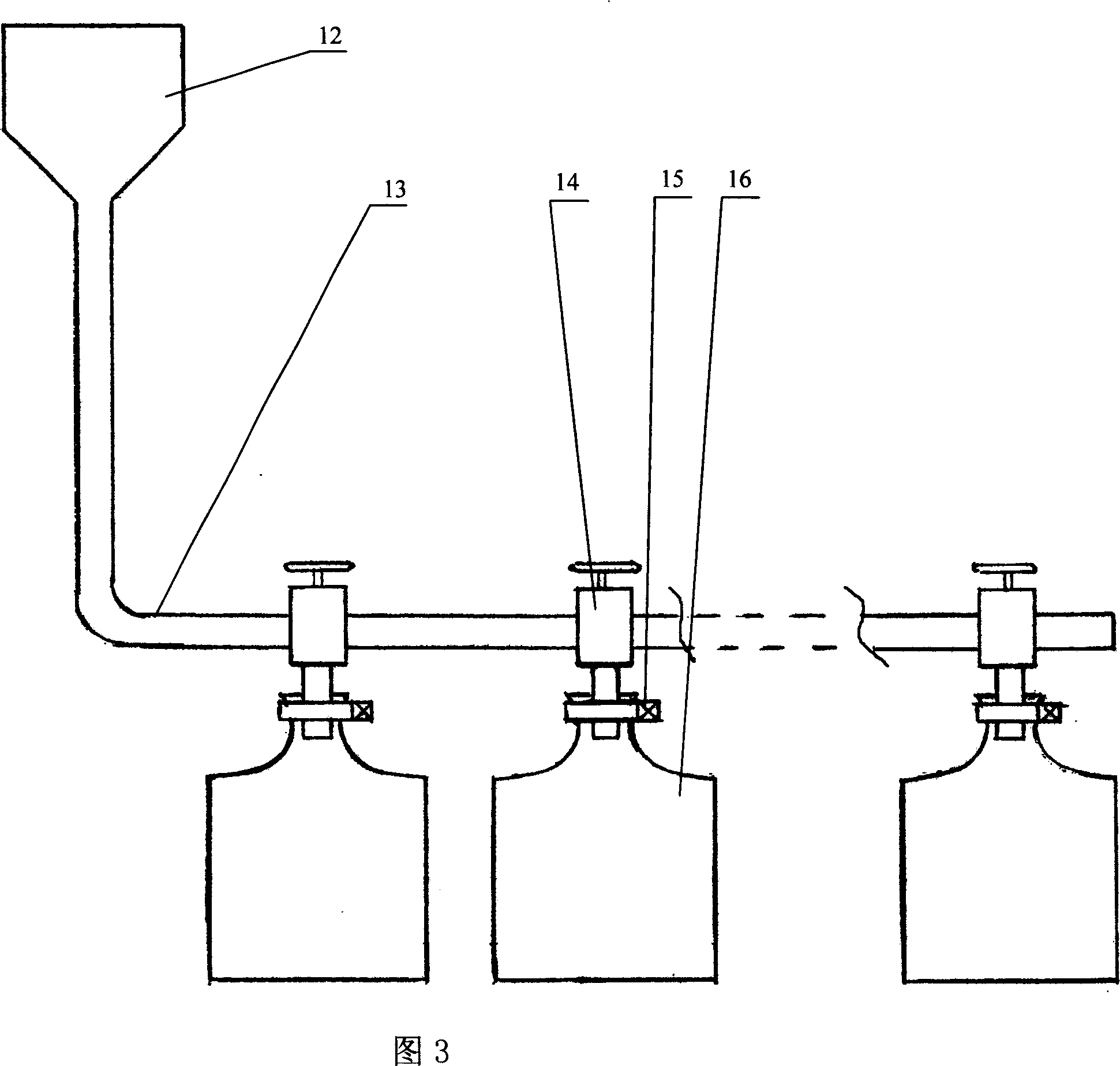

[0043]On the basis of Example 1, in order to facilitate the biochemical treatment, the volume of the PH adjustment reservoir is required to be as large as possible, but for old enterprises, because of the congenital deficiencies in design and manufacture, the volume of the reservoir was originally not large, after two years More than ten years of siltation has "eat" a volume, and two methods are generally used to make up for it. One is to build a new pH-adjusting reservoir to expand the wastewater capacity; the other is to dredge the original pH-adjusting reservoir. We dredged the original pH adjustment reservoir, pumped the wastewater sludge in the pH adjustment reservoir into the mud pool 12 with a mud pump, entered the three-way control valve 5 through the pipeline 2, and then poured it into the clamp 5 to clamp it. In the woven bag 4 on the three-way control valve 5, the waste water is press-filtered out of the woven bag 4 through the pressure filtration generated by the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com