Metal smelting device driven by gravitational potential energy and method thereof

A metal smelting and gravitational potential energy technology, applied in the field of metallurgy, can solve the problems of high resource and energy consumption, large environmental load, etc., and achieve the effects of simple structure, environmental protection and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

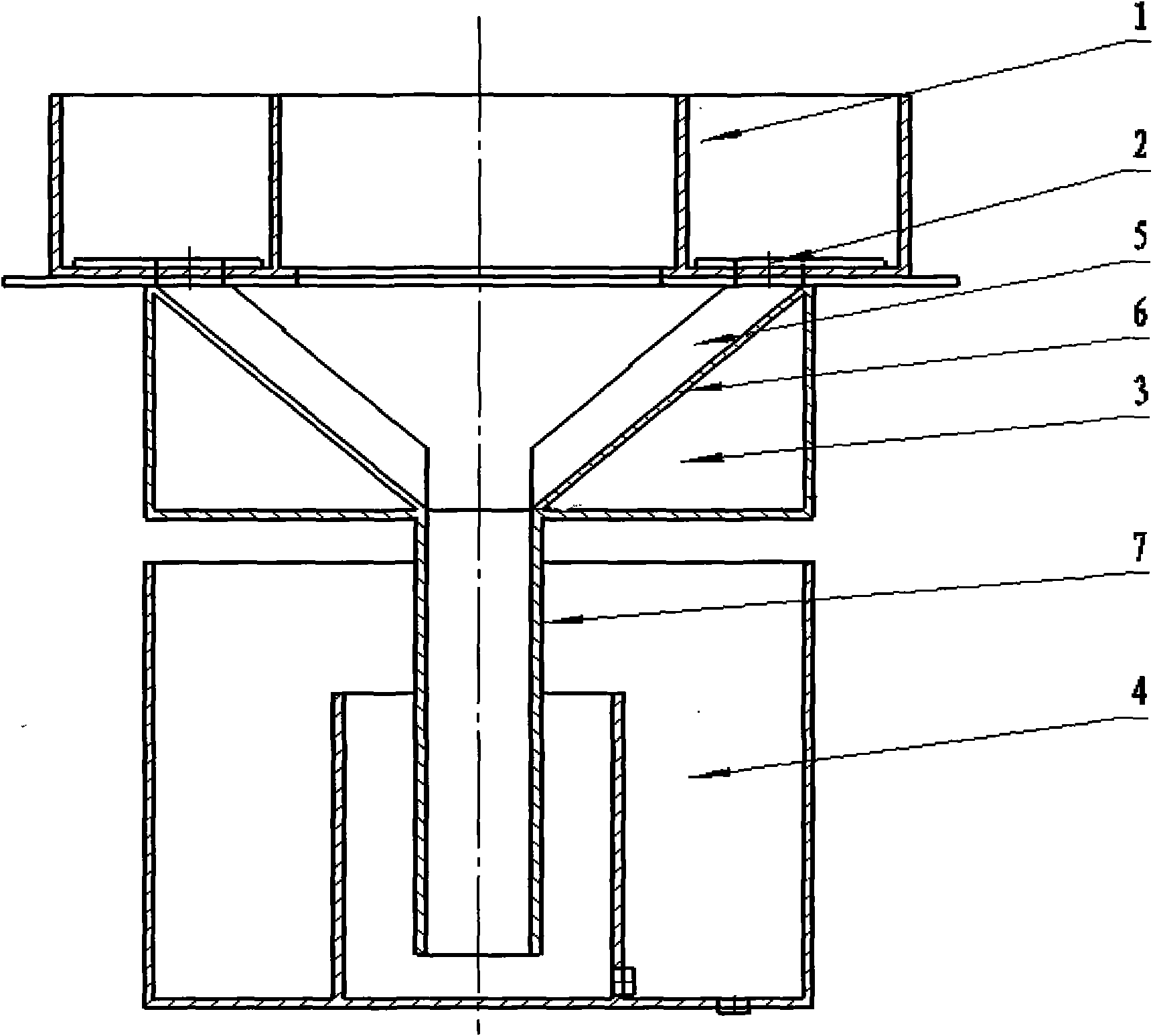

[0028] The cross-sectional structure of a metal smelting device driven by gravity potential energy is as follows figure 1 As shown, the injection tank 1 is a groove structure with 6 injection holes evenly arranged at the bottom; the bottom of the injection tank 1 is connected to the flow regulating plate 2, the flow regulating plate 2 is a flat plate, and the flow regulating plate is evenly provided with 6 Each flow adjustment hole has the same shape as the injection hole. When one injection hole coincides with one flow adjustment hole, other injection holes also coincide with one injection hole. Adjusting the horizontal position of the flow adjustment plate 2 can make the injection hole and the flow adjustment hole be completely connected, partially connected or completely disconnected; when the injection hole is partially connected with the flow adjustment hole, each injection hole is connected to the corresponding flow adjustment hole The connected areas are equal.

[0029] Th...

Embodiment 2

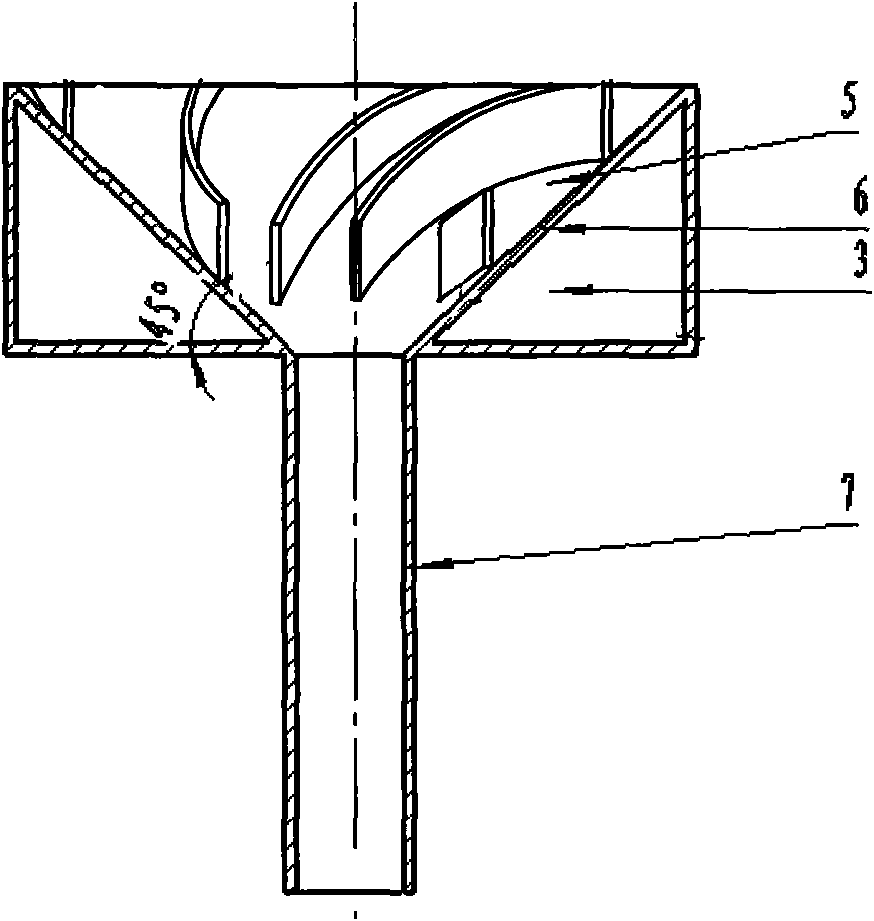

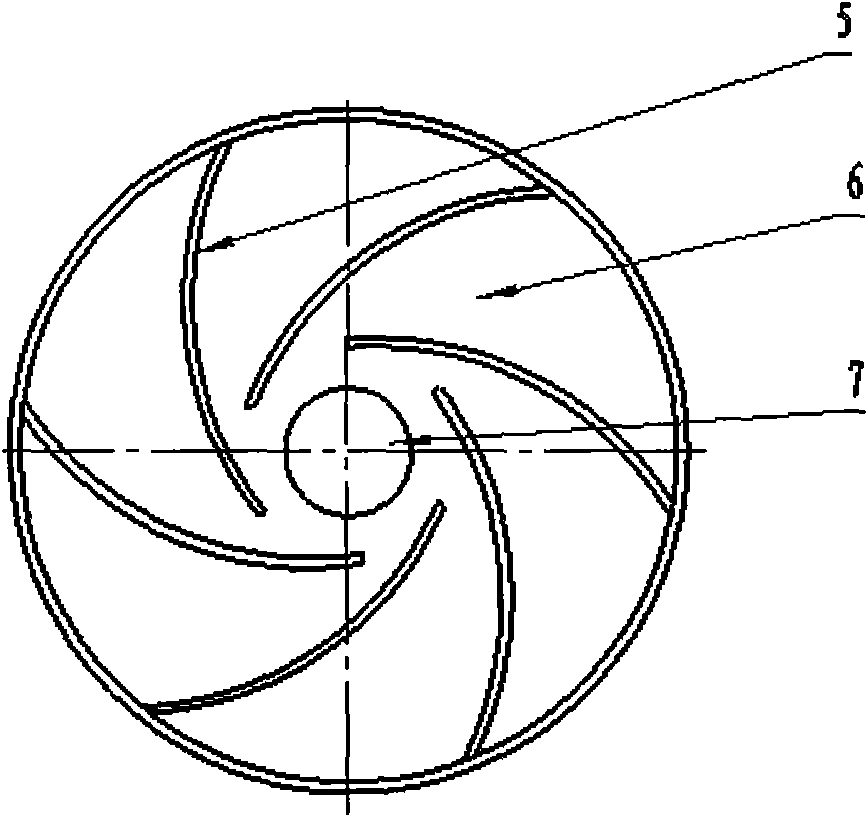

[0039] The adopted metal smelting device driven by gravitational potential energy is the same as that of Embodiment 1, with the difference that: the top view of the deflector is a curved line type. The sectional structure of the funnel-shaped swirl generator is as follows Figure 4 As shown, the top view structure is as Figure 5 Shown.

[0040] The above-mentioned device is used for dephosphorization, desulfurization and desiliconization tests, and the working method is the same as that of Example 1. The content of phosphorus, sulfur and silicon in the molten steel reaches the expected index, and the effect is better than the smelting effect of argon injection and stirring.

Embodiment 3

[0042] The adopted metal smelting device driven by gravitational potential energy is the same as that in Example 1. The difference lies in: the deflector is a straight plate, the lower end of the lower edge of the outer side of each deflector is connected to the top of the mixing pipe, and the diameter of the deflector is The diameter is the same as the mixing tube; the lower edge of the outer side of each deflector is tangent to the deflector surface. The sectional structure of the funnel-shaped swirl generator is as follows Figure 6 As shown, the top view structure is as Figure 7 Shown.

[0043] The above-mentioned device is used for dephosphorization, desulfurization and desiliconization tests, and the working method is the same as that of Example 1. The content of phosphorus, sulfur and silicon in the molten steel reaches the expected index, and the effect is better than the smelting effect of argon injection and stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com