Production method of odorless high-nitrogen livestock and poultry manure fermented organic fertilizer

A technology of livestock and poultry manure and production method, which is applied in the preparation of organic fertilizers, organic fertilizers, inorganic fertilizers, etc., can solve the problems of human and animal health, environmental impact, poor penetration performance of deodorants, and not very obvious effects, and achieves promotion. Root growth and cell division, improving nitrogen fixation and improving the quality of agricultural products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1. In parts by weight, take animal manure, crushed rice straw or other crop stalks and mix evenly, and the weight ratio of animal manure and crushed straw or other crop stalks is 2-8:1, mix well and then add water, the moisture content is 60% to 65%, to obtain fermented material;

[0022] Step 2. Add the prepared microbial agent solution and nitrogen-preserving conditioner to the fermented material prepared in step 1 according to the ratio of 2.5% and 4% by mass of the fermented material, stir and mix evenly, and heat it at a temperature of 60-70°C Ferment for 10 days under the same conditions to get the initial fermentation material. The fermentation adopts strip-stack composting, and the compost raw material added with nitrogen-preserving conditioner is piled up into strips with a height of 0.7-1.3m and a width of 1.2-2.0m. During the heating and high temperature stages, the temperature should be lowered according to the fermentation temperature, and the compost ...

Embodiment 2

[0027] Step 1. In parts by weight, take animal manure, crushed rice straw or other crop stalks and mix evenly, and the weight ratio of animal manure and crushed straw or other crop stalks is 2-8:1, mix well and then add water, the moisture content is 60% to 65%, to obtain fermented material;

[0028] Step 2. Add the prepared microbial agent solution and nitrogen-preserving conditioner to the fermented material prepared in step 1 according to the ratio of 2.5% and 4% by mass of the fermented material, stir and mix evenly, and heat it at a temperature of 60-70°C Ferment for 10 days under the same conditions to get the initial fermentation material. The fermentation adopts strip-stack composting, and the compost raw material added with nitrogen-preserving conditioner is piled up into strips with a height of 0.7-1.3m and a width of 1.2-2.0m. During the heating and high temperature stages, the temperature should be lowered according to the fermentation temperature, and the compost ...

Embodiment 3

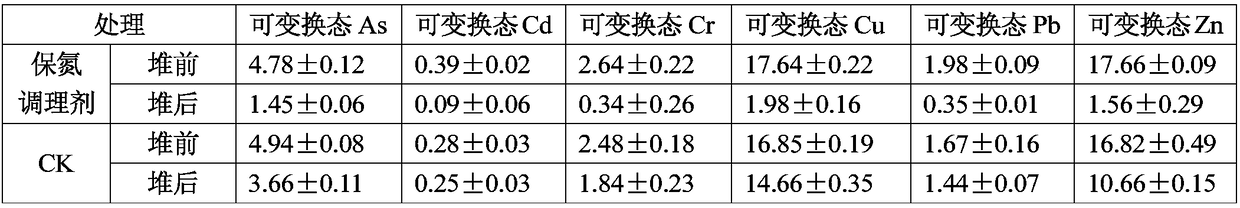

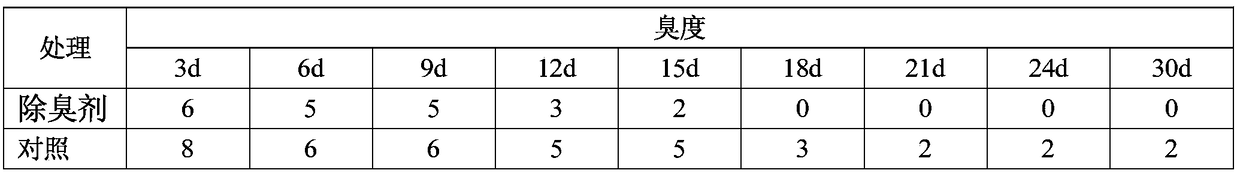

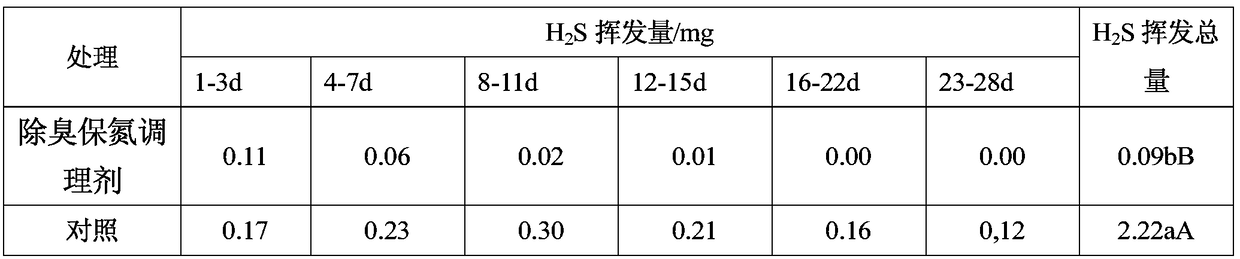

[0036] Effects of Nitrogen Conditioning Agents on the Bioavailability of Heavy Metals in Animal Feces

[0037] Adopt pot test, the vegetable for testing is Chinese cabbage in Jiaozhou, Shandong, and the fertilizer for testing is animal manure compost (referring to embodiment 1 and 2 for the preparation method), compost without adding nitrogen conditioning agent, urea (nitrogen content) 46%), calcium magnesium phosphate fertilizer (phosphorus pentoxide content is 12%) and potassium chloride (potassium oxide content is 60%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com