Production method of high-salt diluted and low-temperature fragrant soy sauce

A high-salt dilute state and production method technology, applied in the field of condiments, can solve the problems of labor and time consumption, damage to the quality and nutritional content of soy sauce, and insufficient nutritional content, so as to reduce the beany smell and raw salt taste, and suppress harmful The growth of bacteria, the effect of aroma and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

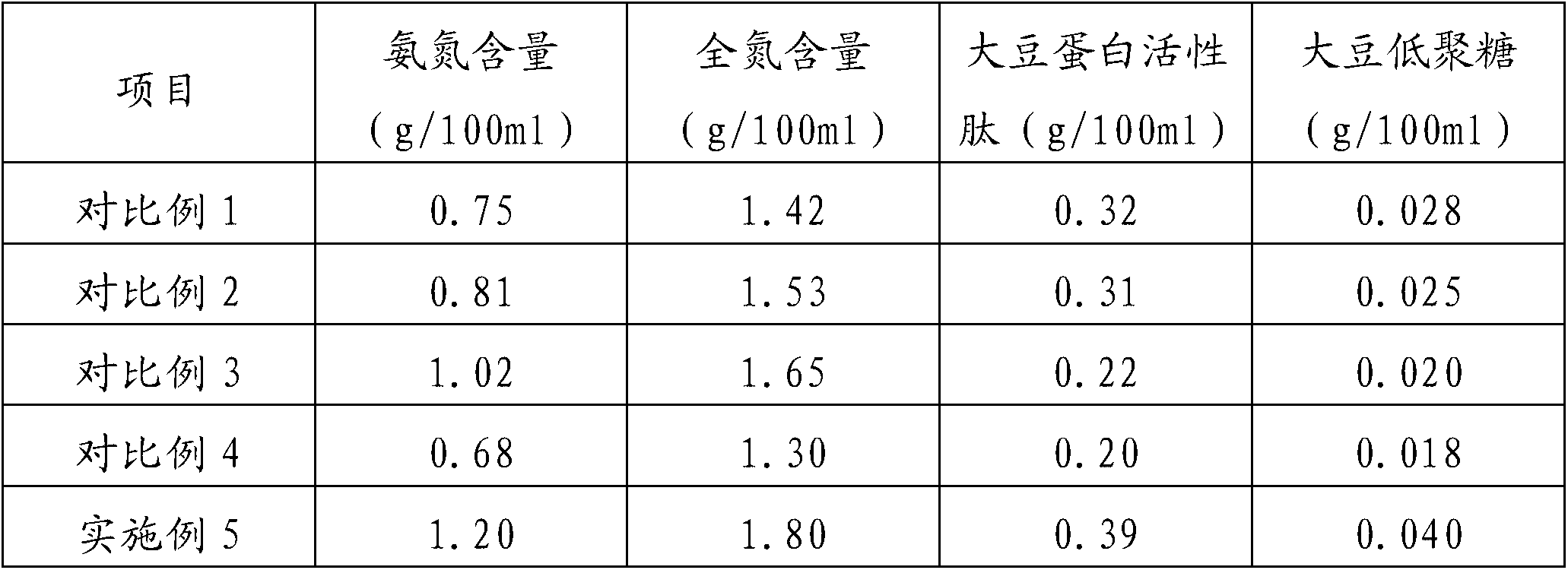

Examples

Embodiment 1

[0036] (1) Raw material preparation: After removing impurities, the raw material wheat is fried and matured at high temperature instantaneously. The expansion degree of wheat is ≥1.40. The ingredients are mixed well.

[0037] (2) Inoculation: Cool down the mixed raw material in step (1) to 40°C, separate and rejuvenate the microorganism Aspergillus oryzae and expand the culture to obtain the Aspergillus oryzae strain, and inoculate the mixed raw material according to the inoculation amount of 0.5% to obtain the koji material .

[0038] (3) Koji making: Keep the thickness of the koji material in the koji pool at 25cm, cultivate the koji at 26°C, and turn the koji at a temperature of 20°C every time the koji material agglomerates. The time for turning the koji should not exceed 25 minutes After turning over the koji, adjust the temperature of the koji material to 26°C again. After the second koji turning, sprinkle water on the ground to keep the relative humidity in the koji po...

Embodiment 2

[0043] (1) Raw material preparation: After the raw material wheat is screened and removed by a full-automatic specific gravity de-stoner machine, it is fried and matured by a sand-bath-type drum-fried wheat machine at a high temperature of 450°C. The wheat puffing degree is ≥ 1.40. After the defatted soybeans are cleaned and moistened, they are cooked and matured by FM high-pressure continuous cooking equipment at a pressure of 1.8 MPa, so that the digestibility of the defatted soybeans is ≥ 85%, and the soybean tissue is completely destroyed. The two processed raw materials are processed according to 0.8: The weight ratio of 1.2 is mixed evenly.

[0044] (2) Inoculation: cool down the mixed raw material in step (1) to 35°C, inoculate the Aspergillus oryzae strains obtained by the separation and rejuvenation of the microorganism Aspergillus oryzae into the mixed raw material according to the inoculation amount of 0.3% to obtain koji material.

[0045] (3) Koji making: Keep th...

Embodiment 3

[0050] (1) Raw material preparation: After the raw material wheat is screened and removed by a fully automatic specific gravity stone removal machine, it is fried and matured by a sand-bath drum frying machine at a high temperature of 520°C. The average puffing degree of the wheat is 1.45. After the defatted soybeans are cleaned and moistened, they are steamed and matured by FM high-pressure continuous cooking equipment at a pressure of 1.85MPa, so that the digestibility of the defatted soybeans is 85%, and the soybean tissue is completely destroyed. The two processed raw materials are 1:1 The weight ratio is mixed evenly.

[0051] (2) Inoculation: cool down the mixed raw material in step (1) to 38°C, inoculate the Aspergillus oryzae strains obtained by the separation and rejuvenation of the microorganism Aspergillus oryzae into the mixed raw material according to the inoculation amount of 0.4% to obtain koji material.

[0052] (3) Koji making: Keep the thickness of the koji ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com