Atomizer

A nebulizer and spray chamber technology, applied in chemical instruments and methods, zirconia, nitrogen and non-metallic compounds, etc., can solve the problems of high application cost, limited atomization uniformity, high cost, etc., and achieve low cost of use , good atomization effect and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

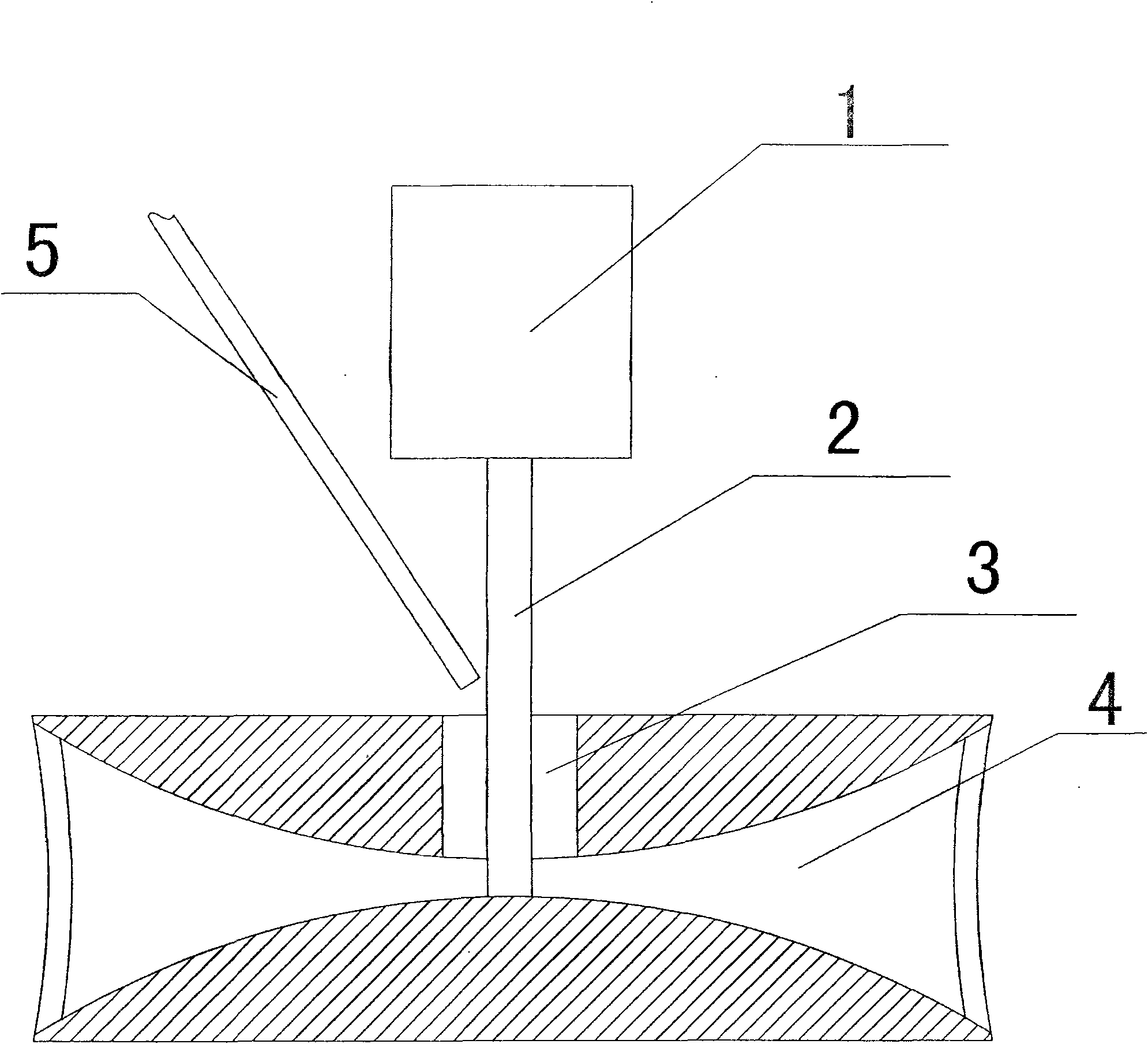

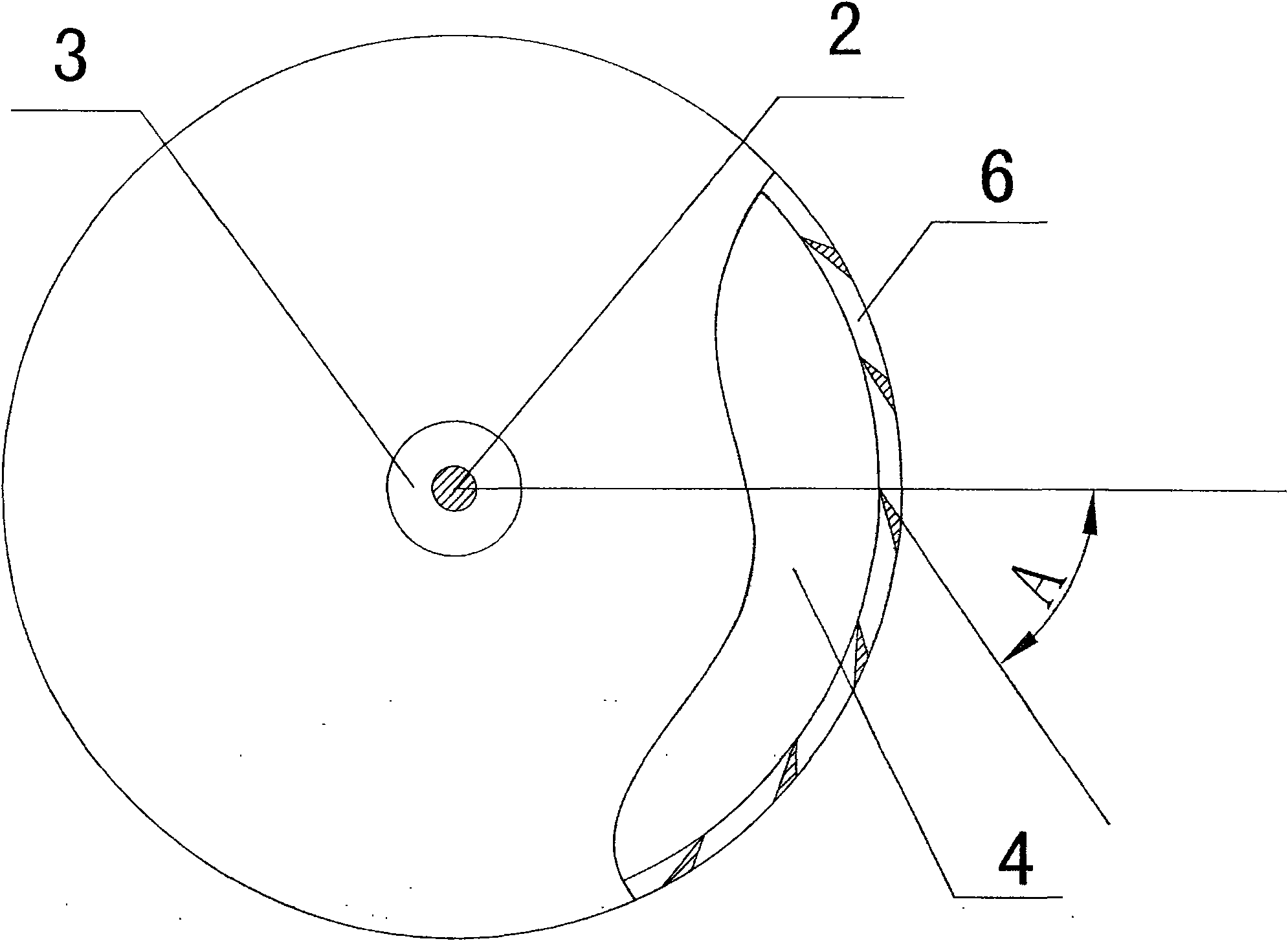

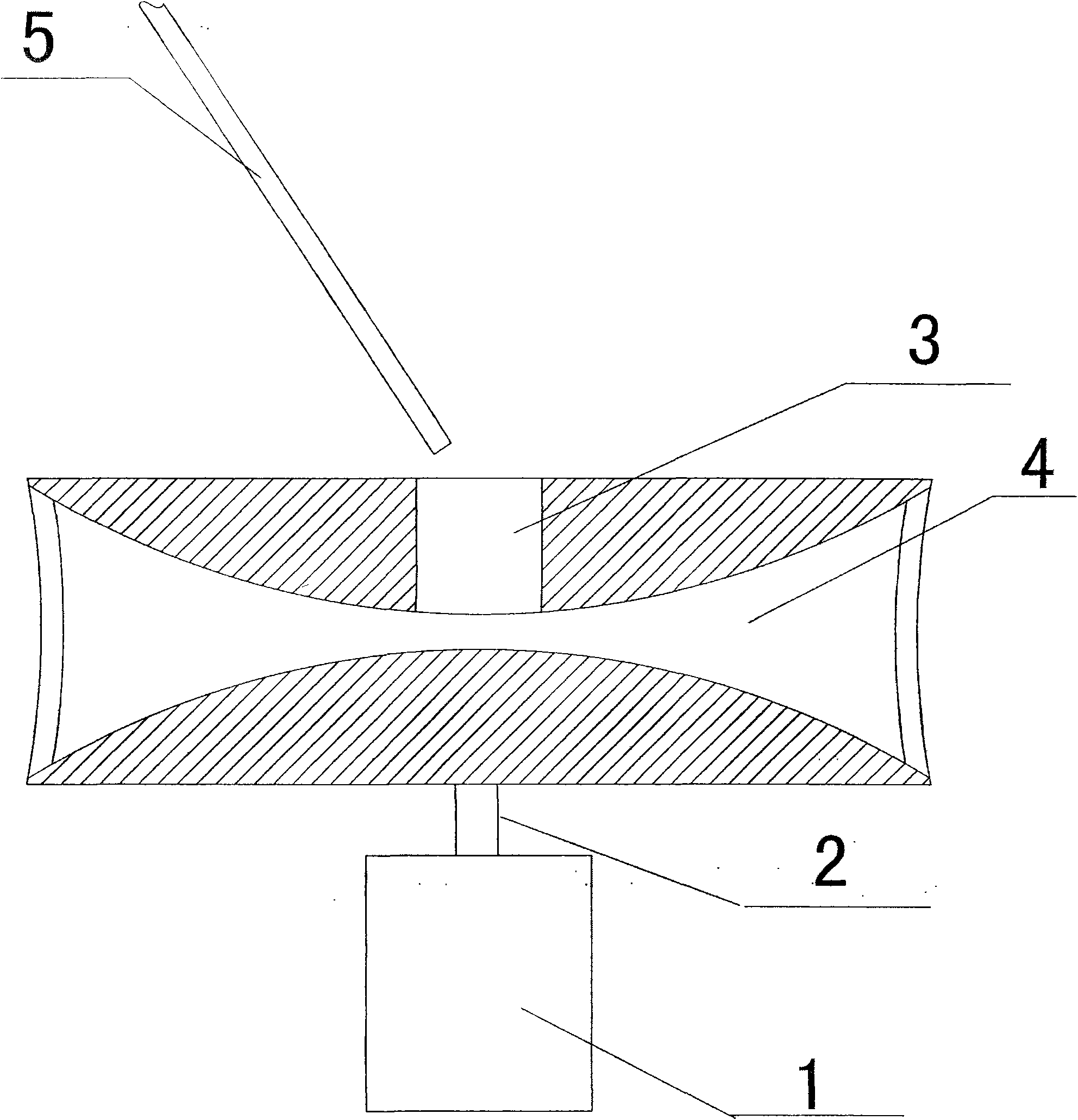

[0007] The main structure of the atomizer of the present invention includes a power machine 1 and a rotating shaft 2. The power machine can use a motor or an engine, etc. The power machine can be directly connected to the rotating shaft, or can be connected to the rotating shaft through a speed change device, and an atomization chamber is installed on the rotating shaft 4. The rotating shaft is installed in the middle of the atomization chamber. The cross-section of the atomization chamber is circular. The air outlet 6 is set up, and the atomization chamber is made of different materials according to the needs. If the speed requirement is high, it is made of high-strength material. The inner cavity of the atomization chamber is designed as a structure with thicker edges and thinner center. The thickness of the edge can be 0.618 times of the maximum cross-sectional radius of the atomization inner cavity. At the same time, it can make the airflow move more smoothly. There are ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com