Patents

Literature

41results about How to "The catalytic reaction is sufficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

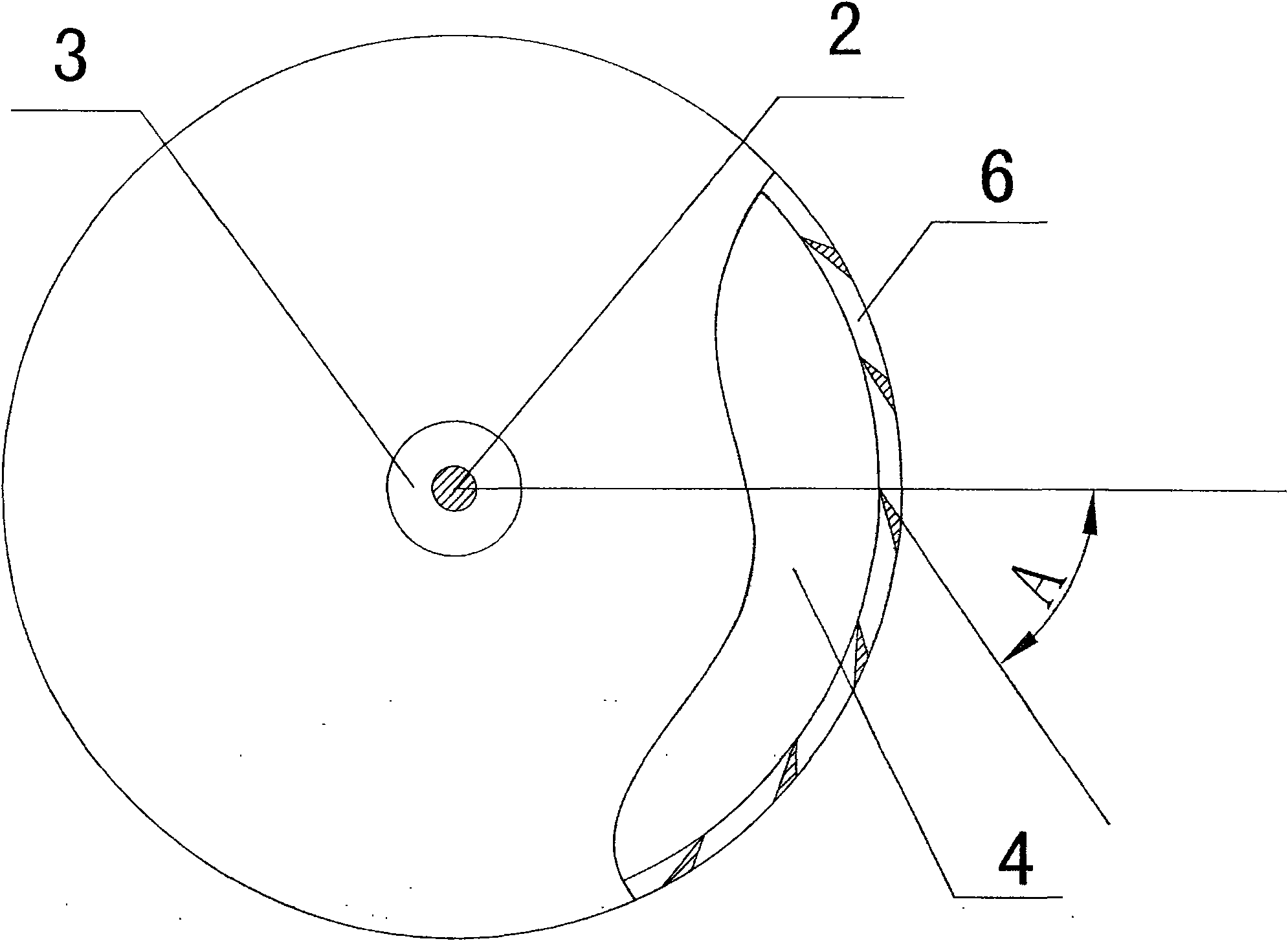

Axial flow device

InactiveCN102734175AUniform irrigationRealize micro-sprayPump componentsAxial flow pumpsImpellerSuction equipment

The invention provides an axial flow device comprising a shell and a transmission device. The shell is provided with the transmission device and is internally provided with a shell cavity; a vortex tube impeller is arranged in the shell cavity; the transmission device is connected with a vortex tube impeller; the vortex tube impeller is provided with a vortex tube which is provided with an impeller opening A and an impeller opening B and is internally provided with a wheel body, and the wheel body is provided with a guide blade; an inclined angle is formed between the guide blade and a rotating shaft of the vortex tube impeller; the guide blade is connected to the inner wall of the vortex tube; a shell cavity opening A is arranged at one end, which corresponds to the impeller opening A, of the shell cavity; and a shell cavity opening B is arranged at the other end of the shell cavity. The axial flow device is more energy-saving and can be used for pressurizing and conveying fluid. The axial flow device can serve as a water pump, vacuum equipment, air suction equipment, an air blower, a compressor, atomizing equipment, sprinkling equipment, a reactor, air blowing equipment, propelling equipment, a sewage processor, a dust remover, a dust collector, dressing equipment, a steam turbine, a water turbine, a wind turbine, a vortex pressurizing device utilizing residual heat of an engine, foam material manufacturing equipment, nano material manufacturing equipment and the like; and the axial flow device can be used for manufacturing a brand new foam material.

Owner:陈久斌

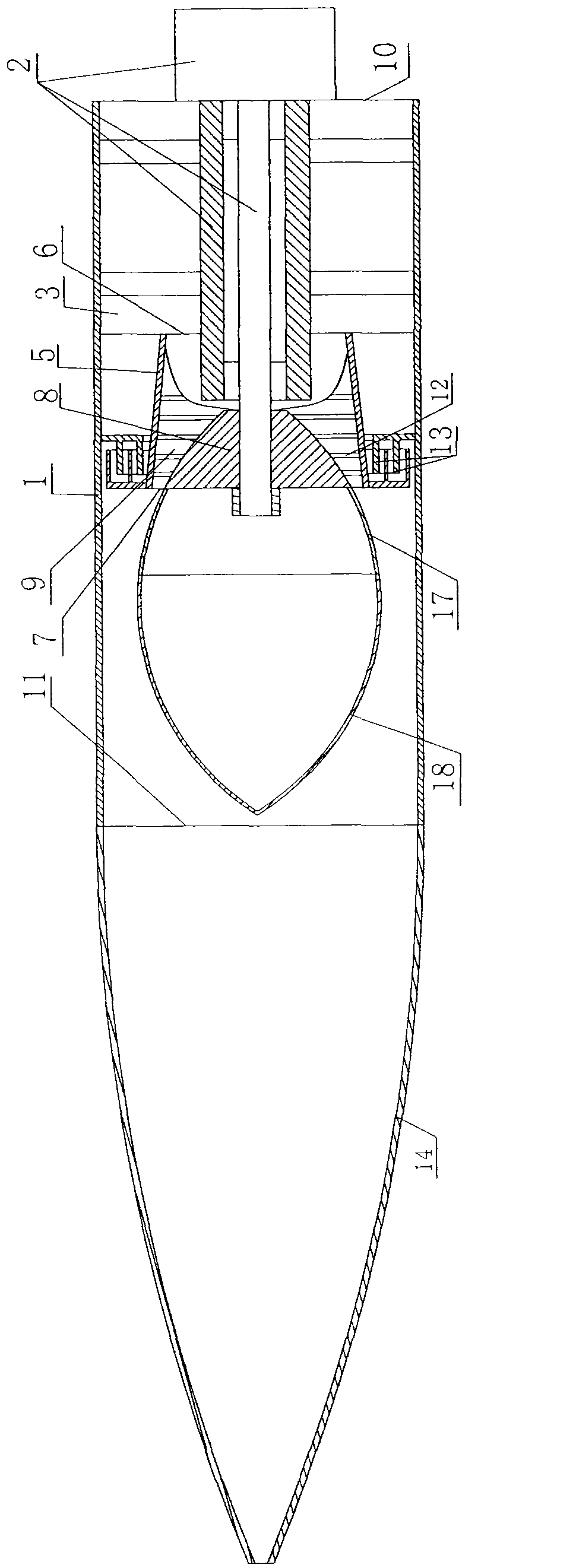

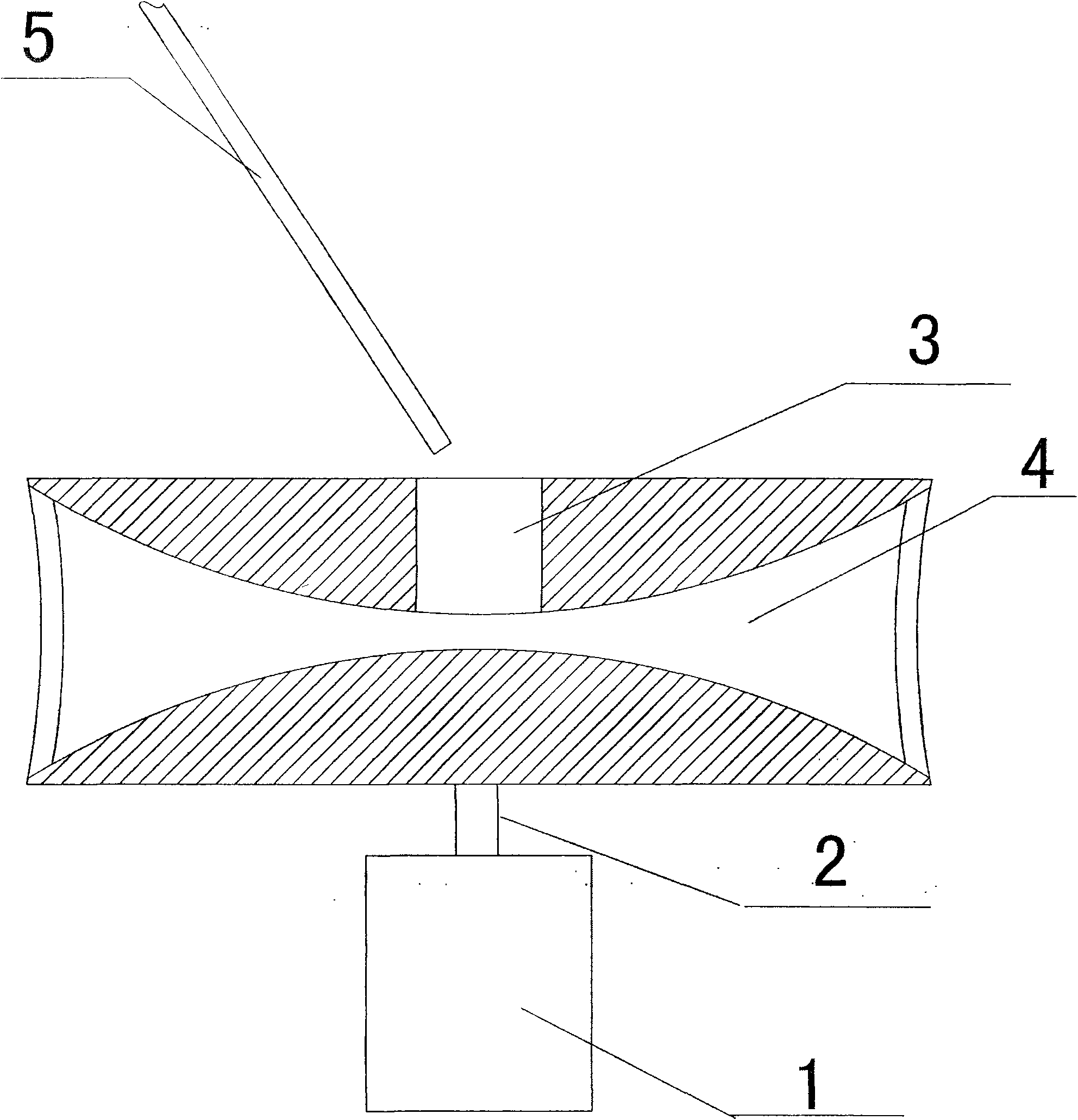

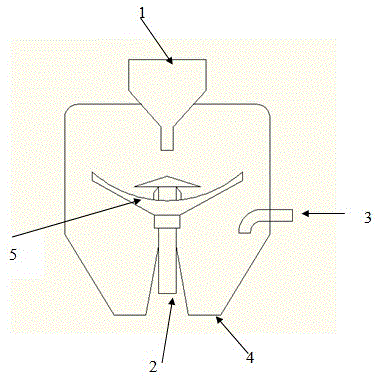

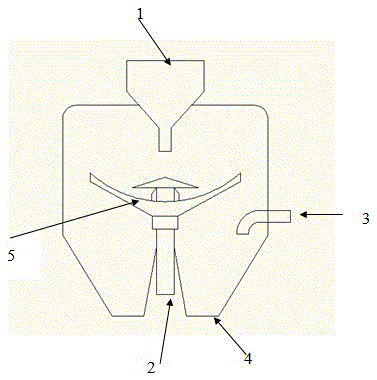

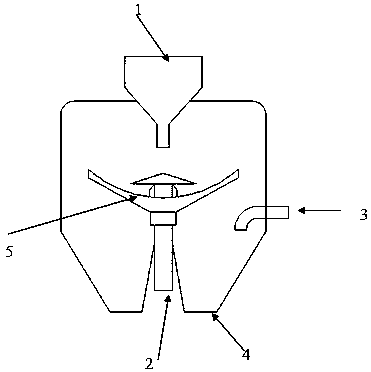

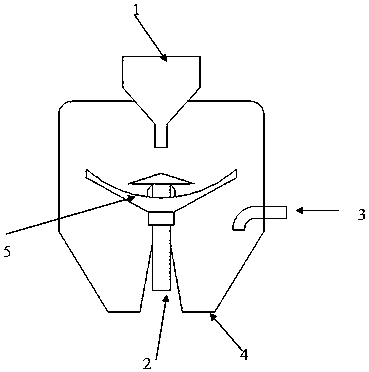

Atomizer

InactiveCN101642735AWell mixedFull chemical reactionDispersed particle separationLiquid spraying apparatusChemical industryChemical reaction

The invention relates to an atomizer which adopts a new atomizing way and a new atomizing principle and sufficiently utilizes fluid motion and vortexes to enable materials and gases to be automatically absorbed to the vortexes from a vortex center area, uniformly mixed by being influenced by the vortexes in the moving process from a vortex center to vortex periphery and thrown out from the atomizer under the action of circular motion centrifugal force to form aerial fog. The atomizer comprises a power machine and a rotating shaft, wherein the rotating shaft is provided with an atomizing chamber, the middle of the atomizing chamber is provided with a gas inlet, and the periphery of the atomizing chamber is provided with a gas outlet. The invention can be used for various fields needing atomizing equipment, can be used for producing the powder of multiple nano materials and can be applied to fields, i.e. material industry, atomizing cooling, smoke gas purification, atomizing drying, refining oil and heavy oil catalytic cracking, chemical reaction, fuel atomization, heavy oil atomization, boiler water deoxygenation, atomized water, pesticide spraying, extinguishment spraying, humidification, sterilization, odour removal, fog making, medicine preparation, medical treatment, chemical industry production, and the like.

Owner:陈久斌

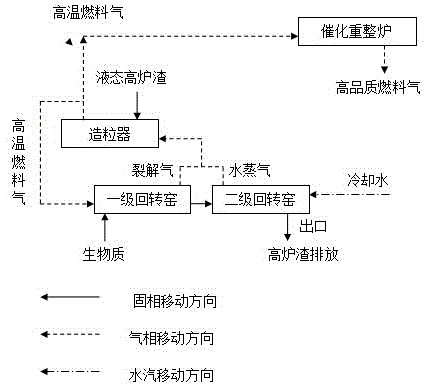

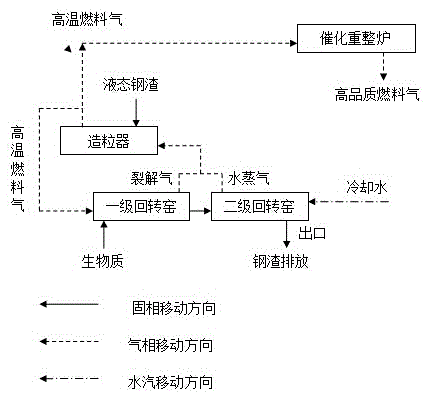

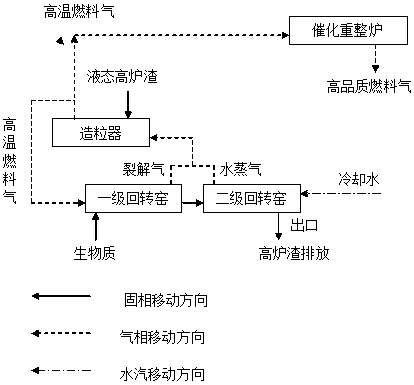

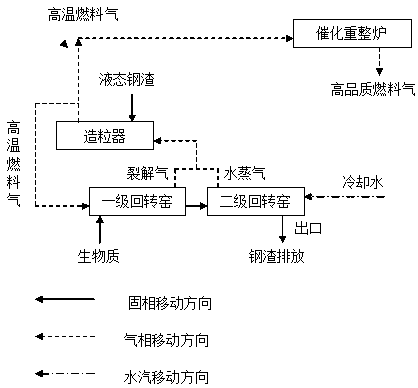

Technology of utilizing blast furnace slag waste heat to reclaim biomass and produce high quality fuel gas

ActiveCN105542859ATake advantage ofImprove energy efficiencyEnergy inputGasification processes detailsSlagWater vapor

The invention discloses a novel method of utilizing liquid blast furnace slag waste heat to crack biomass and produce high quality fuel gas. Through technological control, the liquid blast furnace slag can be effectively cooled, and the heat energy of the slag is effectively utilized, and meanwhile the biomass can be transformed into the high quality energy gas. The technical scheme of the technology is as follows: the liquid blast furnace slag is heated, and the biomass and cooling water are gasified; under catalysis of the blast furnace slag, the biomass cracked gas and the vapor are subjected to catalytic reaction; the tar is gradually catalyzed to generate the energy gas mainly containing CO and H2; and meanwhile, Cl and CO2 in the energy gas is absorbed by alkali substance in the blast furnace slag. The technology greatly saves the energy source while cooling the blast furnace slag, and also produces the high quality energy gas.

Owner:SHANXI WENLONG COAL MINE ENG DESIGN

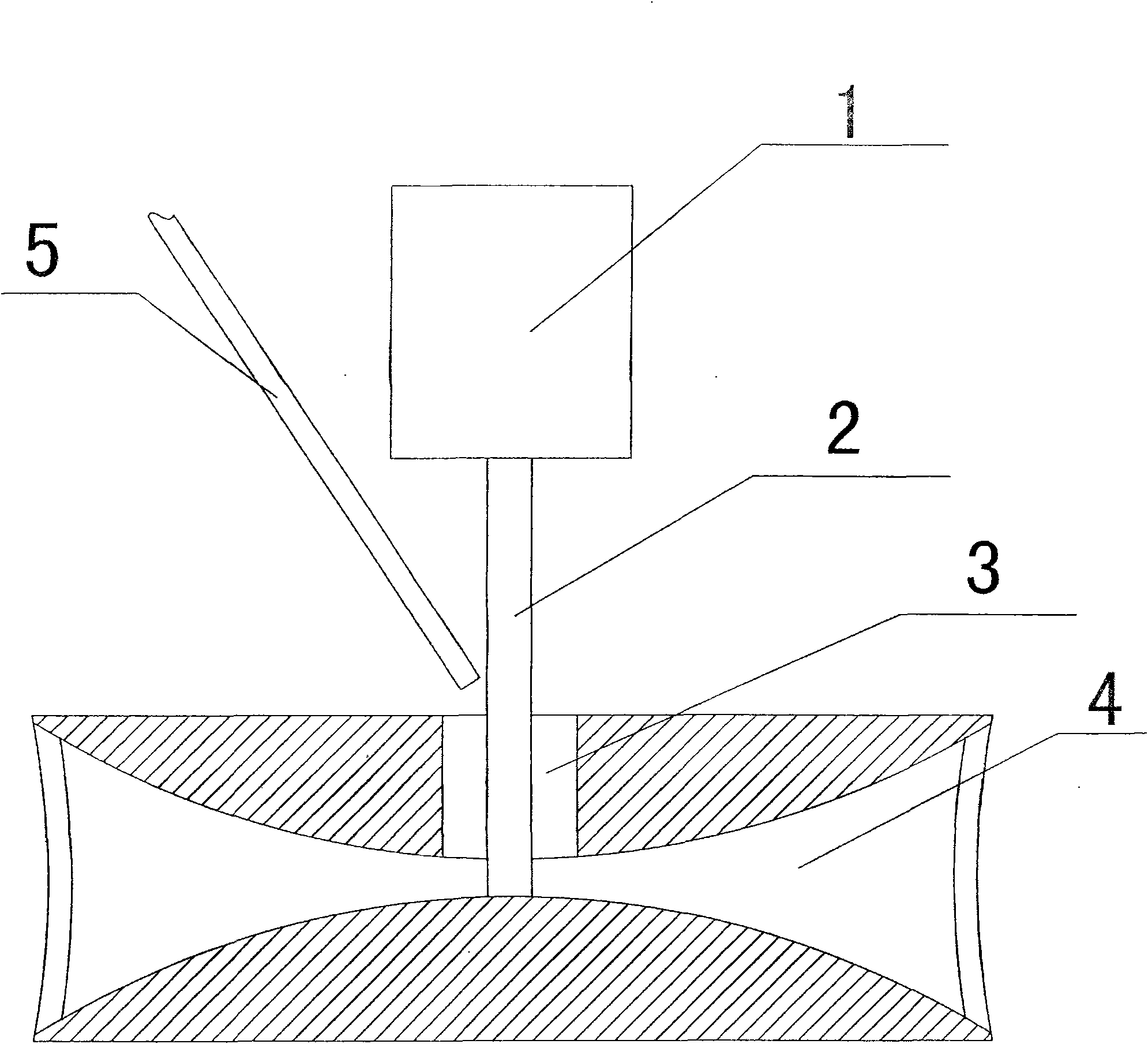

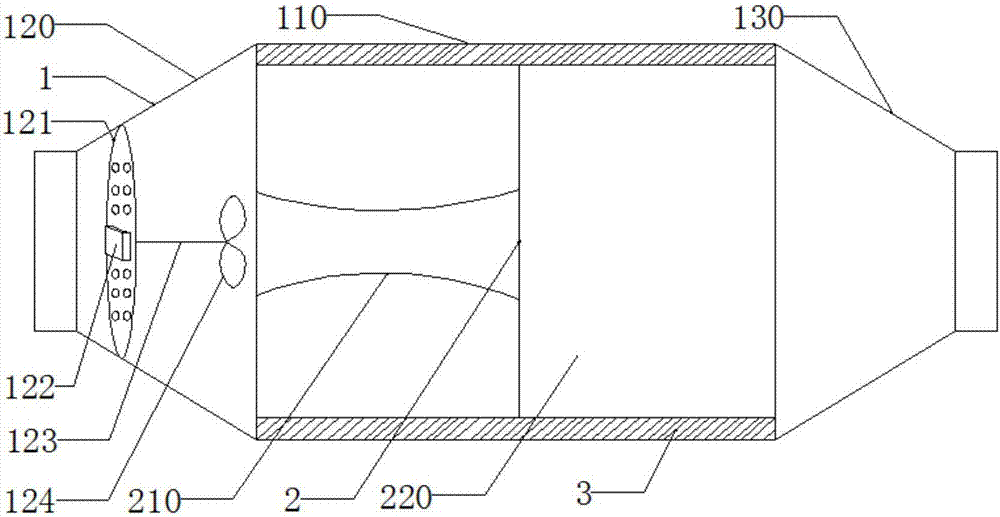

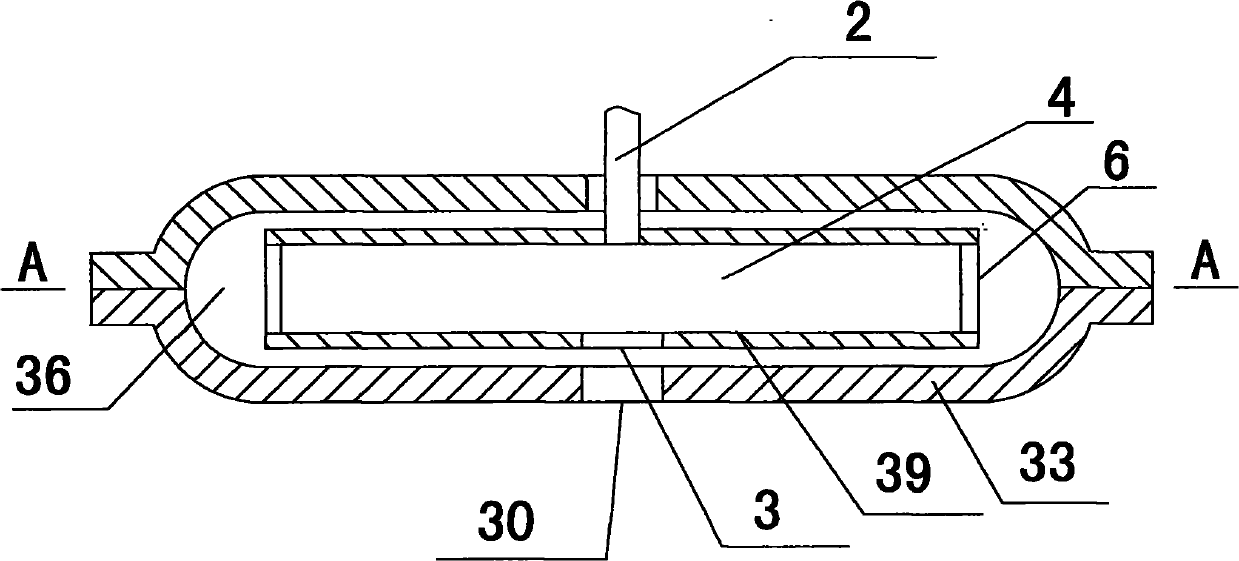

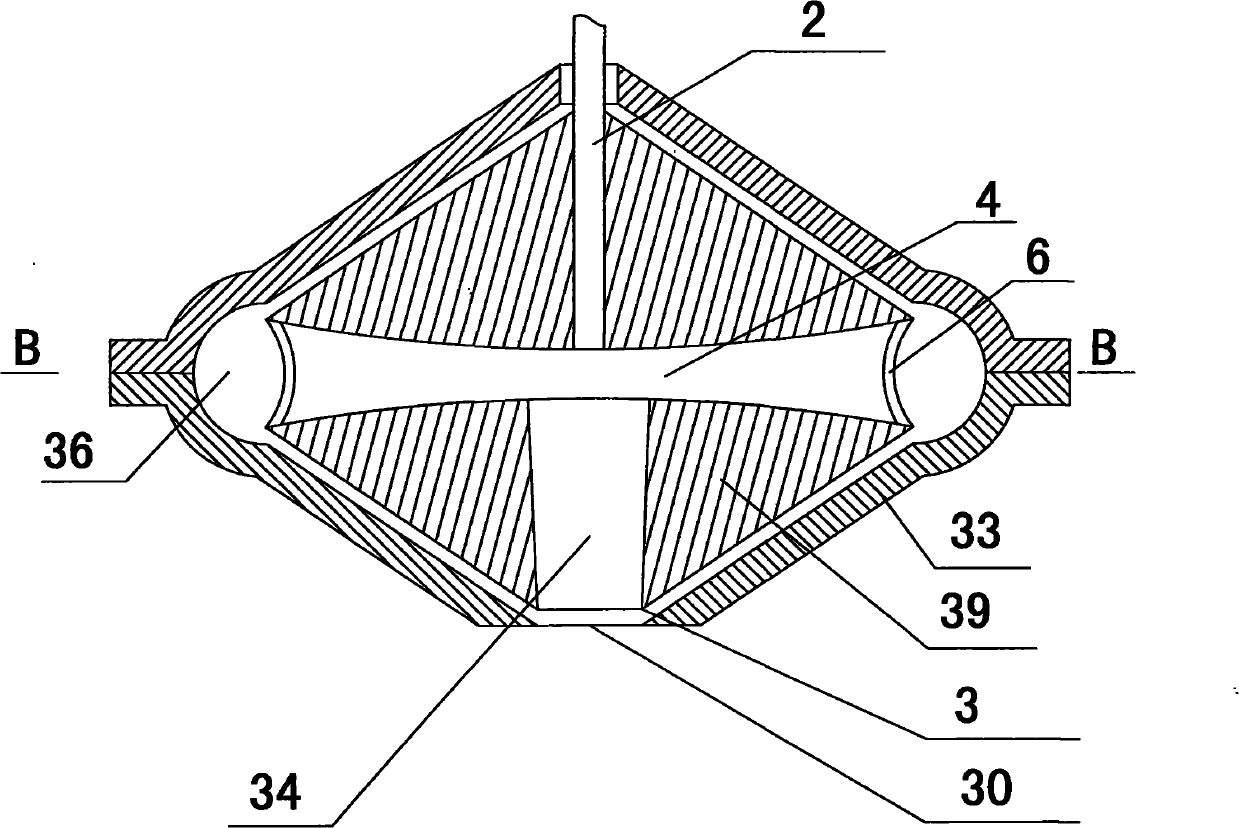

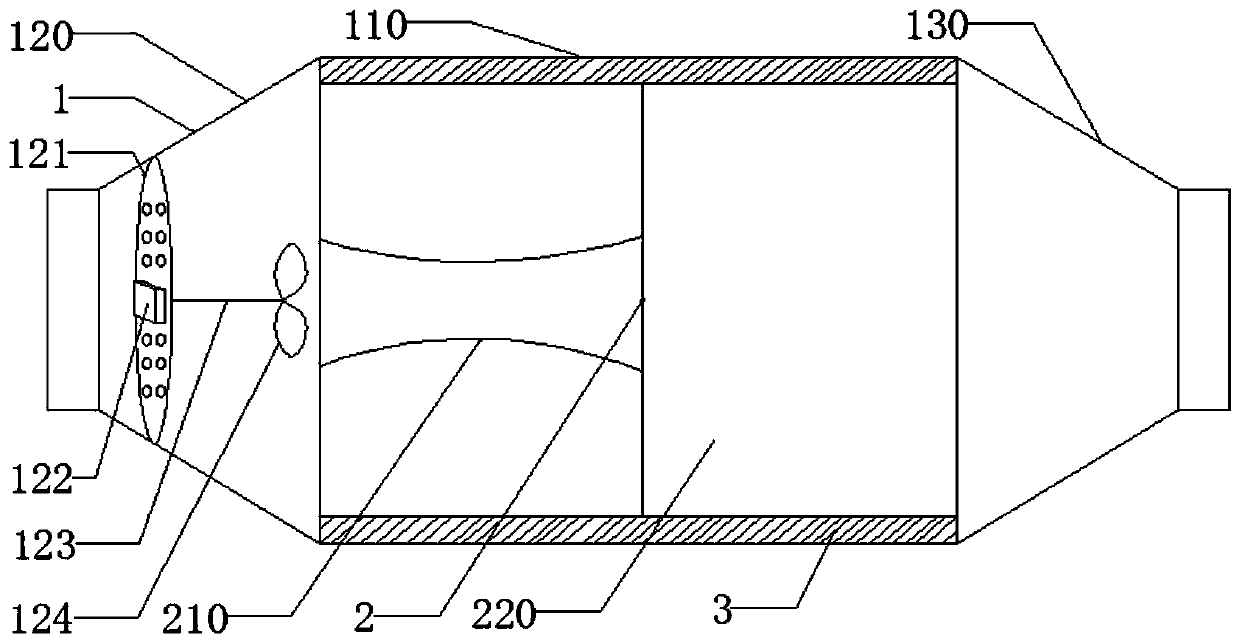

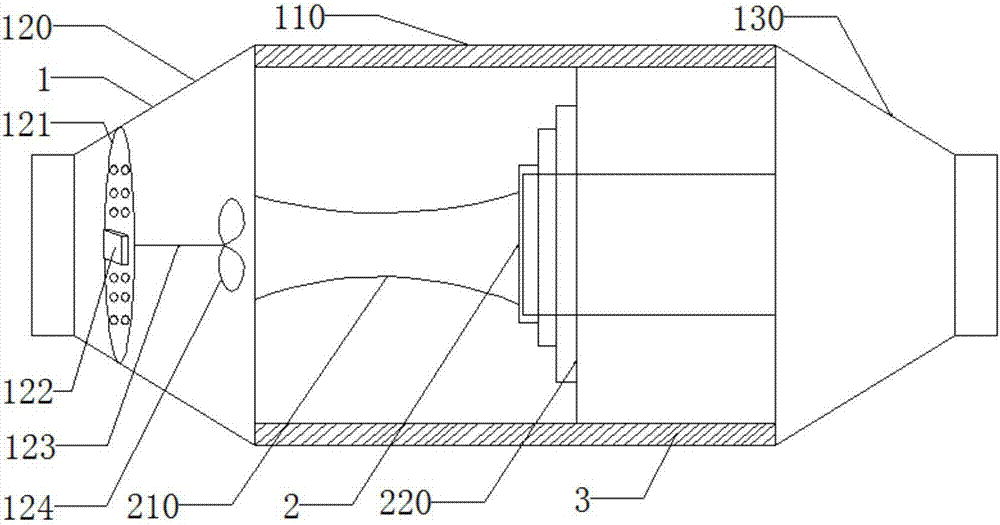

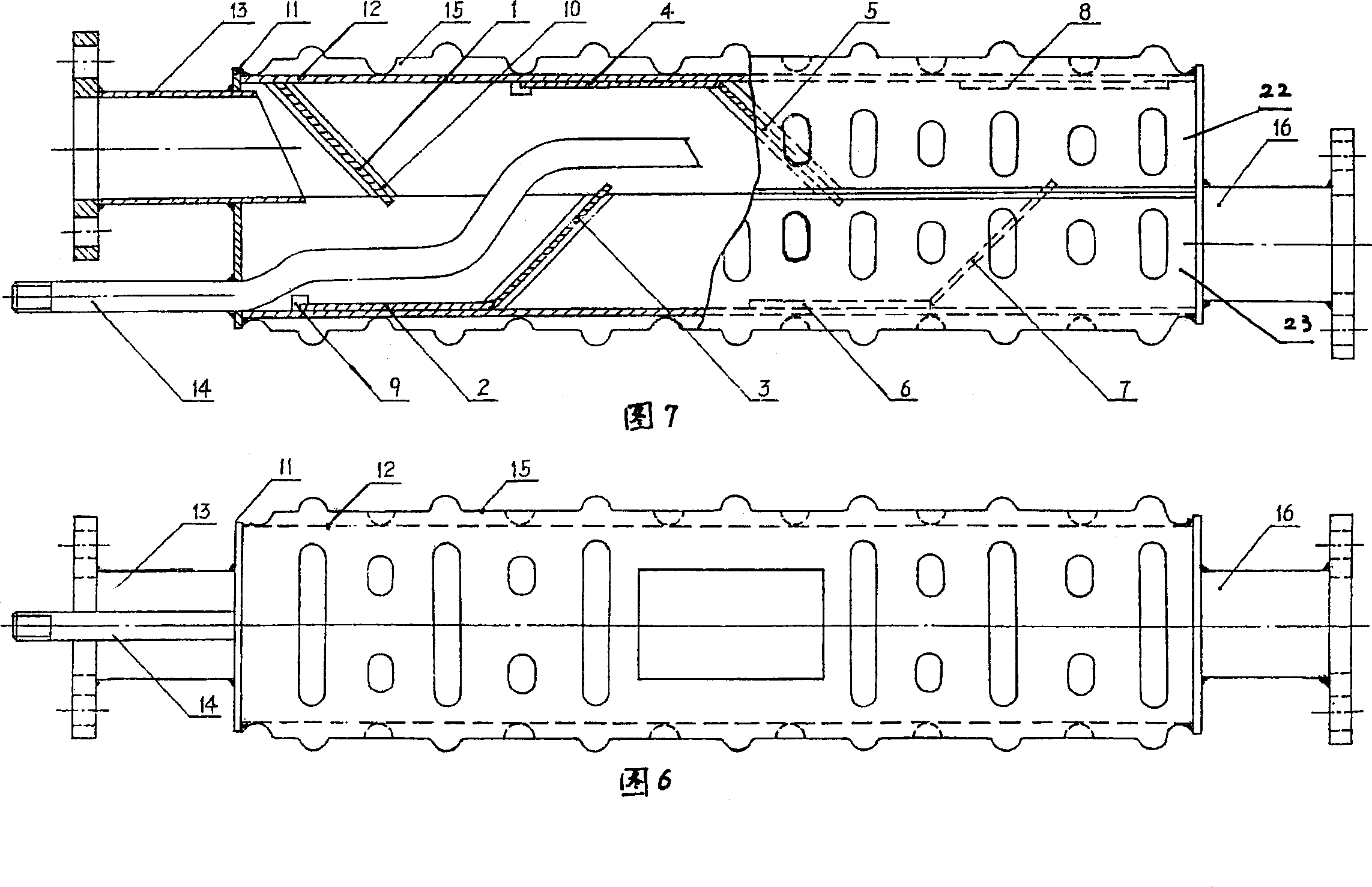

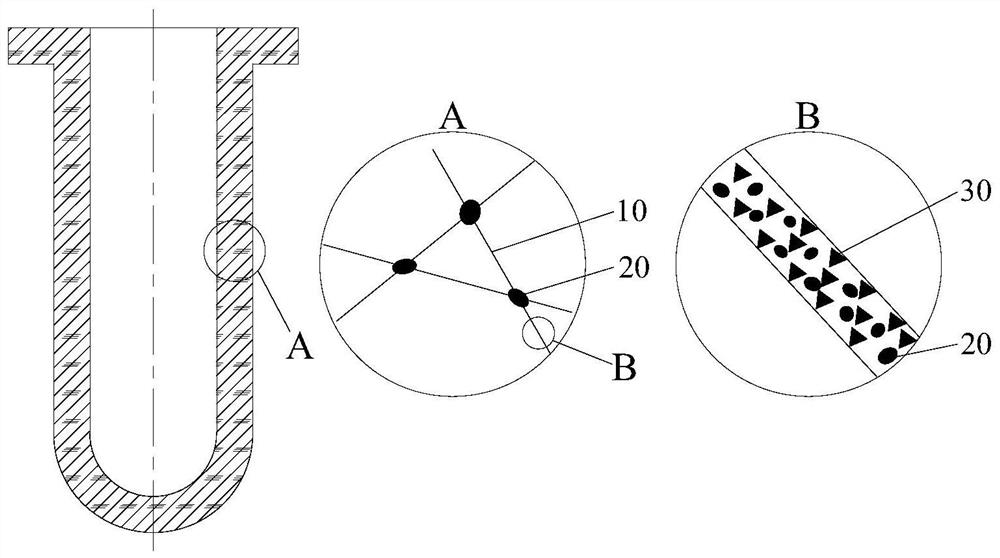

Motor vehicle tail gas catalytic purifying device

ActiveCN107035483AThe catalytic reaction is sufficientImprove conversion efficiency and utilizationInternal combustion piston enginesExhaust apparatusExhaust gasProcess engineering

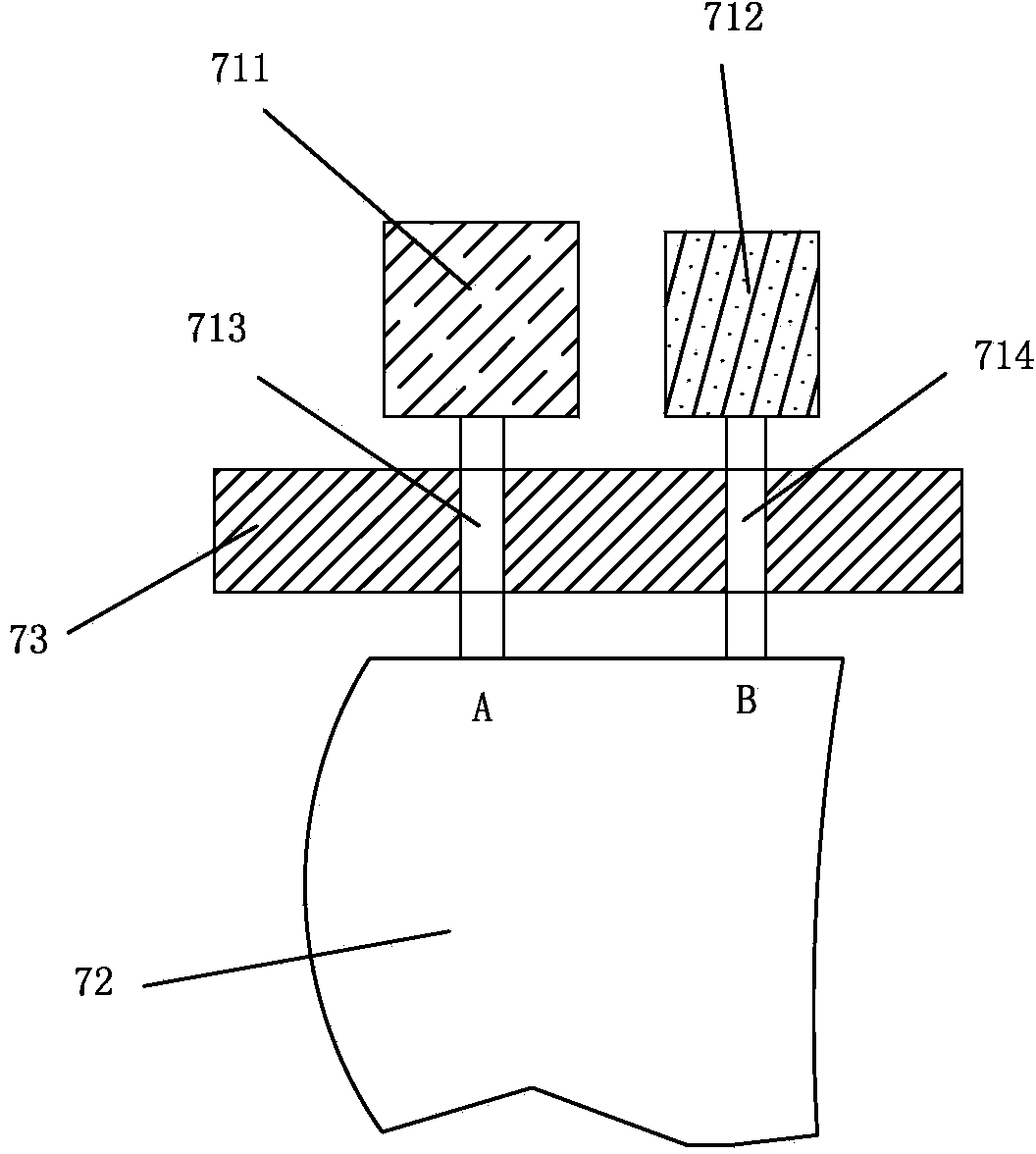

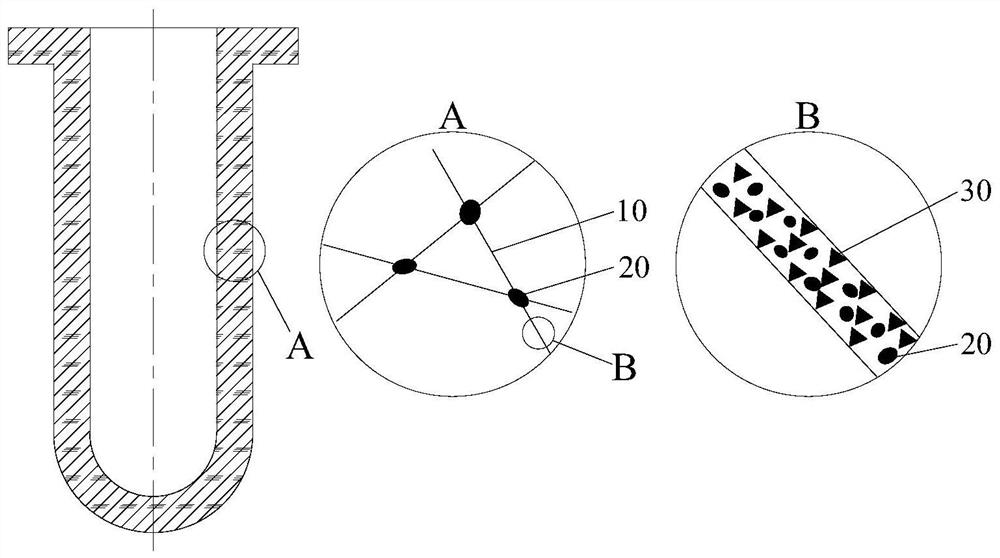

The invention discloses a motor vehicle tail gas catalytic purifying device. The motor vehicle tail gas catalytic purifying device comprises a shell body and a catalyst carrier, wherein the shell body comprises a main body part, a gas inlet part and a gas outlet part, the gas inlet part and the gas outlet part are located on the two sides of the main body part, and the catalyst carrier is arranged in the main body part. The gas inlet part is internally provided with a gas guiding device. The gas guiding device comprises a deflector which is fixedly clamped in the gas inlet part, perpendicular to the gas inlet direction and provided with a plurality of gas guiding holes, and a gas flow stirring device which is fixed to the deflector. The gas flow stirring device comprises a driving device, a stirring rod and at least one pair of blades, wherein the driving device is fixedly arranged on the side, close to the gas inlet part, of the deflector; the stirring rod is connected with the driving device, penetrates through the deflector and extends to the side, away from the gas inlet part, of the deflector; and the blades are fixed to the end, away from the gas inlet part, of the stirring rod. According to the motor vehicle tail gas catalytic purifying device, through the combined action of the deflector and the gas flow stirring device, internal gas flowing is more uniform, and the time for internal gas to flow through the catalyst carrier is prolonged, so that catalytic reaction is more sufficient, thus, the conversion efficiency of the catalytic device is effectively improved, and the utilization rate of the catalytic device is effectively increased.

Owner:卢志旭

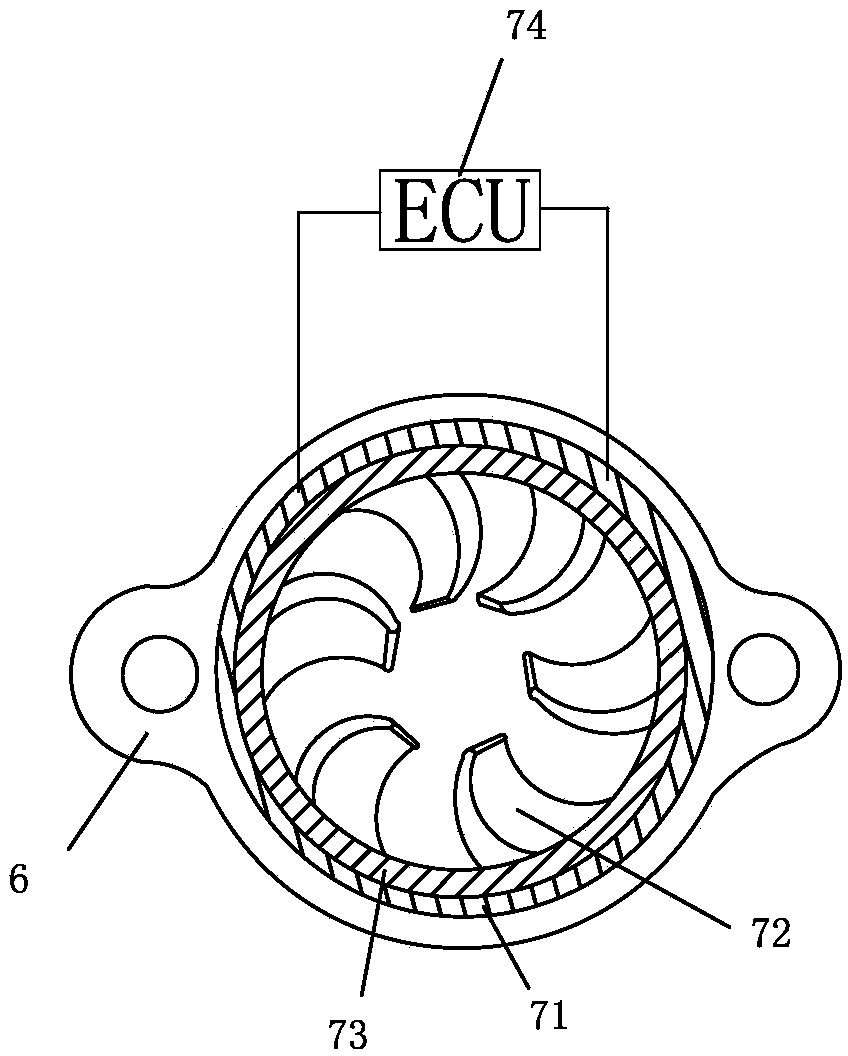

Three-way catalyst with flow rectifier

ActiveCN103422954AControl Flow UniformityReduce exhaust back pressure increaseExhaust apparatusSilencing apparatusEffective powerRing device

The invention relates to a three-way catalyst with a flow rectifier. The three-way catalyst comprises a shell, a catalyst carrier, a liner, an inlet passage and an exhaust passage, wherein the inlet passage is connected with one end of the shell, and the exhaust passage is connected with the other end of the shell. The three-way catalyst also comprises a catalyst flange. The catalyst flange is connected with the inlet passage; the flow rectifier is arranged in the catalyst flange and is located in the air inlet of the inlet passage. The flow rectifier comprises an electromagnetic ring device, an electronic control unit and a plurality of blades, wherein the electromagnetic ring device is coaxial with the catalyst flange; the electronic control unit is connected with the electromagnetic ring device and is used for controlling the electromagnetic ring device to work; the blades are arranged along the circumferential direction of the electromagnetic ring device and are controlled by the electromagnetic ring device to rotate; each blade is connected with the electromagnetic ring device by a connecting rod. According to the three-way catalyst provided by the invention, the blades can be changed within a certain rotation angle range, and are completely matched with all instantaneous conditions of an engine, and therefore, the conversion efficiency and the use ratio of the three-way catalyst are effectively improved, and moreover, maximum effective power is output by the engine.

Owner:AUTOMOBILE RES INST OF TSINGHUA UNIV IN SUZHOU XIANGCHENG

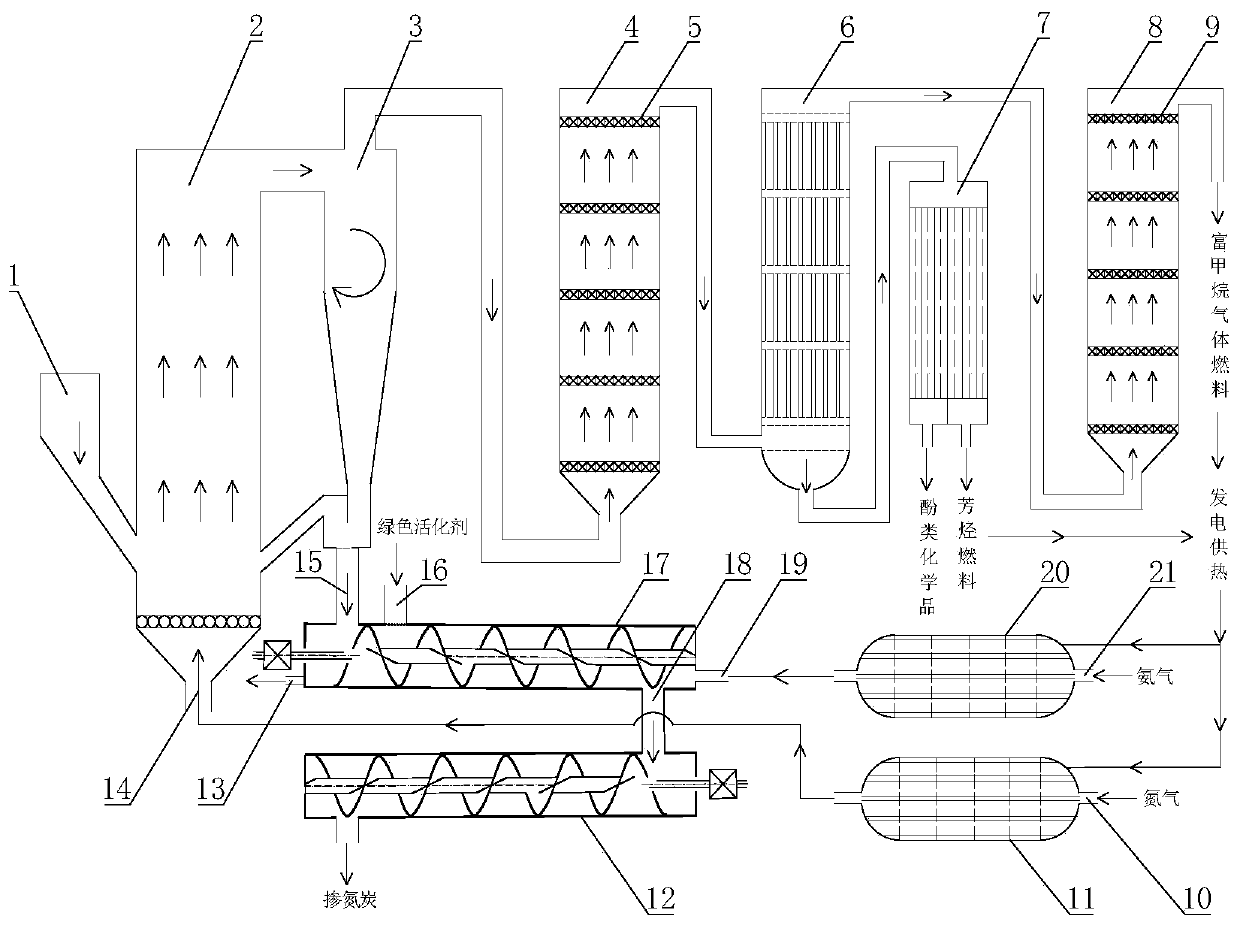

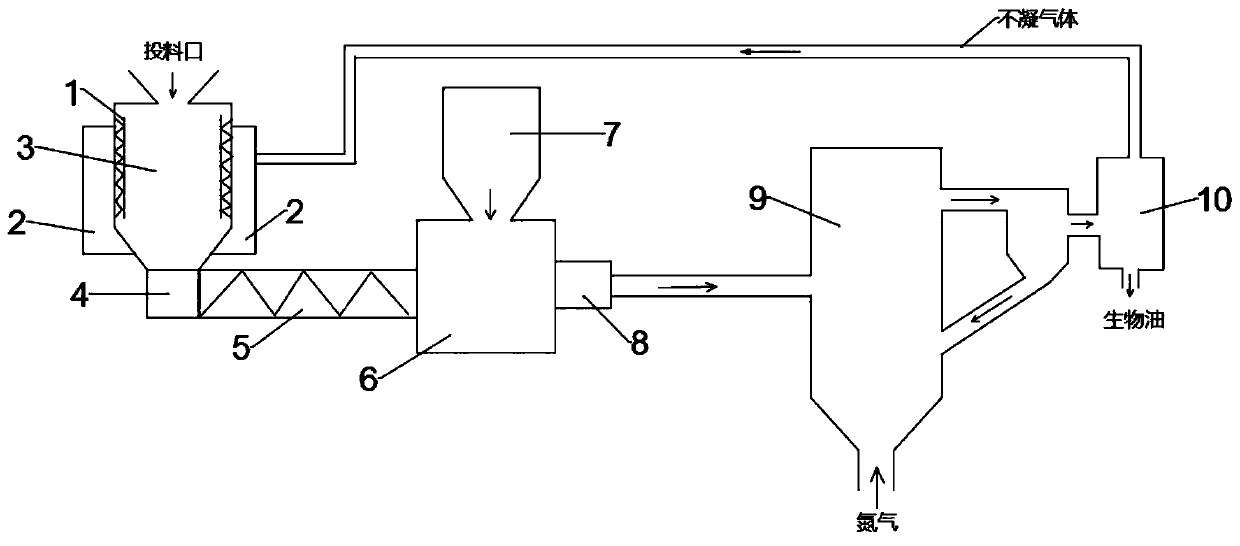

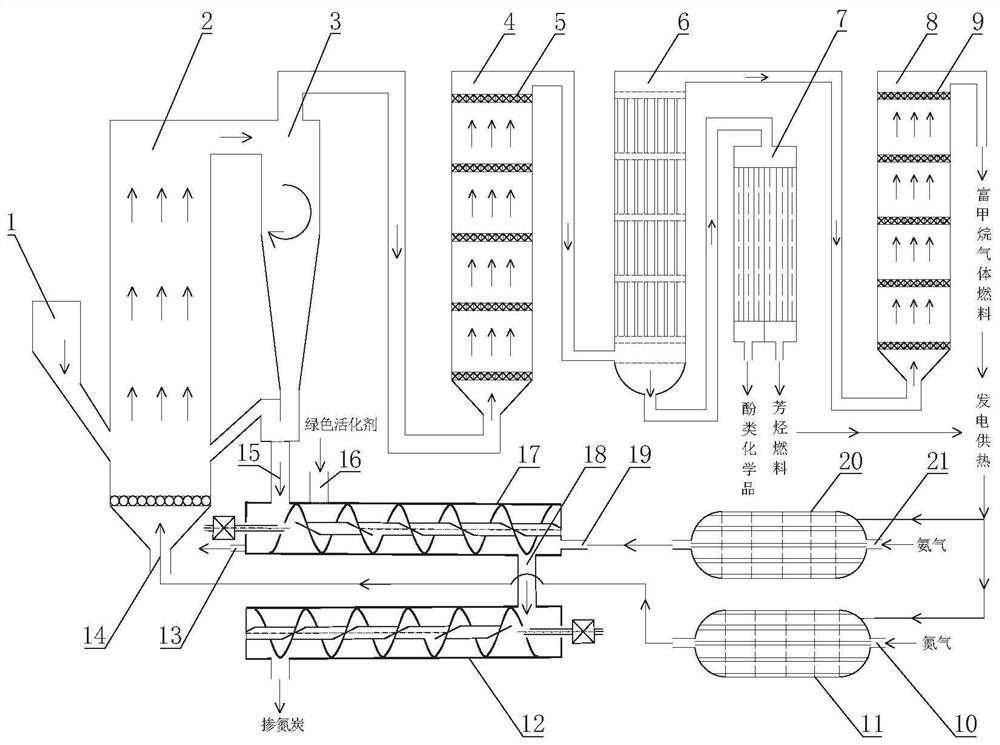

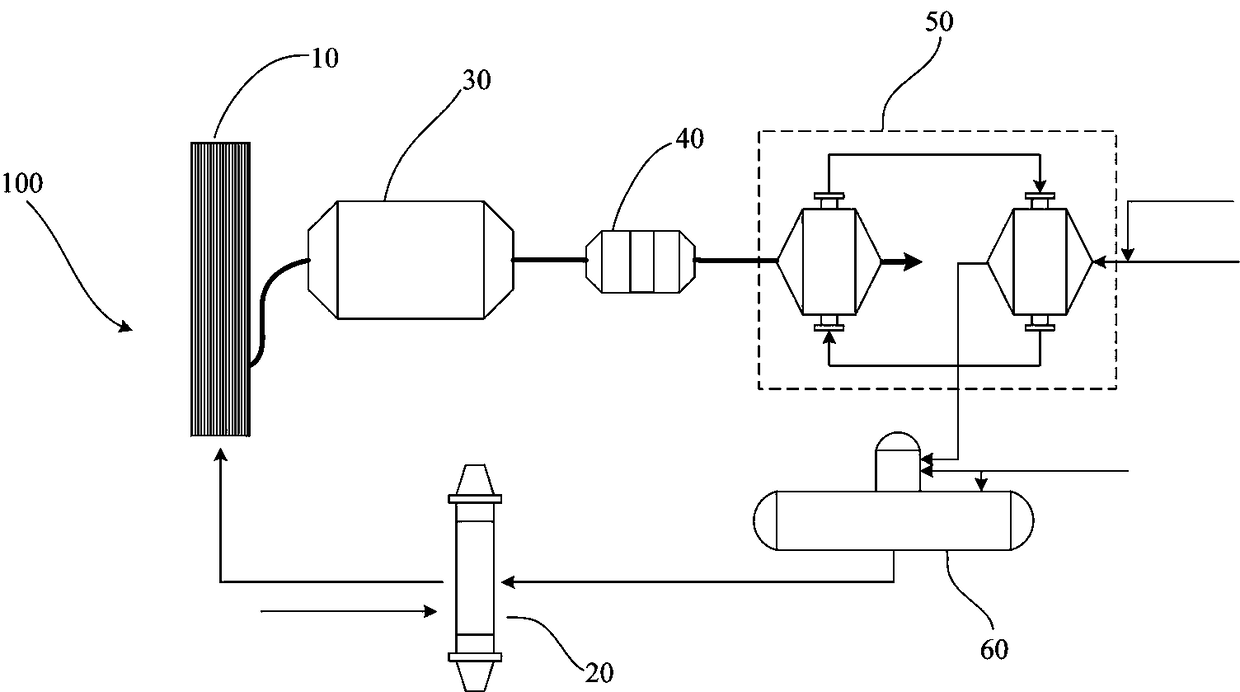

System for coproducing gas-liquid fuel, chemicals and carbon material by catalytic pyrolysis of biomass

ActiveCN111363569AConducive to high-value utilizationEasy to operateProcess control/regulationPhysical/chemical process catalystsCatalytic pyrolysisCatalytic reforming

The invention discloses a system for coproducing a gas-liquid fuel, chemicals and a carbon material by catalytic pyrolysis of biomass. The system comprises a biomass in-situ catalytic pyrolysis poly-generation subsystem, a pyrolysis volatile online catalytic proton extraction system, a non-condensable gas catalytic reforming subsystem and a charcoal activation ammoniation modification subsystem. The biomass in-situ catalytic pyrolysis poly-generation subsystem is used for carrying out in-situ catalytic pyrolysis on the biomass to obtain pyrolysis volatile components and biochar; the pyrolysisvolatile online catalytic proton extraction system is used for carrying out multistage online catalytic upgrading, multistage cooling and separation purification on volatile components to obtain phenolic chemicals and an aromatic hydrocarbon fuel; the non-condensable gas catalytic reforming subsystem performs multistage catalytic reforming on the pyrolysis gas to obtain methane-rich gas fuel for power generation and heat supply; and the charcoal activation ammoniation modification subsystem performs sufficient ammoniation activation modification on charcoal to obtain the high-value nitrogen-doped carbon material. The goal of green, efficient and continuous preparation of electricity, heat, chemicals and carbon materials is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

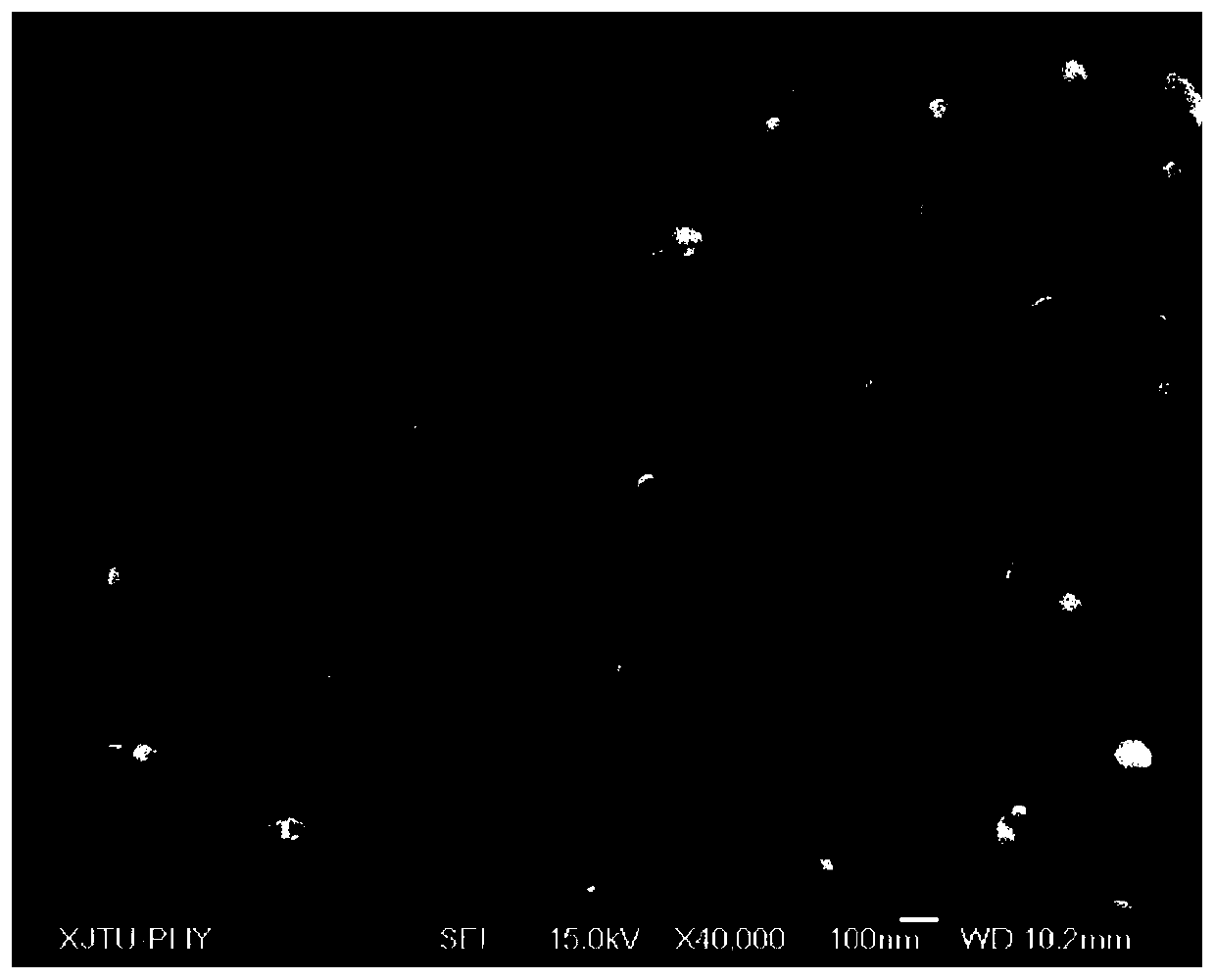

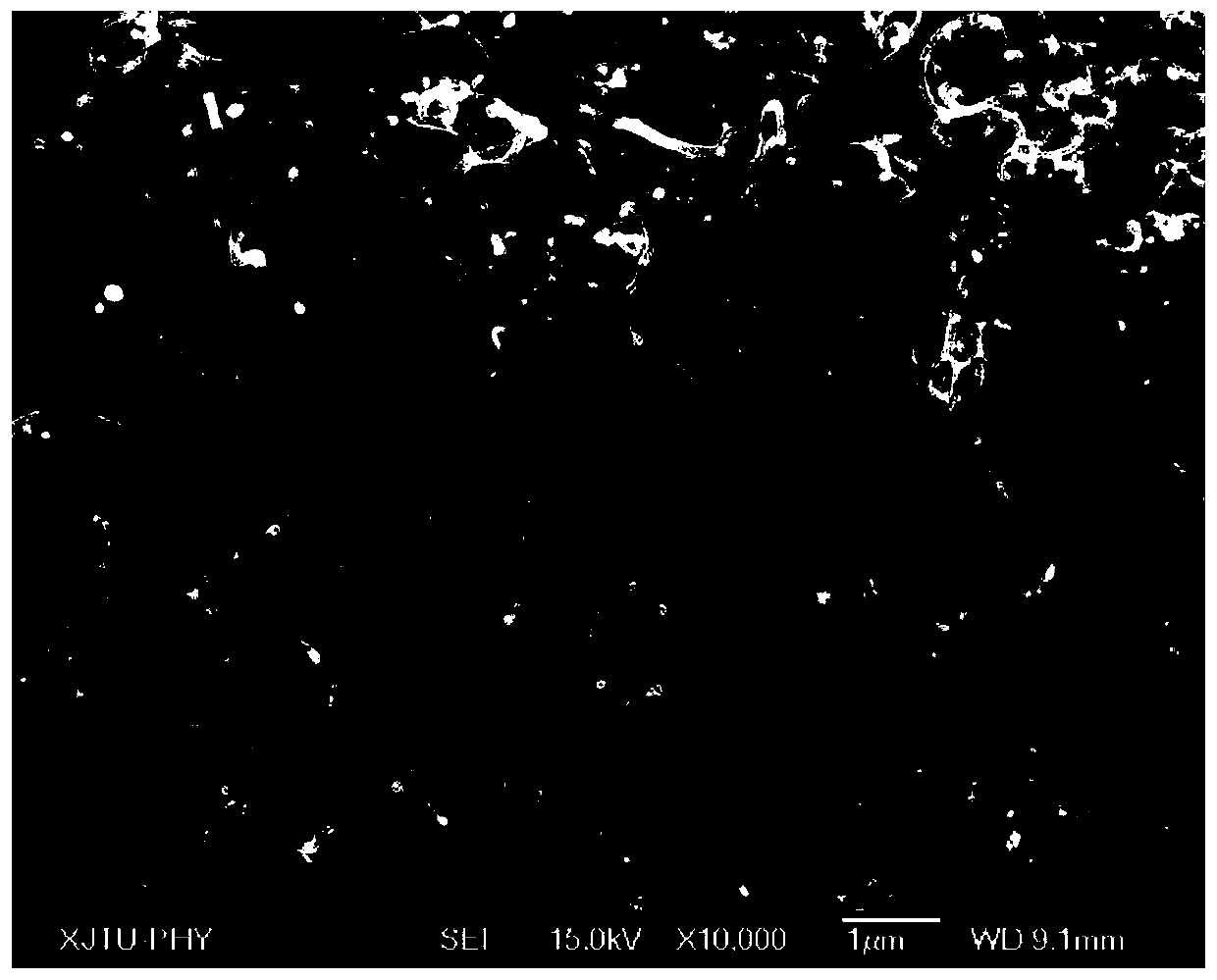

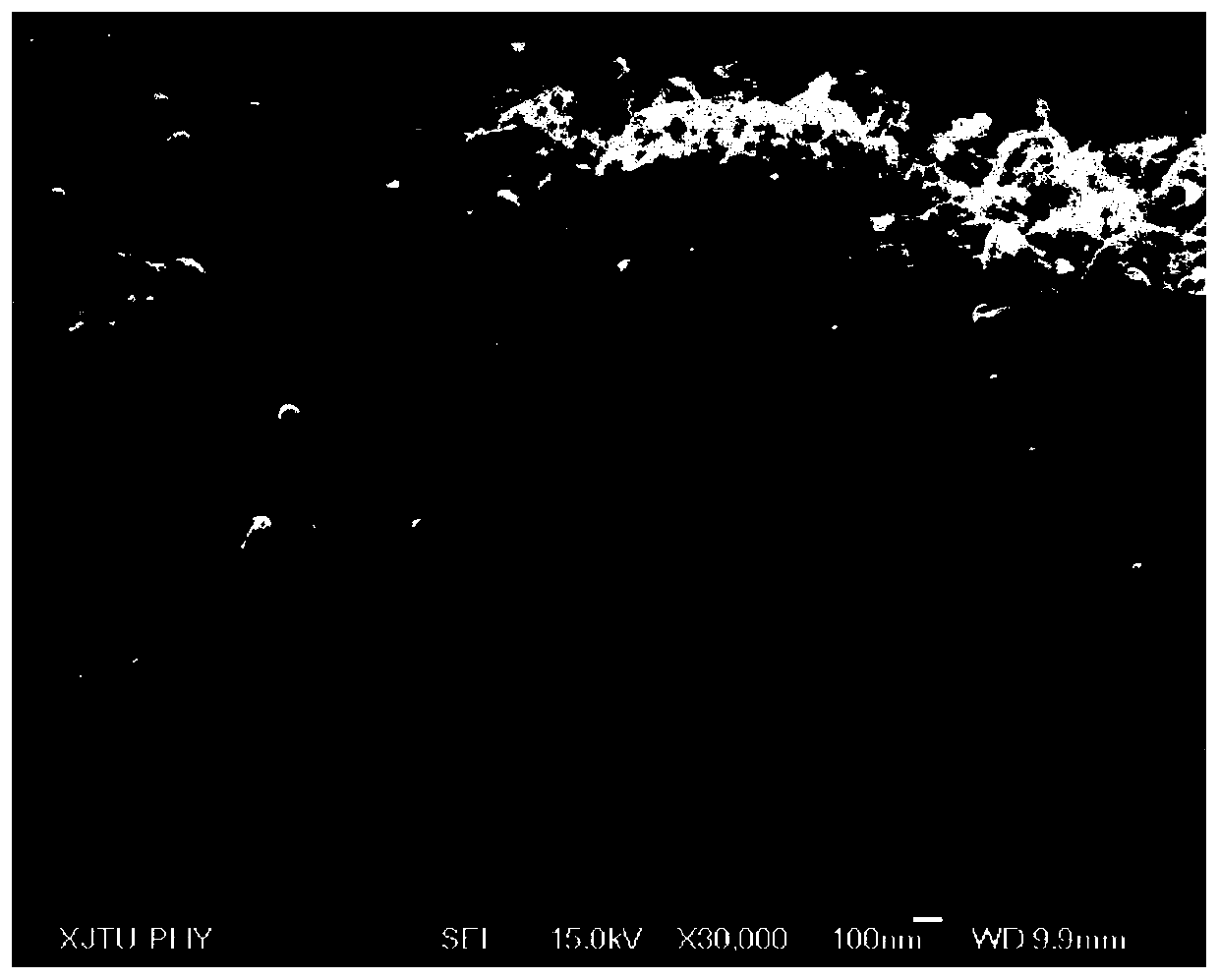

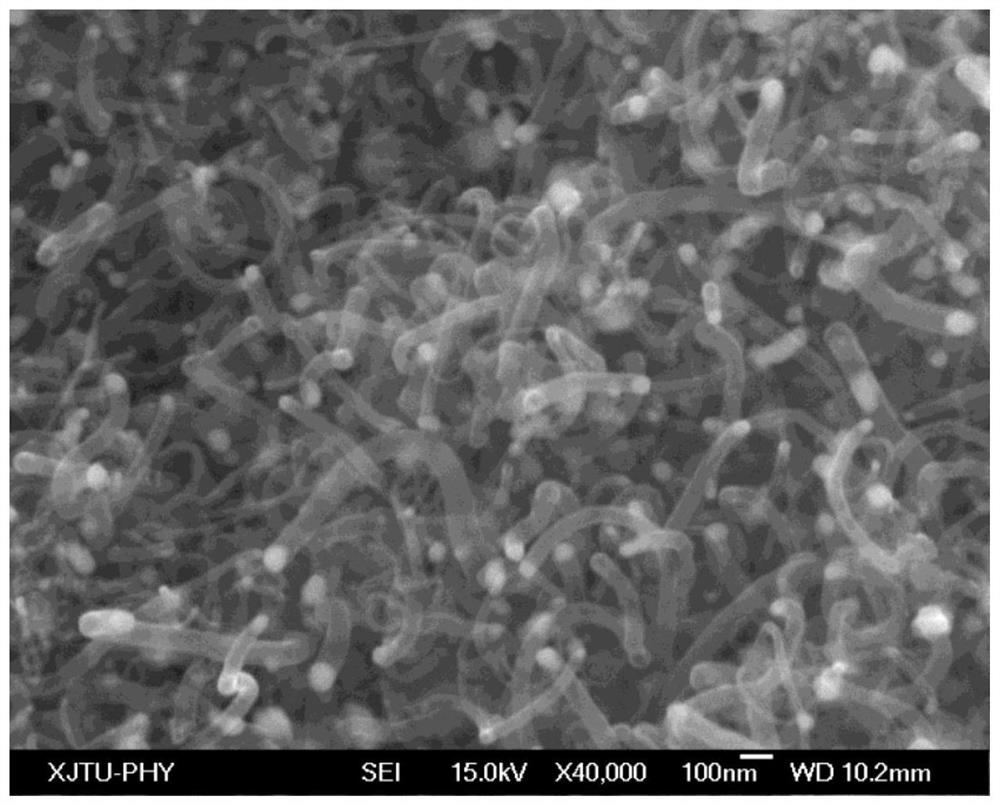

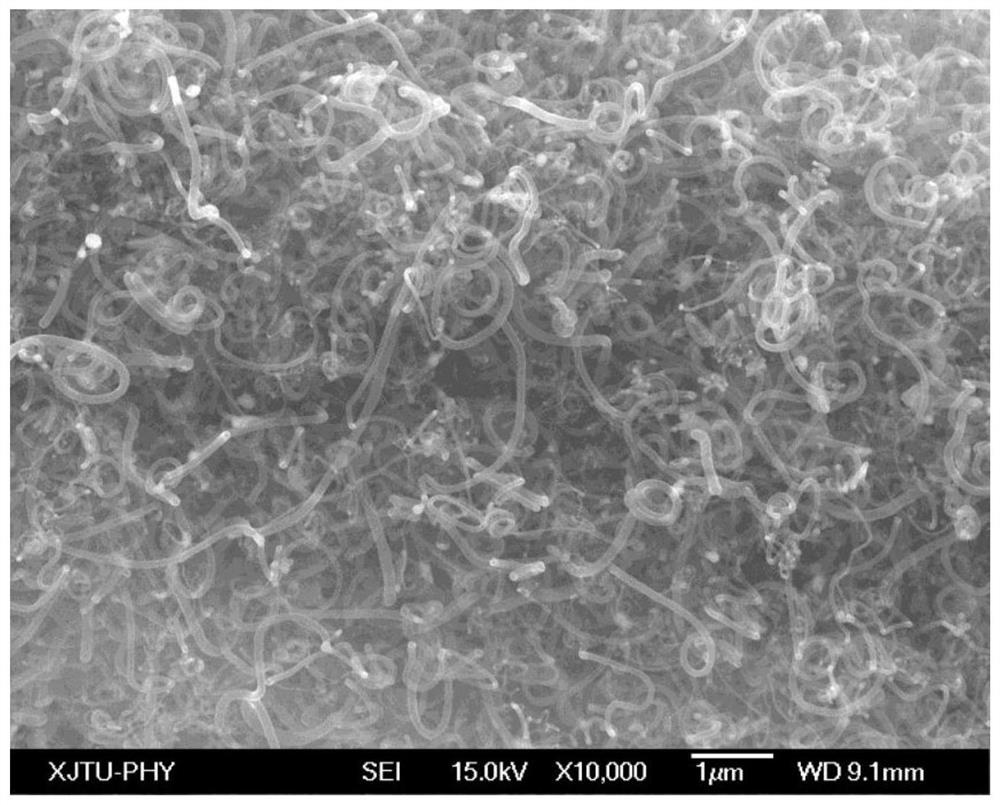

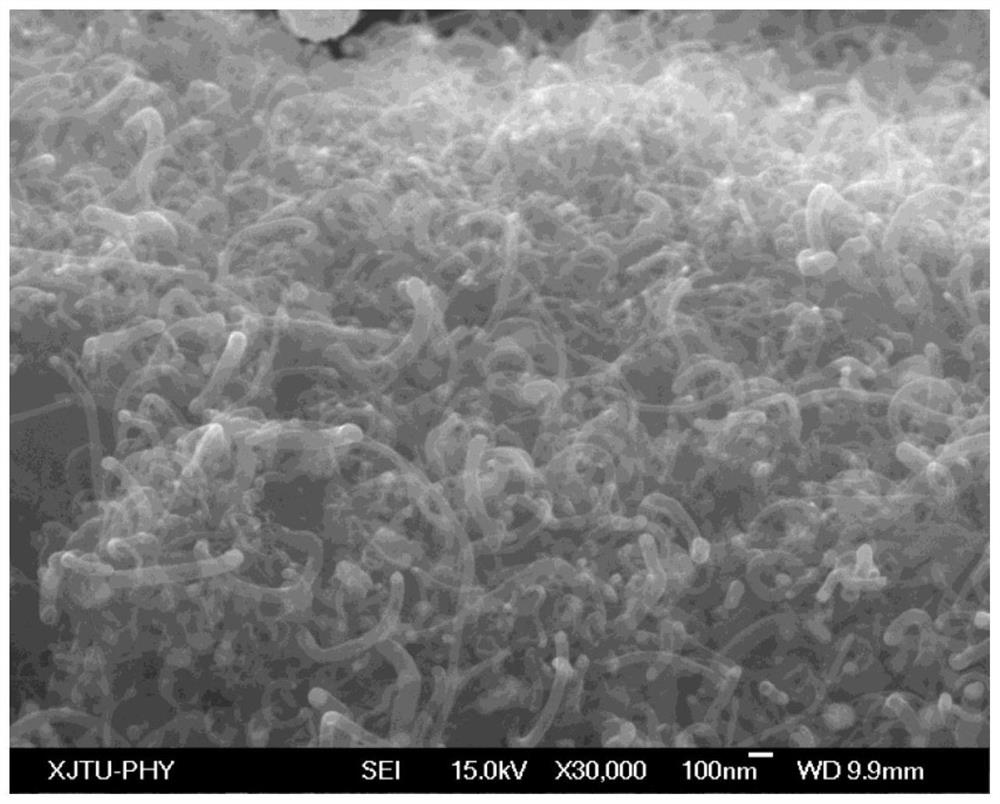

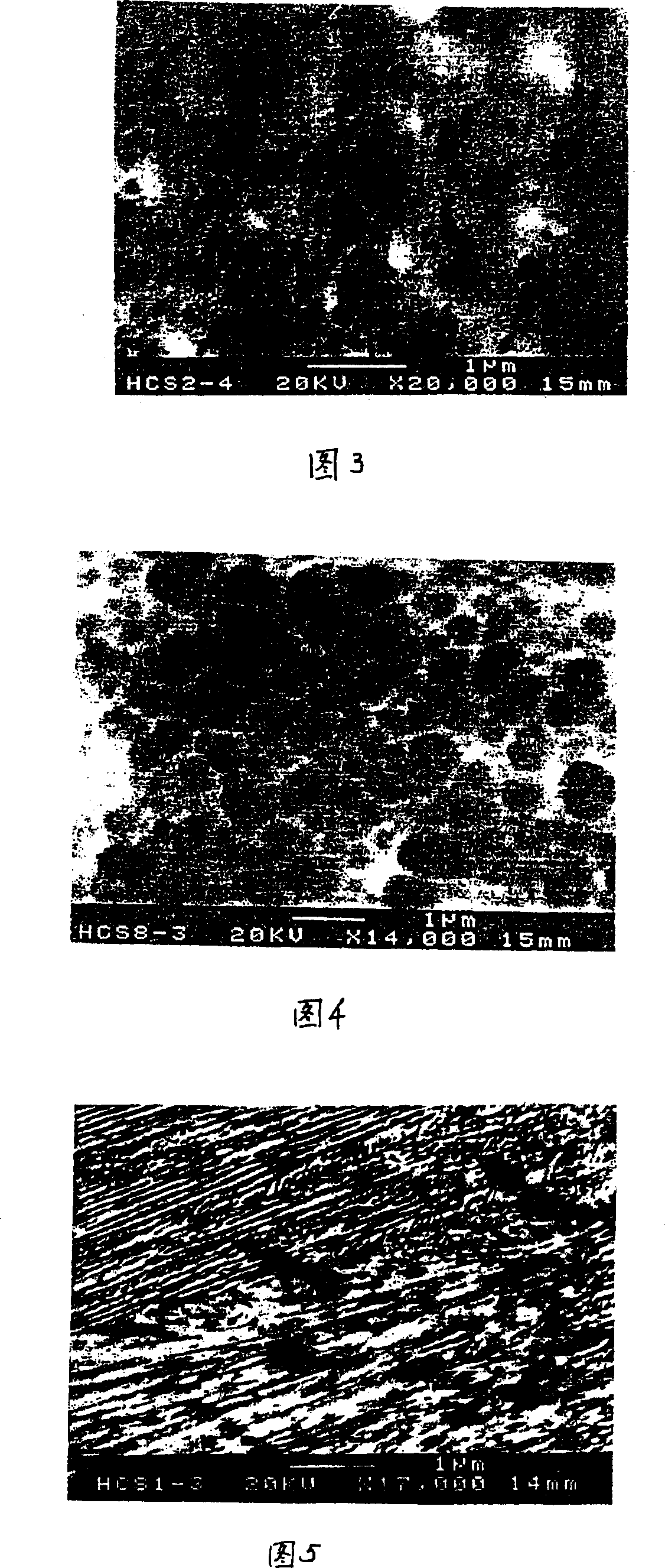

Method for preparing carbon nanotubes from coal

The invention discloses a method for preparing carbon nanotubes from coal. The method comprises the steps that pulverized coal is mixed with water, melamine and a soluble cobalt salt or a nickel salt,then a high-energy ball mill is utilized for wet milling to obtain a slurry-like mixture, and after the mixture is subjected to freeze drying, a porous blocky material is obtained; the blocky material is placed in a high-temperature atmosphere furnace to be sintered in a hydrogen / argon mixed atmosphere, and thus the clustered carbon nanotubes can be prepared; and finally, the pure carbon nanotubes are obtained through pickling and washing with water. The natural coal is utilized as the raw material, the coal does not need to be pre-treated, selectivity to the coal type is low, the yield is high, the diameters of the prepared carbon nanotubes are 40 nm to 100 nm, and the diameters of the carbon tubes are evenly distributed; and the preparation process is simple, a technology is simplified,the equipment requirements are low, the cost is low, and industrial production is easy to realize. The carbon nanotubes have great market demands and broad application prospects in the fields of lithium-ion batteries, super capacitors, nano catalysis, biomedicine, environmental protection and the like.

Owner:XI AN JIAOTONG UNIV +1

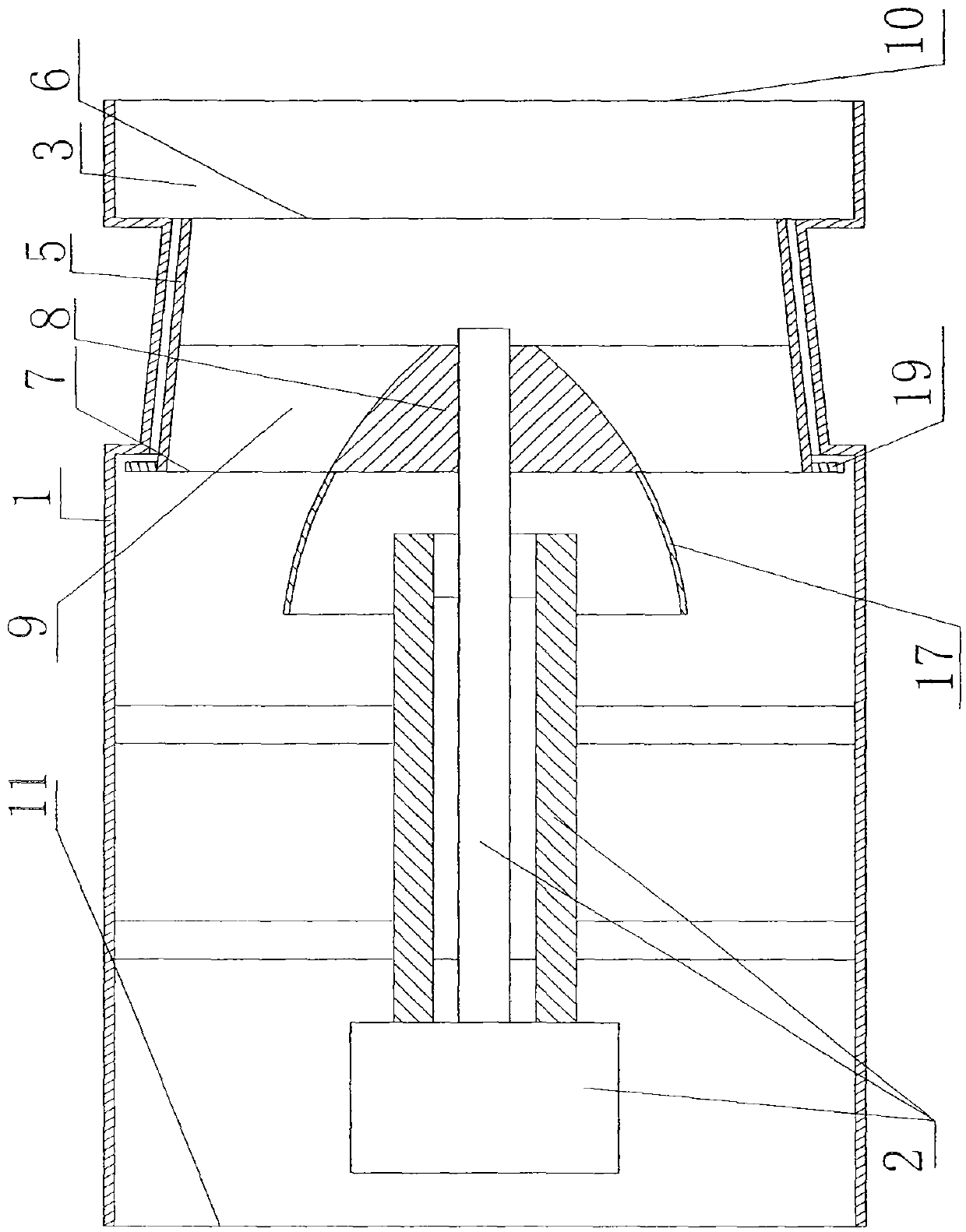

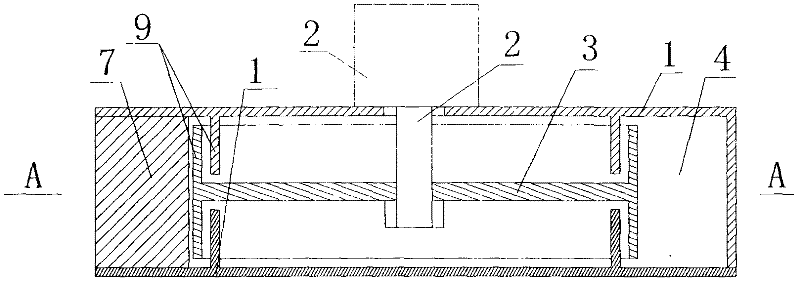

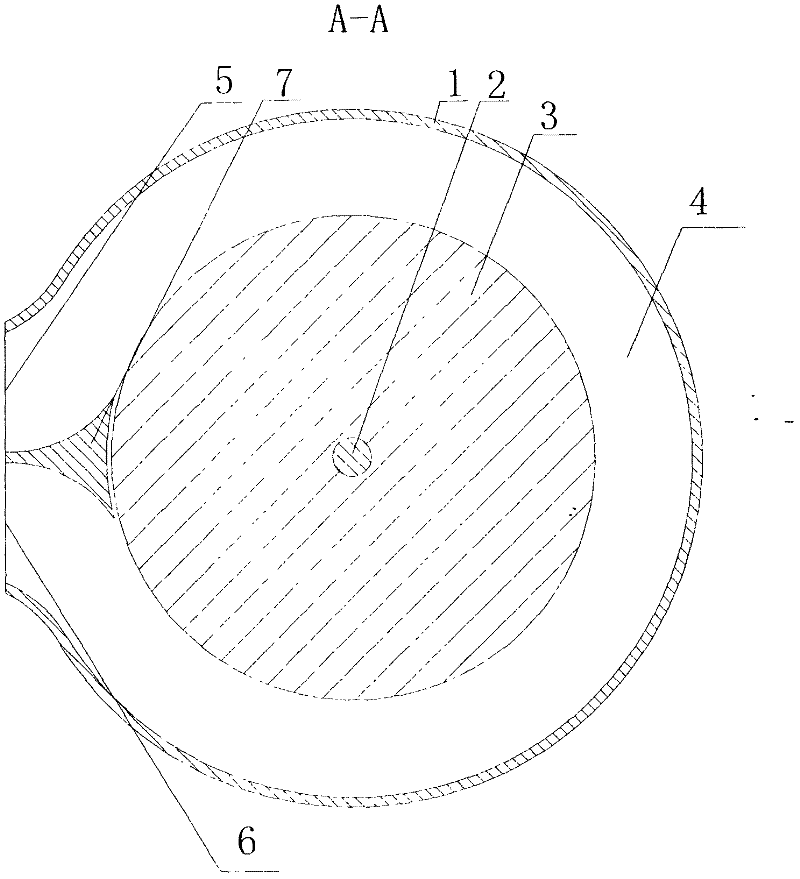

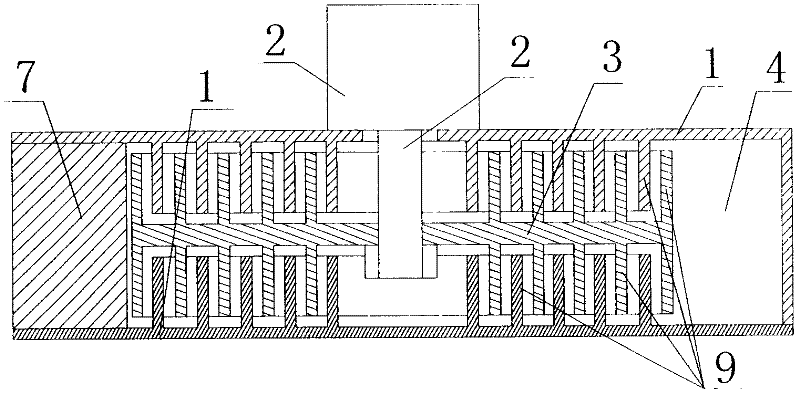

Eddy current device

InactiveCN102086892AEasy to manufactureLow manufacturing costPump componentsFluid-pressure convertersCarbon dioxideEngineering

The invention discloses an eddy current supercharger. The eddy current supercharger comprises a shell and a transmission shaft, wherein a shell cavity is formed in the shell; the transmission shaft is arranged in the shell; an eddy current wheel is arranged in the shell cavity; the transmission shaft is connected with the eddy current wheel in which an eddy current chamber is formed; the middle part of the eddy current chamber is provided with an eddy current chamber inlet; the periphery of the eddy current chamber is provided with an eddy current chamber outlet; the shell cavity is provided with a shell cavity inlet; the eddy current chamber inlet is formed opposite to the shell cavity inlet; and the shell cavity is provided with a shell cavity outlet. In the eddy current supercharger, completely new supercharging principle and method are adopted, circular motion and fluid motion can be fully utilized, fluid is automatically sucked into an eddy current from an eddy current central region by using the eddy current of which the rotation speed gradually increases from the center to the periphery, super-high suction is produced by using the center of the eddy current, and super-high pressure is produced by using the periphery of the eddy current. The eddy current supercharger can be widely used in the fields such as fluid pressurizing, fluid conveying, air suction and the like, can be used as a water pump, a fan, a compressor, a vacuum machine and the like, and can also be used as spray equipment, a nanomaterial atomizer, purification equipment for processing carbon dioxide, sulfur oxide and nitric oxide, a special reactor, an air conditioner and the like.

Owner:陈久斌

Circulator

InactiveCN102384091AImprove atomization effectSmall dropletPump componentsCircumferential flow pumpsChemical reactionWater turbine

The invention relates to a circulator, comprising a housing and a transmission gear, wherein a circulation cavity is arranged in the housing; a transmission gear is mounted on the housing; a rotating wheel is arranged in the housing; the transmission gear and the rotating wheel are connected with each other, the circulating cavity is internally provided with a circulating cavity inlet and a circulating cavity outlet; the circulating cavity expands gradually from one end to the other end, and an isolator is arranged in the housing between the circulating cavity inlet and the circulating cavity outlet. The circulator makes full use of circular motion and fluid motion, can better convert torsion force into pressure or thrust force through fluid, and better convert pressure or thrust force into torsion force through fluid. Moreover, particle mixing is realized through eddy flow, and chemical reaction becomes more sufficient by utilizing eddy flow. The circulator can be used as water pumps, slurry pumps, sewage pumps, blower fans, compressors, spraying equipment, atomizers, reactors, water turbines, steam turbines, wind turbines, vacuum equipment, foam material production equipment, nanometer material equipment and the like. The circulator provided by the invention has the advantages of high efficiency, low abrasion, etc., can be used for manufacturing fire-new foam material, and can usher in material revolution.

Owner:陈久斌

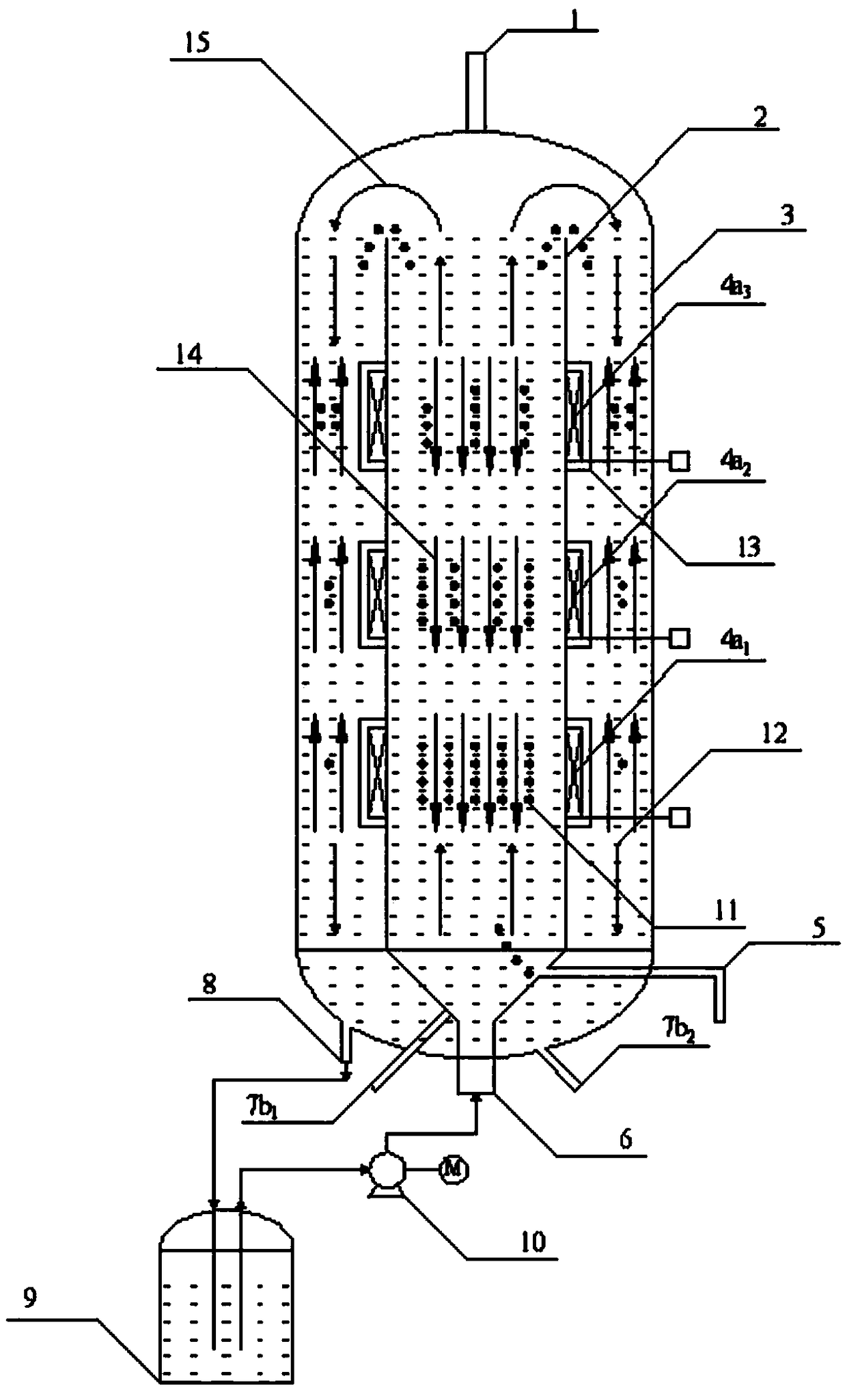

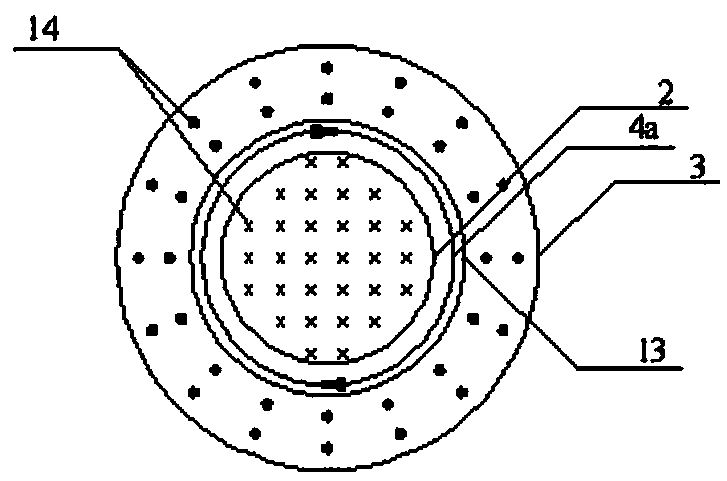

Magnetically stabilized bed for bidirectional utilization of internal and external magnetic fields

ActiveCN109499490AGuaranteed collectionTake advantage ofEnergy based chemical/physical/physico-chemical processesEngineeringTower

The invention discloses a magnetically stabilized bed for bidirectional utilization of internal and external magnetic fields. The magnetically stabilized bed consists of a catalytic reaction inner tower and a catalytic reaction outer tower nested together. A liquid phase solution and a solid phase magnetic catalyst both enter from the bottom of the catalytic reaction inner tower, and flow togetherin a flow direction always opposite to a magnetic field direction. The momentum of the solid phase magnetic catalyst is completely provided by the liquid phase solution, and the magnetic catalyst particles are gradually decelerated under the action of a magnetic field and finally are collected after force balance. Due to fluctuation of liquid phase flow, the initial momentum transferred from a liquid phase to a solid phase is not uniform in distribution, so that three groups of magnetic induction coils are arranged respectively to collect solid phase magnetic catalysts with different momentums. A mixture passes through the catalytic reaction inner tower and the catalytic reaction outer tower in sequence, and the two phases are fully contacted for reaction. The device has a simple and compact structure and can carry out high-efficiency solid-liquid catalytic reaction.

Owner:BEIJING UNIV OF TECH

Axial flow impeller

An axial flow impeller comprises an impeller body which is provided with a guide blade. The guide blade and a rotating shaft of the axial flow impeller form an inclined angle, a transmission shaft connecting device is arranged on the impeller body, and the area of the guide blade is enlarged gradually from two ends of the impeller to the middle part of the impeller. The axial flow impeller fully utilizes circumference motion and fluid motion and utilizes eddy to buffer energy and mix fluid, thus generating higher pushing force and pressure. The axial flow impeller can replace the existing impellers of axial flow water pumps, axial flow fans, spraying devices, atomization devices, screw propellers and the like, saves more energy, lowers noise, and can realize higher rotating speed, higher pressure, longer service life and lower construction cost.

Owner:陈久斌

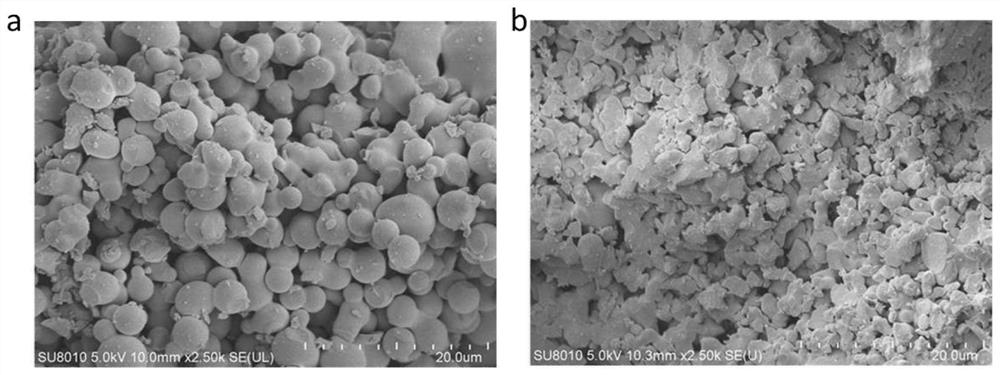

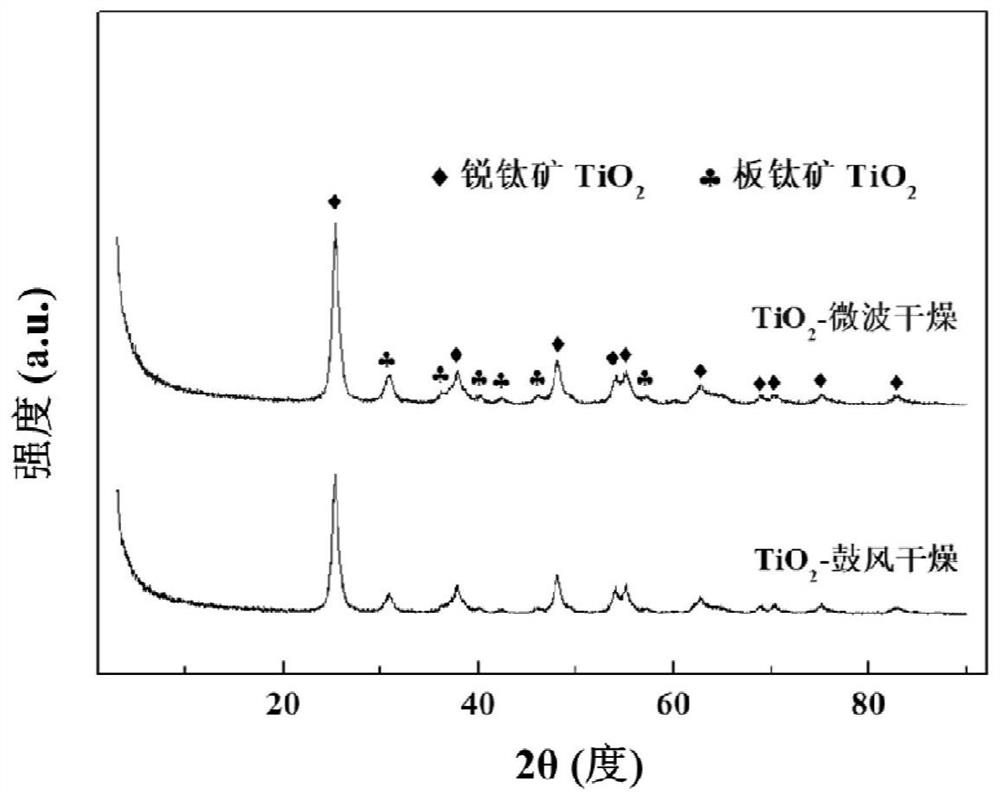

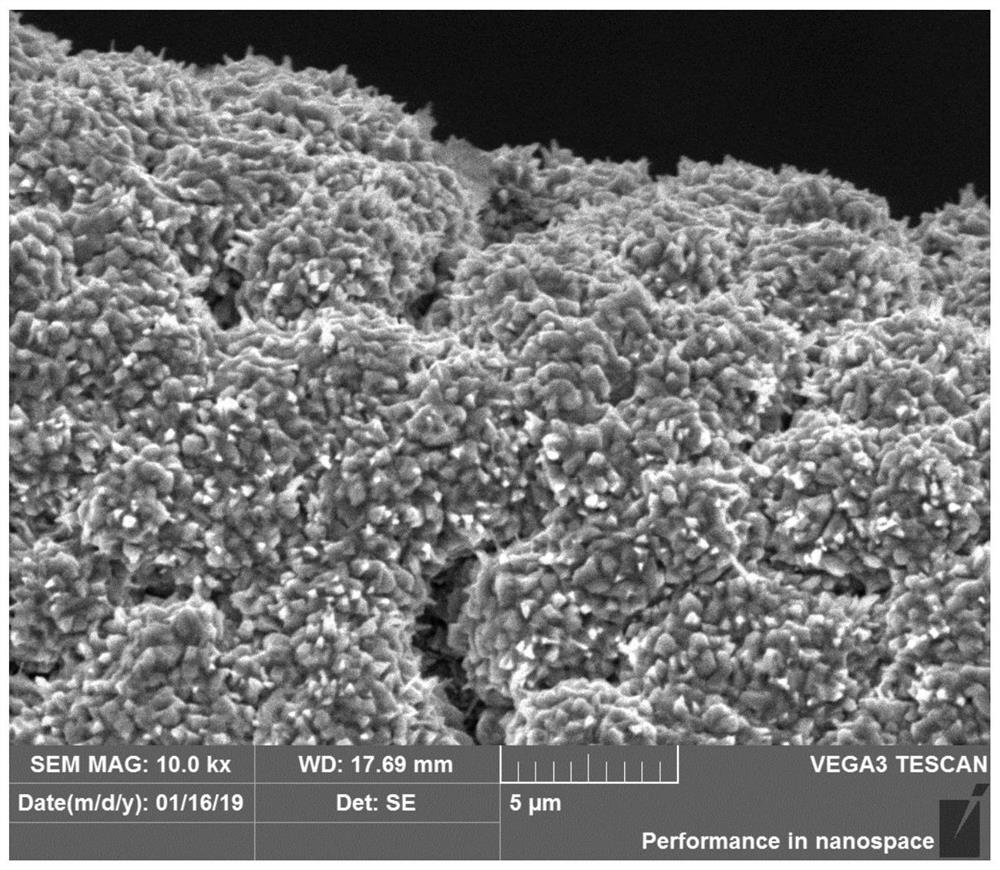

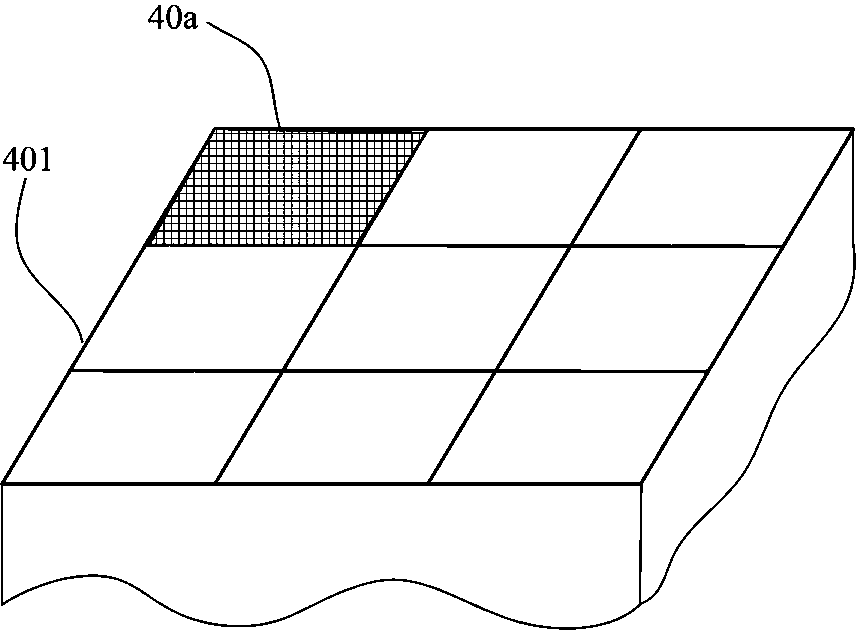

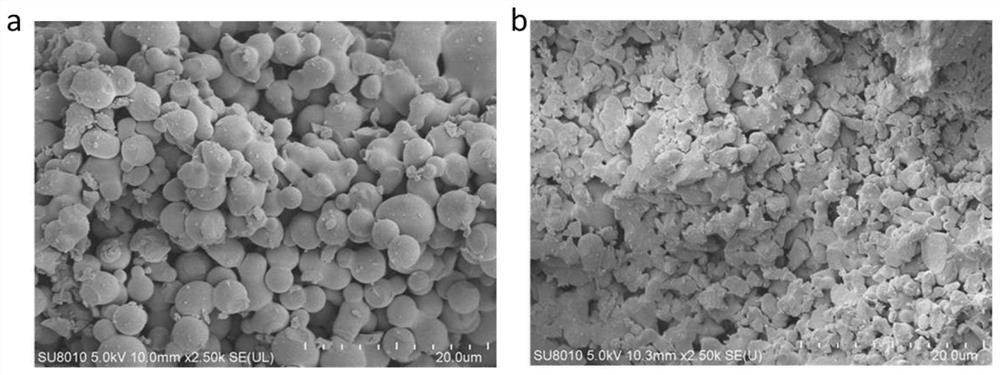

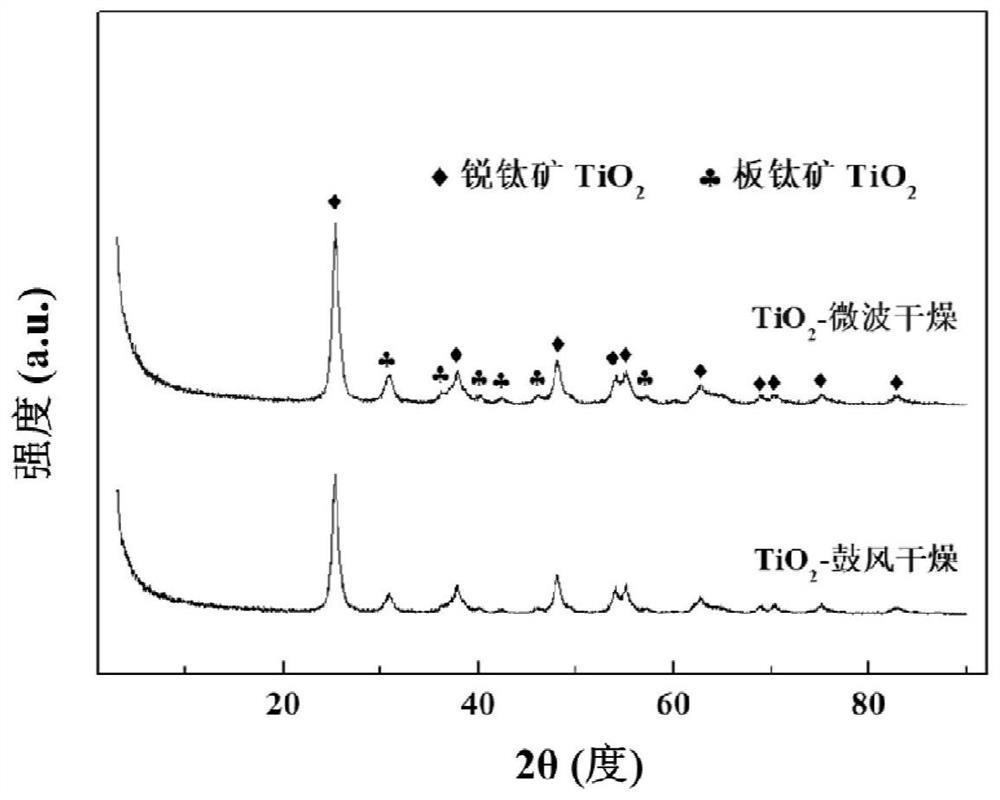

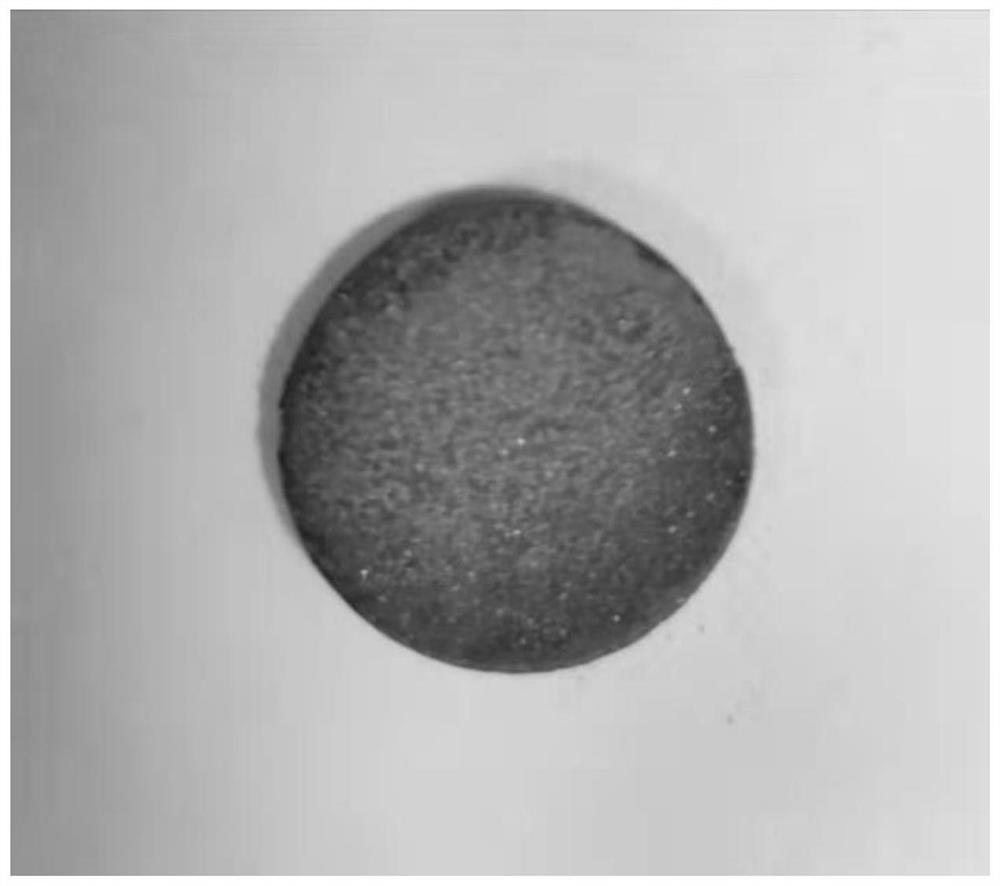

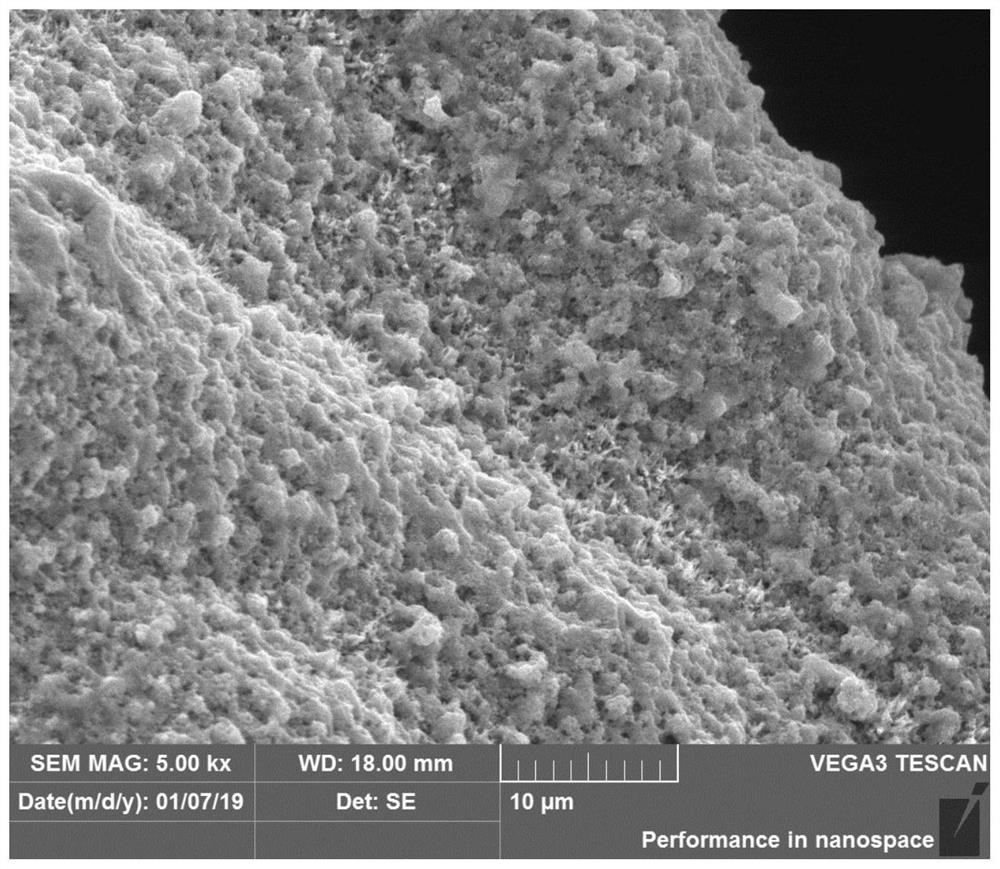

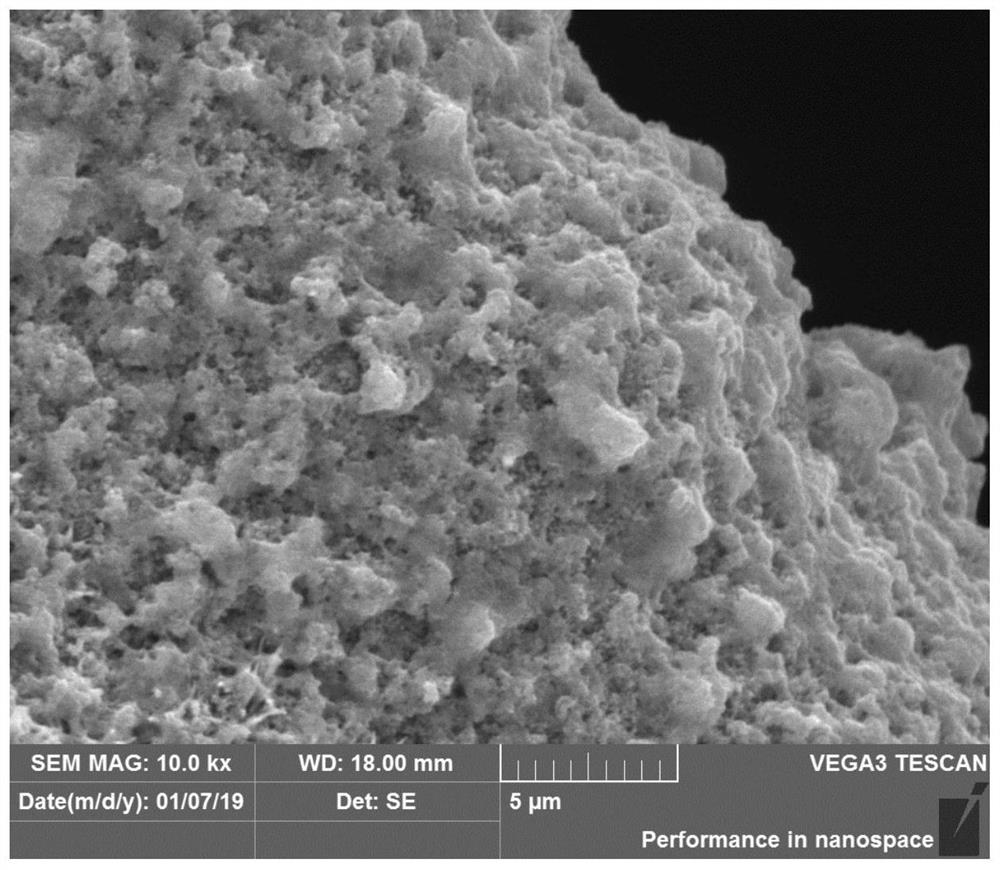

Catalytic filtration composite element as well as preparation method and application thereof

ActiveCN113198456AUniform dispersionLoad balancingGas treatmentDispersed particle filtrationFiberSlurry

The invention provides a catalytic filtration composite element as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing ceramic fibers, silica sol and a dispersing agent to form uniform slurry, mixing the slurry, injecting the mixed slurry into a mold, conducting molding, then performing demolding, and carrying out drying and calcining to obtain a base material; immersing the base material in a first solution, keeping the base material in vacuum for a period of time, taking out the base material, and carrying out microwave drying and roasting to obtain an intermediate element; and immersing the intermediate element in a second solution, keeping the intermediate element in vacuum for a period of time, taking out the intermediate element, and carrying out microwave drying and roasting to obtain the catalytic filtration composite element. The invention further provides the catalytic filtration composite element prepared by using the preparation method and application of the catalytic filtration composite element in synergistic removal of particulate matters and NOx. The composite element is large in pore, high in toughness, large in specific surface area, low in pressure drop, high in filtering efficiency and high in catalytic activity.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Technology for recycling biomass and producing high-quality fuel gas by afterheat of slag

ActiveCN105602621ATake advantage ofImprove energy efficiencyEnergy inputGasification processes detailsThermal energyLiquid state

The invention relates to a technology for recycling biomass and producing high-quality fuel gas by afterheat of slag. Under process control, liquid-state slag can be cooled effectively and heat thereof can be utilized effectively while biomass can be converted into high-quality fuel gas. The technical scheme includes that the liquid-state slag is heated and the biomass and cooling water are gasified; the biomass pyrolysis gas and vapor are in catalytic reaction under catalytic action of the slag, tar generates energy gas including CO and H2 primarily, and Cl and CO2 of the energy gas are absorbed by alkaline substance of the slag. According to the technology, the slag is cooled with high-quality fuel gas obtained on the premise of great energy saving.

Owner:天津亿诚集团有限公司

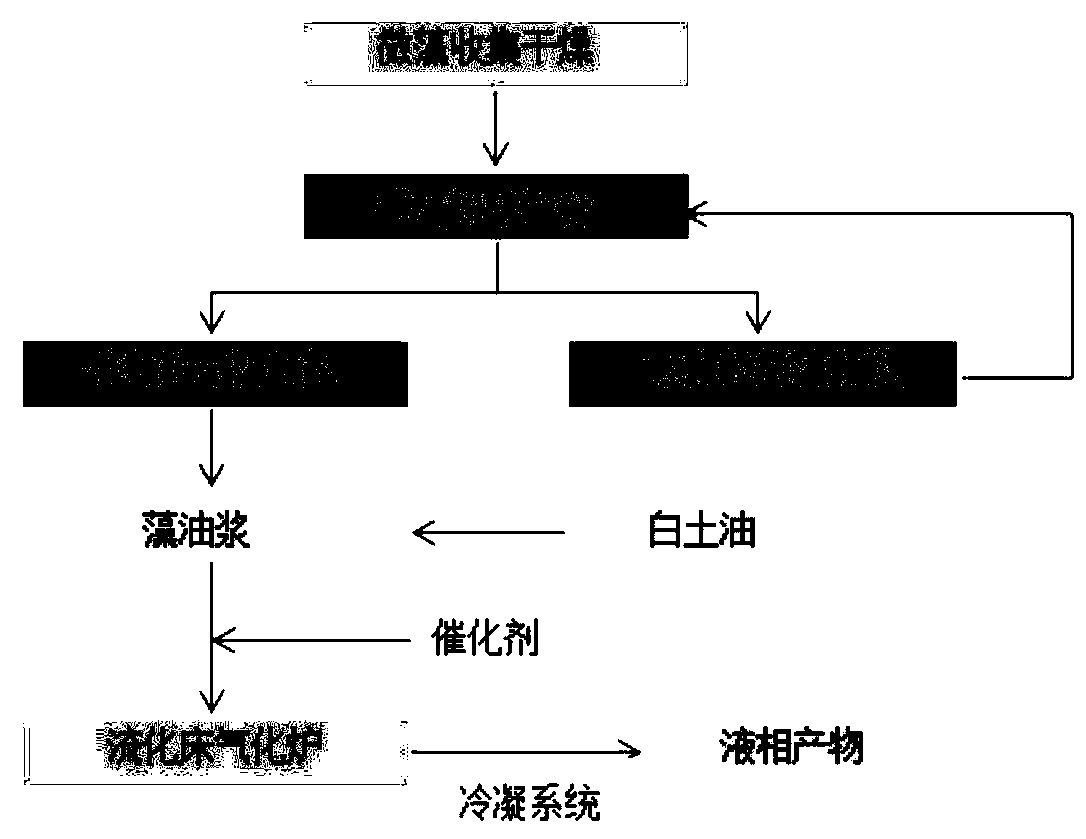

Method for preparing bio-oil from microalgae and clay oil through pyrolysis and system of method

PendingCN110184084AHigh yieldImprove qualityLiquid hydrocarbon mixture productionHydrocarbon oils treatmentFluidized bedSlurry

The invention discloses a method for preparing bio-oil from microalgae and clay oil through pyrolysis. The method comprises the following steps: drying microalgae, crushing and screening the dried microalgae so as to obtain microalgae granules of expected sizes, stirring and mixing the microalgae granules with clay oil according to a ratio so as to obtain microalgae oil slurry, conveying the microalgae oil slurry into a fluidized bed, and carrying out pyrolysis at a set pyrolysis temperature under the action of a catalyst, so as to obtain the bio-oil. By adopting the method, on the basis of waste clay oil is comprehensively utilized, pores of the catalyst are not easily blocked by the microalgae in the pyrolysis process, the catalyst can be prevented from deactivation, then the catalyst iscapable of sufficiently catalyzing reactions, and the reactions can be thorough.

Owner:JIANGSU UNIV

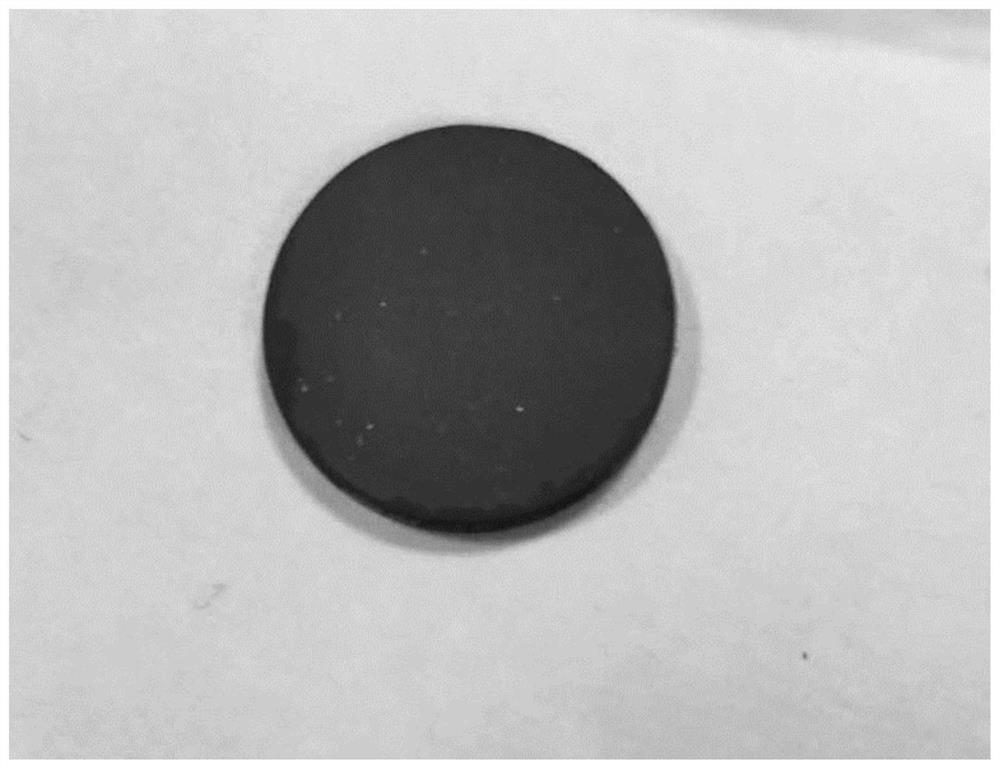

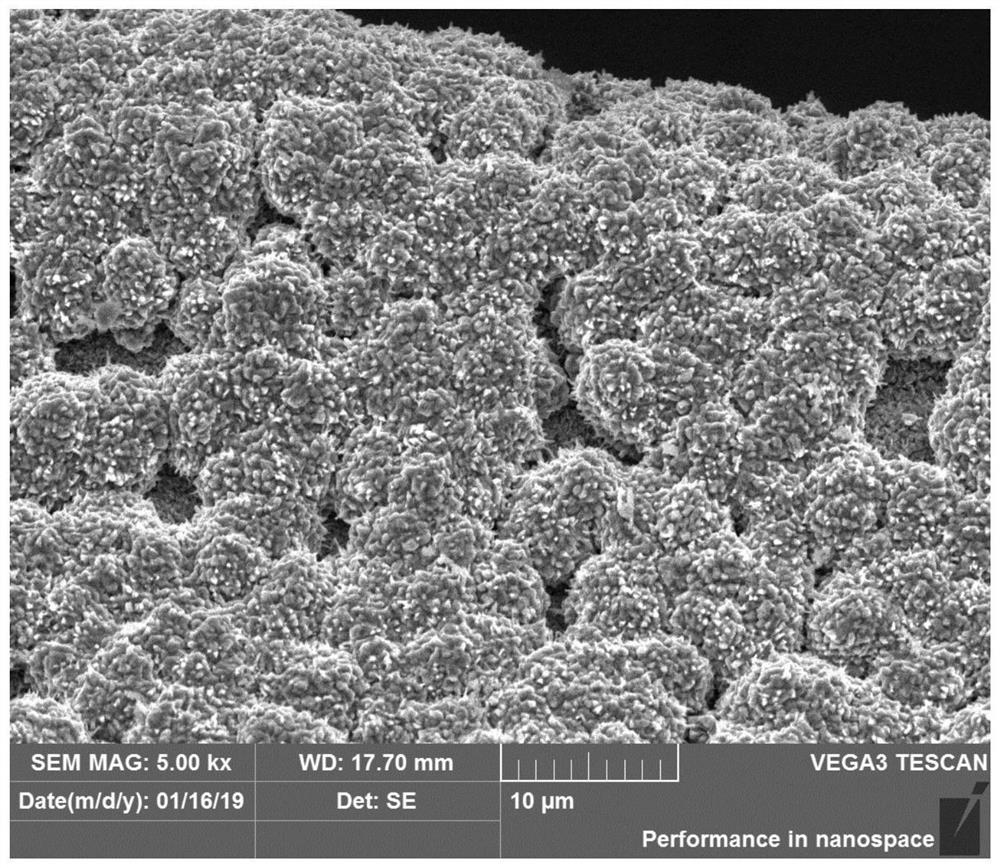

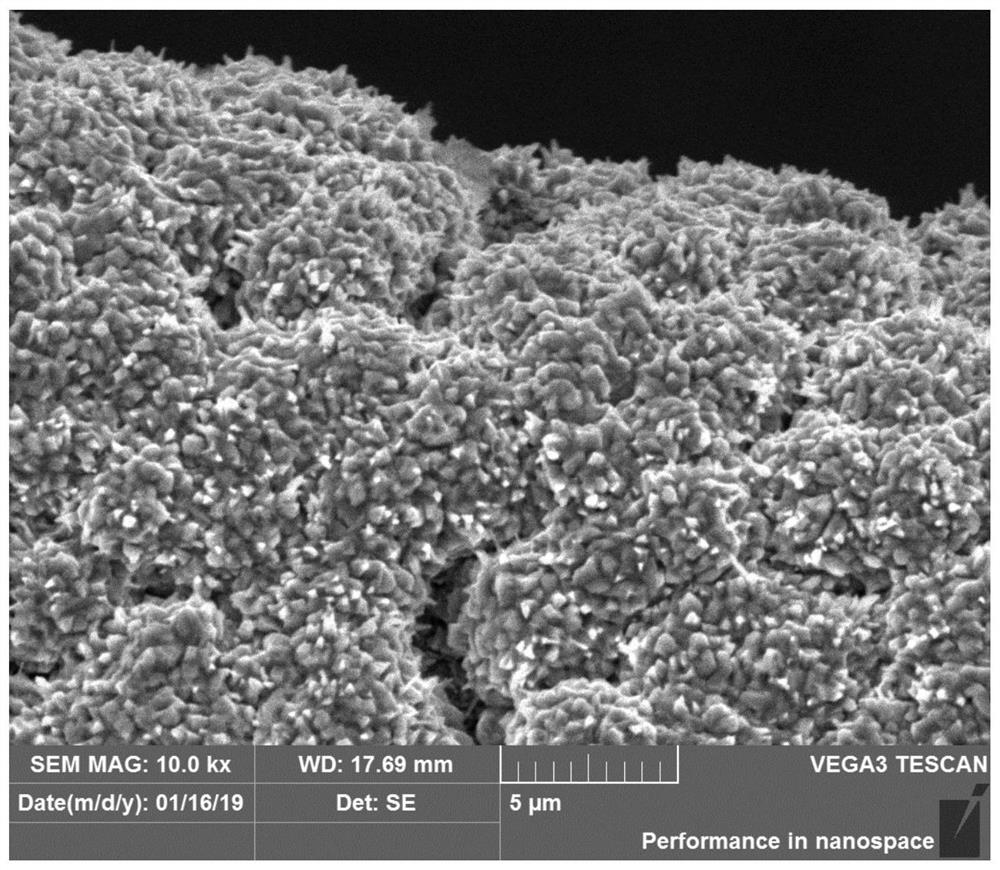

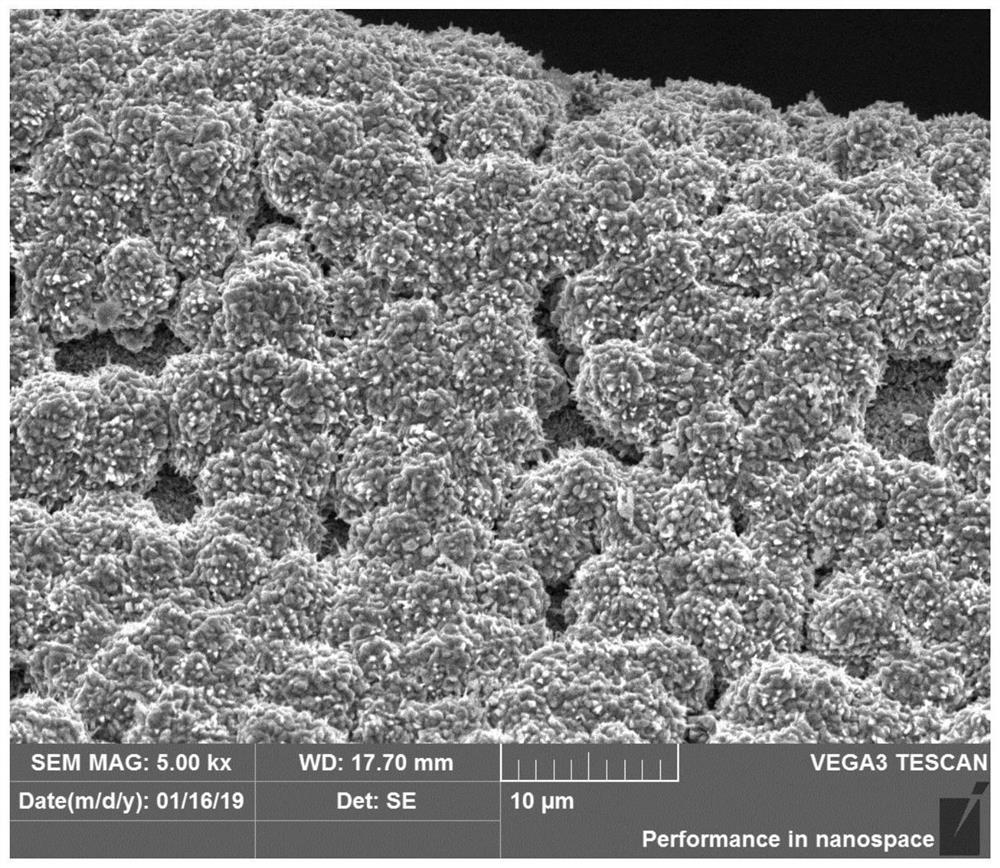

Preparation method of molybdenum-based composite material electrode plate

ActiveCN112831800AHigh catalytic activityIncrease contact areaNon-noble metal oxide coatingsTransportation and packagingPtru catalystTitanium tetrachloride

The invention relates to a preparation method of a molybdenum-based composite material electrode plate, which comprises the following steps: in a glove box filled with argon, pouring molybdenum powder and nickel powder into excessive titanium tetrachloride, fully stirring, filtering, putting mixed powder stained with the titanium tetrachloride into a quartz tube of a tube furnace, introducing oxygen, carrying out heat treatment, putting the mixed powder subjected to heat treatment into a graphite mold for spark plasma sintering, soaking a sintered sample into titanium tetrachloride again, filtering, taking out the sample, putting the sample into the quartz tube of the tubular furnace again, and sequentially introducing oxygen and hydrogen sulfide for heat treatment to obtain the molybdenum-based composite material electrode plate. The method is low in cost, convenient to operate and controllable in process. The obtained electrode plate has relatively high catalytic activity and good conductivity, also has certain mechanical properties and machinability, can be used as a catalyst, a current collector and an electrode directly to be applied to catalytic water decomposition, and has a wide large-scale industrial production prospect.

Owner:HENAN UNIV OF SCI & TECH

A kind of preparation method of molybdenum-based composite material electrode plate

ActiveCN112831800BHigh catalytic activityIncrease contact areaNon-noble metal oxide coatingsTransportation and packagingPtru catalystTitanium tetrachloride

Owner:HENAN UNIV OF SCI & TECH

Metal type diesel vehicle tail gas catalytic cleaner

InactiveCN104047686ASimple structureHigh activityExhaust apparatusSilencing apparatusParticulatesCleansing Agents

The invention discloses a metal type diesel vehicle tail gas catalytic cleaner. The metal type diesel vehicle tail gas catalytic cleaner comprises a shell and a carrier arranged in the shell, wherein the carrier comprises a front-grade carrier located at the front part of the shell and a back-grade carrier located at the back part of the shell; the front-grade carrier is coated with a diesel oxidized form catalyst coating; the back-grade carrier is coated with a particle oxidized form catalytic cleaning agent coating. The front-grade carrier is coated with the diesel oxidized form catalyst coating to process CO and HC in diesel engine tail gas; the back-grade carrier is coated with the particle oxidized form catalytic cleaning agent coating to process PM (Particulate Matters) in the diesel engine tail gas; the front-grade carrier and the back-grade carrier are arranged in one barrel; the structure is simple, a processing process is simple and the cost is saved.

Owner:ZHEJIANG DA FENG AUTOMOBILE TECH

A method for preparing carbon nanotubes from coal

Owner:XI AN JIAOTONG UNIV +1

Motor vehicle exhaust catalytic purification device

ActiveCN107035483BEmission reductionImprove conversion efficiencyInternal combustion piston enginesExhaust apparatusProcess engineeringCatalyst support

The invention discloses a motor vehicle tail gas catalytic purifying device. The motor vehicle tail gas catalytic purifying device comprises a shell body and a catalyst carrier, wherein the shell body comprises a main body part, a gas inlet part and a gas outlet part, the gas inlet part and the gas outlet part are located on the two sides of the main body part, and the catalyst carrier is arranged in the main body part. The gas inlet part is internally provided with a gas guiding device. The gas guiding device comprises a deflector which is fixedly clamped in the gas inlet part, perpendicular to the gas inlet direction and provided with a plurality of gas guiding holes, and a gas flow stirring device which is fixed to the deflector. The gas flow stirring device comprises a driving device, a stirring rod and at least one pair of blades, wherein the driving device is fixedly arranged on the side, close to the gas inlet part, of the deflector; the stirring rod is connected with the driving device, penetrates through the deflector and extends to the side, away from the gas inlet part, of the deflector; and the blades are fixed to the end, away from the gas inlet part, of the stirring rod. According to the motor vehicle tail gas catalytic purifying device, through the combined action of the deflector and the gas flow stirring device, internal gas flowing is more uniform, and the time for internal gas to flow through the catalyst carrier is prolonged, so that catalytic reaction is more sufficient, thus, the conversion efficiency of the catalytic device is effectively improved, and the utilization rate of the catalytic device is effectively increased.

Owner:卢志旭

Biomass catalytic pyrolysis co-production system for gas-liquid fuels, chemicals and carbon materials

ActiveCN111363569BConducive to high-value utilizationEasy to operateProcess control/regulationPhysical/chemical process catalystsCatalytic pyrolysisCatalytic reforming

Owner:HUAZHONG UNIV OF SCI & TECH

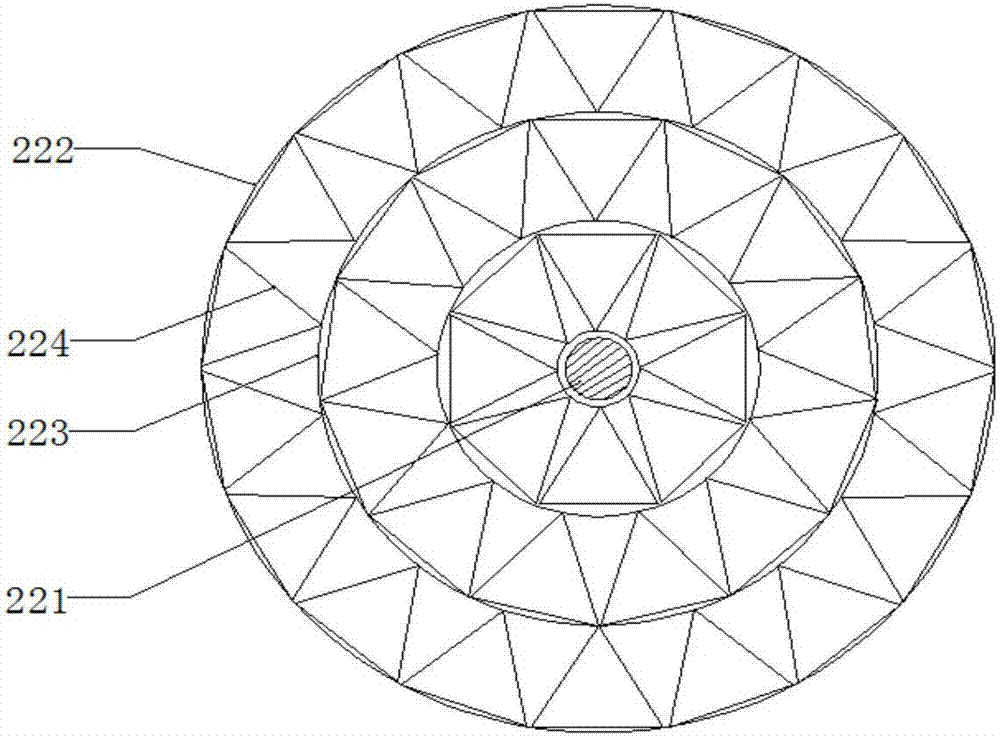

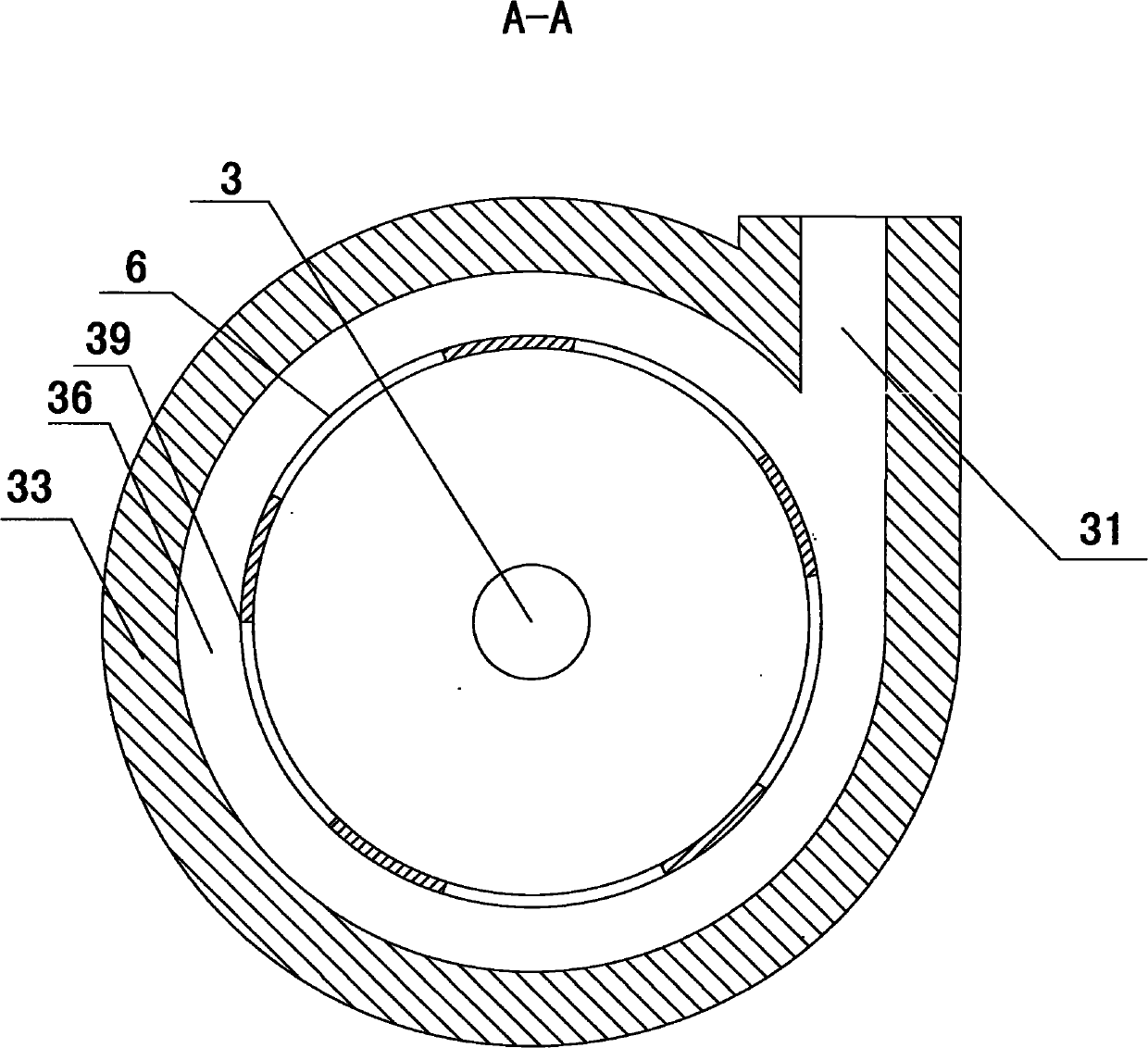

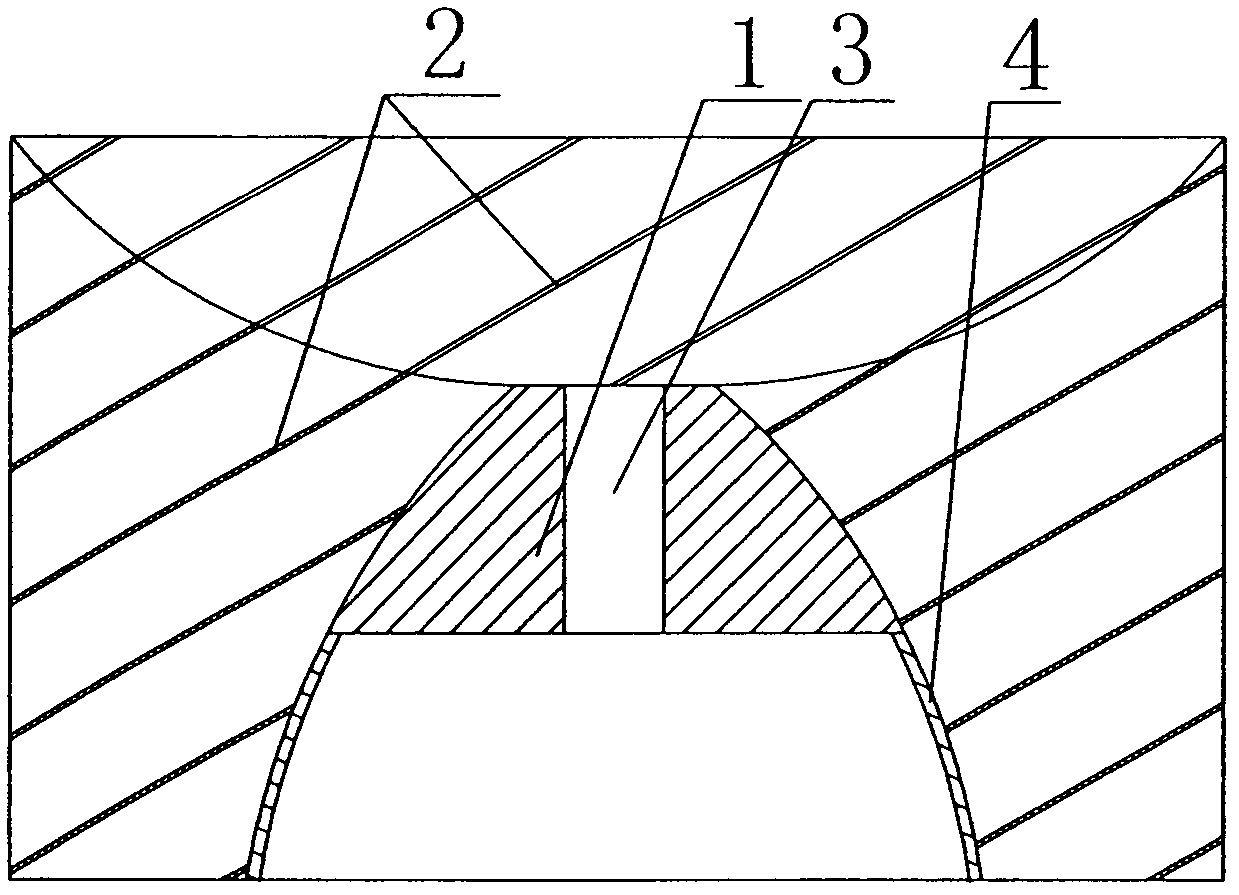

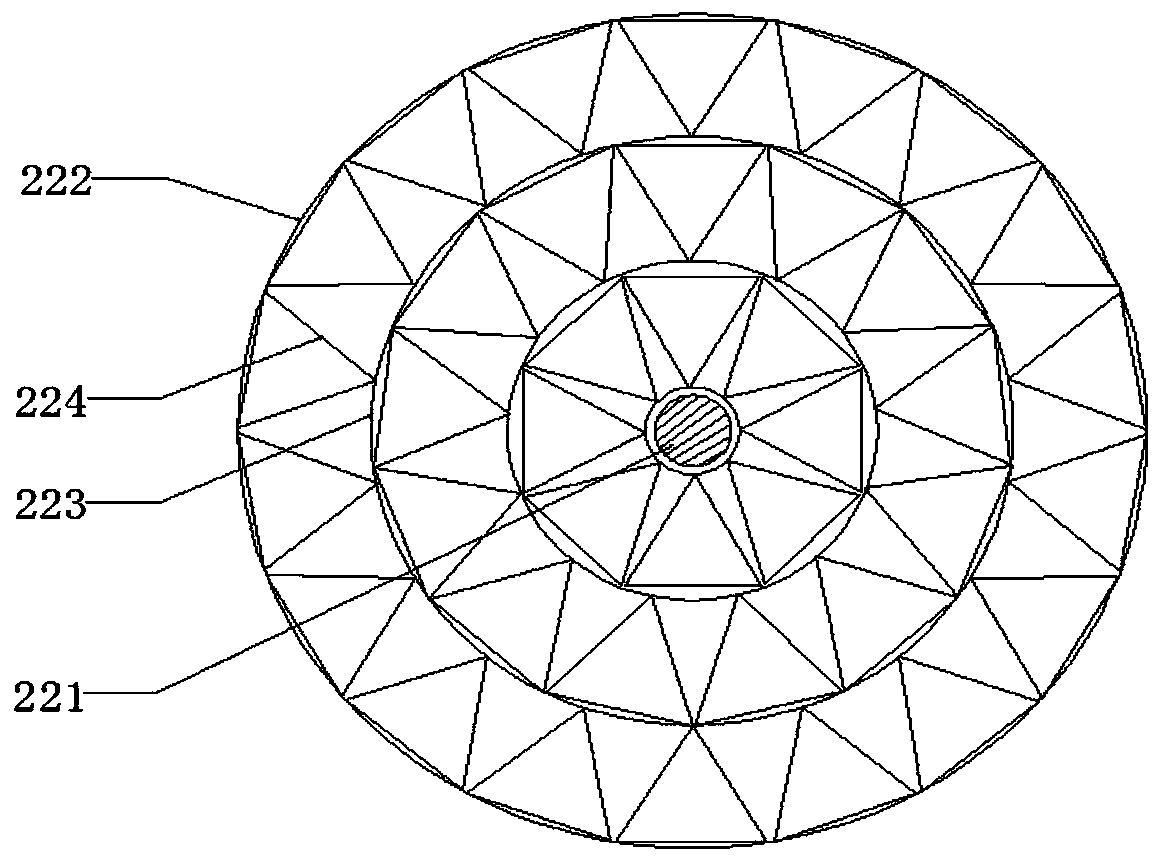

Catalyzing device for purifying motor vehicle exhaust

ActiveCN107084031AImprove conversion efficiencyIncrease profitCatalyst carriersHeterogenous catalyst chemical elementsCatalyst supportMultiple layer

The invention discloses a catalyzing device for purifying motor vehicle exhaust. The catalyzing device comprises a shell, a catalyst carrier, a liner and an outer layer. The shell comprises a body part, an air inlet part and an air outlet part, wherein the air inlet part and the air outlet part are located on the two sides. The catalyst carrier is located in the body part. The liner is arranged between the catalyst carrier and the body part. The catalyst carrier sequentially comprises a first carrier and a second carrier in the air inlet direction, wherein the first carrier comprises a pair of upper carrier body and lower carrier body, and the opposite faces of the upper carrier body and the lower carrier body are protruding arc faces; and the second carrier and the first carrier are arranged side by side and are in close contact, and the second carrier comprises an inner core. The outer layer comprises an outer shell located on the outermost layer and multiple layers of first partition plates sequentially arranged around the inner core, wherein a triangular unit space is formed between every two adjacent first partition plates, and the end face of the inner core and the end faces of the first partition plates in the shell are in a protruding shape. By means of the catalyzing device for purifying the motor vehicle exhaust, due to the arrangement that the second-stage catalyst carrier is combined with the partition plates, the time for airflow flowing through the catalyst carrier is prolonged, the catalyzing reaction is more sufficient, and the utilization rate of the catalyzing device is effectively increased.

Owner:诺言新材料科技(无锡)有限公司

Technology of utilizing waste heat of blast furnace slag to recycle biomass and produce high-quality fuel gas

ActiveCN105542859BTake advantage ofImprove energy efficiencyEnergy inputGasification processes detailsThermal energySlag

The invention discloses a novel method of utilizing liquid blast furnace slag waste heat to crack biomass and produce high quality fuel gas. Through technological control, the liquid blast furnace slag can be effectively cooled, and the heat energy of the slag is effectively utilized, and meanwhile the biomass can be transformed into the high quality energy gas. The technical scheme of the technology is as follows: the liquid blast furnace slag is heated, and the biomass and cooling water are gasified; under catalysis of the blast furnace slag, the biomass cracked gas and the vapor are subjected to catalytic reaction; the tar is gradually catalyzed to generate the energy gas mainly containing CO and H2; and meanwhile, Cl and CO2 in the energy gas is absorbed by alkali substance in the blast furnace slag. The technology greatly saves the energy source while cooling the blast furnace slag, and also produces the high quality energy gas.

Owner:SHANXI WENLONG COAL MINE ENG DESIGN

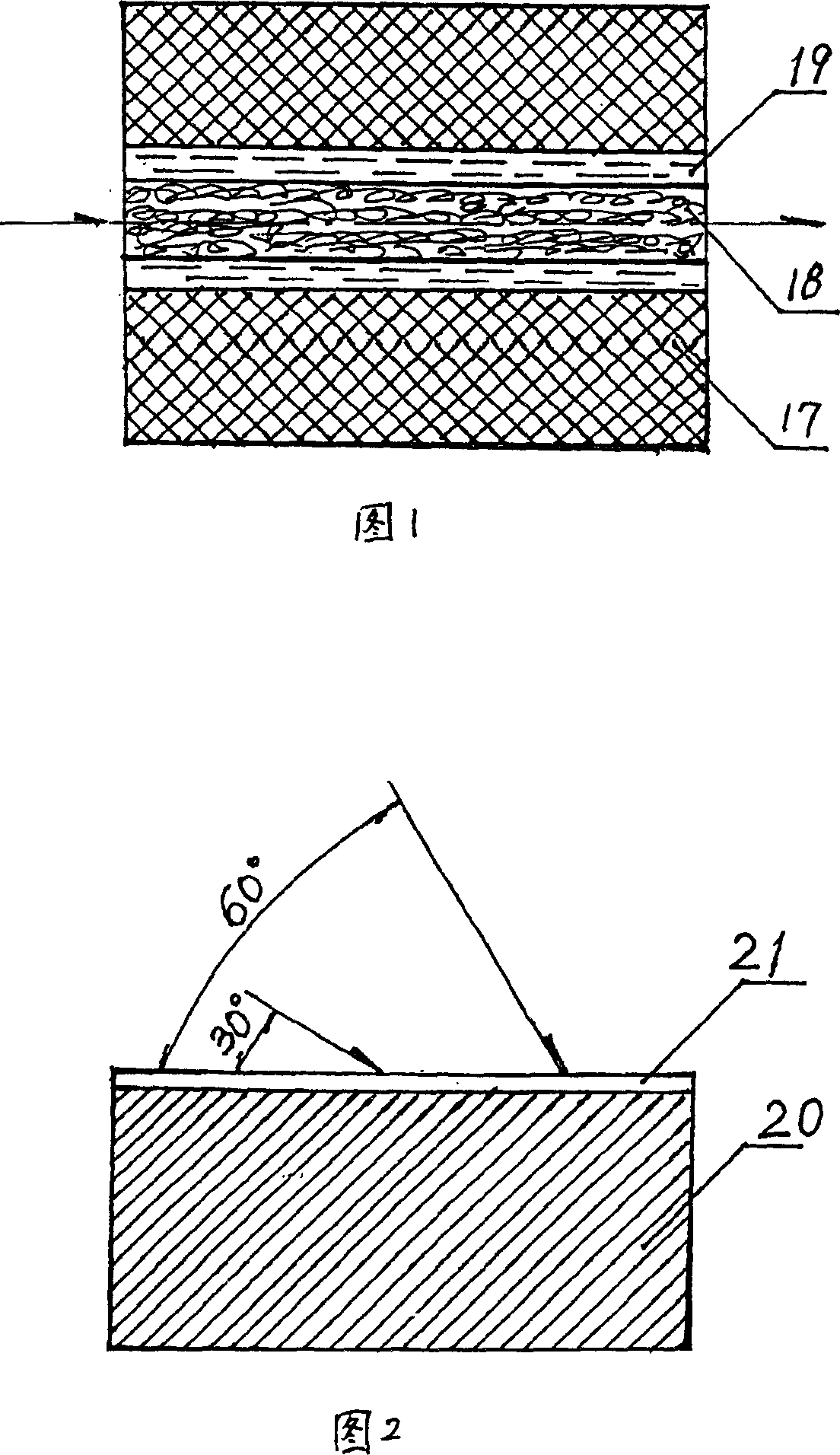

Catalytic purifier for motor vehicle exhaust and its preparing method and use

InactiveCN1987061AAdaptableImprove thermal conductivityCatalyst carriersExhaust apparatusCatalytic oxidationEngineering

A jet-type catalytic cleaner for the tail gas of motor-driven vehicle is composed of a reaction chamber with tail gas inlet tube and tail gas outlet tube and divided into front and back chambers, and two groups of nanocrystal catalyst plates arranged respectively in said front and back chambers by the relative angle of 30-60 deg.

Owner:陈阳

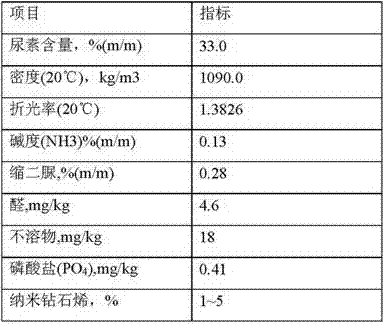

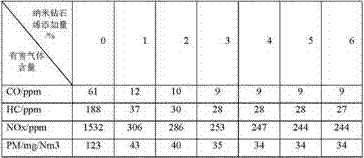

Diesel engine exhaust treating fluid containing nanometer diamondene and preparation method thereof

InactiveCN107096382ASpeed up decompositionEmission reductionDispersed particle separationProduct gasSURFACTANT BLEND

The invention specifically relates to a diesel engine exhaust treating fluid containing nanometer diamondene, belonging to the technical field of automobile exhaust treatment. The diesel engine exhaust treating fluid comprises the following raw materials by weight: 60 to 65 parts of deionized water, 30 to 35 parts of urea, 1 to 5 parts of nanometer diamondene and 0.1 to 2 parts of a surfactant. The diesel engine exhaust treating fluid provided by the invention can reduce the emission of harmful gas in automobile exhaust and is green and environment-friendly.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

Technology of utilizing waste heat of steel slag to recycle biomass and produce high-quality fuel gas

ActiveCN105602621BTake advantage ofImprove energy efficiencyEnergy inputBulk chemical productionThermal energyWater vapor

Owner:天津亿诚集团有限公司

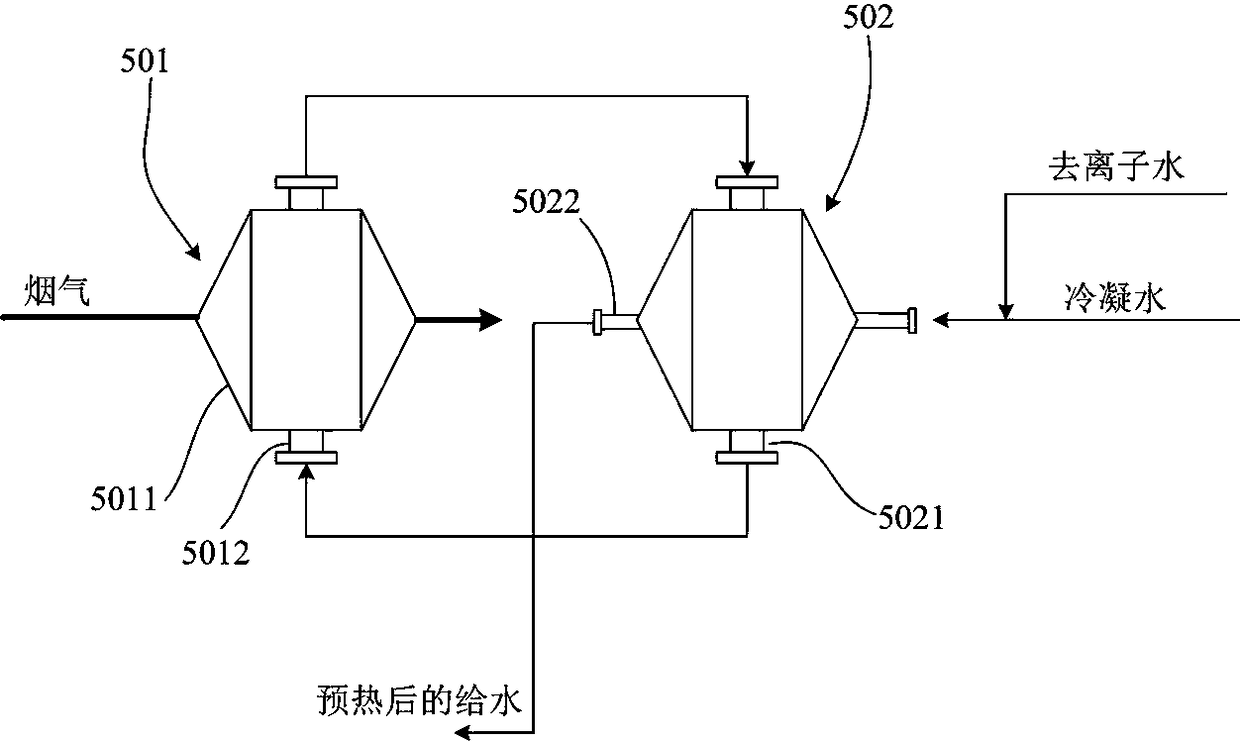

Alkali Recovery Boiler Low Temperature Denitrification System and Process

ActiveCN105749740BIncrease temperatureImprove removal efficiencyRecuperative heat exchangersDispersed particle separationFlue gasReaction temperature

The invention relates to the technical field of alkali recovery boiler flue gas treatment, in particular to an alkali recovery boiler low-temperature denitration system and process.The system comprises an alkali recovery boiler, a heater, an electrostatic dust collection device, a low-temperature denitration device, a waste heat recovery device and a water feeding and storing device.The heater is arranged to heat water provided for the alkali recovery boiler so as to increase the temperature of flue gas to be close to catalytic reaction temperature, so that catalysis denitration reaction is more sufficient and NOx removal efficiency is improved.

Owner:武汉凯比思电力设备有限公司

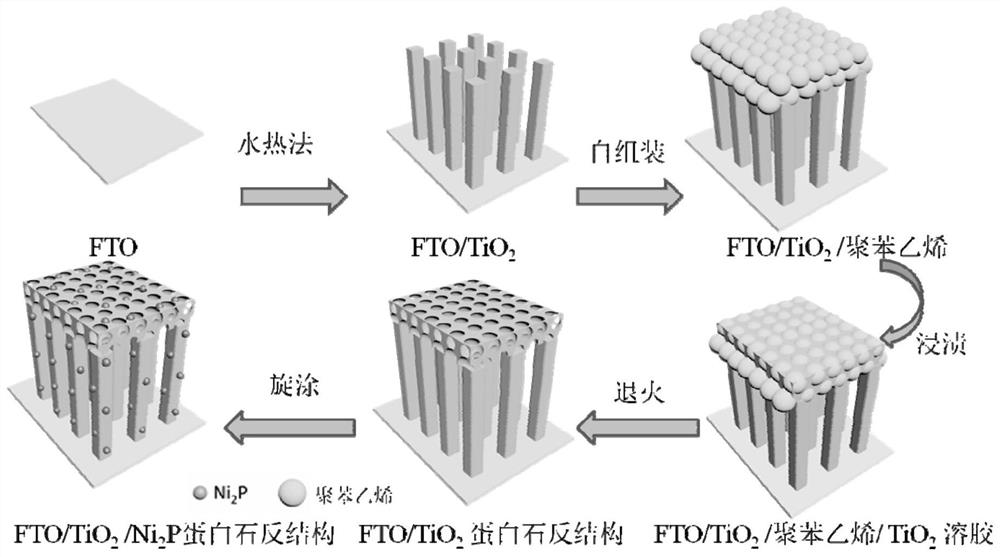

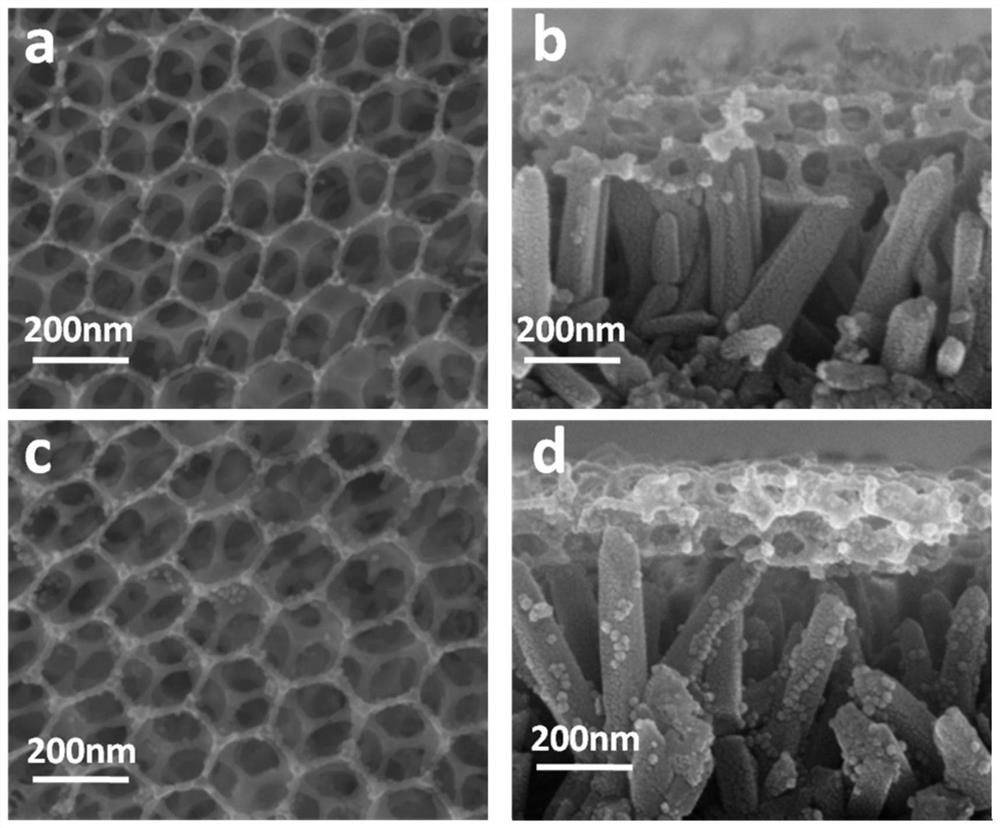

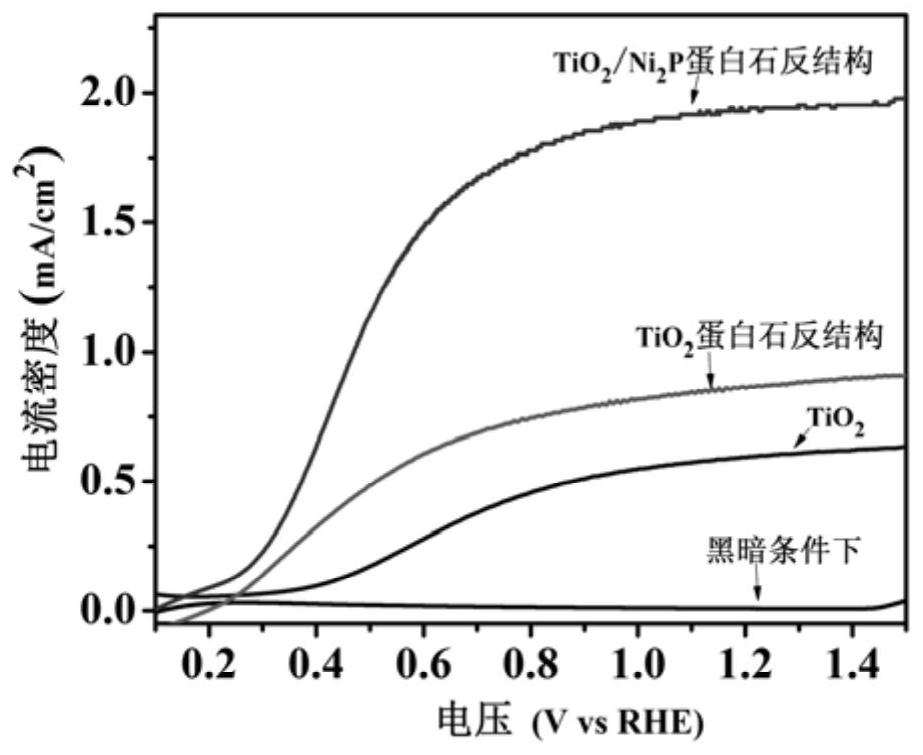

One adopts ni 2 A method to enhance photocatalysis with p nanocrystals

ActiveCN109482218BThe catalytic reaction is sufficientGood catalytic effectCatalyst activation/preparationHydrogen productionPolystyreneCatalytic effect

The invention relates to a 2 The method for P nanocrystal enhanced photocatalysis, it comprises the following steps: (a) adopt hydrothermal method to support TiO on the substrate surface 2 array; (b) on the TiO 2 At least one layer of polystyrene nanofilm is supported on the surface of the array; (c) the product of step (b) is immersed in the titania sol precursor solution, taken out and dried, and then placed in an oxygen atmosphere for calcination; then spin-coated on its surface containing Ni 2 The n-hexane solution of P nanocrystals can be baked in a glove box to remove organic matter. In this way, not only can the inverse structure of opal be fully catalyzed, but also the Ni 2 P will also affect TiO 2 Play a very good catalytic effect.

Owner:SUZHOU UNIV

Catalytic filter composite element and its preparation method and application

ActiveCN113198456BUniform dispersionLoad balancingGas treatmentDispersed particle filtrationFiberSlurry

The invention provides a catalytic filter composite element and a preparation method and application thereof. The preparation method includes mixing ceramic fibers, silica sol and dispersant to form a uniform slurry, mixing the slurry into a mold, demoulding after molding, drying and calcining to obtain a base material; immersing the base material in a first The solution is kept in a vacuum for a period of time, taken out, microwave-dried, and roasted to obtain an intermediate element; the intermediate element is immersed in the second solution, kept in a vacuum for a period of time, taken out, microwave-dried, and roasted to obtain the catalytic filter composite element. The present invention further provides the catalytic filter composite element obtained by the above preparation method and its application in the synergistic removal of particulate matter and NOx. The above composite element has large pores, high toughness, large specific surface area, low pressure drop, high filtration efficiency and high catalytic activity.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

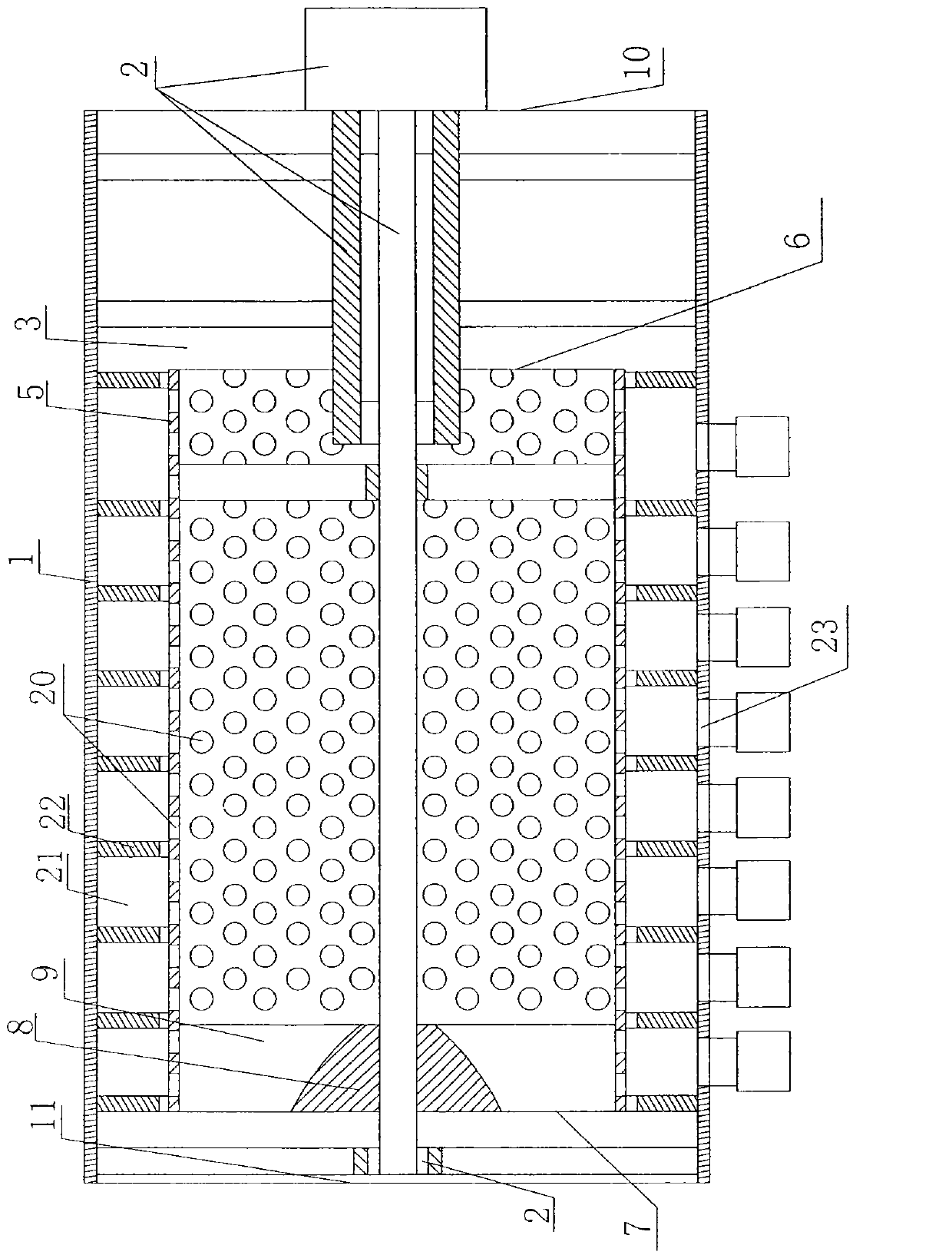

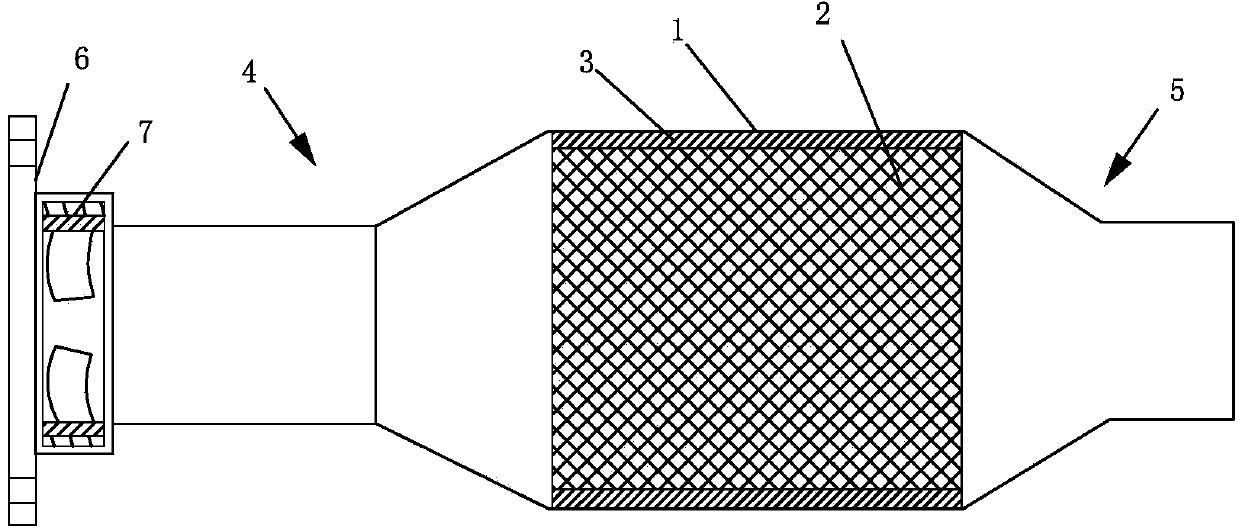

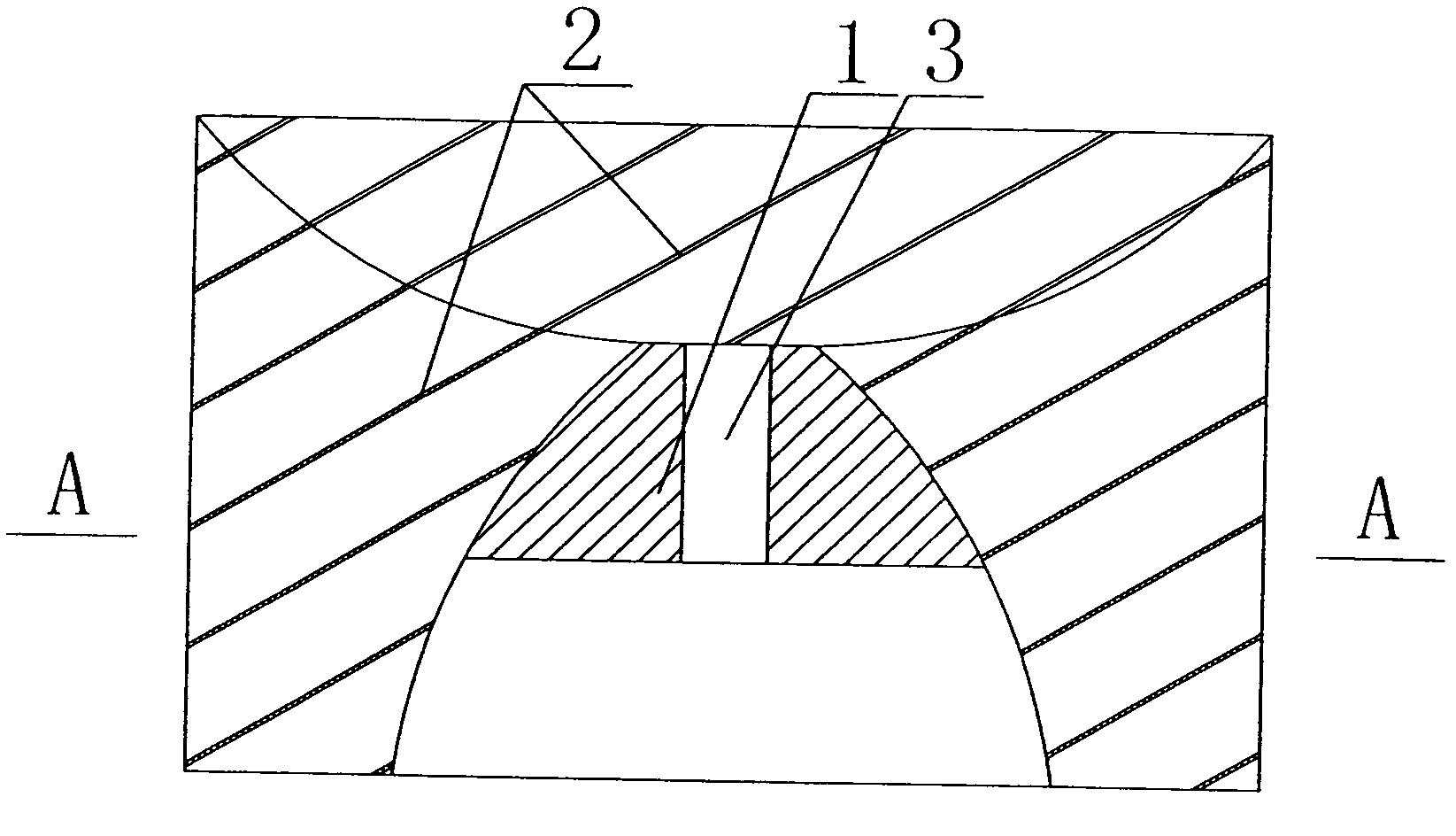

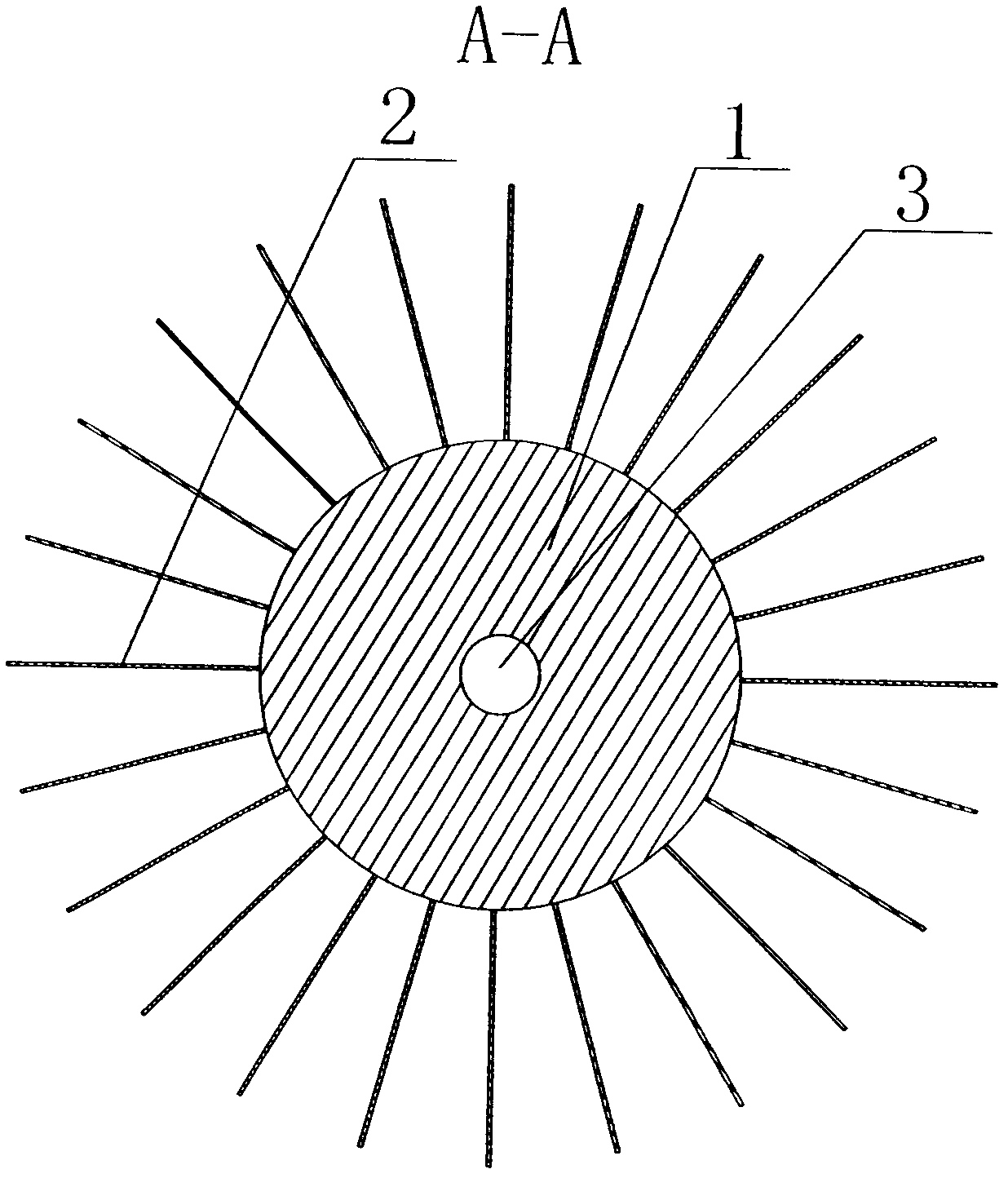

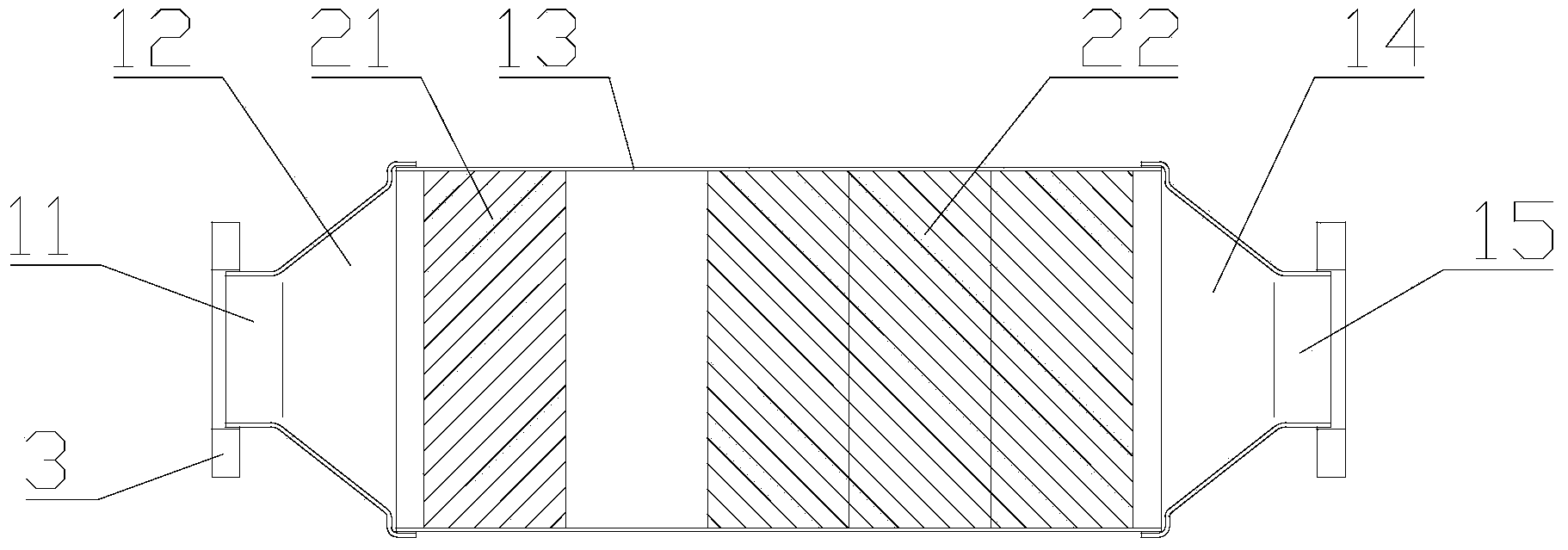

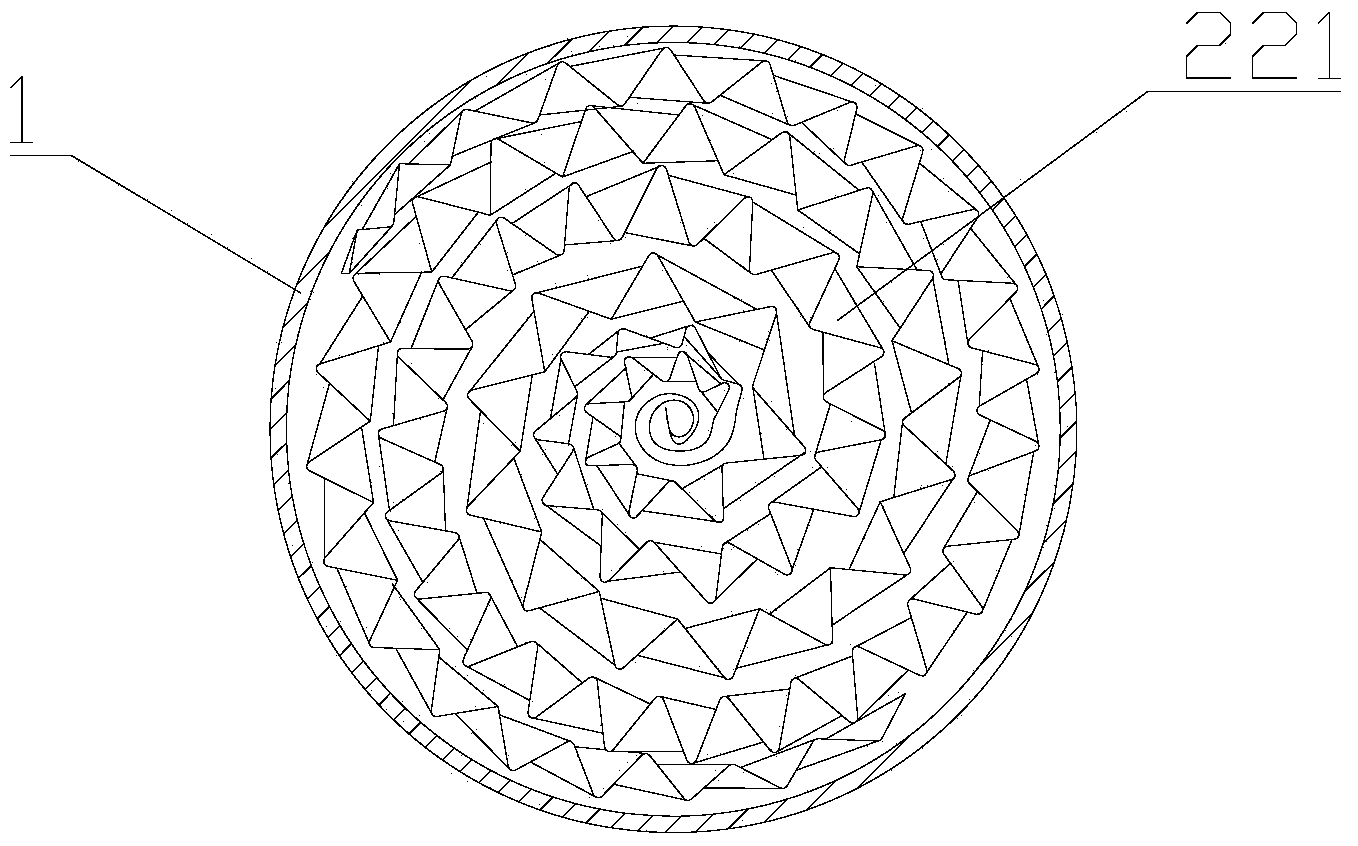

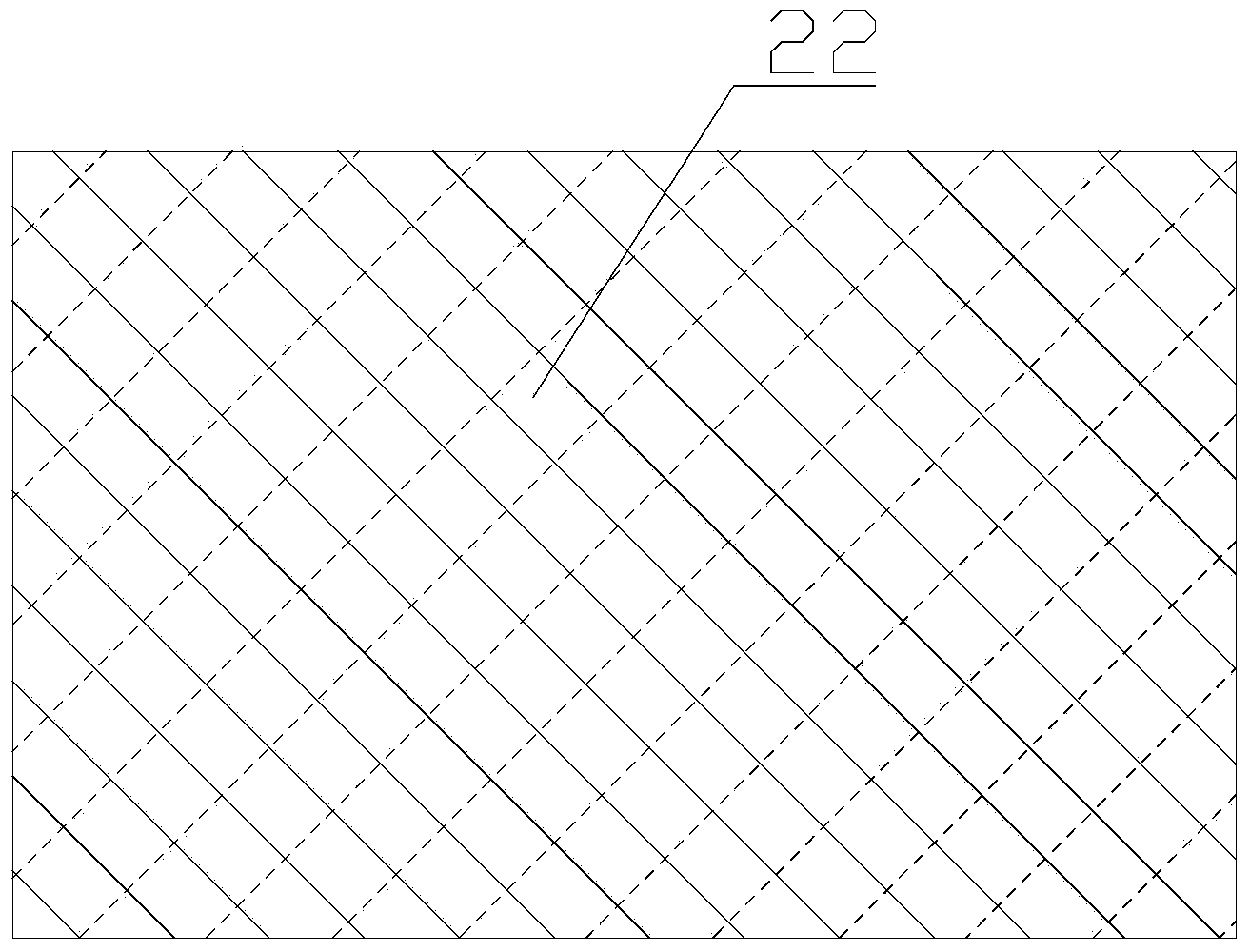

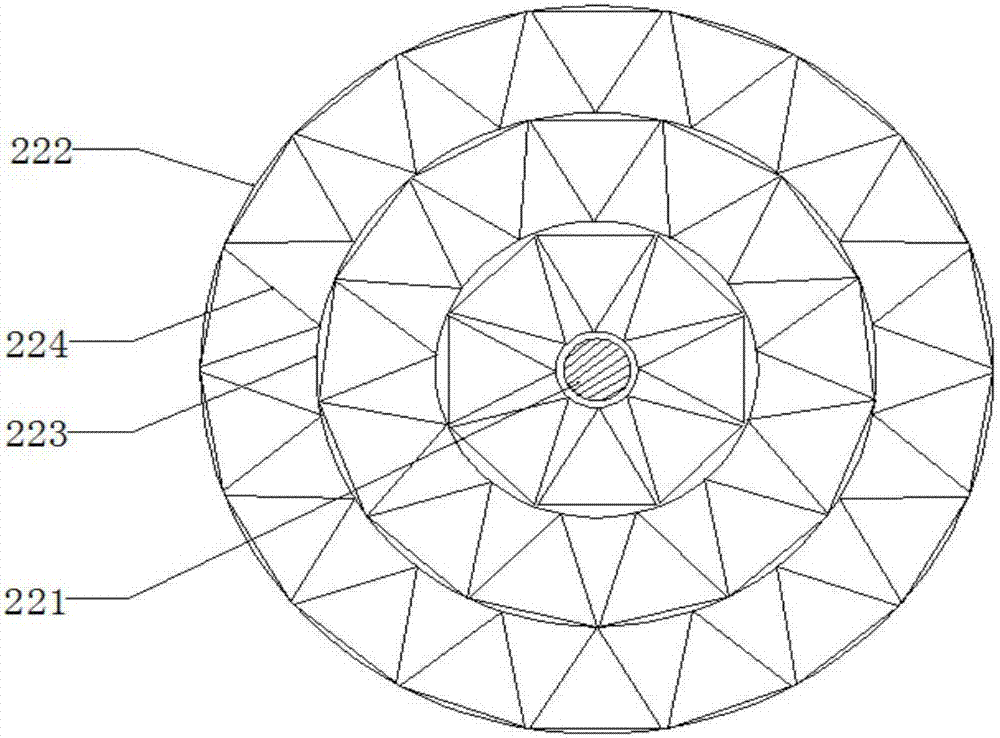

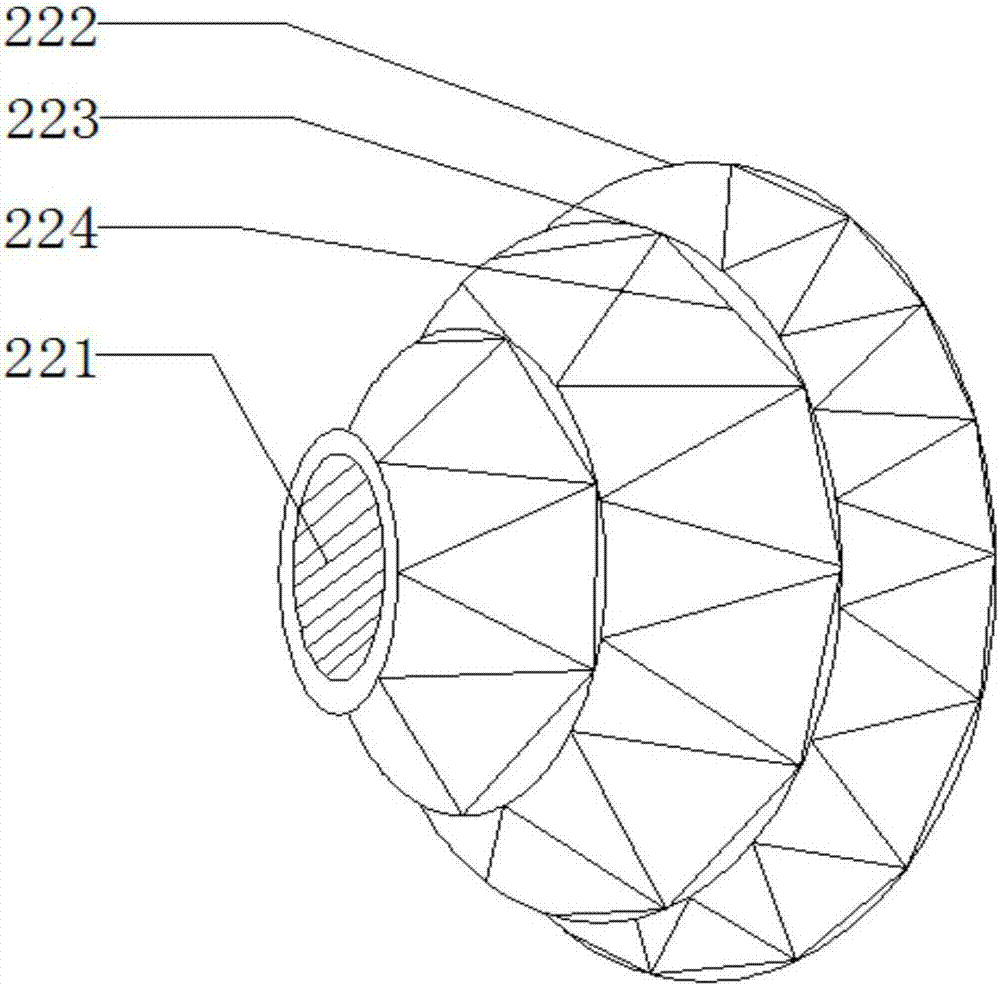

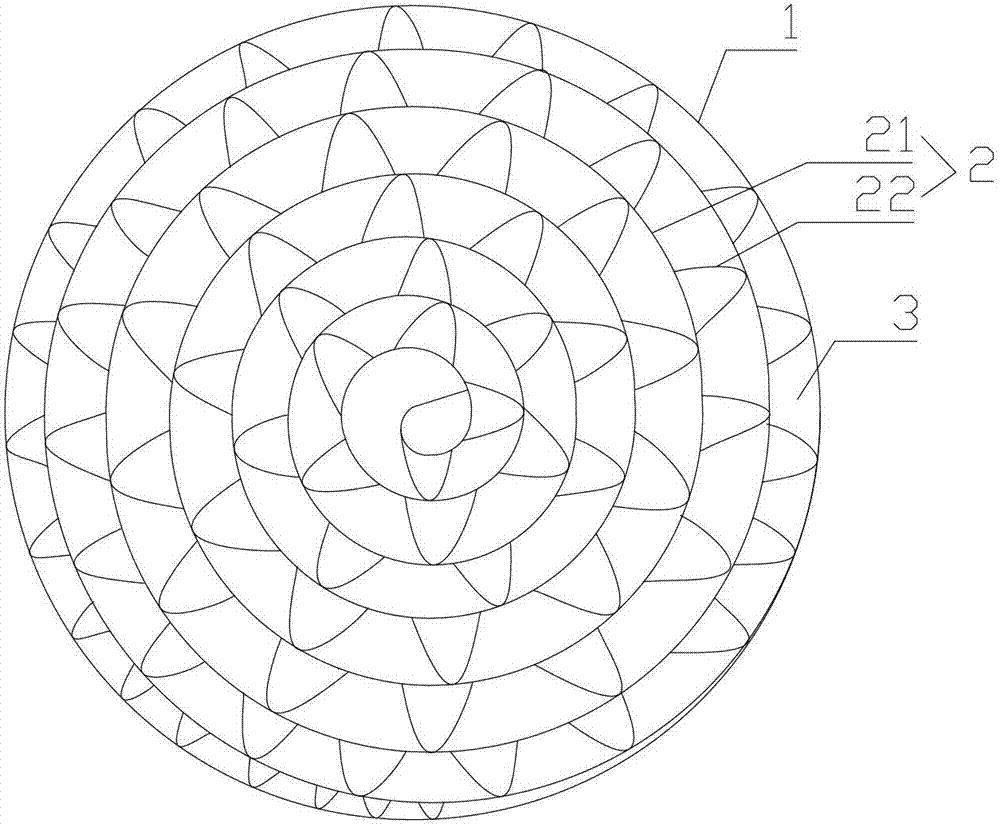

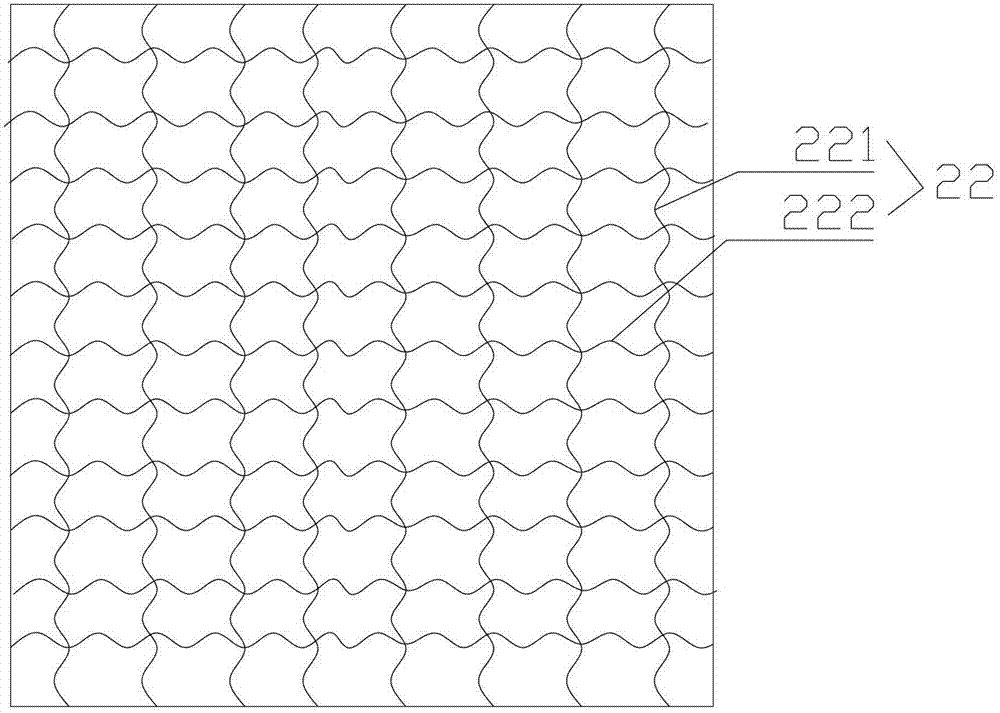

Carrier for motor vehicle exhaust catalytic purifier

InactiveCN102865128AHigh activityImprove efficiencyExhaust apparatusSilencing apparatusExhaust gasContact time

The invention discloses a carrier for a motor vehicle exhaust catalytic purifier. The carrier comprises a barrel (1) and a core (2) arranged in the barrel (1). The carrier is characterized in that the core comprises a surface plate (21) and a corrugated plate (22), wherein the surface plate and the corrugated plate are wound to form pore passages (3), and the corrugated plate comprises first waves (221) and second waves (222) which are arranged in a crossed manner, so that the pore passages are nonlinear constraint pore passages. The carrier fro the motor vehicle exhaust catalytic purifier has the advantages that the pore passages are the nonlinear constraint pore passages owing to the waves which are arranged in the crossed manner, contact area of exhaust and a catalytic coating is increased, and contact time of the exhaust and the catalytic coating is prolonged, so that catalytic reaction is sufficient, and activity and efficiency of the catalytic purifier are obviously improved.

Owner:ZHEJIANG DA FENG AUTOMOBILE TECH

Preparation method of multi-component alloy electrode material

The invention relates to a preparation method of a multi-component alloy electrode material. The method comprises the following steps: firstly dissolving ammonium molybdate and citric acid in water, then slowly adding thiourea into the solution, fully stirring to obtain a solution system, placing the solution system in a water bath kettle, carrying out water bath heating, and continuously stirring in the heating process; when a solution system in the water bath begins to become turbid, pouring weighed metal powder into the solution system to be continuously heated in the water bath and stirred; when the mixed system continues to become viscous jelly, taking out the jelly, and putting into a muffle furnace to be calcined so as to obtain precursor powder; and loading the precursor powder into a graphite mold, placing the graphite mold into a discharge ion sintering furnace, and sintering to finally obtain the multi-element alloy electrode material. According to the invention, the method is simple in step, low in raw material cost and controllable in process, the obtained finished electrode has stable catalytic activity and good conductivity, machining can be completed to be made into various shapes to a certain extent, and large-scale production is expected to be achieved.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com