Preparation method of multi-component alloy electrode material

A technology of electrode materials and multi-element alloys, applied in electrodes, electrolytic components, electrolytic processes, etc., can solve problems such as unfavorable operation and processing, difficulty in fully exerting the catalytic performance of materials, and poor mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

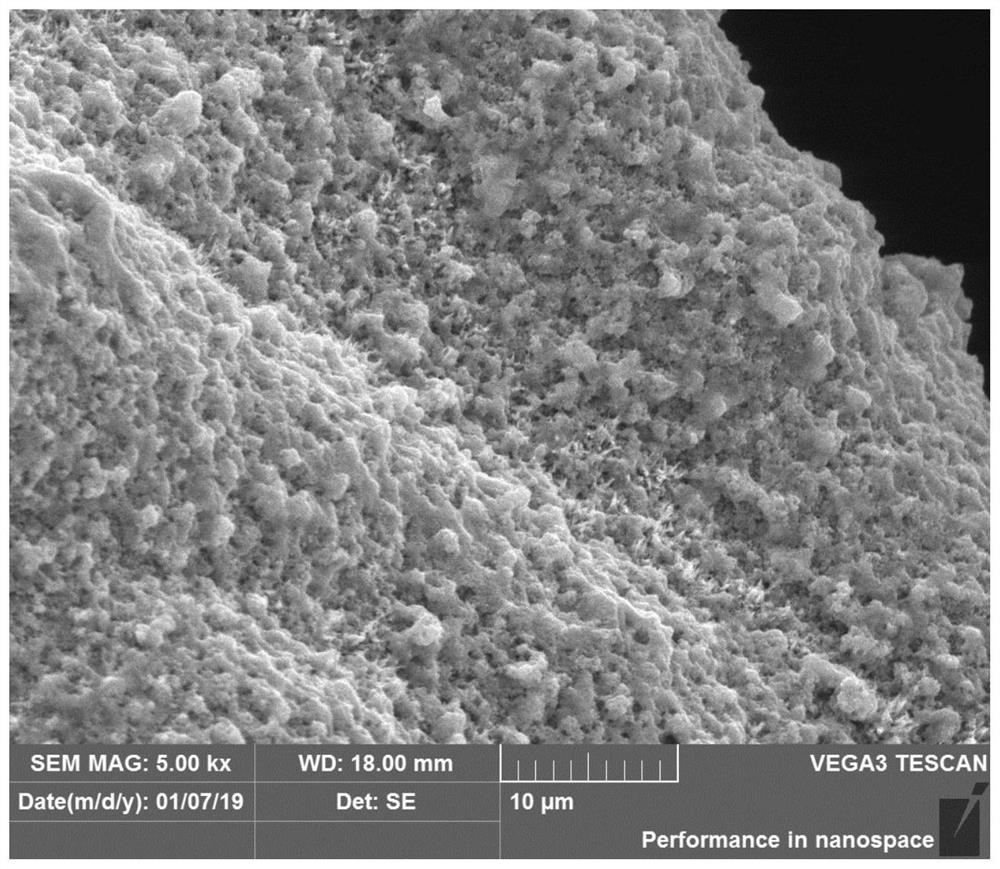

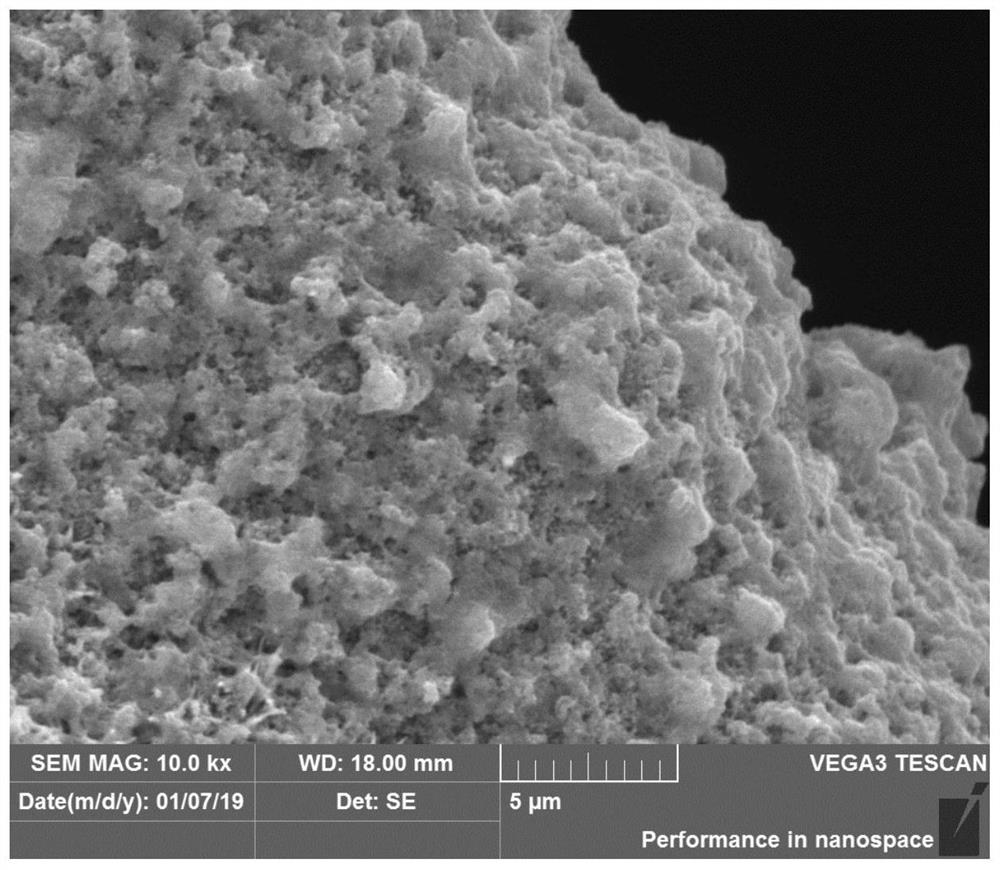

[0027] A preparation method of a multi-element alloy electrode material, mainly comprising the following steps:

[0028] Step 1. Weigh a certain amount of ammonium molybdate and citric acid, pour the two into a beaker and add water to dissolve them, stir well, then slowly add a certain amount of thiourea into it, stir fully until the solution is clear, and obtain a solution system .

[0029] The ammonium molybdate concentration range in the solution system obtained here is 0.1-0.5 mol / L, the citric acid concentration range is 4-12 mol / L, and the thiourea concentration range is 1.5-7.5 mol / L. Based on the reaction principle of ammonium molybdate and thiourea: (NH 4 ) 2 Mo 4 o 13 +15CS(NH 2 ) 2 +9H 2 O=4MoS 2 +(NH 4 ) 2 SO 4 +6NH 4 SCN+18NH 3 +9CO 2

[0030] The amount and concentration of raw materials need to be strictly controlled. If the concentration and amount are too small, too little catalytic phase will be formed, which is not conducive to improving the c...

Embodiment 1

[0041] (1) Weigh 1.235g of ammonium molybdate and 7.69g of citric acid, pour the two into a beaker and add water to dissolve them, stir well and then slowly add 1.14g of thiourea, stir well until the solution is clear to obtain a solution system .

[0042] (2) Place the solution system in step 1 in a water bath for heating in a water bath, the heating temperature of the water bath is 90° C., and keep stirring during the heating process.

[0043] (3) Weigh 1g of nickel powder and 2g of tungsten powder. When the solution in the water bath in step (2) starts to become turbid, slowly pour the nickel powder and tungsten powder into the solution system, and continue heating the resulting mixed system in a water bath And keep stirring.

[0044] (4) When the mixed system obtained in step (3) becomes a viscous jelly, take out the viscous jelly and place it in a muffle furnace for calcination. The calcination temperature is 500° C., and the calcination time is 4 hours. After that, the...

Embodiment 2

[0048] (1) Weigh 1.235g of ammonium molybdate and 13g of citric acid, pour the two into a beaker and add water to dissolve them, stir well, then slowly add 3g of thiourea, and fully stir until the solution is clear to obtain a solution system.

[0049] (2) Place the solution system in step 1 in a water bath for heating in a water bath at a temperature of the water bath, and keep stirring during the heating process.

[0050] (3) Weigh 2g of nickel powder and 1g of DT300 steel powder. When the solution in the water bath in step (2) starts to become turbid, slowly pour the nickel powder and steel powder into the solution system, and continue the resulting mixed system in the water bath Heat with constant stirring.

[0051] (4) When the mixed system obtained in step (3) becomes a viscous jelly, take out the viscous jelly and place it in a muffle furnace for calcination. The calcination temperature is 550° C., and the calcination time is 6 hours. After that, the precursor powder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com