Catalytic filtration composite element as well as preparation method and application thereof

A composite element, catalytic filtration technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems of easy agglomeration and distribution of catalysts, unsatisfactory catalytic performance, high price, etc., and achieve a short preparation cycle and reduce production. Cost and operating pressure drop, effect of increasing reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

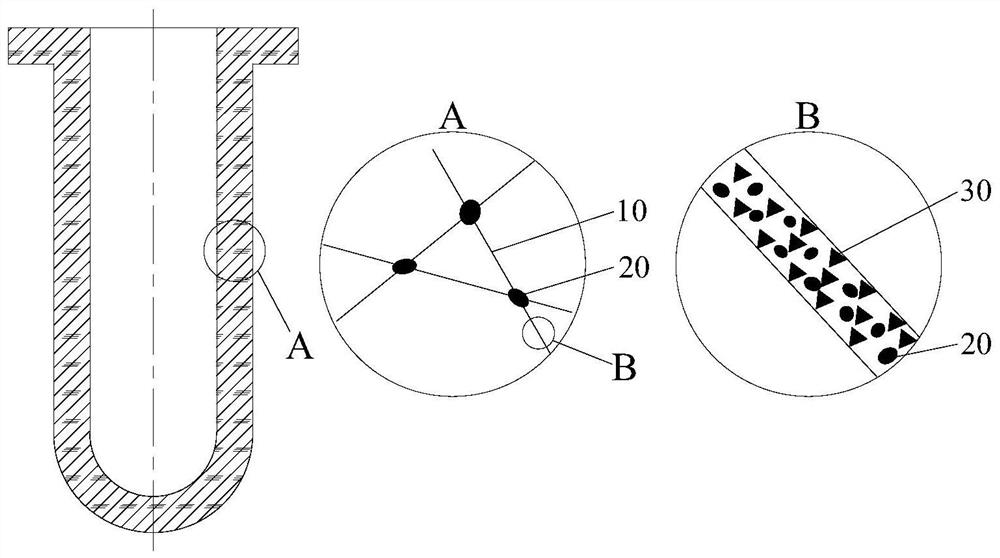

[0056] This embodiment provides a catalytic filter composite element, the preparation method of which comprises:

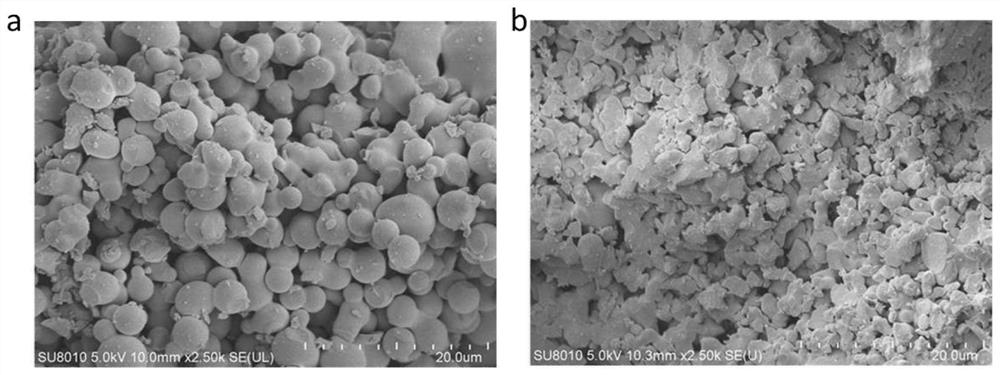

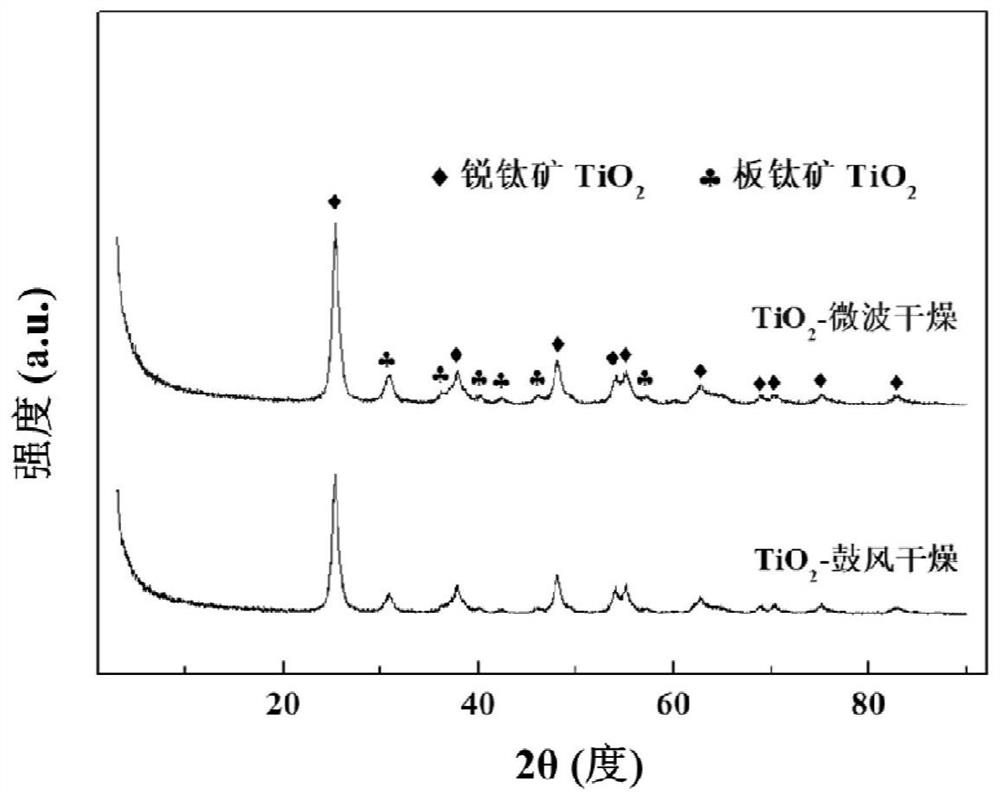

[0057] 1. Based on the total mass of the slurry as 100%, 2% aluminum silicate fiber, 0.5% sodium carboxymethyl cellulose, and 97.5% (calculated by the mass of silica) silica sol were stirred in a high-speed disperser for 90 minutes to form Uniform slurry. Inject the slurry into the mold, and use vacuum suction to remove most of the liquid from the mold. When most of the liquid in the slurry is removed, the speed of the vacuum suction gas is 10m / min-12m / min ;When the slurry is formed and no liquid leaks out, take it out, place the formed slurry in a microwave dryer with a power of 700W and dry it to a constant weight. At this time, the silica sol inside the slurry is completely dried and solidified to form a rigid structure; then 600°C Calcined for 3 hours, the heating rate during the calcination process was 10° C. / min, and it was taken out after returning to room...

Embodiment 2

[0064] This example provides a method for preparing a catalytic filter composite element. Compared with Example 1, the only difference is that the power of microwave drying in Step 2 is 231W, and other experimental steps and experimental parameters are the same as in Example 1.

Embodiment 3

[0066] This example provides a method for preparing a catalytic filter composite element. Compared with Example 1, the only difference is that the microwave drying power in Step 2 is 700W, and other experimental steps and experimental parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com