Axial flow impeller

An axial flow impeller and impeller technology, applied in the field of impeller components, can solve the problems of inability to produce finer droplets, inability to achieve higher speed, inability to generate spray airflow, etc., to avoid fluid impact damage, low maintenance costs, and use costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

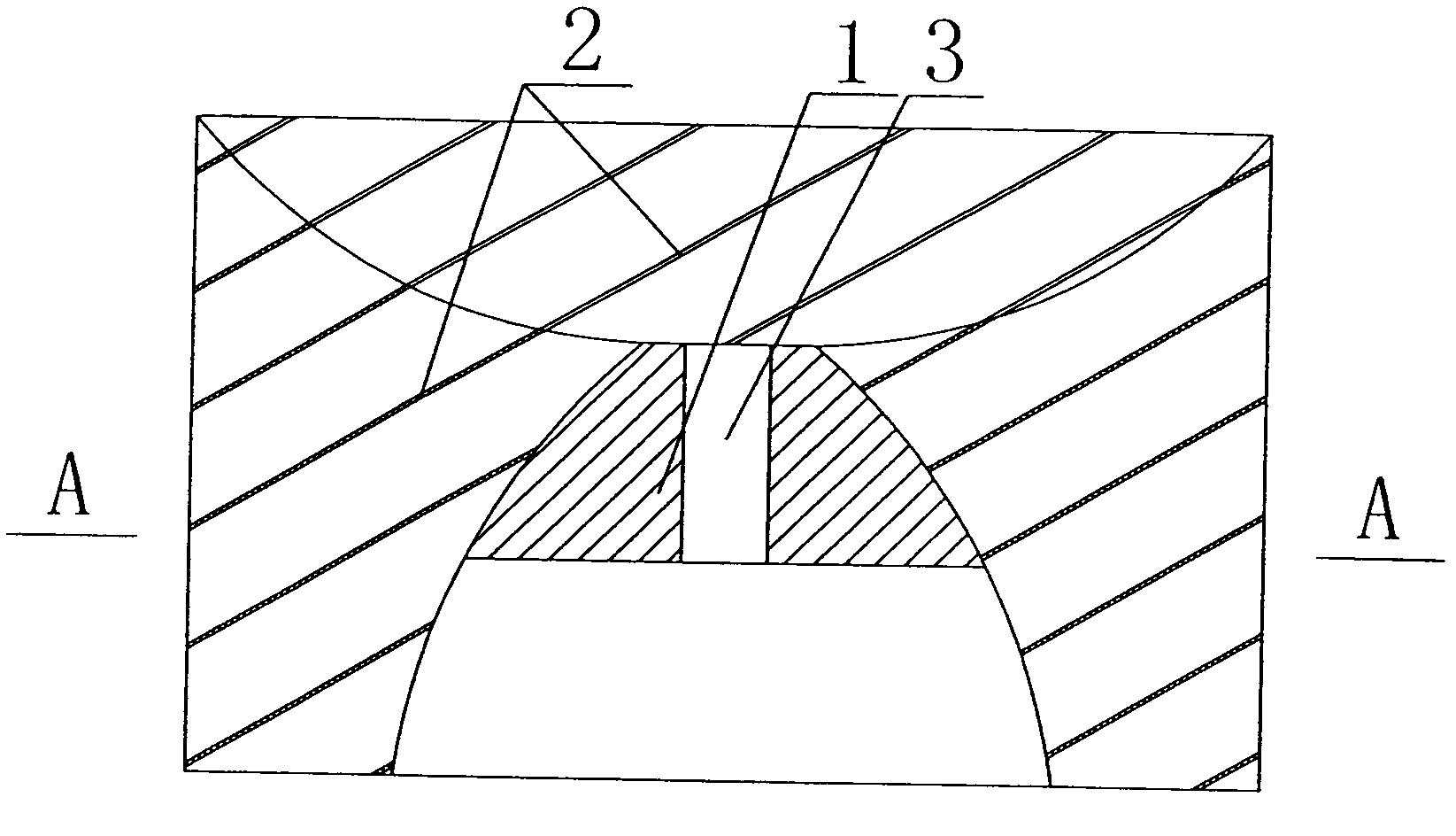

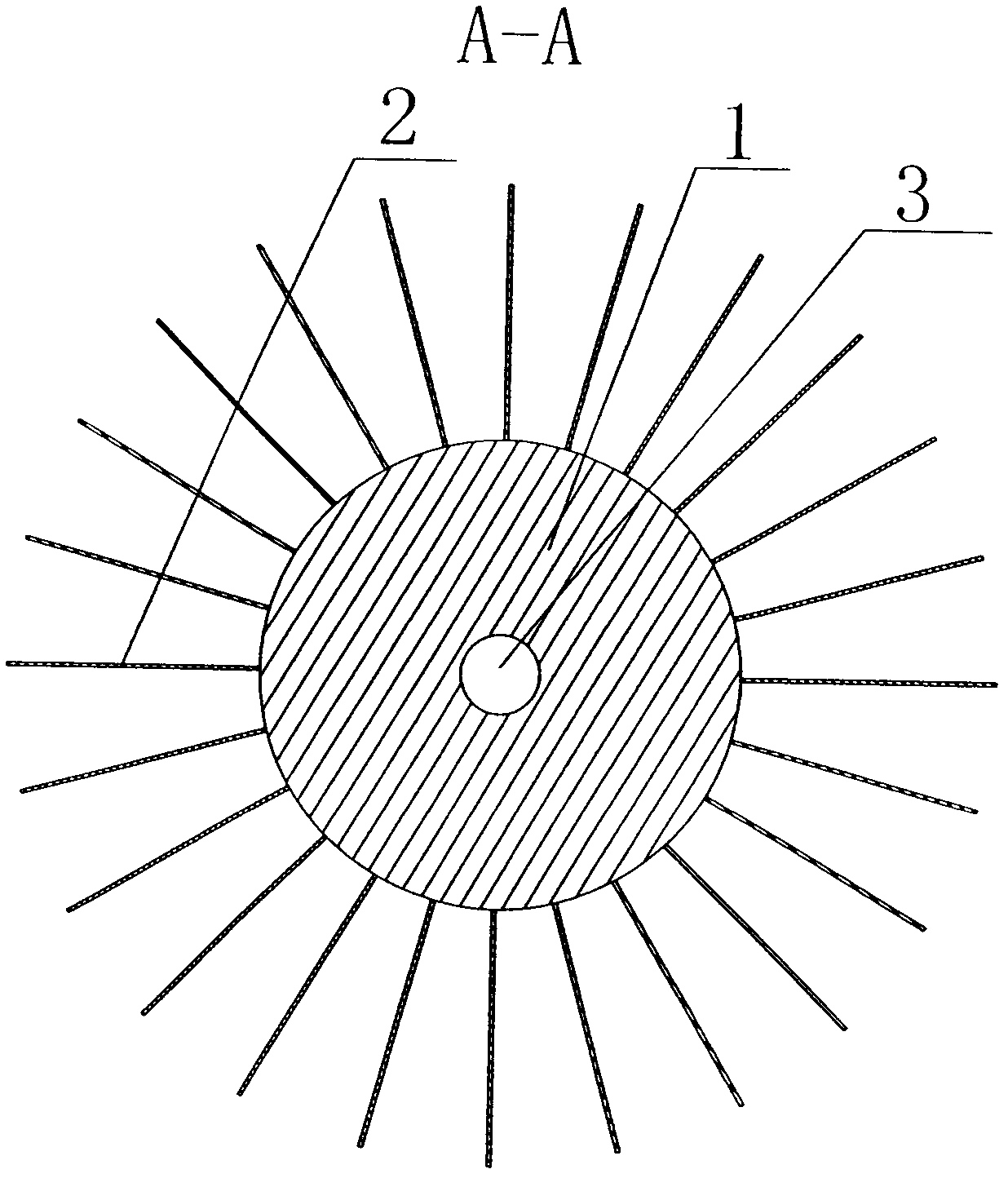

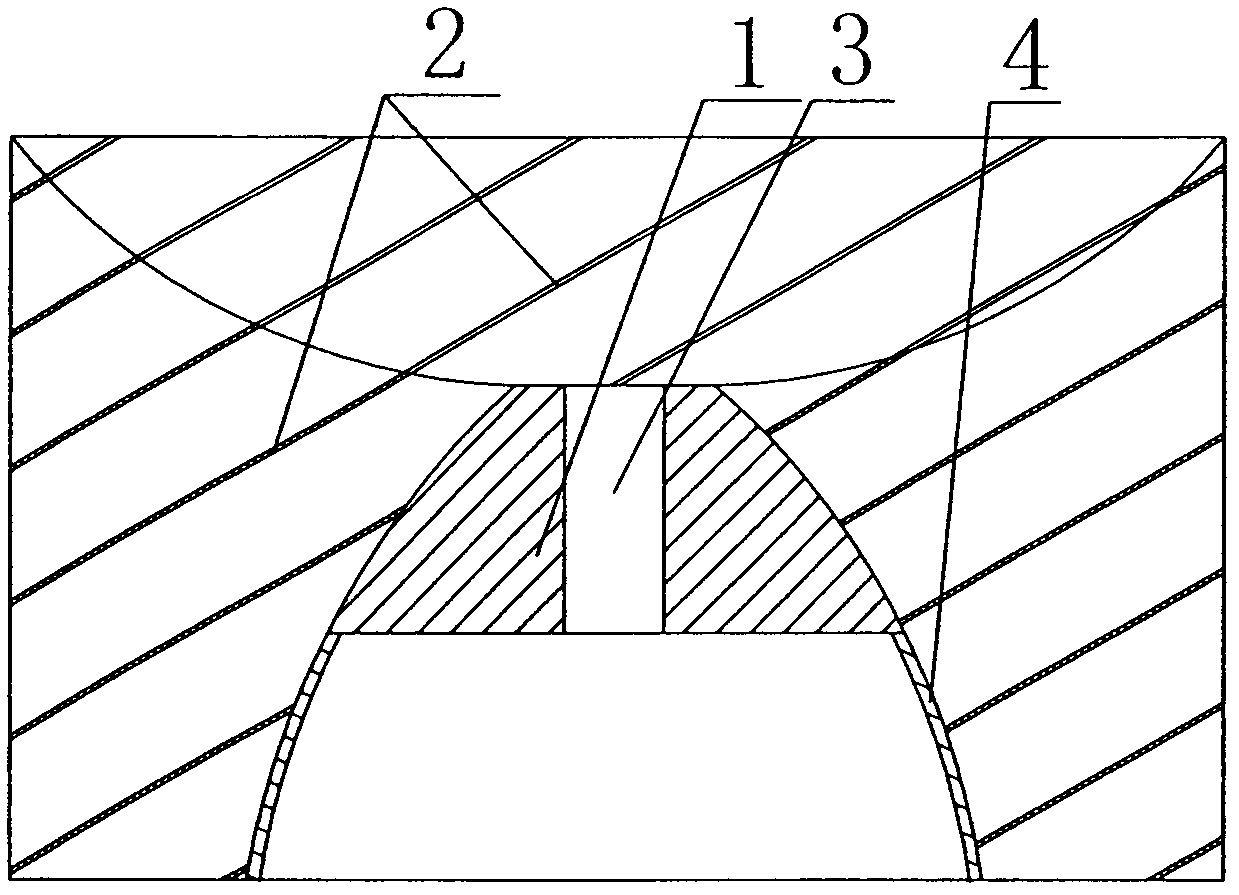

[0026] The main structure of the axial flow impeller of the present invention includes 1. The guide vane 2 is arranged on the wheel body 1, and the guide vane 2 is inclined to the axial direction of the axial flow impeller. The transmission shaft connecting device 3 is arranged on the wheel body 1. The area of the guide vane 2 is from Both ends of the impeller gradually increase toward the middle of the impeller.

[0027] Wheel body 1 can be made of different materials according to needs: high-speed requirements can be made of high-strength materials; high-strength materials that need to be pressurized to transport fluids with high temperature; high-temperature resistant high-strength materials; corrosive chemical fluids are made of corrosion-resistant materials ; The wheel body can use metal, ceramic, glass, carbon fiber, plastic, foam material and other materials. The wheel body of metal materials can be cast and formed by casting process, or can be manufactured by welding, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com