Magnetically stabilized bed for bidirectional utilization of internal and external magnetic fields

A technology of magnetically stabilized bed and external magnetic field, which is applied in chemical/physical/physicochemical processes, chemical/physical/physicochemical processes, chemical instruments and methods, etc., which can solve the problems of difficult recovery of magnetic catalysts and the utilization rate of magnetic field energy. Low-level problems, to achieve the effect of increased contact time, longer flow distance, and reduced magnetic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The method of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

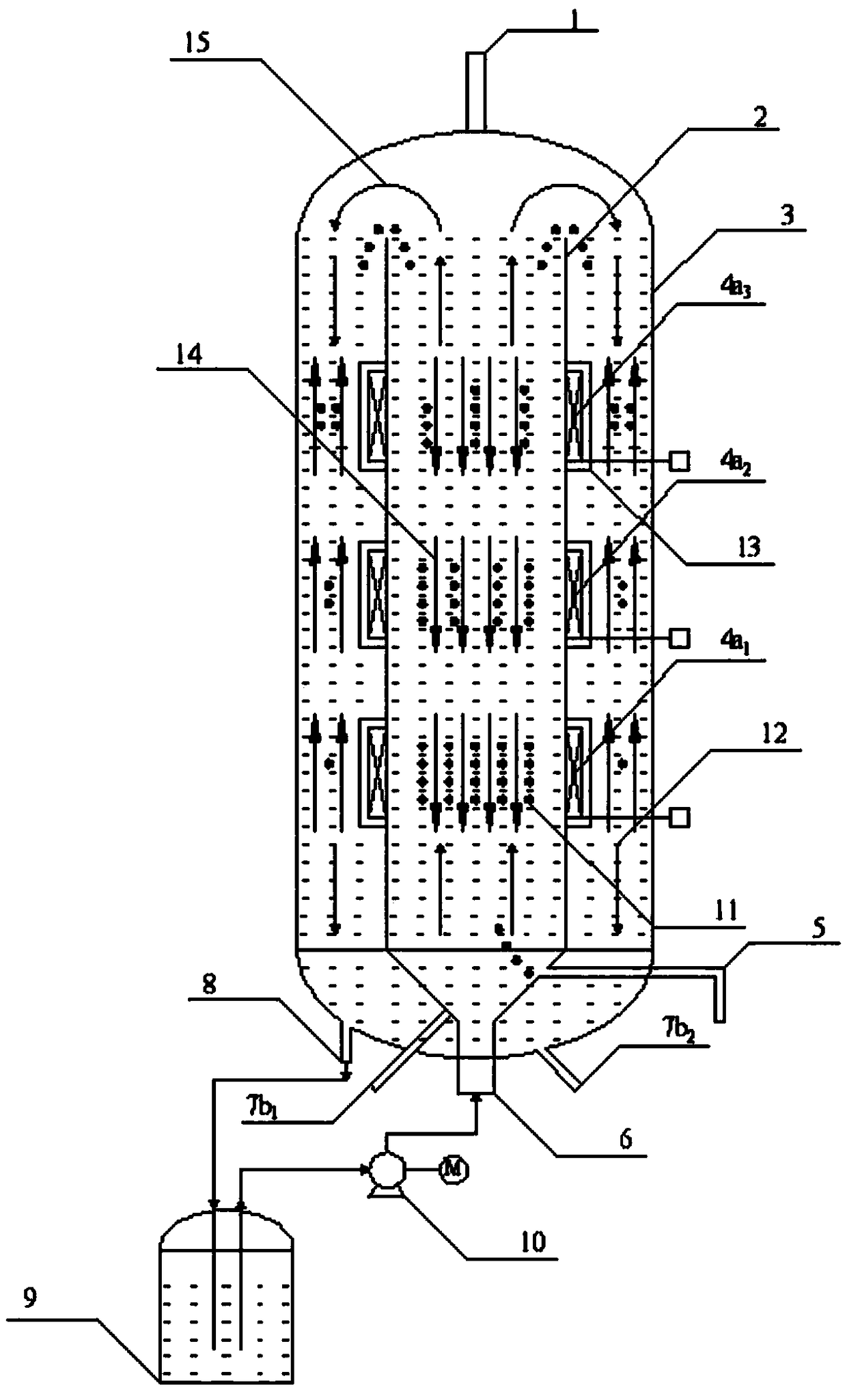

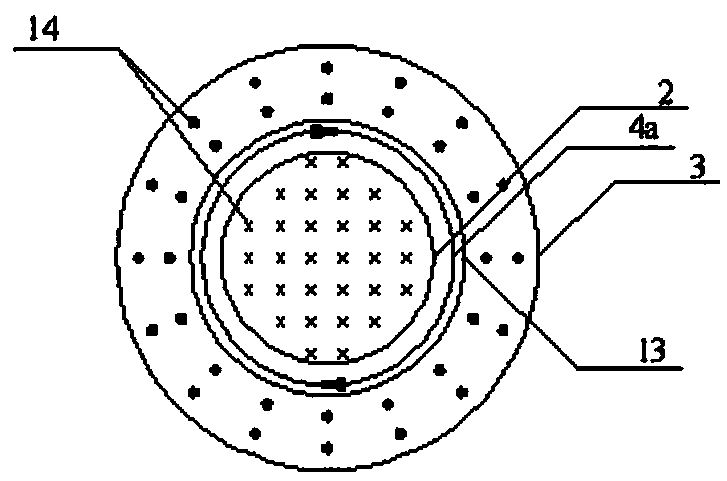

[0027] Such as Figure 1-2 Shown, the specific implementation process of this magnetically stabilized bed is as follows:

[0028]S1 turns on the liquid phase circulation variable frequency pump (10), so that the liquid phase solution (12) in the liquid phase circulation storage tank (9) enters the catalytic reaction inner tower (2);

[0029] S2 passes into the solid phase magnetic catalyst (11) from the solid phase inlet (5), so that it flows together under the impetus of the liquid phase solution (12);

[0030] The mixture of S3 solid-phase magnetic catalyst (11) and liquid-phase solution (12) passes through the first coil (4a) successively in the catalytic reaction inner tower (2) 1 ), the second coil (4a 2 ), the third coil (4a 3 ), the solid-phase magnetic catalyst (11) is gradually balanced by force and collected;

[0031] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com