A method for preparing carbon nanotubes from coal

A carbon nanotube, coal technology, applied in nanocarbon, carbon nanotubes, chemical instruments and methods, etc., can solve the problems of yield, purity and cost impact of carbon nanotube preparation products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] First, take 100 grams of long-flame coal coarse powder and mix it with 25 grams of melamine, 11 grams of cobalt chloride (containing 5 grams of metallic cobalt ions) and 50 grams of water to obtain mixture A. Put mixture A in a ball mill jar, and add metal steel balls for high-energy ball milling until uniformly dispersed slurry mixture B is obtained. After the mixture B is placed in a freeze dryer for freeze drying, the porous block C can be obtained. The block C is placed in a high-temperature atmosphere furnace, mixed with hydrogen and argon gas containing 5% hydrogen, and heated at 1100° C. for 2 hours to prepare clustered carbon nanotubes. Further purification can be carried out by multiple times of acid washing and water washing, and after centrifugation and drying, a cluster-like carbon nanotube powder with a diameter of 60-100 nanometers can be obtained.

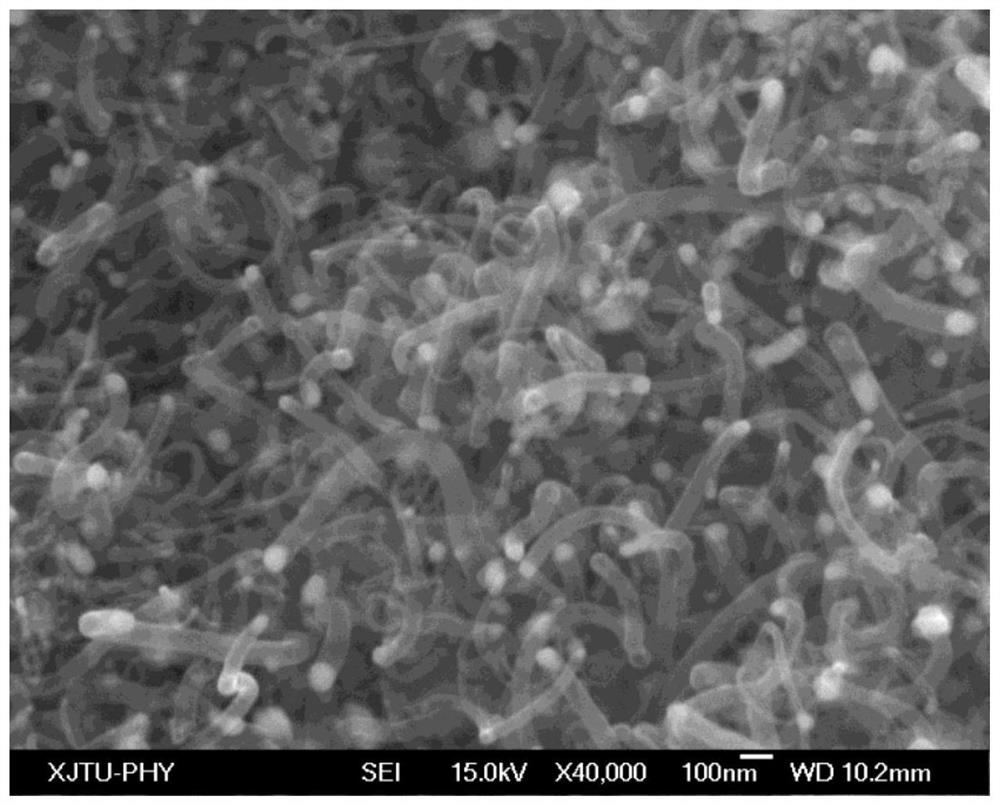

[0039] figure 1 Scanning electron microscope image of the prepared carbon nanotubes, Figure 5 It is a t...

Embodiment 2

[0041] First, take 50 grams of anthracite coarse powder and mix it with 10 grams of melamine, 6.5 grams of nickel chloride (containing 3 grams of metallic nickel ions) and 25 grams of water to obtain mixture A. Put mixture A in a ball mill jar, and add metal steel balls for high-energy ball milling until uniformly dispersed slurry mixture B is obtained. After the mixture B is placed in a freeze dryer for freeze drying, the porous block C can be obtained. The block C is placed in a high-temperature atmosphere furnace, mixed with hydrogen and argon gas containing 5% hydrogen, and heated at 800° C. for 2 hours to prepare clustered carbon nanotubes. Further purification can be carried out by multiple times of acid washing and water washing, and after centrifugation and drying, a clustered carbon nanotube powder with a diameter of about 40-50 nanometers can be obtained.

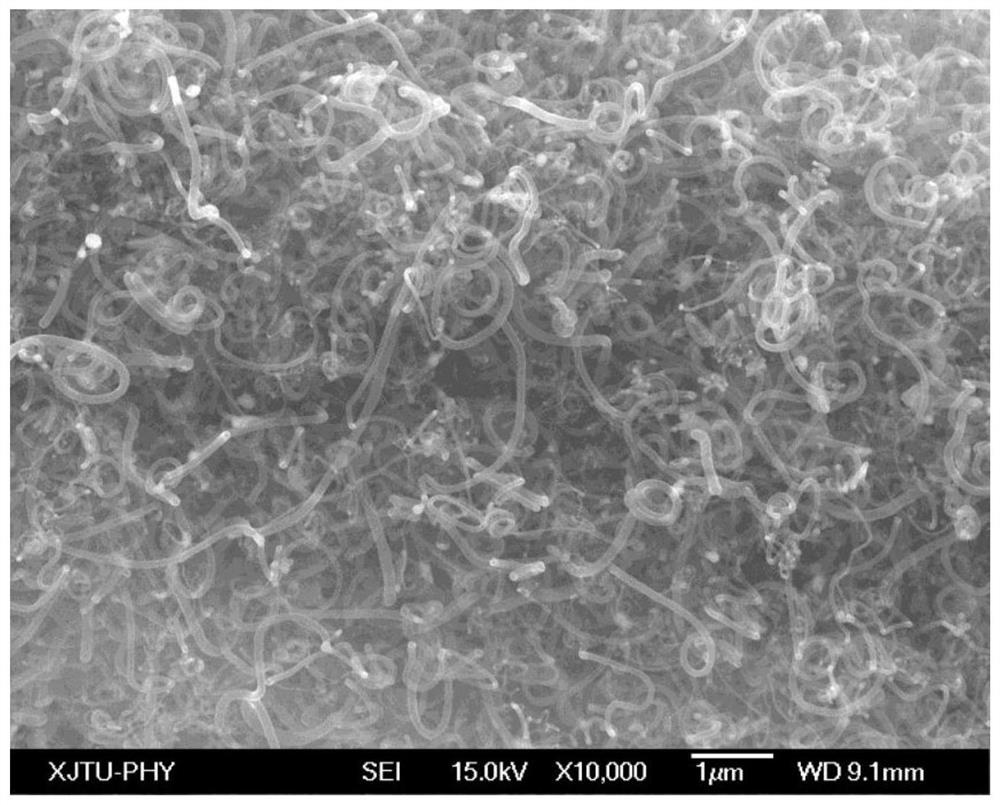

[0042] figure 2 The scanning electron microscope image of the prepared carbon nanotubes shows that the carbo...

Embodiment 3

[0044]First, take the mixture of 100 grams of coking coal and lignite, mix it with 25 grams of melamine, a total of 31.4 grams of cobalt nitrate and nickel nitrate (containing a total of 10 grams of metallic cobalt ions and nickel ions) and 50 grams of water to obtain mixture A. Put mixture A in a ball mill jar, and add metal steel balls for high-energy ball milling until uniformly dispersed slurry mixture B is obtained. After the mixture B is placed in a freeze dryer for freeze-drying, the porous block C can be obtained. The block C is placed in a high-temperature atmosphere furnace, mixed with hydrogen and argon gas containing 5% hydrogen, and heated at 600° C. for 4 hours to prepare clustered carbon nanotubes. Further purification can be carried out by multiple times of acid washing and water washing, and after centrifugation and drying, a clustered carbon nanotube powder with a diameter of about 60-80 nanometers can be obtained.

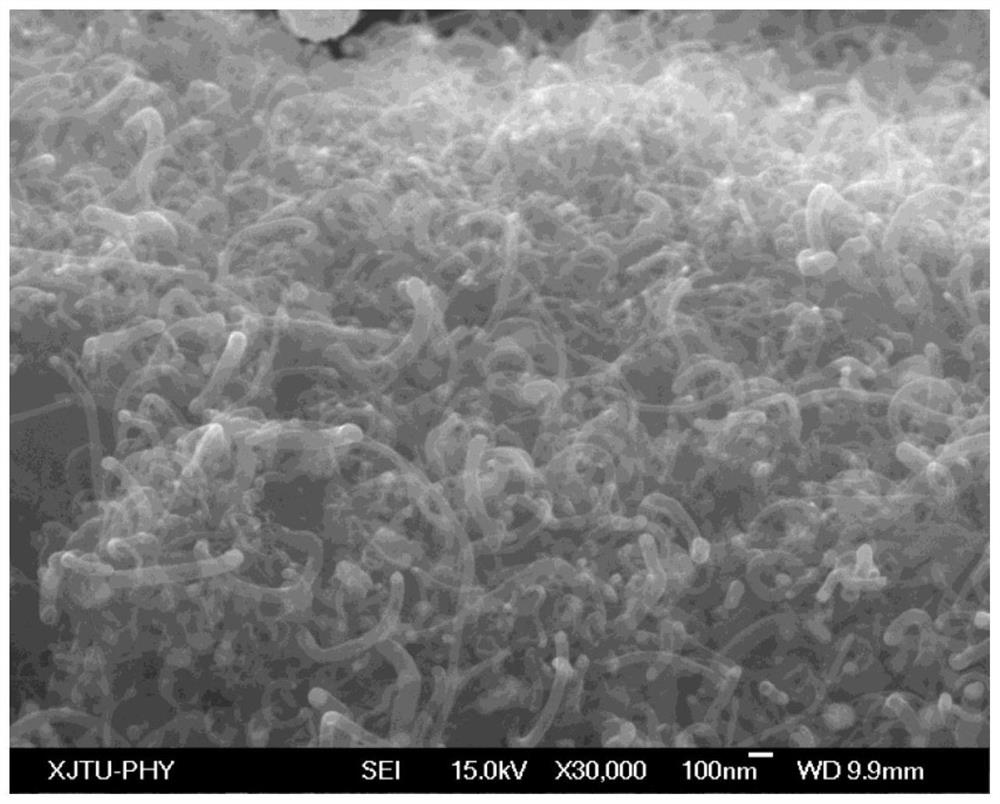

[0045] image 3 Scanning electron micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com