Method for preparing carbon nanotubes from coal

A carbon nanotube and coal technology, applied in nanocarbon, carbon nanotubes, chemical instruments and methods, etc., can solve the problems of yield, purity and cost impact of carbon nanotube preparation products, and achieve batch preparation, improve The effect of catalytic efficiency and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] First, take 100 grams of long-flame coal coarse powder and mix it with 25 grams of melamine, 11 grams of cobalt chloride (containing 5 grams of metallic cobalt ions) and 50 grams of water to obtain mixture A. Put mixture A in a ball mill jar, and add metal steel balls for high-energy ball milling until uniformly dispersed slurry mixture B is obtained. After the mixture B is placed in a freeze dryer for freeze drying, the porous block C can be obtained. The block C is placed in a high-temperature atmosphere furnace, mixed with hydrogen and argon gas containing 5% hydrogen, and heated at 1100° C. for 2 hours to prepare clustered carbon nanotubes. Further purification can be carried out by multiple times of acid washing and water washing, and after centrifugation and drying, a cluster-like carbon nanotube powder with a diameter of 60-100 nanometers can be obtained.

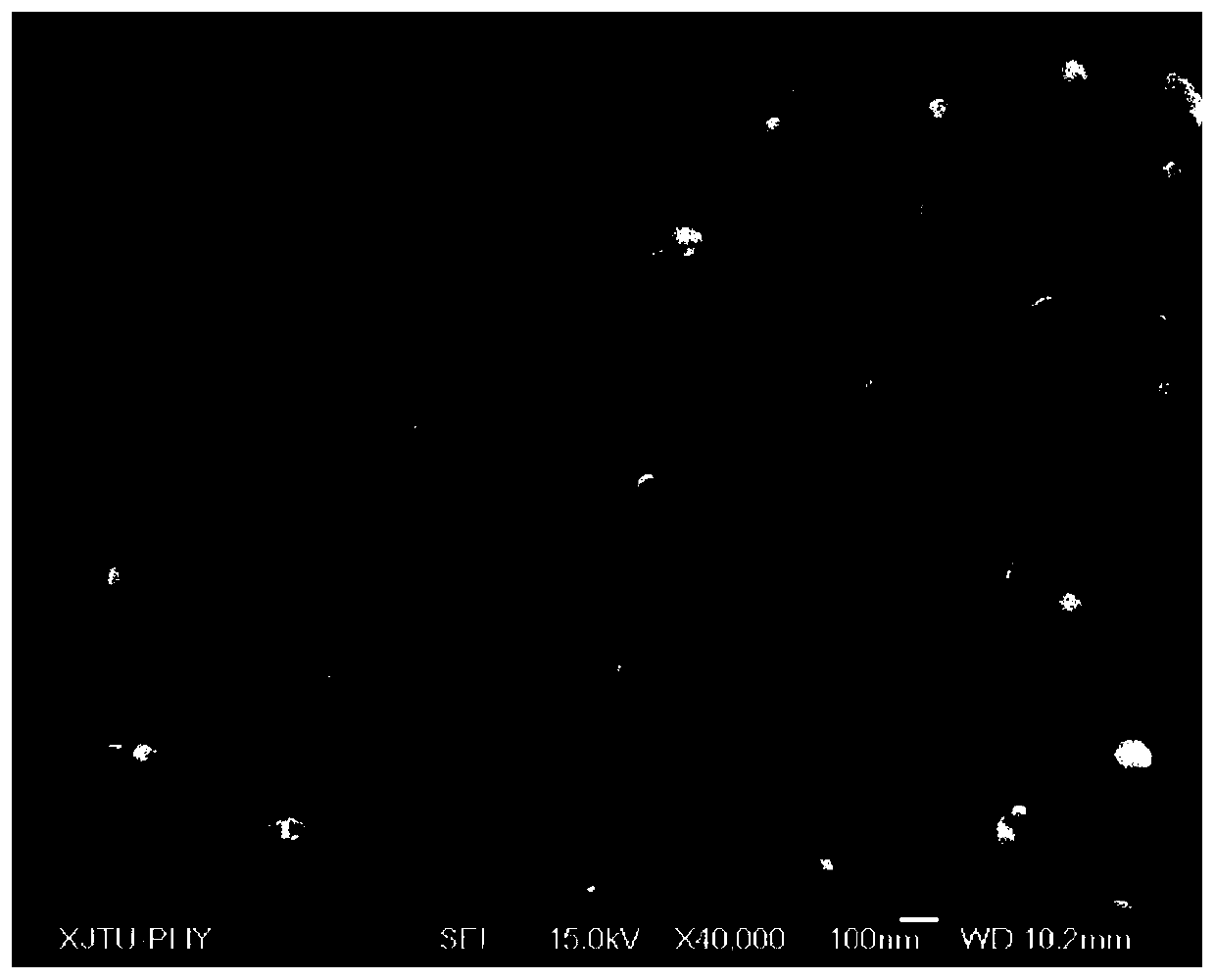

[0039] figure 1 Scanning electron microscope image of the prepared carbon nanotubes, Figure 5 It is a t...

Embodiment 2

[0041] First, take 50 grams of anthracite coarse powder and mix it with 10 grams of melamine, 6.5 grams of nickel chloride (containing 3 grams of metallic nickel ions) and 25 grams of water to obtain mixture A. Put mixture A in a ball mill jar, and add metal steel balls for high-energy ball milling until uniformly dispersed slurry mixture B is obtained. After the mixture B is placed in a freeze dryer for freeze drying, the porous block C can be obtained. The block C is placed in a high-temperature atmosphere furnace, mixed with hydrogen and argon gas containing 5% hydrogen, and heated at 800° C. for 2 hours to prepare clustered carbon nanotubes. Further purification can be carried out by multiple times of acid washing and water washing, and after centrifugation and drying, a clustered carbon nanotube powder with a diameter of about 40-50 nanometers can be obtained.

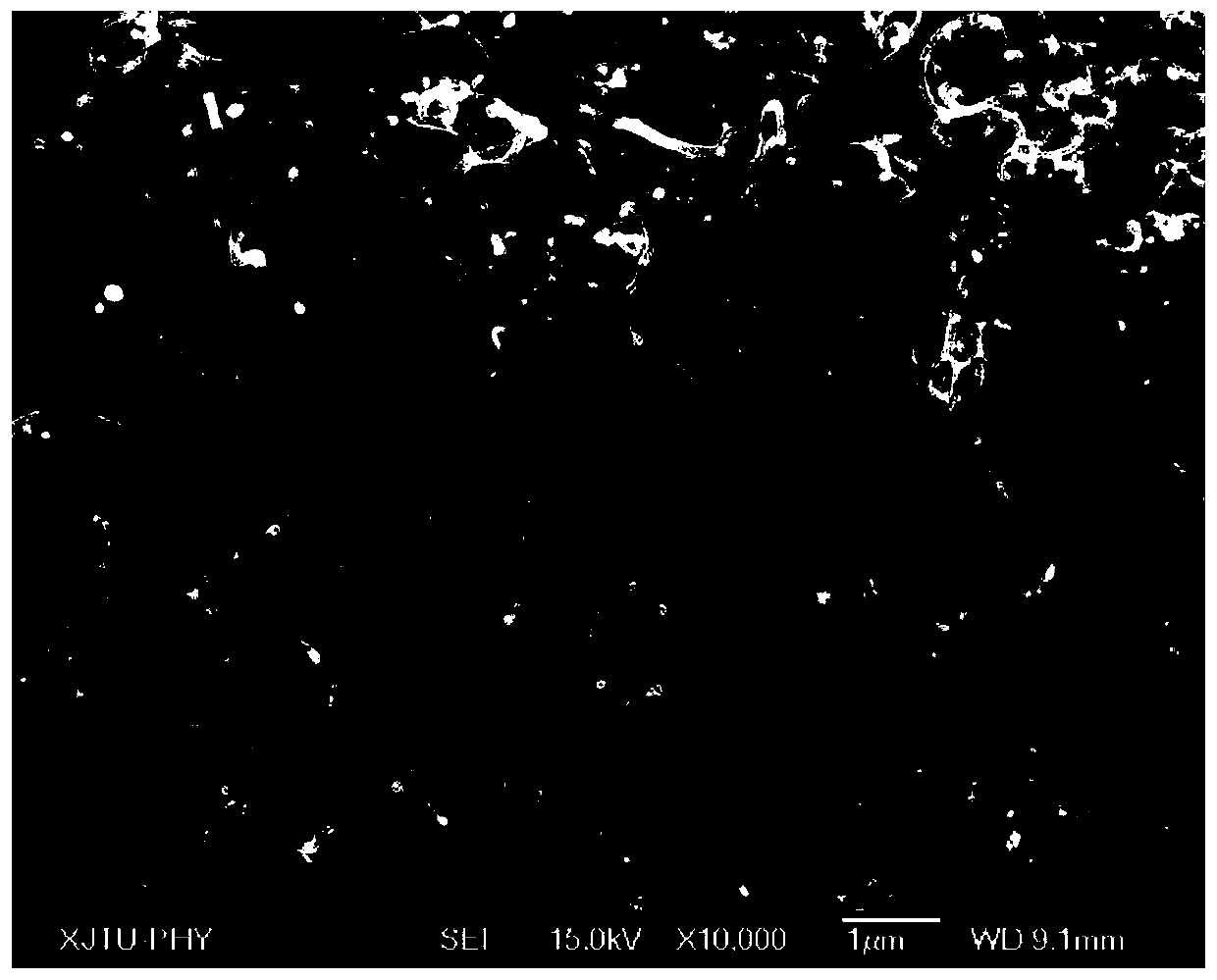

[0042] figure 2 The scanning electron microscope image of the prepared carbon nanotubes shows that the carbo...

Embodiment 3

[0044]First, take the mixture of 100 grams of coking coal and lignite, mix it with 25 grams of melamine, a total of 31.4 grams of cobalt nitrate and nickel nitrate (containing a total of 10 grams of metallic cobalt ions and nickel ions) and 50 grams of water to obtain mixture A. Put mixture A in a ball mill jar, and add metal steel balls for high-energy ball milling until uniformly dispersed slurry mixture B is obtained. After the mixture B is placed in a freeze dryer for freeze-drying, the porous block C can be obtained. The block C is placed in a high-temperature atmosphere furnace, mixed with hydrogen and argon gas containing 5% hydrogen, and heated at 600° C. for 4 hours to prepare clustered carbon nanotubes. Further purification can be carried out by multiple times of acid washing and water washing, and after centrifugation and drying, a clustered carbon nanotube powder with a diameter of about 60-80 nanometers can be obtained.

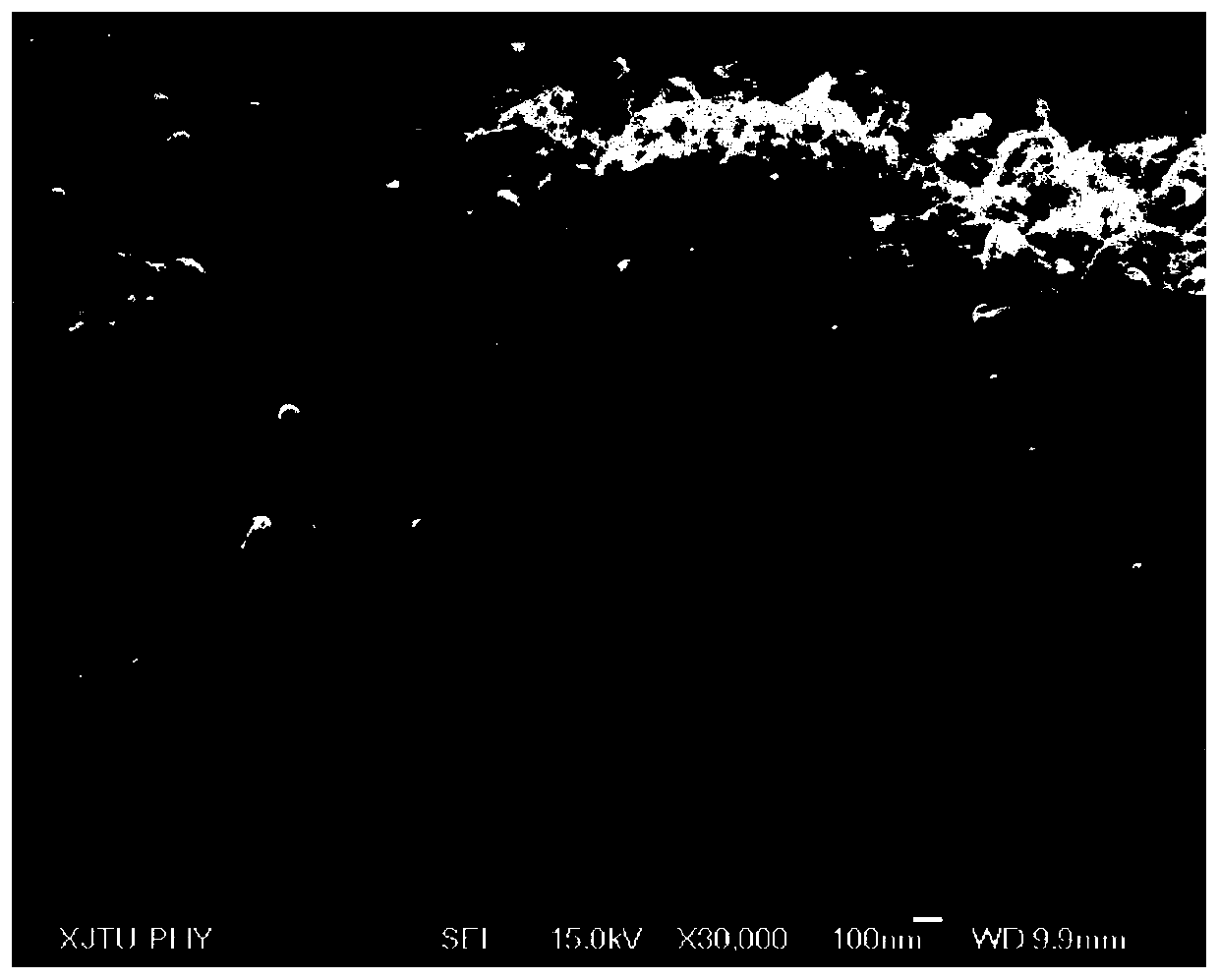

[0045] image 3 Scanning electron micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com