Carrier for motor vehicle exhaust catalytic purifier

A technology for catalytic converters and motor vehicles. It is applied in the direction of machines/engines, exhaust devices, mechanical equipment, etc. It can solve the problems of high-efficiency catalytic conversion of catalytic coatings, short contact time between catalytic coatings and airflow, and small contact areas. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

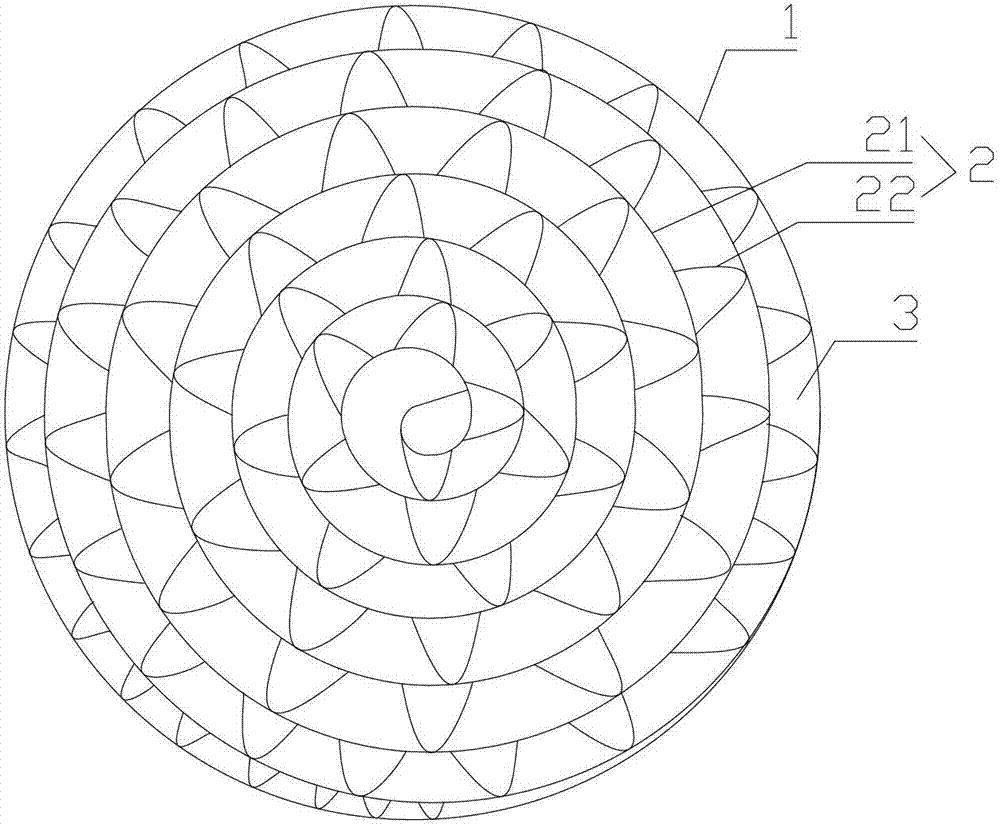

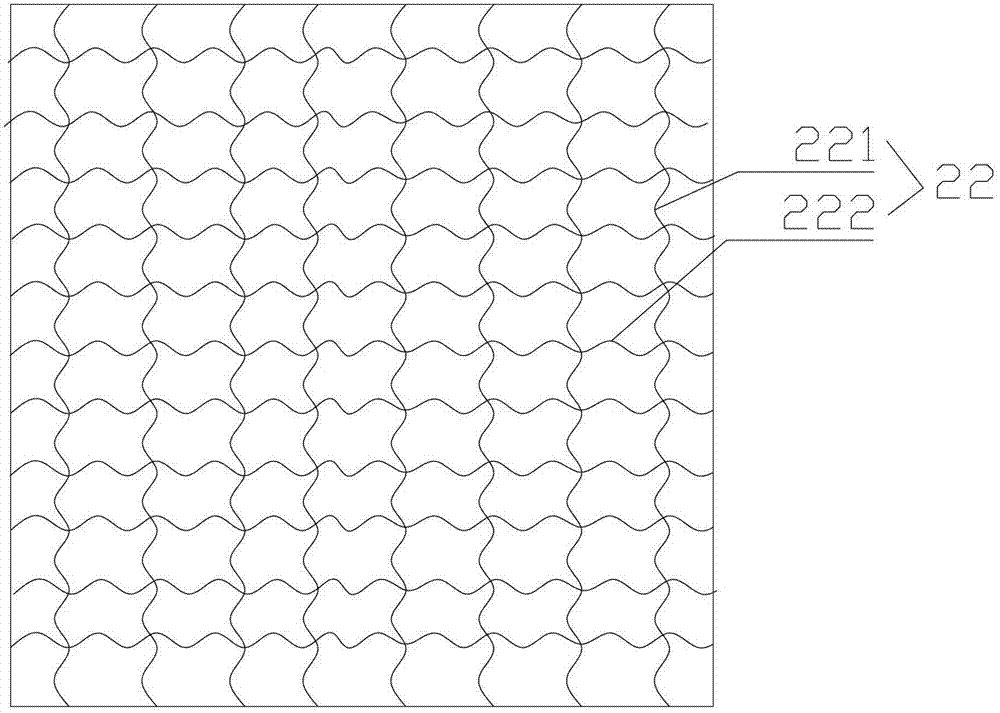

[0017] Such as figure 1 and figure 2 As shown, a carrier for a motor vehicle exhaust catalytic converter includes a cylinder body 1 and a core body 2 disposed in the cylinder body. The core body includes a flat plate 21 and a corrugated plate 22, and the corrugated plate is arranged on the flat plate. The flat plate is wound to form a spiral passage 3, and the first corrugation 221 and the second corrugation 222 intersected on the corrugated plate divide the spiral passage into non-wired tunnels. The corrugated board is formed by bidirectional pressing on a flat plate. The first corrugations and the second corrugations are vertically intersected, the first corrugations are arranged along the circumferential direction of the core, the second corrugations are arranged along the axial direction of the core, and the depth of the first corrugations is Smaller than the depth of the second corrugations, several first corrugations are arranged in parallel at equal intervals, and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com