Catalytic purifier for motor vehicle exhaust and its preparing method and use

A technology for catalytic purifiers and motor vehicles, applied in chemical instruments and methods, mechanical equipment, catalyst carriers, etc., which can solve the problems of purifier effectiveness, durability decline, channel wall catalyst coating peeling off, exhaust emission not up to standard, etc. , to achieve the effect of long service life, low cost and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

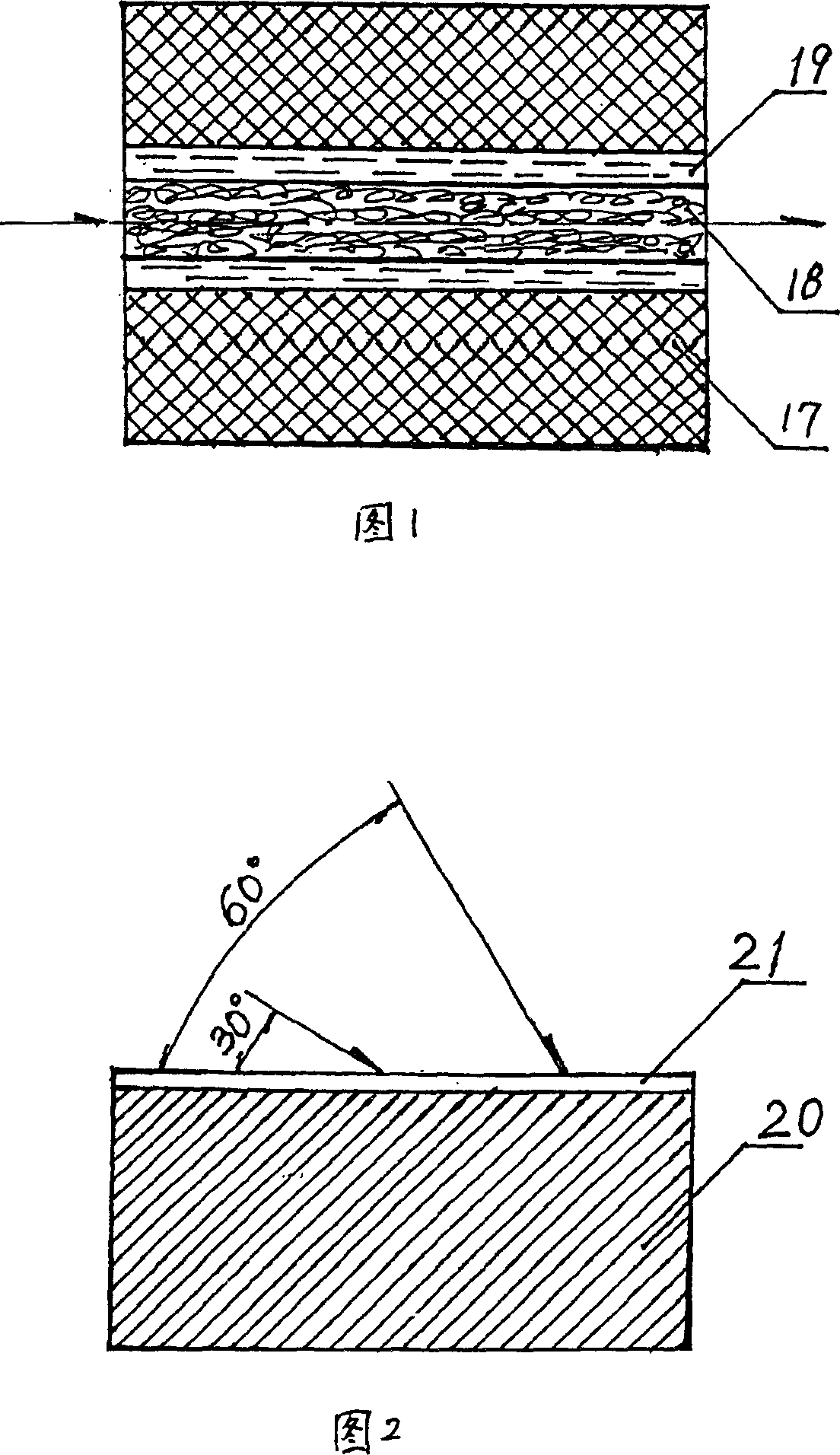

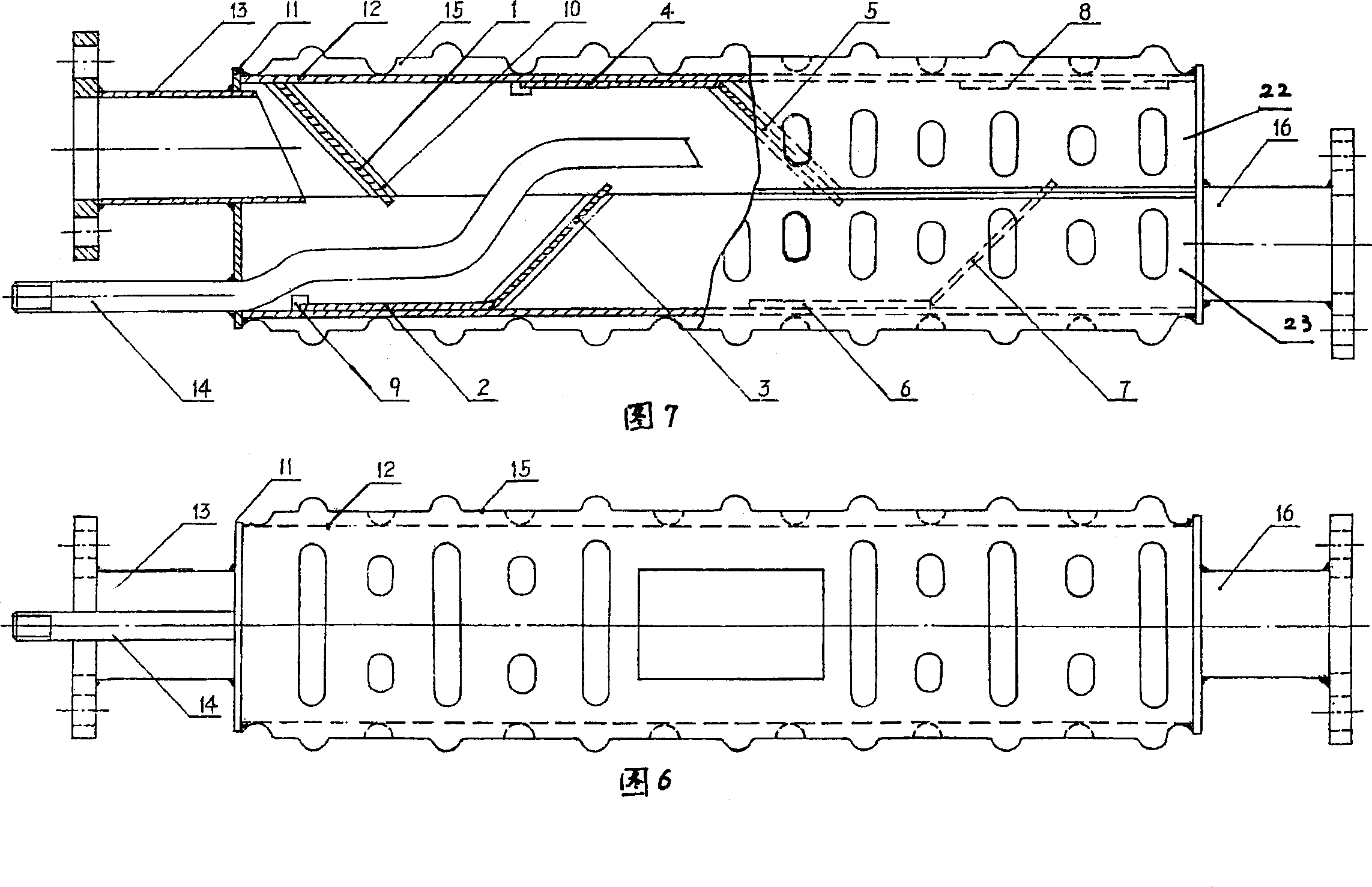

[0051] As shown in Figures 6-7, the nanocrystal catalytic purifier of the present invention comprises a reaction chamber, an exhaust gas inlet pipe 13 communicated with one side of the reaction chamber, an exhaust gas exhaust pipe 16 communicated with the other side of the reaction chamber, and a zero set in the reaction chamber. One-dimensional nanocrystal catalyst plates 1-4, one-dimensional nanocrystal catalyst plates 5-8, etc., the reaction chamber is composed of an anterior chamber and a rear chamber arranged in the reaction chamber housing 12 and the reaction chamber housing 12, forming the reaction chamber of the reaction chamber A heat shield 15 is arranged outside the casing 12 . The air intake pipe 14 is introduced from one side of the reaction chamber, and enters the rear chamber after being preheated by the tail gas in the front chamber.

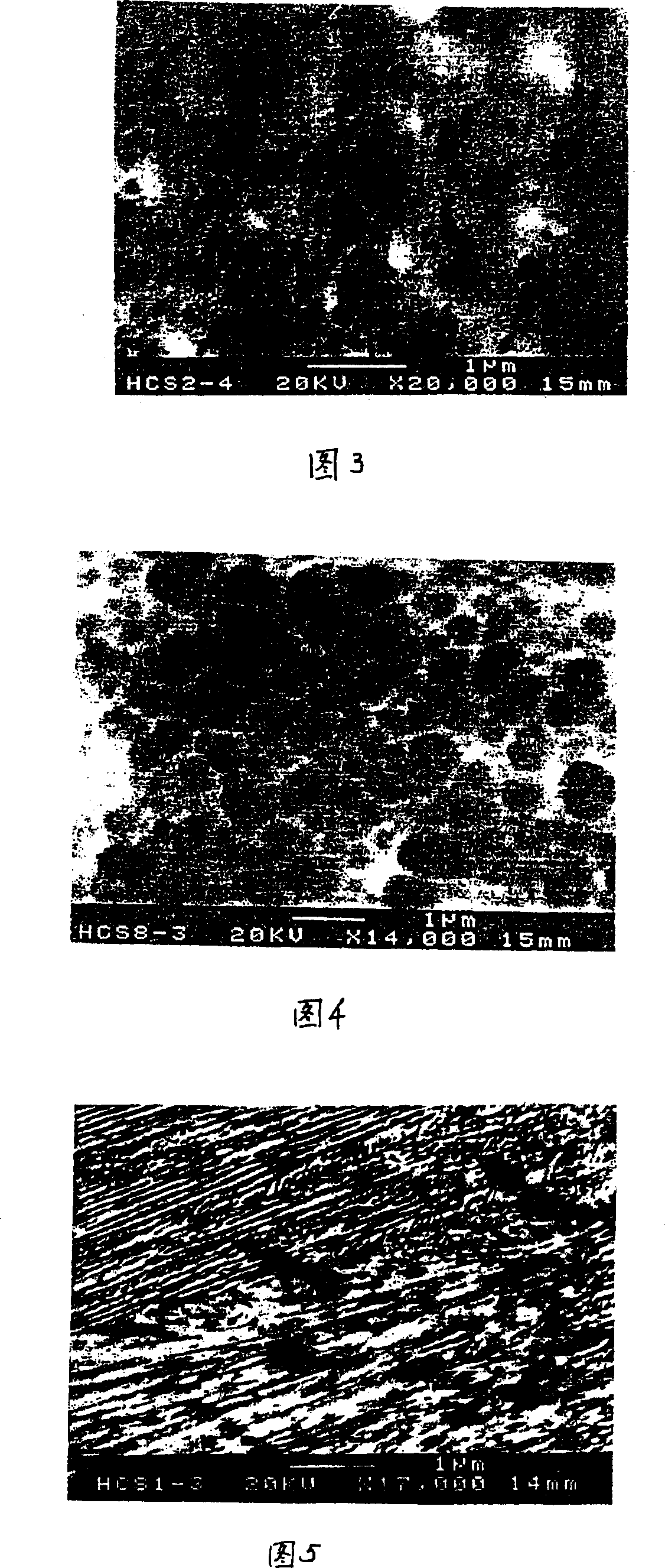

[0052] Among them, the front chamber is set at an angle of 30-60 degrees to each other with four levels of 10-30nm zero-dimensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com