Diesel engine exhaust treating fluid containing nanometer diamondene and preparation method thereof

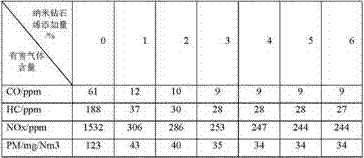

A nanodiamondene and exhaust gas treatment technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as poor fuel economy, increased vehicle use costs, and catalyst failure, so as to reduce PM emissions and accelerate Effect of decomposition speed and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

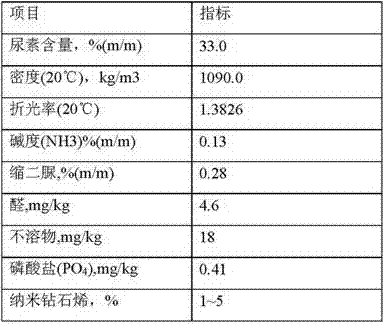

Embodiment 1

[0027] A diesel engine exhaust treatment liquid containing nano-diamondene, which is composed of the following raw materials in parts by weight: 60 parts of deionized water, 30 parts of urea, 1 part of nano-diamondene, 0.05 parts of sodium dodecylbenzenesulfonate, polyethylene 0.05 part of glycol octyl phenyl ether;

[0028] Described nano-diamantene is a modified nano-diamantene, which is prepared by the following method:

[0029] a. Ultrasonic alkaline cleaning: put nanodiamondene into an ultrasonic cleaning machine equipped with lye, the ultrasonic frequency is 50KHz, the lye concentration is 5% NaOH solution, the alkaline cleaning temperature is 35°C, rotate and stir, and the stirring speed is 50rpm, cleaning 20min;

[0030] b. Ultrasonic washing: Dilute the nano-diamonds after alkali washing into an ultrasonic cleaning machine equipped with deionized water. The ultrasonic frequency is 50KHz, the stirring speed is 45rpm, and the stirring time is 20min. Take the supernatan...

Embodiment 2

[0040] A diesel engine exhaust treatment fluid containing nano-diamantene, consisting of the following raw materials in parts by weight: 62 parts of deionized water, 33 parts of urea, 3 parts of nano-diamantene, 0.525 parts of sodium dodecylbenzenesulfonate, polyethylene 0.525 parts of glycol octyl phenyl ether;

[0041] Described nano-diamantene is a modified nano-diamantene, which is prepared by the following method:

[0042] a. Ultrasonic alkaline cleaning: Put nanodiamondene into an ultrasonic cleaning machine equipped with lye, the ultrasonic frequency is 55KHz, the lye concentration is 10% NaOH solution, the alkaline cleaning temperature is 42.5°C, rotate and stir, and the stirring speed is 60rpm, cleaning 30min;

[0043] b. Ultrasonic washing: Dilute the nano-diamonds after alkali washing into an ultrasonic cleaning machine equipped with deionized water. The ultrasonic frequency is 55KHz, the stirring speed is 47rpm, and the stirring time is 25min. Take the supernatant...

Embodiment 3

[0053] A diesel engine exhaust treatment fluid containing nano-diamantene, consisting of the following raw materials in parts by weight: 65 parts of deionized water, 35 parts of urea, 5 parts of nano-diamantene, 1 part of sodium dodecylbenzenesulfonate, polyethylene 1 part of glycol octyl phenyl ether;

[0054] Described nano-diamantene is a modified nano-diamantene, which is prepared by the following method:

[0055] a. Ultrasonic alkaline cleaning: Put nanodiamondene into an ultrasonic cleaning machine equipped with lye, the ultrasonic frequency is 60KHz, the lye concentration is 15% NaOH solution, the alkaline cleaning temperature is 50°C, rotate and stir, and the stirring speed is 70rpm, cleaning 40min;

[0056] b. Ultrasonic water washing: Dilute the nano-diamonds after alkali washing into an ultrasonic cleaning machine equipped with deionized water. The ultrasonic frequency is 60KHz, the stirring speed is 50rpm, and the stirring time is 30min. Take the supernatant to me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com