Eddy current device

The technology of a vortex chamber and a vortex wheel, which is applied in the field of vortex devices, can solve the problems of difficult to handle by-products, unsatisfactory purification effect, and incomplete purification, and achieve the effect of low use cost, low maintenance cost, and good pressurization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

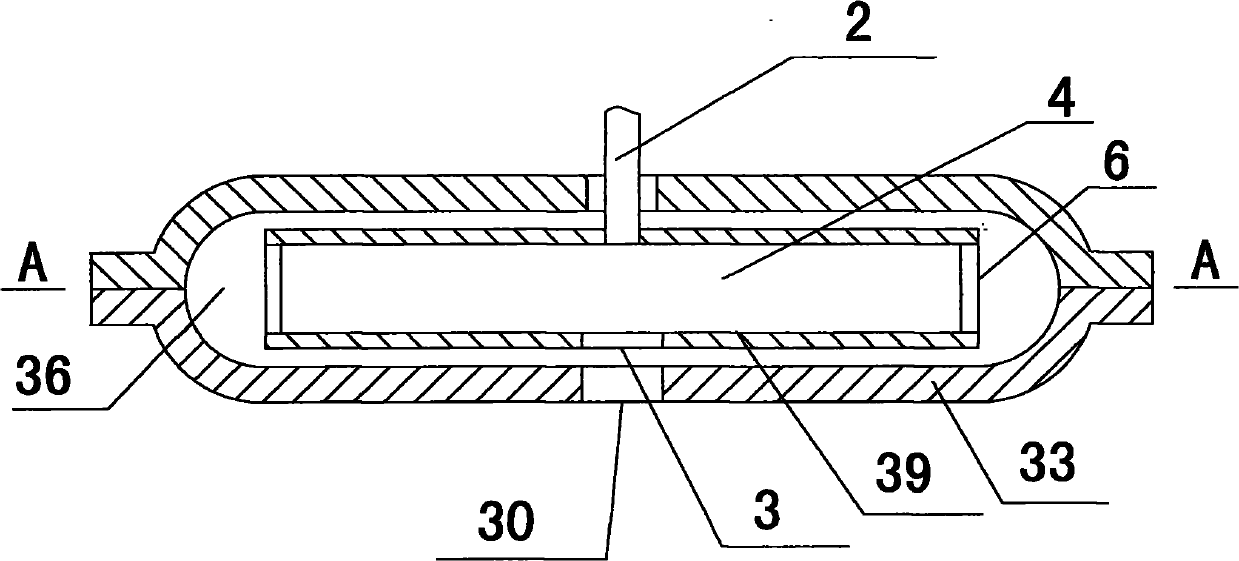

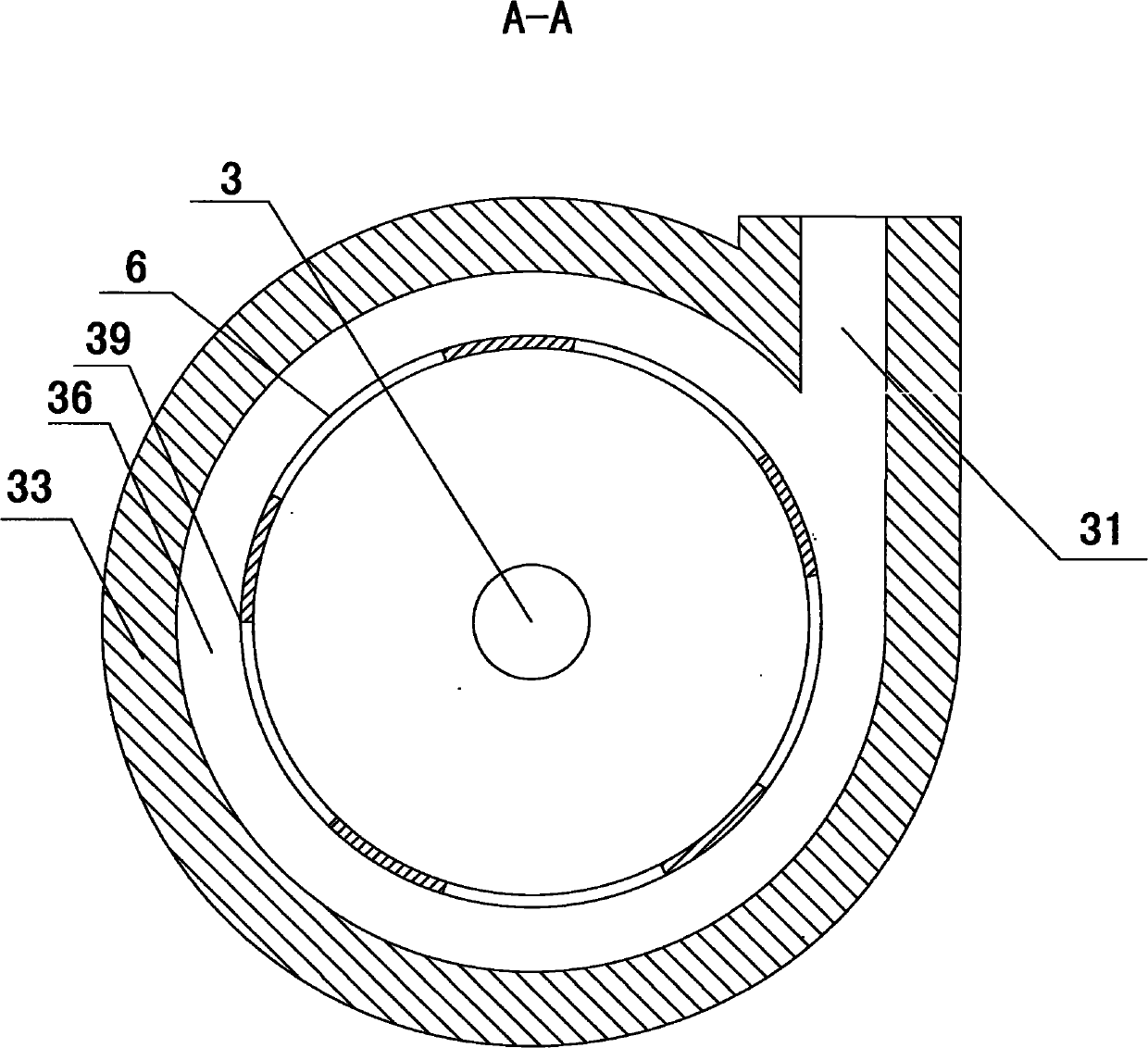

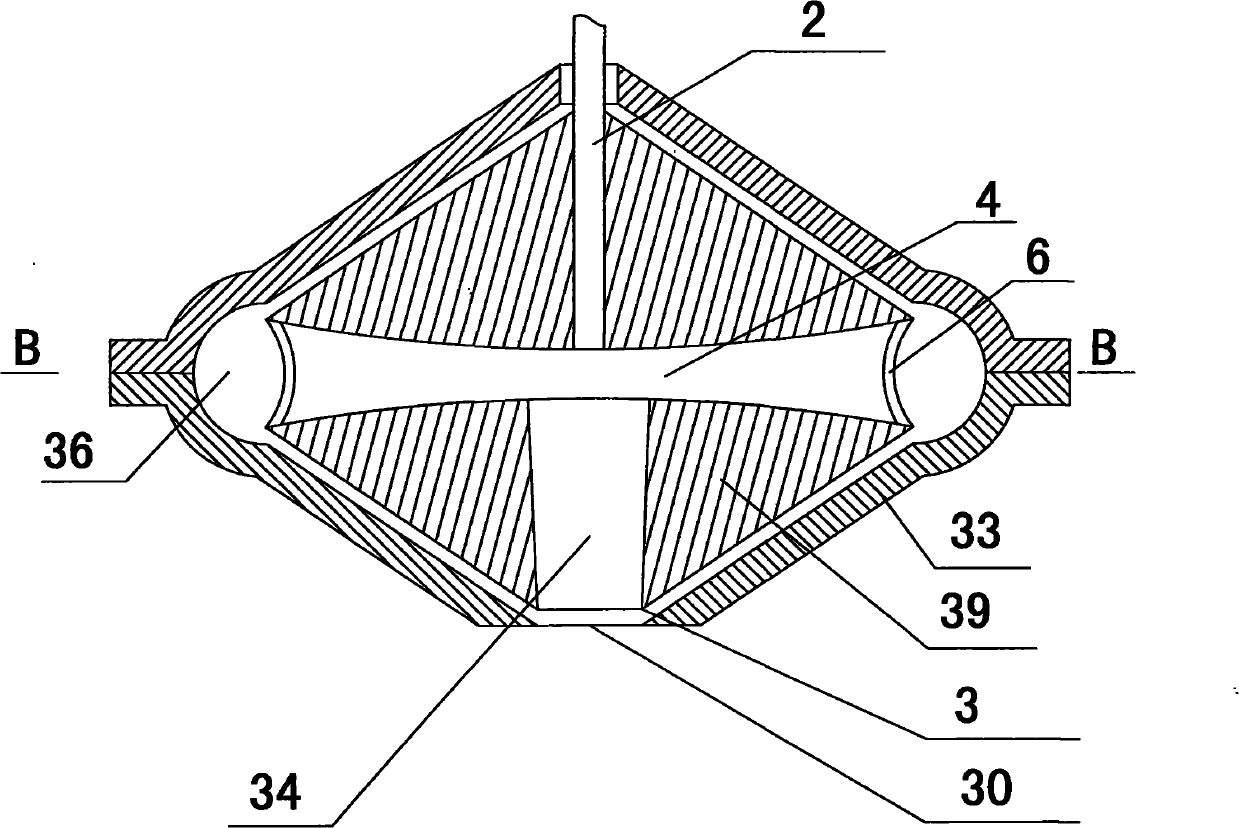

[0048] The main structure of the vortex generator of the present invention includes a housing 33 and a transmission shaft 2. A housing cavity 36 is provided in the housing 33. The transmission shaft 2 is installed in the housing 33. A vortex wheel 39 is arranged in the housing cavity 36. The transmission shaft 2 and the vortex wheel 39 connection, the vortex wheel 39 is provided with a vortex chamber 4, the vortex chamber inlet 3 is provided in the middle of the vortex chamber 4, the vortex chamber outlet 6 is provided on the periphery of the vortex chamber 4, the housing cavity 36 is provided with a housing cavity inlet 30, the vortex chamber inlet 3 and the housing cavity inlet 30 Correspondingly, the casing cavity 36 is provided with a casing cavity outlet 31 .

[0049] The scope of the casing 33 includes the base, the casing, and the power unit, and each part can be collectively referred to as a casing. The housing can also be integrated with the power device to form an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com