Low-temperature plasma cooperating two-phase catalyzing device and harmful exhaust gas processing method

A technology of low-temperature plasma and low-temperature plasma, which is applied in the direction of separation methods, chemical instruments and methods, and noise reduction devices, can solve the problems of short residence time and insufficient chemical reaction, etc., and achieve prolonged residence time, simple structure, and convenient disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

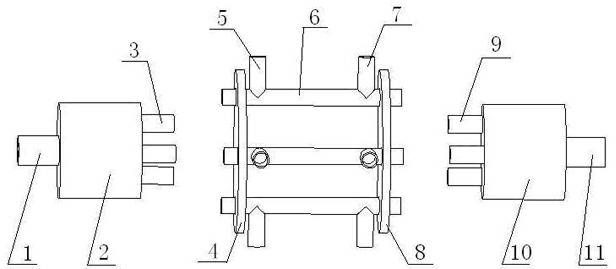

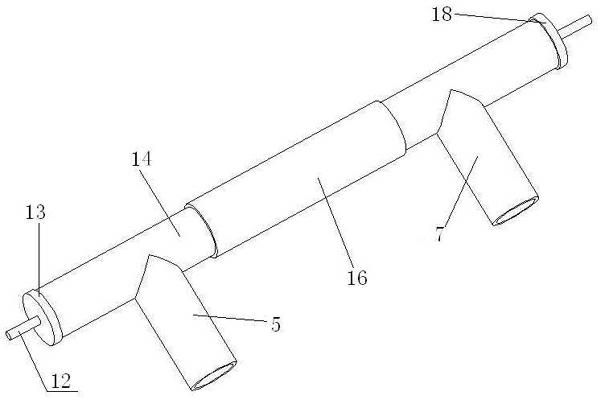

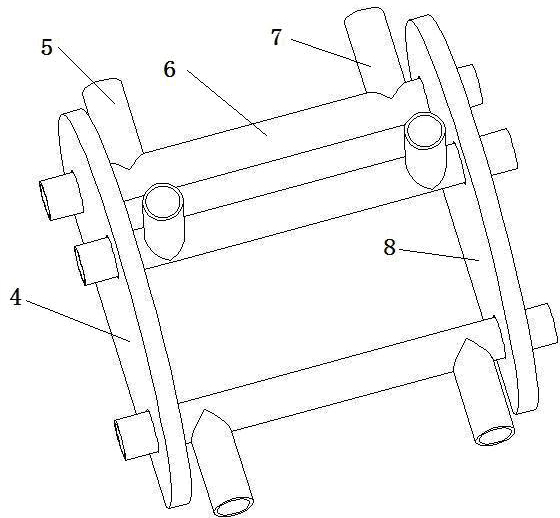

[0018] The invention is a low-temperature plasma cooperative "two-phase" catalytic device for treating harmful emissions from diesel engines. During the test, first connect the high-voltage electrodes 12 and low-voltage electrodes 16 of three or more plasma generators in parallel, then connect the high-voltage electrodes to the variable-frequency and variable-voltage plasma power supply, and ground the low-voltage electrodes to generate plasma. Silicone tubes are used to connect between the exhaust port A3 and the air inlet A5 and between the exhaust port B7 and the air inlet B9. The exhaust gas from the diesel engine first passes into the oxidation phase catalytic device 2 for reaction, then passes through the plasma generator 6 to react with the active substrate, and finally passes into the reduction phase catalytic device 10 for further r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com