Turbine exhaust condenser

a turbine exhaust and condenser technology, applied in the direction of machines/engines, indirect heat exchangers, light and heating apparatus, etc., can solve the problems of trapped gases seriously corroding the inside of the conventional carbon steel elongated finned tube, and the overall efficiency of turbine exhaust condensers is often limited, so as to increase the capacity, increase the height and length, and increase the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

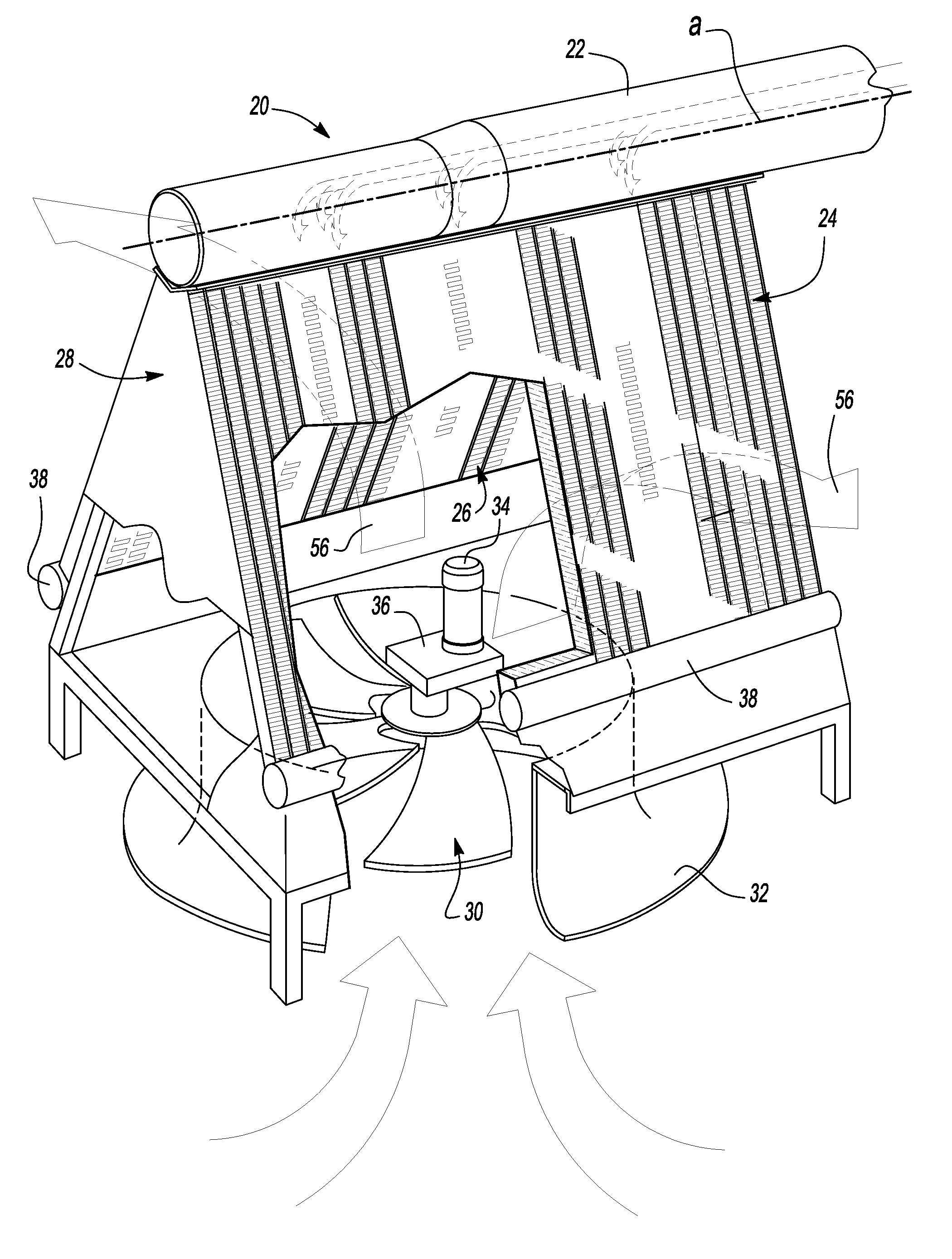

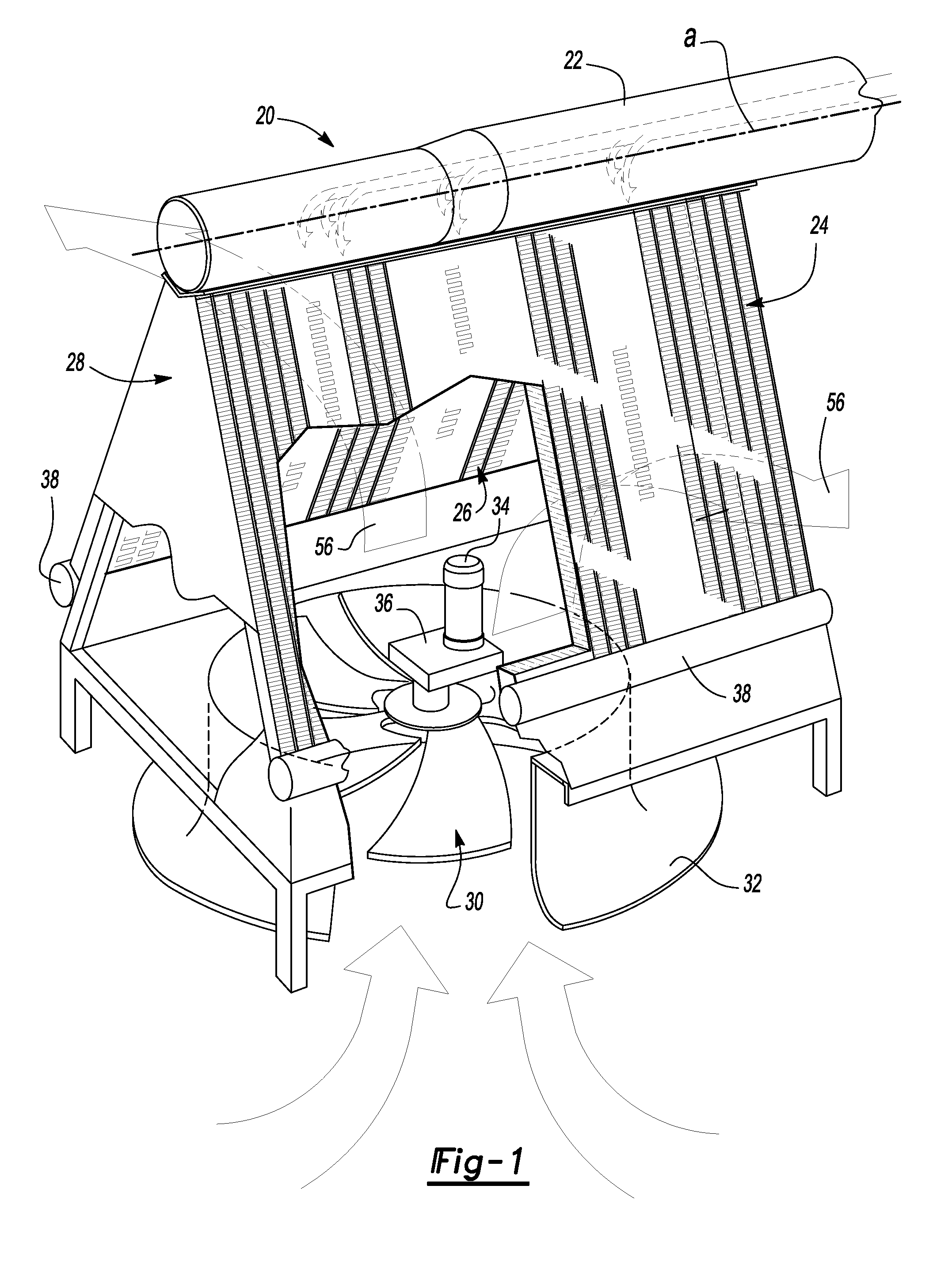

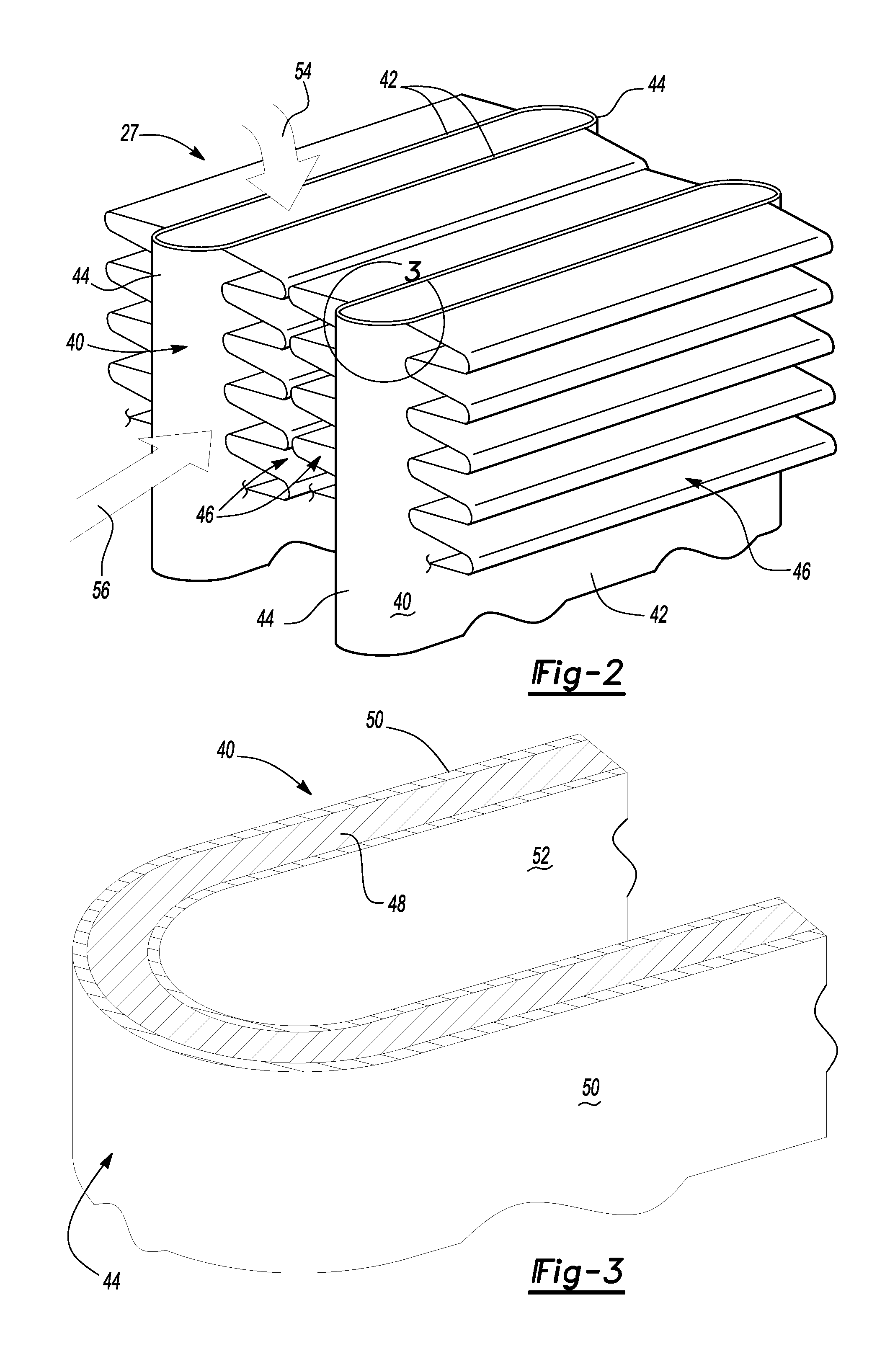

[0013]As set forth above, the air cooled steam condenser of this invention is particularly, but not exclusively adapted to condense steam from the exhaust of a steam turbine. A steam turbine is a mechanical device that extracts thermal energy from pressurized steam and converts it to rotary shaft motion. Steam turbines have been used commercially for over 100 years and are particularly suited to be used to drive an electric power generator. About 80% of all electricity generated in the world is by use of steam turbines. Air cooled steam condenser systems are commonly used in various industries as set forth above. However, there are limits in the overall efficiency of current turbine exhaust steam condensers due to the higher pressure drops experienced at low turbine back pressure. Further, air-cooled steam condensers for condensing steam from a steam turbine also accumulate corrosive non-condensable gases, such as carbon dioxide and air. Such trapped gases can corrode the inside sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com