Method for controlling direction of solidification structure of cast ingot through electricity conductive crystallizer electroslag remelting

A technology for electroslag remelting and solidification structure, applied in the field of metallurgy, can solve the problems of fixed direction of ingot solidification structure and difficult to control flexibly, and achieve the effect of surface quality assurance, reducing melting speed and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

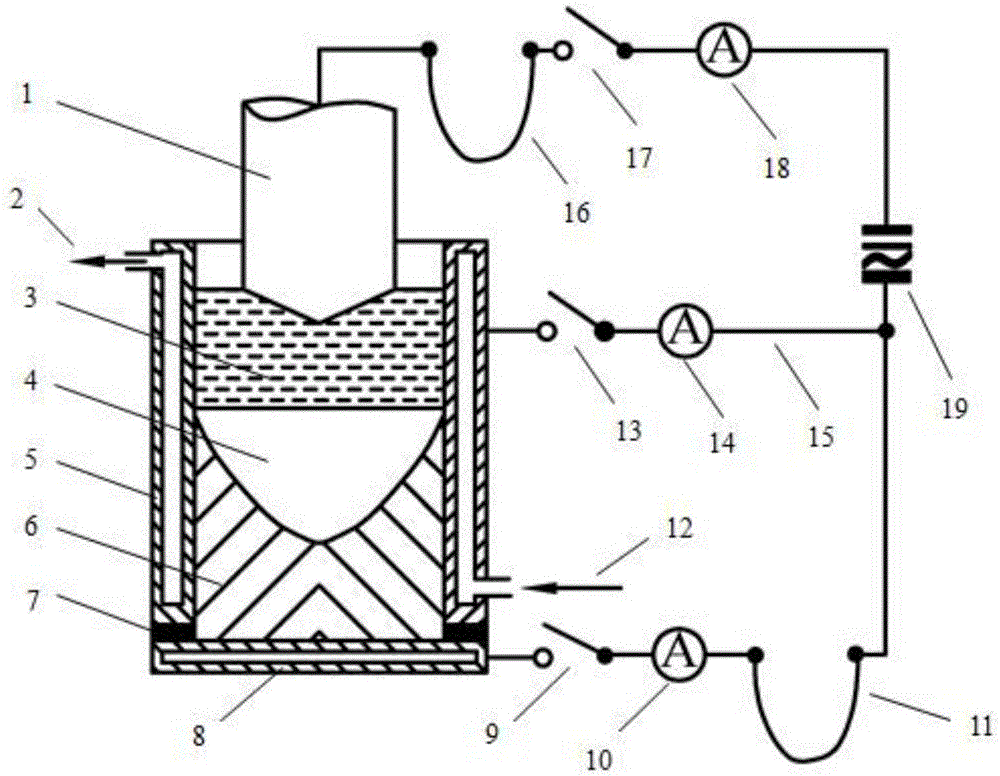

[0045] A method for electroslag remelting of a conductive mold to control the direction of solidification structure of an ingot. The schematic diagram of electroslag remelting is as follows figure 1 As shown, the selected steel type is H13 steel, which specifically includes the following steps:

[0046] Step 1, preparation and baking of slag:

[0047] (1) Prepare 30Kg of high-conductivity slag; wherein, the slag contains components and their mass percentages: CaF 2 : 50~60%, CaO: 18~24%, Al 2 o 3 : 20-25%, MgO: 2-5%, the sum of the mass percentages of each component is 100%, and the electrical conductivity of the slag system at 1900K is 380Ω -1 m -1 ;

[0048] (2) Mix the slag evenly and put it into a resistance furnace for baking. After baking at 600°C for 5 hours, turn off the power to let the slag cool down with the furnace, remove the moisture in the slag, and set aside;

[0049] Step 2, preparatory work:

[0050] (1) Determine the filling ratio and the insertion de...

Embodiment 2

[0059] A method for electroslag remelting of a conductive mold to control the direction of solidification structure of an ingot. The schematic diagram of electroslag remelting is as follows figure 1 As shown, the selected steel type is cold work die steel D2, which specifically includes the following steps:

[0060] Step 1, preparation and baking of slag:

[0061] (1) Prepare 140Kg of high-conductivity slag; wherein, the slag contains components and their mass percentages: CaF 2 : 50~70%, CaO: 10~20%, Al 2 o 3 : 20-30%, SiO 2 : ≤10%, the sum of the mass percentages of each component is 100%, and the conductivity of the slag system at 1900K is 460Ω -1 m -1 ;

[0062] (2) Mix the slag evenly and put it into a resistance furnace for baking. After baking at 600°C for 5 hours, turn off the power to let the slag cool down with the furnace, remove the moisture in the slag, and set aside;

[0063] Step 2, preparatory work:

[0064] (1) Determine the filling ratio and the inser...

Embodiment 3

[0073] A method for electroslag remelting of a conductive mold to control the direction of solidification structure of an ingot. The schematic diagram of electroslag remelting is as follows figure 1 As shown, the selected steel type is D2 steel, which specifically includes the following steps:

[0074] Step 1, preparation and baking of slag:

[0075] (1) Prepare 140Kg of high-conductivity slag; wherein, the slag contains components and their mass percentages: CaF 2 : 50~70%, CaO: 10~20%, Al 2 o 3 : 20-30%, SiO 2 : ≤10%; the sum of the mass percentages of each component is 100%, and the conductivity of the slag system at 1900K is 460Ω -1 m -1 ;

[0076] (2) Mix the slag evenly and put it into a resistance furnace for baking. After baking at 600°C for 5 hours, turn off the power to let the slag cool down with the furnace, remove the moisture in the slag, and set aside;

[0077] Step 2, preparatory work:

[0078] (1) Determine the filling ratio and the insertion depth of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com